Compounding flame retardation polystyrene composition and preparation method thereof

A technology of polystyrene and compound flame retardant, which is applied in the field of polystyrene composition modified by compound flame retardant and its preparation, can solve the problems of fire spread, melting drop, etc. Small addition amount and remarkable flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

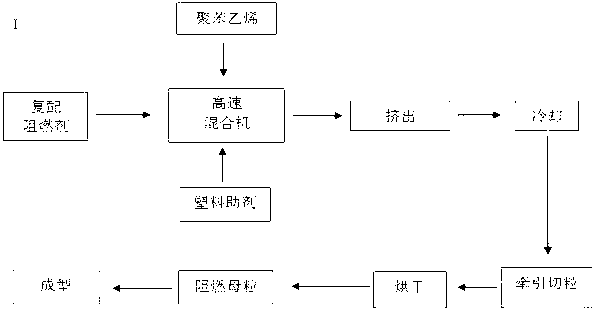

Method used

Image

Examples

Embodiment 1

[0037]The composite flame retardant polystyrene composition, the raw material formula is: 100g polystyrene resin; 60g composite flame retardant; 2g polyethylene wax 420P; 7g toughening agent SBS; 3g antioxidant 1010.

[0038] Among them, the compound flame retardant is 36g of decabromodiphenylethane, 6g of antimony trioxide, 12g of zinc borate, and 6g of linear thermoplastic phenolic resin powder. Use 0.6g of silane coupling agent KH-570.

[0039] The obtained pellets of the flame retardant polystyrene composition, the sample strips obtained by injection molding have passed the UL-94 standard test, and the flame retardant effect can reach V-0 level.

Embodiment 2

[0041] The difference between this embodiment and embodiment 1 is:

[0042] The ratio of the flame retardant is: 39g of decabromodiphenylethane, 4.8g of antimony trioxide, 12g of zinc borate, and 4.2g of linear thermoplastic phenolic resin powder. Use 0.9g of silane coupling agent KH-570.

[0043] The obtained pellets of the flame retardant polystyrene composition, the sample strips obtained by injection molding have passed the UL-94 standard test, and the flame retardant effect can reach V-0 level.

Embodiment 3

[0045] The preparation method of this embodiment is the same as that of Example 1, except that:

[0046] Compound flame retardant polystyrene composition, raw material formula is: 100g polystyrene resin; 70g compound flame retardant; 2g liquid paraffin; 7g ethylene-butyl acrylate binary copolymer; 3g antioxidant 168.

[0047] Among them, the proportion of the compound flame retardant is 45.5g of decabromodiphenylethane, 7g of antimony trioxide, 12.5g of zinc borate, and 5g of linear thermoplastic phenolic resin powder. Use 1.0 g of silane coupling agent KH-570.

[0048] The obtained pellets of the flame retardant polystyrene composition, the sample strips obtained by injection molding have passed the UL-94 standard test, and the flame retardant effect can reach V-0 level.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com