Patents

Literature

40results about How to "Suitable for assembly line production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Room-temperature litchi storage preservative, and preparation method and application of preservative

ActiveCN103564039ASimple and fast operationSuitable for assembly line productionFruit and vegetables preservationPesticide residuePhytic acid

The invention relates to the technical field of litchi preservation, and particularly discloses a room-temperature litchi storage preservative, and a preparation method and an application of the preservative. The preservative mainly comprises carboxymethyl-chitosan, nisin, natamycin, tea polyphenol, epsilon-polylysine, citric acid and phytic acid; litchi fruit is soaked in a preservation solution, and then aired, so that the litchi fruit can be stored at a room temperature; the quality and low level browning of the litchi fruit can be kept for a long time at the room temperature. Litchi treated by the preservative has the characteristics that the preservative is good in preservation effect, safe, environment-friendly, simple to operate and convenient to use; the preservative is extensive in source, low in cost, edible, and easy to degrade; no pesticide residue risk exists; short-term preservation during room-temperature storage and room-temperature logistics can be achieved; the preservative is a novel preservation material with a great development potential.

Owner:SOUTH CHINA AGRI UNIV

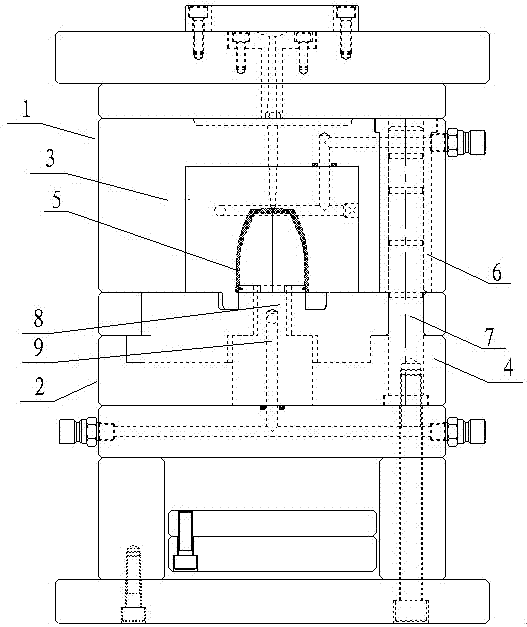

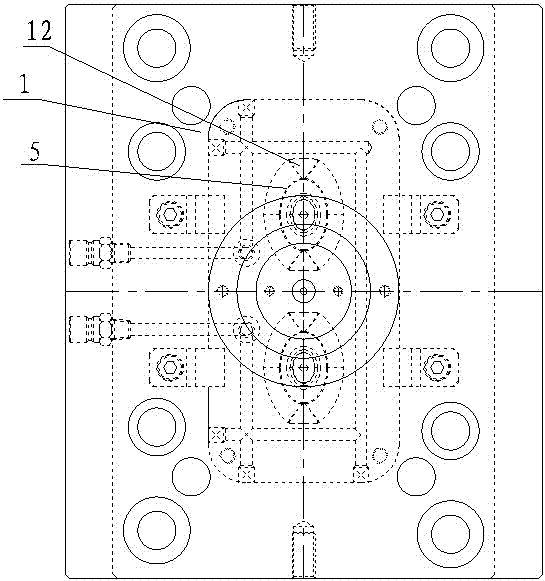

