Preparation method of halogen-free flame retardant rigid polyurethane foam insulation material for exterior wall insulation

A polyurethane rigid foam and exterior wall insulation technology, which is applied in the field of preparation of halogen-free flame-retardant polyurethane rigid foam insulation materials, can solve the problems of failing to meet B1 fire protection requirements, poor dispersion and compatibility, easy migration, etc., and achieve Flame retardant effect Smoke and toxicity, suppression of smoke and toxicity, effect of high decomposition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

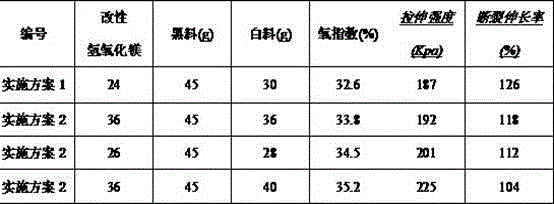

Examples

Embodiment 1

[0021] First, mix the flame retardant magnesium hydroxide and special coupling agent in a high-speed mixer at a temperature of 100°C in a ratio of 100:1 to obtain an activated flame retardant, and then mix it with the synergistic flame retardant antimony trioxide A modified flame retardant was obtained.

[0022] The modified flame retardant, phosphorus-containing flame-retardant polyether polyol, catalyst, foaming agent and stabilizer are used in a certain proportion to obtain a combined white material. Mix with black material diphenylmethane diisocyanate crude MDI at a ratio of 1:1.2 to make a board to obtain an environmentally friendly flame-retardant polyurethane rigid foam.

Embodiment 2

[0024] First, mix the flame retardant magnesium hydroxide and special coupling agent in a high-speed mixer at a temperature of 100°C in a ratio of 100:1.5 to obtain an activated flame retardant, and then mix it with a synergistic flame retardant zinc borate to obtain an improved flame retardant.

[0025] The modified flame retardant, phosphorus-containing flame-retardant polyether polyol, catalyst, foaming agent and stabilizer are used in a certain proportion to obtain a combined white material. And the black material toluene diisocyanate TDI is mixed according to 1:1.6 to make the board to obtain the environment-friendly flame-retardant polyurethane rigid foam.

Embodiment 3

[0027] First, mix the flame retardant magnesium hydroxide and special coupling agent in a high-speed mixer at a temperature of 120°C in a ratio of 100:1.5 to obtain an activated flame retardant, and then mix it with a synergistic flame retardant barium metaborate to obtain Modified flame retardant.

[0028] The modified flame retardant, phosphorus-containing flame-retardant polyether polyol, catalyst, foaming agent and stabilizer are used in a certain proportion to obtain a combined white material. And the black material polymethylene polyphenyl polyisocyanate PAPI is mixed at a ratio of 1:1.6 to make a board to obtain an environmentally friendly flame-retardant polyurethane rigid foam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com