Fire retardation coating material, preparation method and uses thereof

A flame-retardant coating and flame-retardant technology, which is applied in the field of flame-retardant coatings and PET textile cloth, can solve the problems of poor flame-retardant properties of PET tarpaulins, and achieve good flame-retardant effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

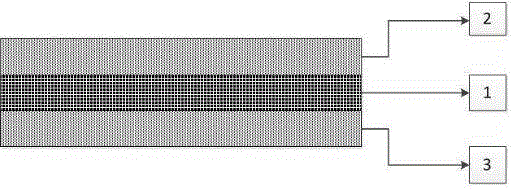

Image

Examples

Embodiment 1

[0025] Preparation of titanium dioxide slurry: Take 50kg of DINP and add it into the dispersion tank, then add 60kg of titanium dioxide powder under the condition that the rotation speed of the mixer is 50rmp / min, and stir for 0.5 hours. Grinding is carried out with a three-roll machine, and the grinding time is 2 to 5 hours. When the fineness of the slurry is 5 to 20 μm, the grinding is finished.

[0026] The raw materials used in Experiment 1 were all commercially available.

Embodiment 2

[0028] The configuration of the mixed solvent in the flame-retardant coating: Accurately weigh 50kg of ethyl acetate, 15kg of acetone, 10kg of cyclohexanone, and 25kg of 80# gasoline into a 200L dispersion bucket in sequence. Then set the rotation speed of the mixer to 50rmp / min, and stir for 3 min. Then the 200-mesh filter screen filters the material to obtain a mixed solvent.

[0029] The raw materials used in Experiment 2 were all commercially available.

Embodiment 3

[0031] Flame retardant coating configuration: take 8.0kg of mixed solvent and 20.0kg of plasticizer DINP and add them to a 200L dispersion bucket, and add 37.0kg of polyvinyl chloride paste resin, 10.0kg of PTFE suspension resin, 10.0kg titanium dioxide slurry, then adjust the rotation speed to 1500rmp / min, and disperse for 30 minutes. Then add 5.0kg of calcium carbonate under the condition that the rotating speed of the mixer is 50rmp / min, and after dispersing for 5 minutes, adjust the rotating speed to 1500rmp / min, and disperse for 15 minutes. Then, 2.0kg heat stabilizer, 0.3kg anti-ultraviolet agent, 0.3kg bactericide, 5.0kg flame retardant were added sequentially at a rotating speed of 1500rmp / min, and stirred for 5 minutes. After the addition is complete, stir for 5-15 minutes to obtain a homogeneous mixture. Add an appropriate amount of mixed solvent to adjust the viscosity of the coating to 1000-5000mpa.s, filter and pack to obtain a flame-retardant coating.

[0032] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com