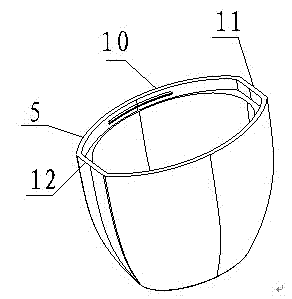

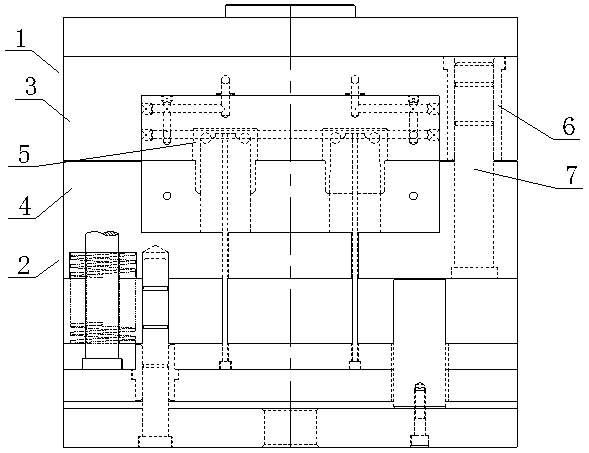

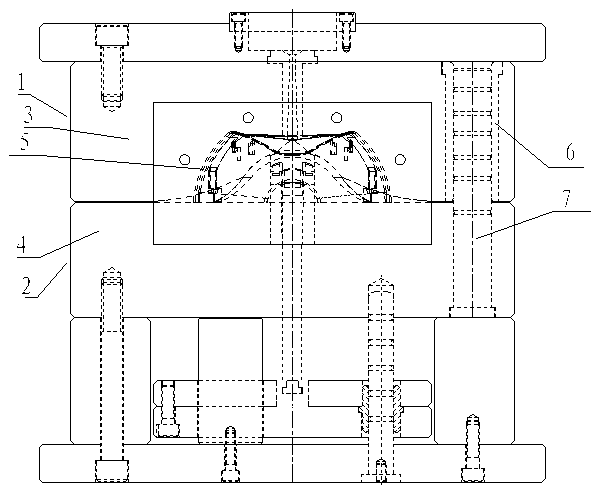

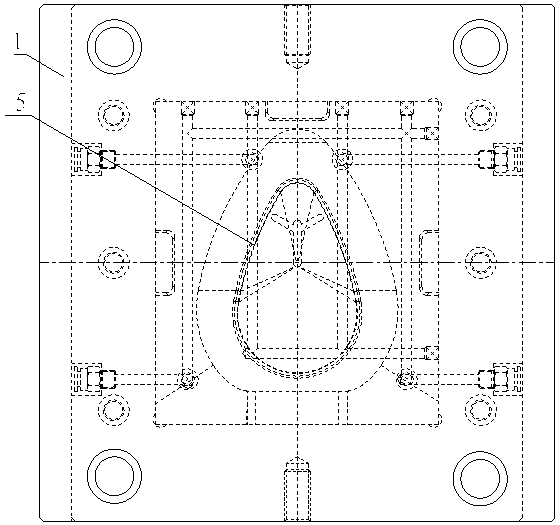

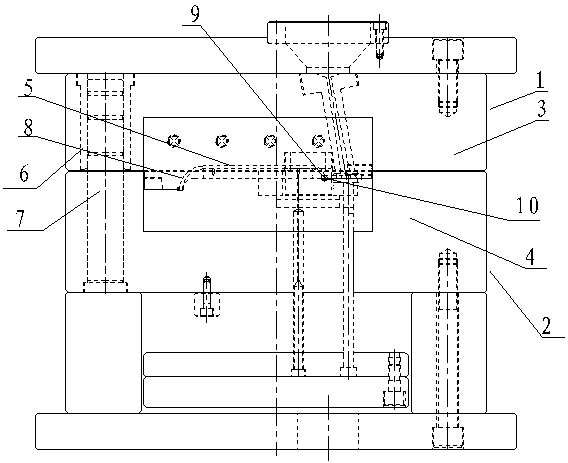

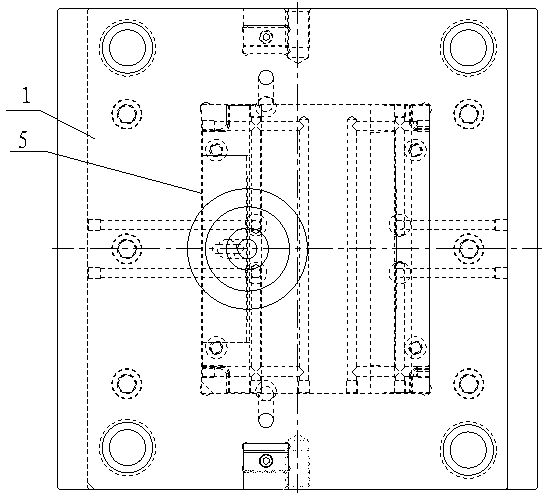

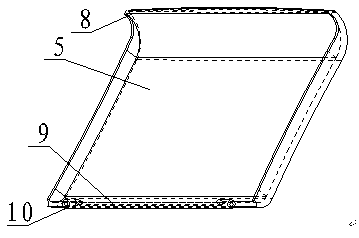

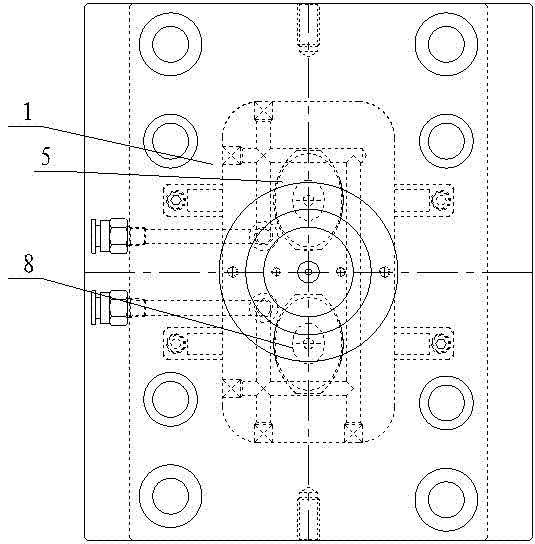

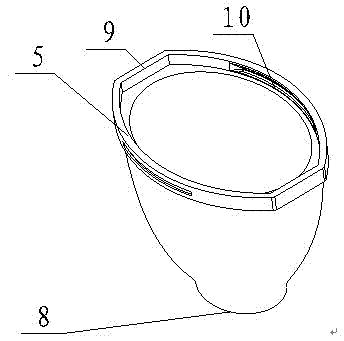

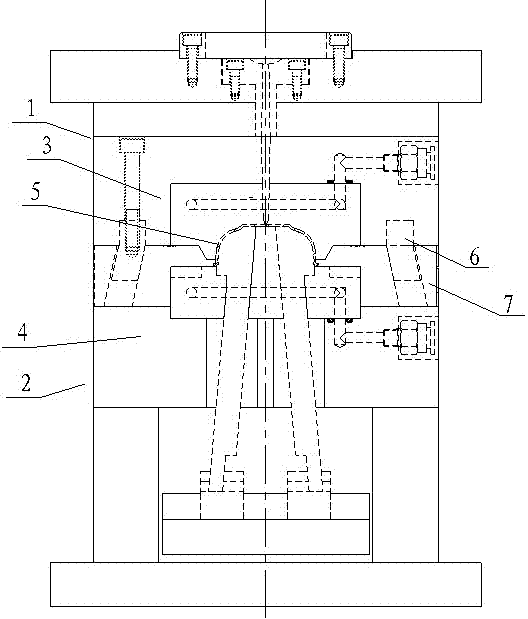

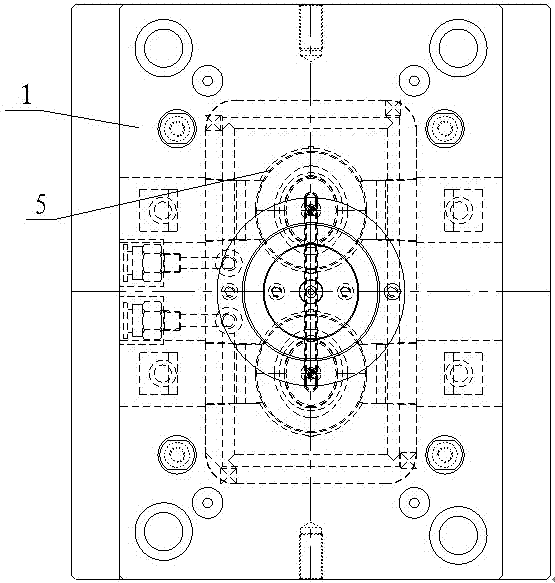

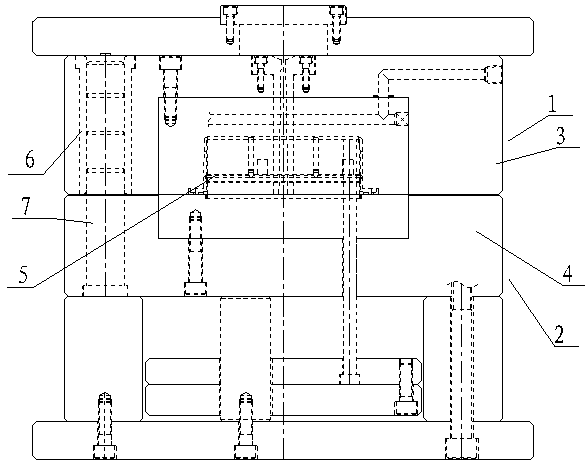

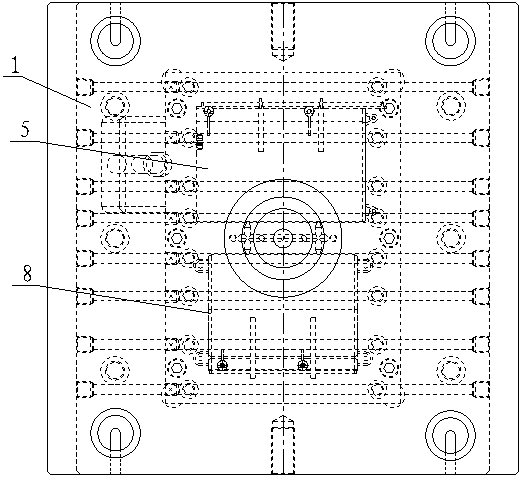

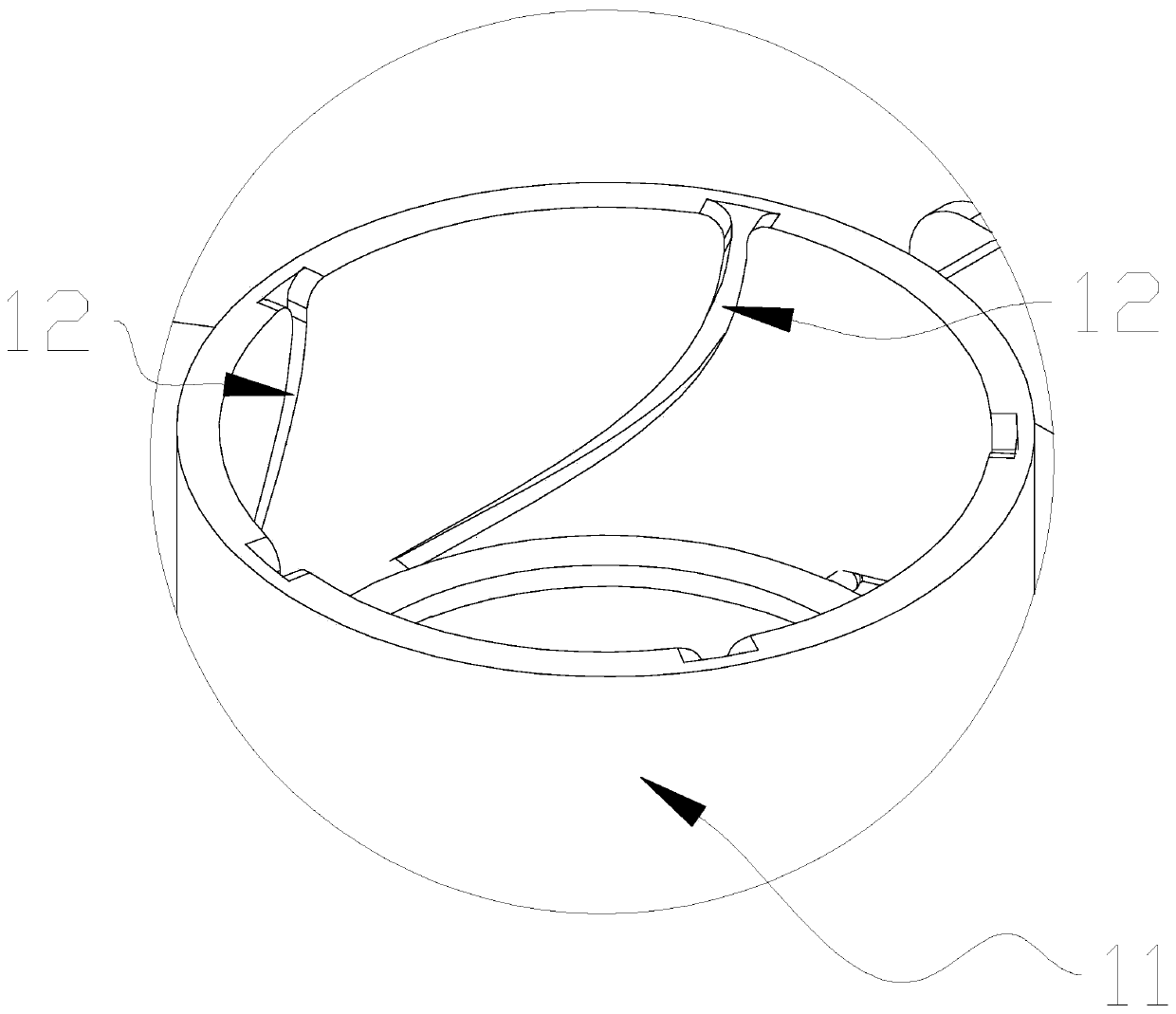

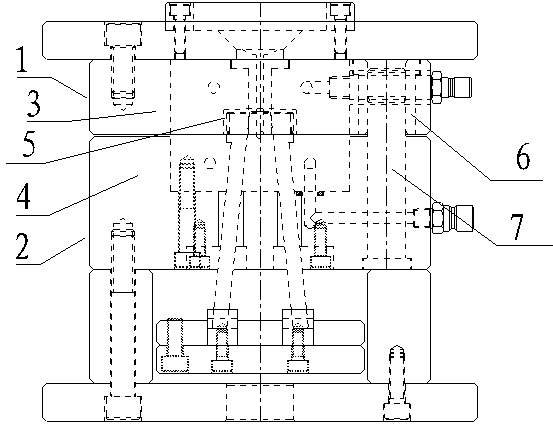

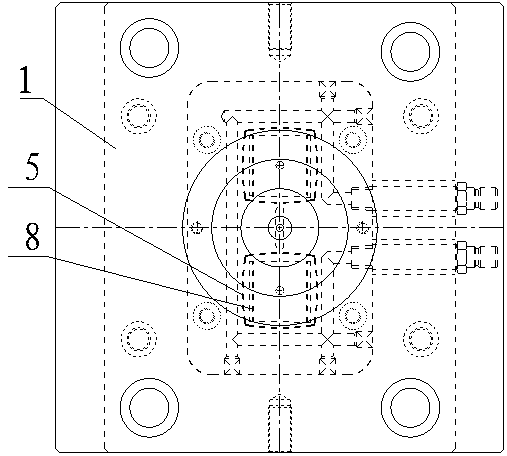

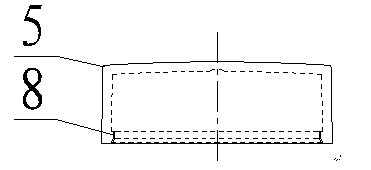

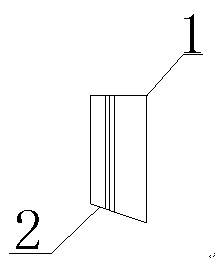

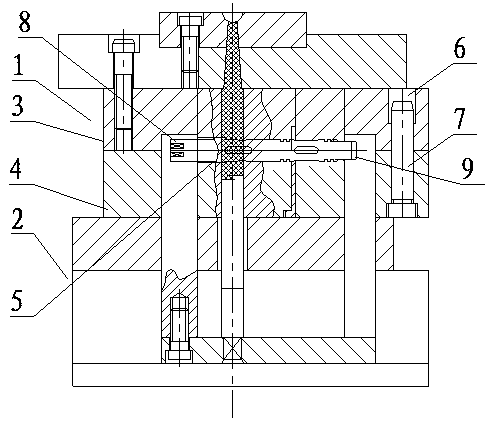

