Modified aluminum pigment and preparation method thereof, and coating containing same

An aluminum pigment, modified technology, used in inorganic pigment processing, chemical instruments and methods, coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

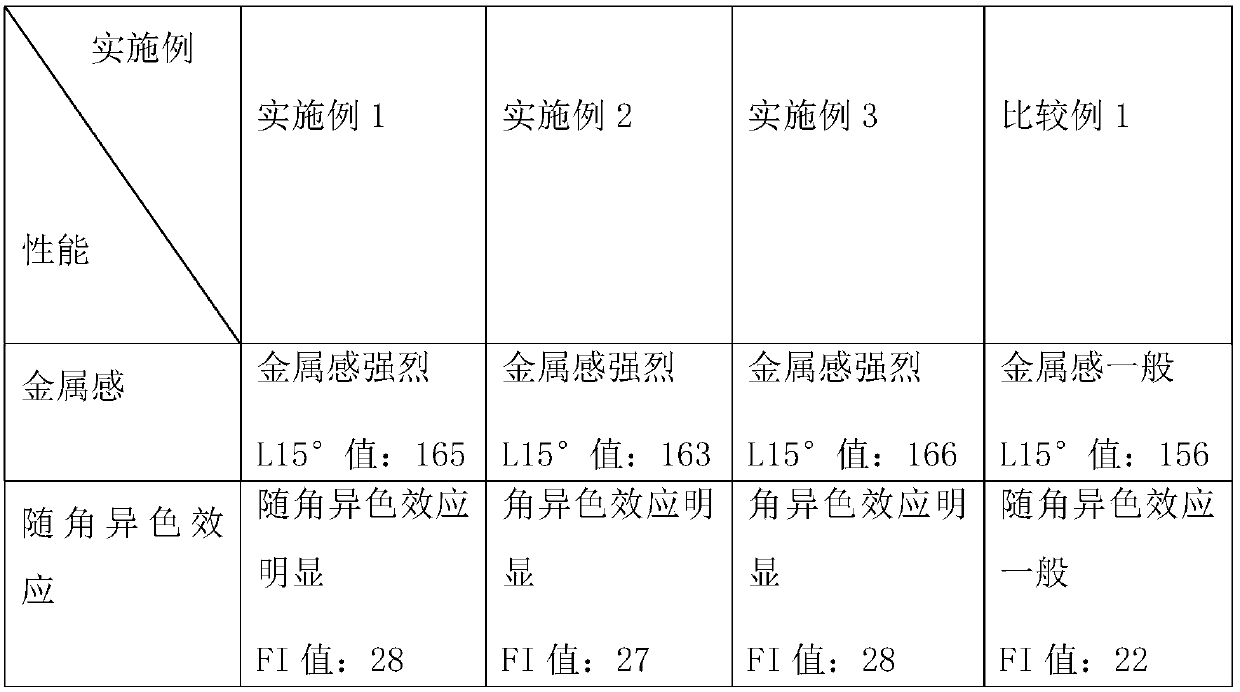

Embodiment 1

[0044]Add oleic acid to a glass reactor. Nano-rutile titanium dioxide was mixed with an equal mass of monoalkoxy unsaturated fatty acid titanate coupling agent (LD-105) and stirred to form a homogeneous mixture. The mixture is added into the oleic acid while stirring, so that the final content of the nano-titanium dioxide in the composite is about 2% by weight. During the reaction, the rotational speed was controlled at about 200 rev / min. The temperature of the reactor was controlled at 80 degrees, and after 2 hours, the reactor was shut down to cool down to room temperature, the compound was released, and left to stand for 24 hours. Supernatant liquid crosses 500 mesh screens to remove a small amount of impurity that is brought into in the raw material, collects filtrate and obtains the composite of nano-titanium dioxide and oleic acid that 4kg nano-titanium dioxide content is about 2% by weight.

[0045] Get the composite of 3kg nano-titanium dioxide and oleic acid from th...

Embodiment 2

[0049] Stearic acid was added to a glass reactor. Nano-rutile titanium dioxide was mixed with an equal mass of monoalkoxy unsaturated fatty acid titanate coupling agent (LD-105) and stirred to form a homogeneous mixture. The mixture is added into the stearic acid while stirring, so that the final content of the nano-titanium dioxide in the composite is about 1% by weight. During the reaction, the rotational speed was controlled at about 200 rev / min. Control the temperature of the reactor at 80°C, shut down the reactor after 2 hours and cool it down to room temperature, release the complex, and let it stand for 24 hours. Supernatant liquid crosses 500 mesh sieves to remove a small amount of impurity that is brought into in the raw material, collects filtrate and obtains the compound of nano-titanium dioxide and stearic acid that 5kg nano-titanium dioxide content is about 1% by weight.

[0050] Get the compound of 4kg nano-titanium dioxide and stearic acid from the above-menti...

Embodiment 3

[0054] Add lauric acid to a glass reactor. Nano-rutile titanium dioxide was mixed with an equal mass of monoalkoxy unsaturated fatty acid titanate coupling agent (LD-105) and stirred to form a homogeneous mixture. The mixture is added into the lauric acid while stirring, so that the final content of the nano-titanium dioxide in the composite is about 4% by weight. During the reaction, the rotational speed was controlled at about 200 rev / min. Control the temperature of the reactor at 90°C, shut down the reactor after 2 hours and cool it down to room temperature, release the complex, and let it stand for 24 hours. Supernatant liquid crosses 500 mesh sieves to remove a small amount of impurity that is brought into in the raw material, collects filtrate and obtains the compound of nano-titanium dioxide and lauric acid that 3kg nano-titanium dioxide content is about 4% by weight.

[0055] Get the composite of 2kg nano-titanium dioxide and lauric acid from the above-mentioned comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com