Corrosion crack expansibility characterization and life estimation method

A technique for crack propagation and life estimation, which is used to test the strength of materials by applying repetitive force/pulsation force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

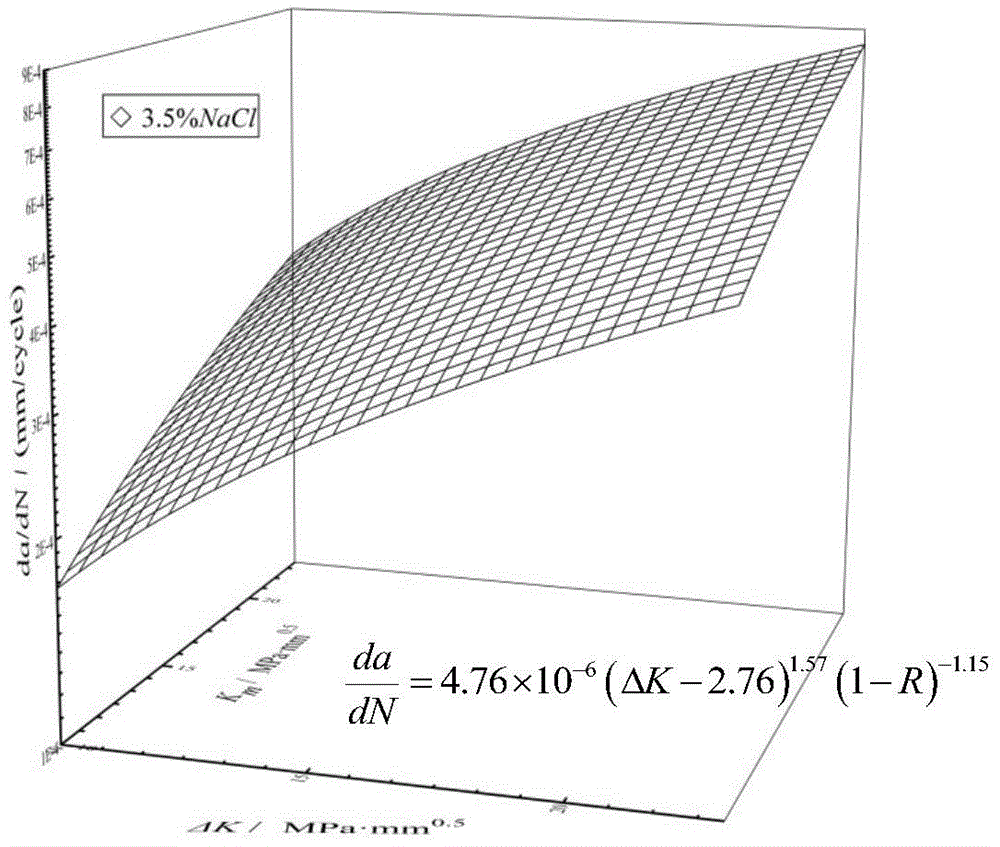

[0064] Image 6 For the flow chart of the method of the present invention, the present invention is realized in three steps, specifically:

[0065] Step 1. Corrosion crack growth performance da / dN-ΔK curve

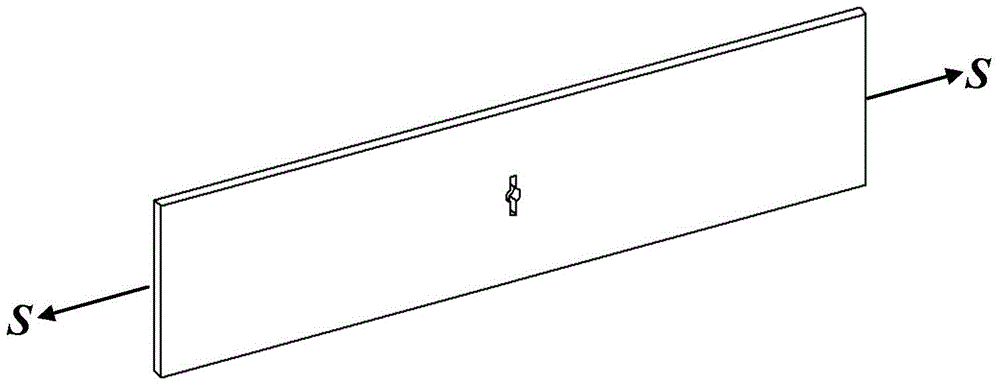

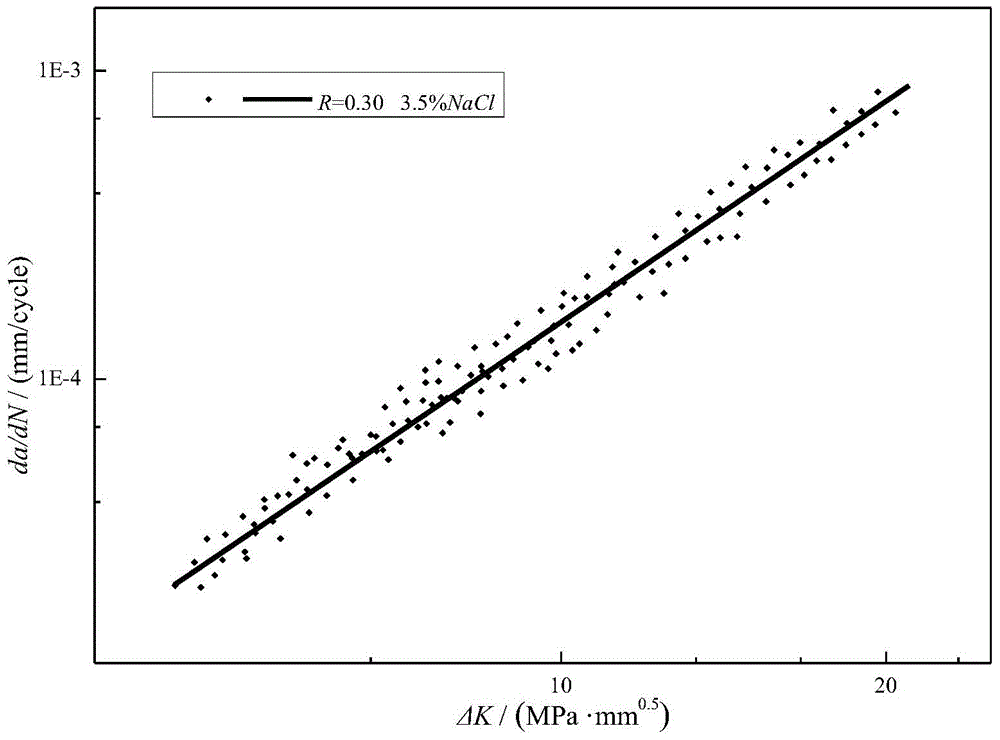

[0066] figure 1 is the schematic diagram of the loading of the central crack tensile M(T) specimen, according to figure 1 The loading form and the national standard "Metallic Materials Fatigue Crack Growth Rate Test Method" (GB-T6398), the crack growth test is carried out in a corrosive environment. Apply the specified stress ratio R, observe and record the left and right crack lengths during the crack growth process, and calculate the average crack growth length a according to the left and right crack lengths, and obtain the constant load crack growth a-N data of aluminum alloy materials, using the secant method data processing

[0067] ( d a d ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com