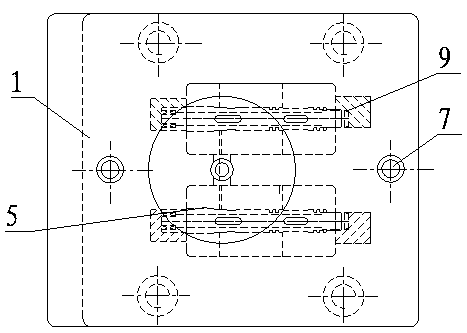

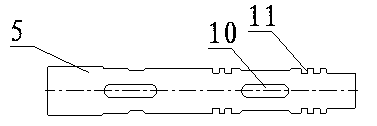

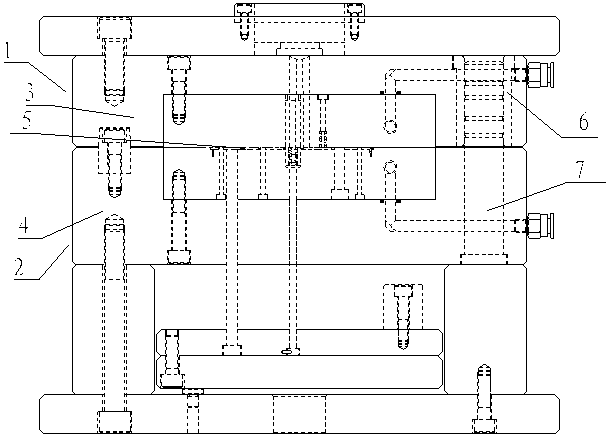

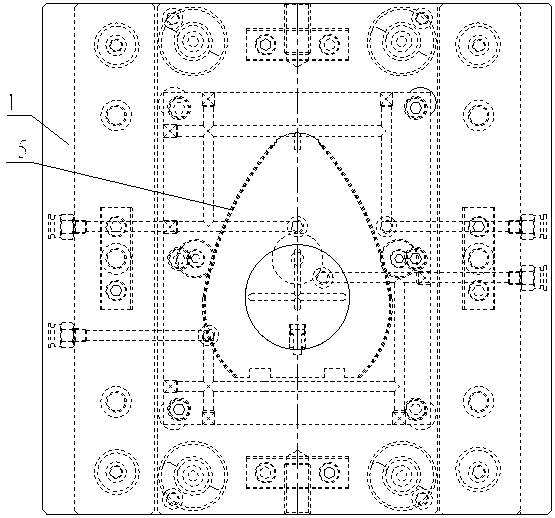

Plastic rubber forming mold of make-up base transparency cover

The invention discloses a plastic rubber forming mold of a make-up base transparency cover. The plastic rubber forming mold of the make-up base transparency cover comprises a fixed mold, a movable mold, a feeding port and a cooling water flow channel, wherein a fixed template of the fixed mold is provided with a guide sleeve in which a movable guide post is inserted; the guide post is fixed on a movable template of the movable mold; the movable mold is opened or closed through the guide post; the movable mold and the fixed mold are correspondingly