Antibacterial fire-retardant polycarbonate composite material and preparation method thereof

A technology of flame-retardant polycarbonate and composite materials, which is applied in the field of antibacterial flame-retardant polycarbonate composite materials and its preparation, can solve the problems of loss of antibacterial performance, poor material durability, poor antibacterial effect, etc., and achieve good antibacterial effect, Good flame retardant effect, good color stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

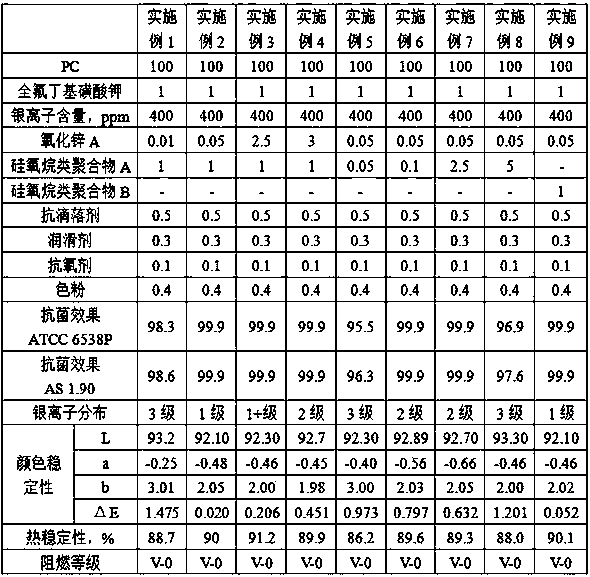

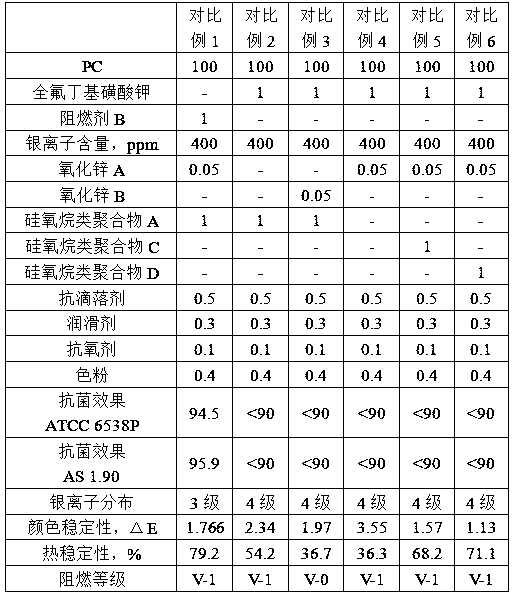

[0029] The present invention is further illustrated by the following examples, but the present invention is not limited by the following examples.

[0030] The sources of raw materials used in the present invention are as follows, but are not limited by the following raw materials.

[0031] Flame retardant B: sodium benzenesulfonate;

[0032] Silver ion source: Silver ion antibacterial agent, IKM50G, Japan Zeomic;

[0033] Anti-dripping agent: polytetrafluoroethylene coated with acrylonitrile-styrene copolymer;

[0034] Zinc oxide A: Mitsubishi, D50=400nm;

[0035] Zinc oxide B: D50=5 microns;

[0036] Silicone polymer A: molecular weight 200,000;

[0037] Silicone polymer B: molecular weight 300,000;

[0038] Silicone polymer C: molecular weight 100,000;

[0039] Silicone polymer D: molecular weight 500,000;

[0040] Lubricant: POLY TS 30A Korean Pacific Chemical;

[0041] Antioxidant: 2112, Adico;

[0042] Toner: titanium dioxide 2233;

[0043] The preparation meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com