Seamless PET (polyester) laser transfer membrane and preparation method thereof

A technology of laser transfer and seamless plate seam, which is applied in chemical instruments and methods, ink transfer from original manuscripts, coatings, etc., can solve problems such as bad odor, and achieve good corona retention, good wear resistance and scratch resistance, and weather resistance The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Mixing transfer coating: Add 14kg of water-based acrylic acid and cellulose acetate butyrate system, 10kg of sodium methallyl sulfonate, 4kg of polyethylene glycol, 3kg of ethyl acetate, and 68kg of deionized water into a stainless steel container in sequence Inside, stir evenly, the stirring speed is 500 rpm, and the stirring temperature is 50°C. After stirring evenly, add 1 kg of ammonia water to adjust the pH value to 8.0 to make a transfer coating.

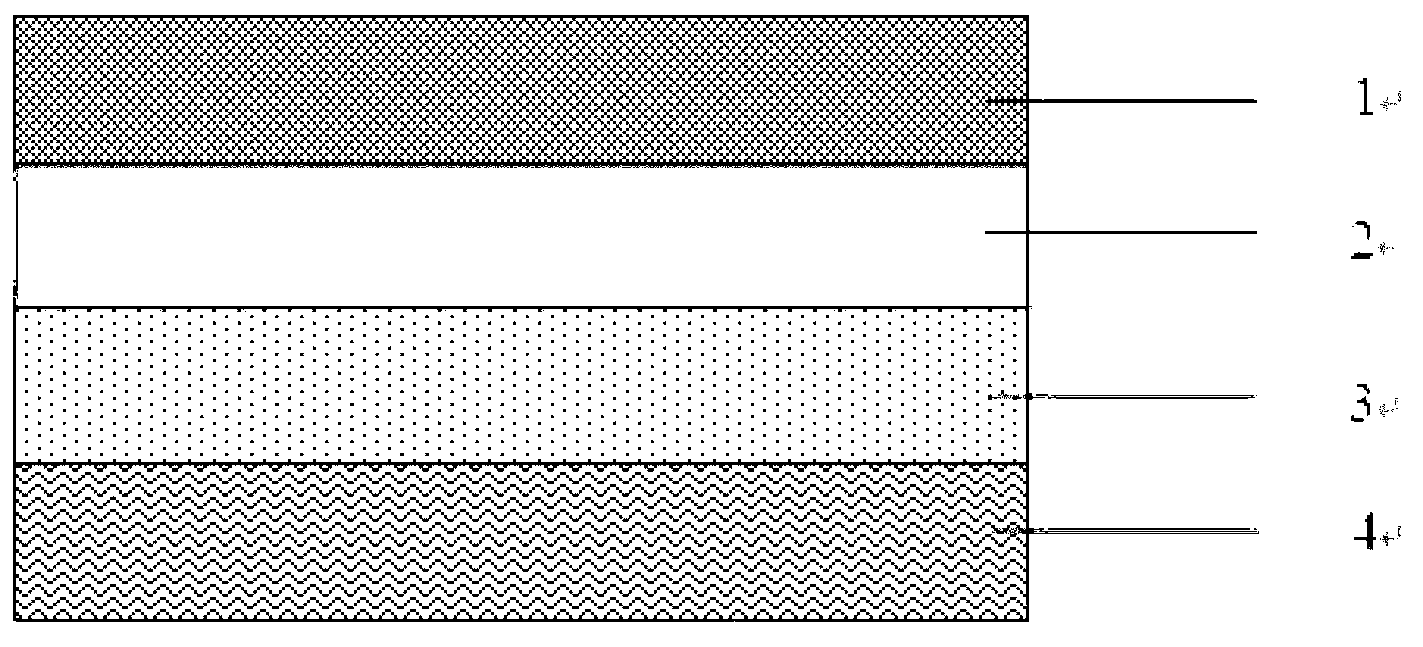

[0043] (2) Coating: apply the mixed transfer coating to the PET base film 1 with a thickness of 9 μm through a clean and wear-free anilox roller, and dry it continuously at a temperature of 90°C for 6 seconds to form a protective film. Layer 2. The anilox roller is made of ceramics, the number of lines is 90 mesh, and the depth is 35μ. The length of the oven is 18m, and the temperature is low and high. The oven temperature is set at 80°C, 100°C, 120°C, 140°C, and 80°C.

[0044] (3) Molding:

[0045] Described mo...

Embodiment 2

[0051] (1) Mixing transfer coating: Add 80kg of water-based acrylic acid and cellulose acetate butyrate system, 12kg of sodium styrene sulfonate, 8kg of polyethylene glycol, 14kg of ethyl acetate, and 80kg of deionized water into the stainless steel container in sequence, and evenly Stirring, the stirring speed is 700 rpm, and the stirring temperature is 55°C. After stirring evenly, add 6kg of ammonia water, adjust the pH value to 8.0, and make the transfer coating.

[0052] (2) Coating: Apply the mixed transfer coating to the PET base film 1 with a thickness of 12 μm through a clean and non-abrasive anilox roller, and dry it continuously at 120°C for 10s to form a protective film. Layer 2. The anilox roll is electro-engraved, the number of lines is 110 mesh, and the depth is 40μ. The length of the oven is 22m, and the temperature is low and high. The oven temperature is set at 80°C, 100°C, 120°C, 140°C, and 80°C. The transfer coating coating amount is 1.4g / m 2 .

[0053]...

Embodiment 3

[0060] (1) Mixing transfer coating: Add 40kg of water-based acrylic acid and cellulose acetate butyrate system, 16kg of sodium methallyl sulfonate, 12kg of polyethylene glycol, 14kg of ethyl acetate, and 108kg of deionized water into a stainless steel container in sequence Inside, stir evenly, the stirring speed is 800 rpm, and the stirring temperature is 65°C. After stirring evenly, add 10kg of ammonia water, adjust the pH value to 9.0, and make the transfer coating.

[0061] (2) Coating: apply the mixed transfer coating onto the PET base film 1 with a thickness of 24 μm through a clean and non-abrasive anilox roller, and dry it continuously at 100°C for 12s to form a protective film. Layer 2. The anilox roll is a squeeze roll with a thread count of 130 mesh and a depth of 40μ. The length of the oven is 20m, and the temperature is low and high. The oven temperature is set at 80°C, 100°C, 120°C, 140°C, and 80°C. The coating amount of the transfer coating is 1.2g / m 2 .

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com