Rolling mill transmission system key component fatigue life early warning method based on load spectrum analysis

A technology of transmission system and fatigue life, which is applied in the field of fatigue life warning of key components of rolling mill transmission system, component life prediction, and calculation of fatigue life of key components of rolling mill transmission system in the rolling process, which can solve inconsistency and budget There are problems such as large errors between life and actual conditions, and achieve the effects of strong engineering practicability, high applicability and operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045]The present invention will be further described below in conjunction with the accompanying drawings and specific implementation examples.

[0046] A method for early warning of fatigue life of key components of a rolling mill transmission system based on load spectrum analysis of the present invention will be described in detail below by way of examples.

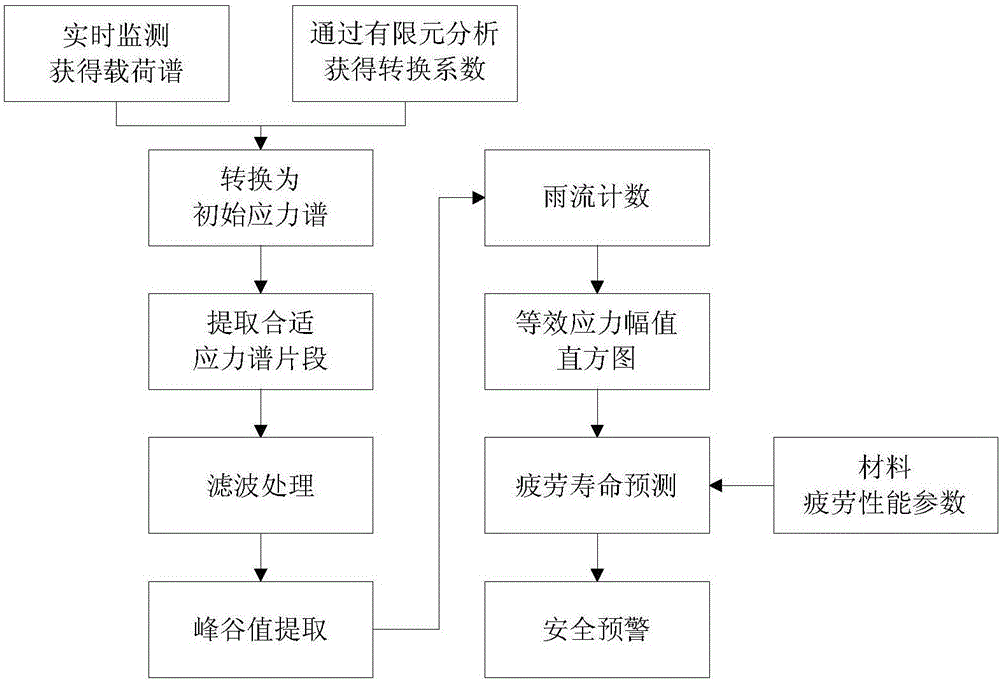

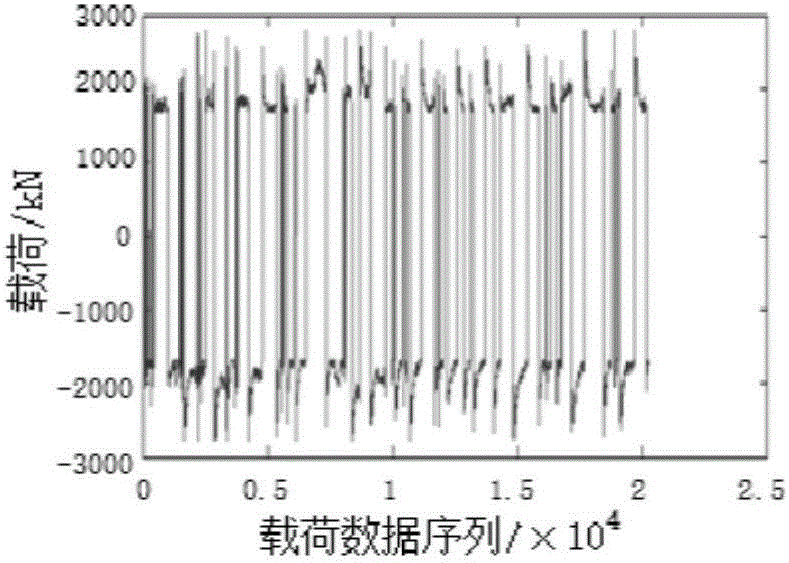

[0047] The gist of the present invention is to effectively and quickly convert the load spectrum obtained from the actual measurement, perform waveform classification, compression denoising, peak and valley value extraction and mathematical statistics on the converted stress spectrum to obtain the equivalent stress spectrum histogram, and then On this basis, combined with the fatigue performance parameters of the material, the fatigue life prediction of the key components of the transmission system is carried out by applying the modified Meiner's law. In the present invention, the calculation process of the fatigue lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com