engaged to form two forming cavities which are symmetrically arranged along an axial line of the movable template; the forming cavities are semi-enclosed cavities with openings at the upper ends thereof; the openings of the forming cavities are sealed openings which are formed by sequentially connecting two symmetrically distributed circular arc sides and two symmetrically distributed straight sides; the circular arc sides are outwards convex circular arcs; and the movable template is also embedded with a movable mold core in which a straight cooling water flow channel in a lengthways direction is arranged. Through the way mentioned above, the plastic rubber forming mold of the make-up base transparency cover, disclosed by the invention, has the advantages of simplifying production procedures, enabling the practical production to be more convenient and faster, saving human and material resources, being suitable for flow-line production of products, saving production cost and increasing production efficiency of enterprises.

Owner:苏州市吴中区木渎华利模具加工店

Ultraviolet aluminium-silver size coating with light curing

A ultraviolet light solidified aluminium silver slurry coating consists of acrylic resin 20-50wt%, acrylic ester monomer 10-50wt%, light initiating agent 3-10wt%, aluminium silver slurry 2-15wt%, aluminium silver slurry orienting agent 4-15wt%, assistants 0.3-2.5wt% and solvent 15-30wt%. It achieves fast curing speed, less organic volatile substances, higher production efficiency, better adhesion, hardness and abrasive-resistant performance.

