Antistatic halogen-free fire retardation ultra-high molecule weight polyethylene material and preparation method thereof

A technology of ultra-high molecular weight and polyethylene, which is applied in the field of antistatic halogen-free flame-retardant ultra-high molecular weight polyethylene materials and its preparation, can solve the problems of high resistivity and poor flame retardancy, achieve good wear resistance, improve resistance Static electricity and flame retardancy, effect of reducing surface resistance and volume resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

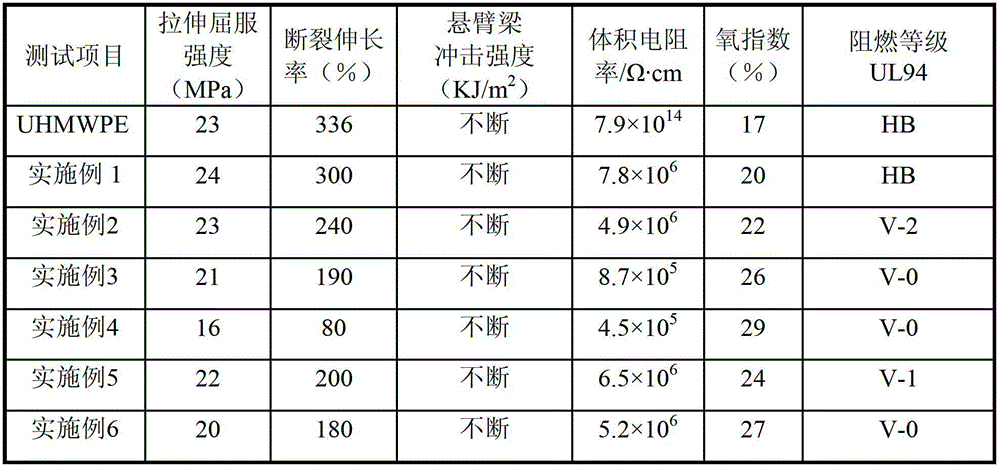

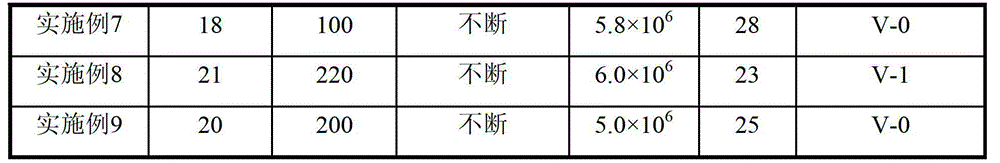

[0020] In parts by weight, 100 parts of ultra-high molecular weight polyethylene with a viscosity-average molecular weight of 8 million, 5 parts of titanate coupling agent-treated expandable graphite with a particle size of 80 meshes, and 0.3 parts of antioxidant 1010 are mixed evenly, and 1 part Nucleating agent zinc stearate, 0.5 part flow modifier PPA, 1 part conductive carbon black. The mixture was then melt-pressed at 220° C. and 20 MPa (MPa: megapascal) by compression molding. The properties of the prepared materials are listed in Table 1.

Embodiment 2

[0022] In parts by weight, 100 parts of ultra-high molecular weight polyethylene with a viscosity-average molecular weight of 8 million, 10 parts of titanate coupling agent-treated expandable graphite with a particle size of 80 meshes, and 0.3 parts of antioxidant 1010 are mixed uniformly, and 1 part Nucleating agent zinc stearate, 0.5 part flow modifier PPA, 1 part conductive carbon black. Then the mixture was melt-pressed at 220° C. and 20 MPa by compression molding. The properties of the prepared materials are listed in Table 1.

Embodiment 3

[0024] In parts by weight, 100 parts of ultra-high molecular weight polyethylene with a viscosity-average molecular weight of 8 million, 20 parts of titanate coupling agent-treated expandable graphite with a particle size of 80 meshes, and 0.3 parts of antioxidant 1010 are mixed uniformly, and 1 part Nucleating agent zinc stearate, 0.5 part flow modifier PPA, 1 part conductive carbon black. Then the mixture was melt-pressed at 220° C. and 20 MPa by compression molding. The properties of the prepared materials are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com