A kind of aliphatic water reducing agent prepared by utilizing straw and preparation method thereof

A technology of aliphatic water-reducing agent and straw, which is applied in the field of aliphatic water-reducing agent and its preparation, can solve the problems that have not yet seen the experimental application effect, achieve good promotion and application prospects, improve low water-reducing rate, and improve retardation bad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

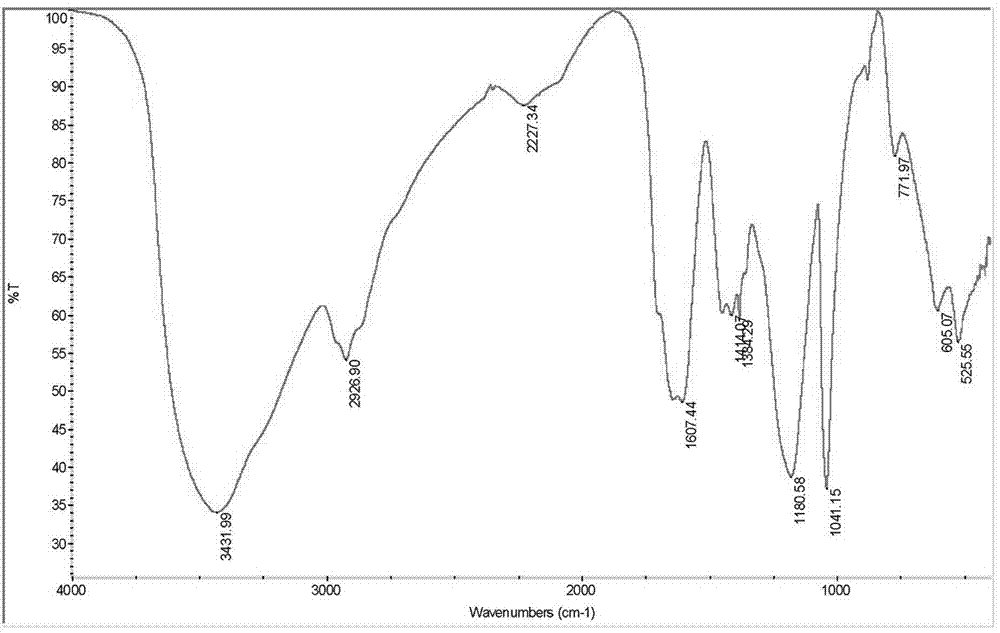

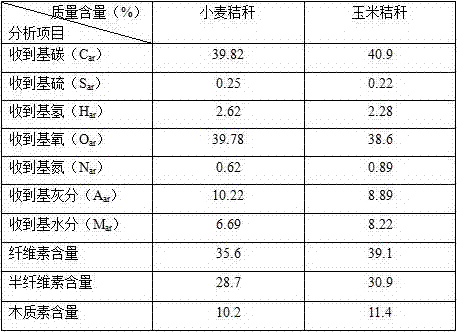

[0047] The aliphatic water reducer prepared from straw provided in this example is specifically prepared through the following steps:

[0048] (1) Pretreating the straw, which is wheat straw;

[0049] After crushing the straw through a 40-mesh sieve, take 20 g as a test sample, add 200 mL of sulfuric acid with a mass concentration of 2%, stir and mix evenly, soak for 24 hours, filter and rinse the straw with water until it is neutral, and then set aside;

[0050] (2) Preparative aliphatic water reducer, the specific process is:

[0051] First, add 10 mol of water to the reaction kettle, then add 0.4 mol of sodium sulfite to fully dissolve, and use strong stirring to assist in accelerating the dissolution of sodium sulfite;

[0052] Second, add 0.9 mol of acetone to the above-mentioned dissolved sodium sulfite solution, sulfonate for 10 minutes; then add 12 g of straw pretreated in step (1), and stir for 30 minutes;

[0053]Third, slowly add 4.5 mol of formaldehyde (formaldeh...

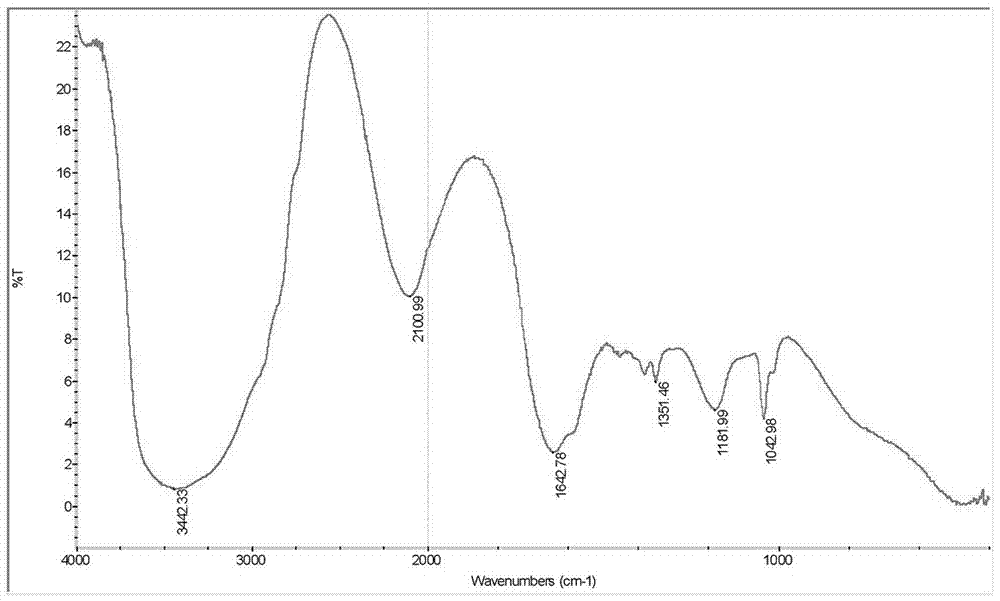

Embodiment 2

[0056] The preparation method of the aliphatic water-reducer prepared from straws provided in this example is the same as that in Example 1, except that some material types and dosages have been properly adjusted, as described below.

[0057] In this example, corn stalks are used to prepare aliphatic water reducer, and the straw pretreatment is soaked in hydrochloric acid with a mass concentration of 4%. During the preparation of aliphatic water reducer, in terms of molar ratio, water: sodium sulfite: acetone : formaldehyde=10:0.3:0.8:4; the amount of straw after pretreatment is 11.25g;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com