Owner:CHINA LUCKY FILM CORP +1

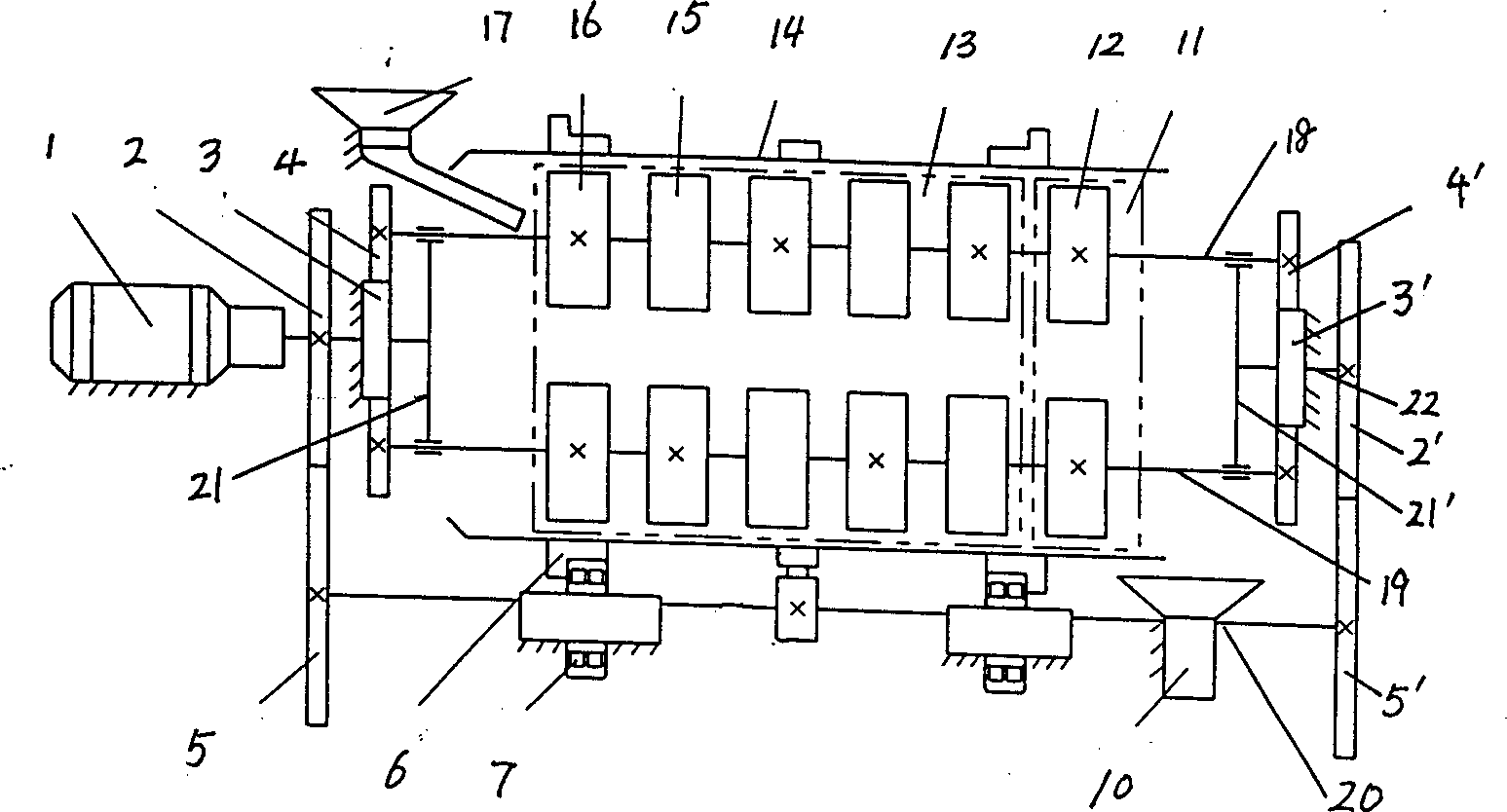

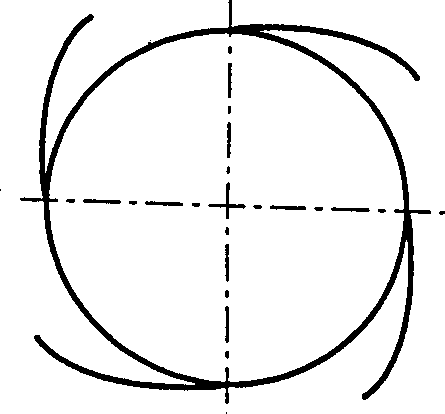

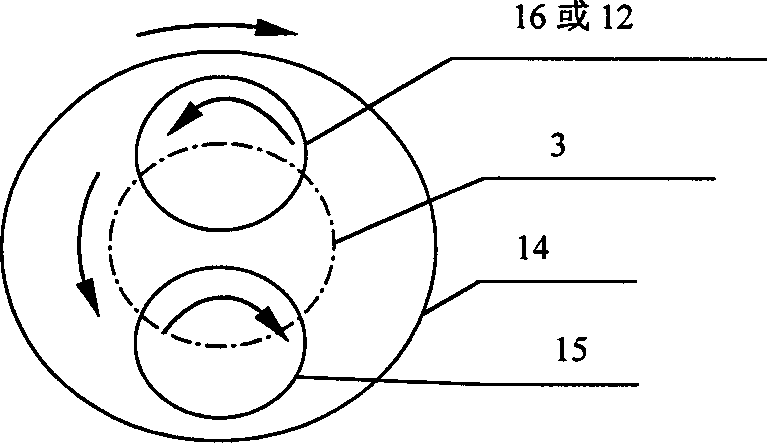

