Coloured flame-retardant polypropylene fibre, preparation and use thereof

A flame retardant polypropylene and fiber technology, which is used in the manufacture of fire retardant filaments, melt spinning, and single-component polypropylene rayon. and other problems, to achieve the effects of improved spinning performance, no suffocation, and less smoke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

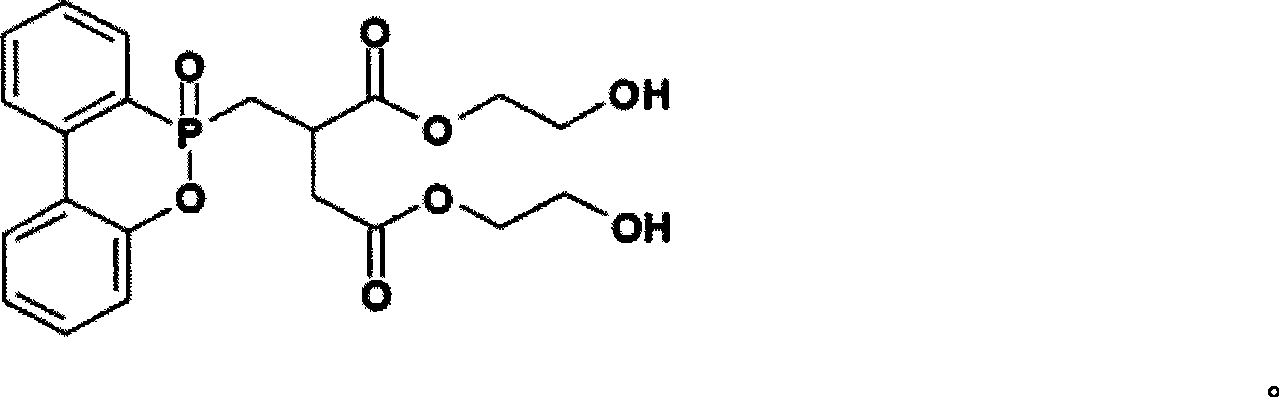

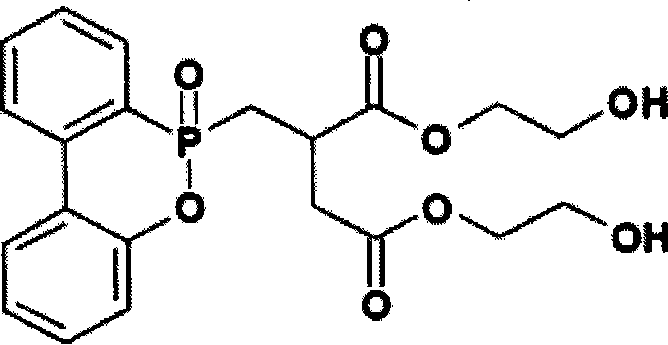

Image

Examples

Embodiment 1

[0044] The preparation of nano magnesium hydroxide:

[0045] In 10wt% magnesium chloride aqueous solution, add the mixture of polyethylene glycol octyl phenyl ether and sodium dodecylbenzenesulfonate whose total weight is 2wt% of the total weight of magnesium chloride aqueous solution, sodium dodecylbenzenesulfonate and polyethylene glycol The weight ratio of alcohol octyl phenyl ether is 1:3; add dropwise 5wt% NaOH aqueous solution under stirring, adjust the pH value to 8.5, and set the temperature at 30°C for precipitation reaction for 2 hours. Filter, wash, and dry to obtain nanometer Mg(OH) 2 powder. The average particle diameter of the nano-magnesium hydroxide is 30nm.

Embodiment 2

[0047] Preparation of nano aluminum hydroxide:

[0048] In 30wt% magnesium chloride aqueous solution, add the mixture of polyethylene glycol octyl phenyl ether and sodium dodecylbenzenesulfonate whose total weight is 1wt% of the total weight of magnesium chloride aqueous solution, sodium dodecylbenzenesulfonate and polyethylene glycol The mass ratio of alcohol octyl phenyl ether is 1:1; add 3wt% NaOH aqueous solution dropwise under stirring, adjust the pH value to 10, the temperature is 10°C, and precipitate for 1.5 hours. , washing, and drying to obtain nano-Al(OH) 3 powder. The average particle size of the nano aluminum hydroxide is 100nm.

Embodiment 3

[0050] Preparation of flame retardant masterbatch:

[0051] The following are parts by weight.

[0052] 10 parts of phosphorus flame retardant, 4 parts of aluminum hydroxide of embodiment 1, 1 part of magnesium hydroxide of embodiment 2, 85 parts of fiber grade polypropylene chips.

[0053] The SHL-35 type twin-screw extruder produced by Shanghai Chemical Machinery No. 4 Factory is used to add a static mixer known in the art, the feed screw is 50r / min, and the main screw is 150r / min. Using melt extrusion, cooled under water into strips, and pelletized. The size of the masterbatch is about 3×2×2mm, and the cutting speed is 400r / min. The temperature range of each zone of the blending screw is 200-230°C

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com