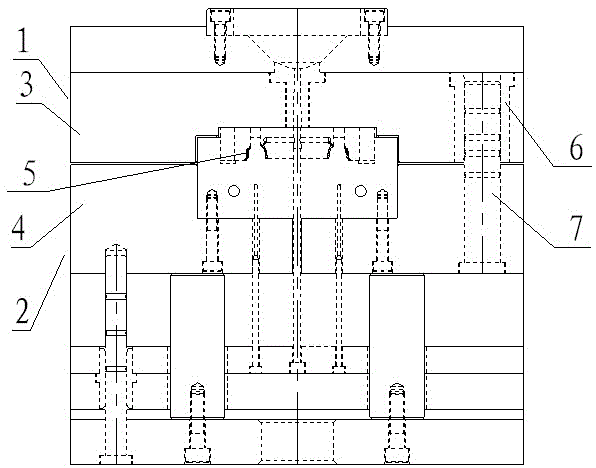

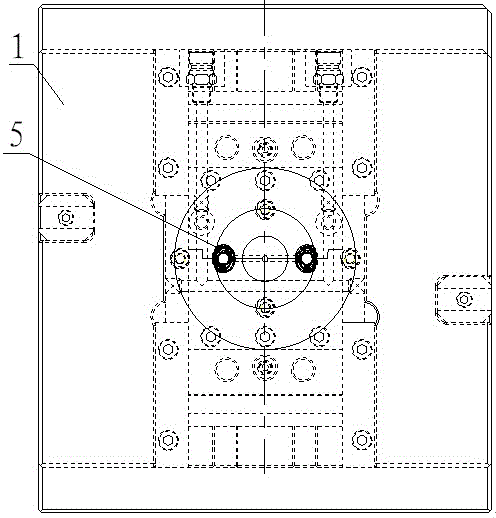

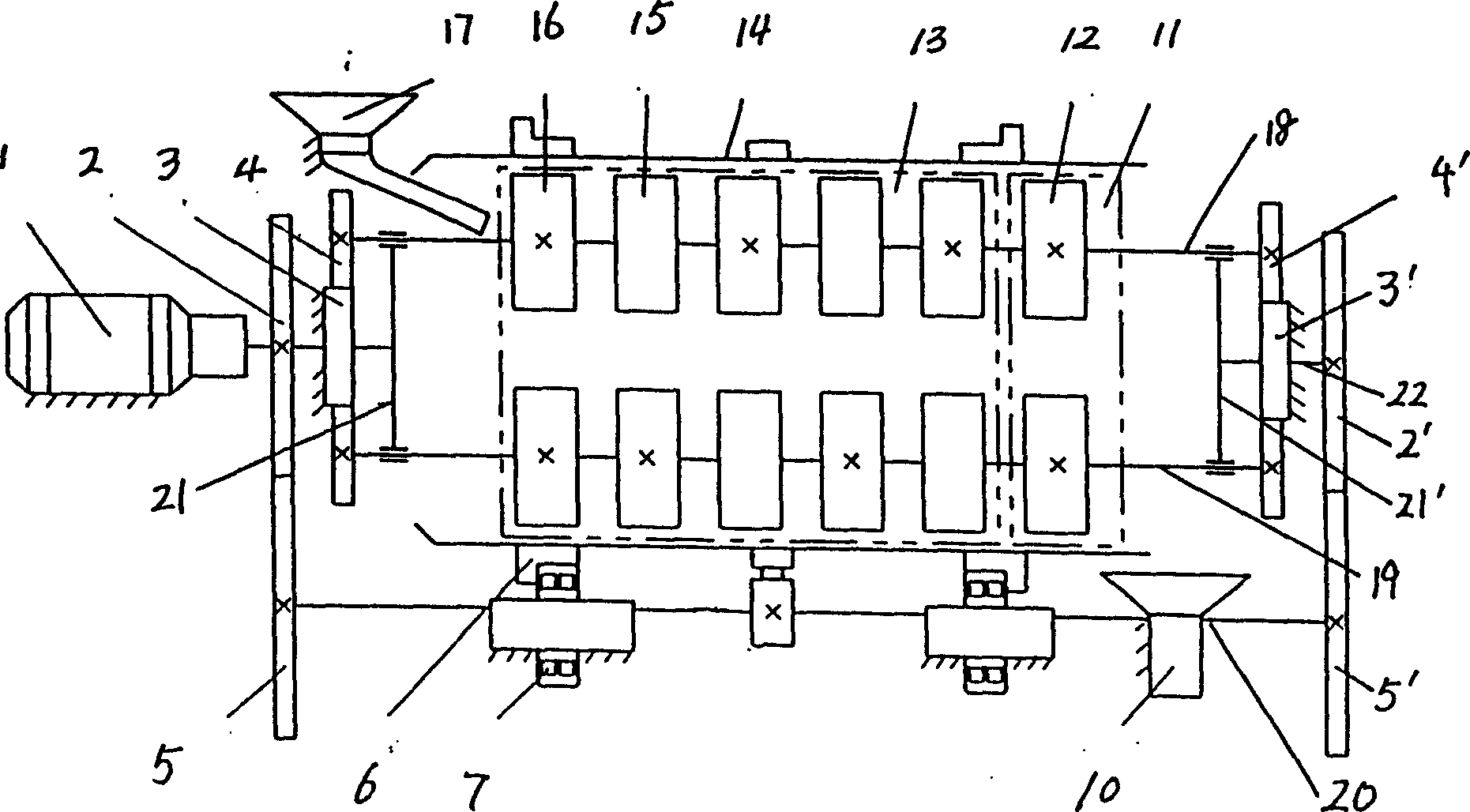

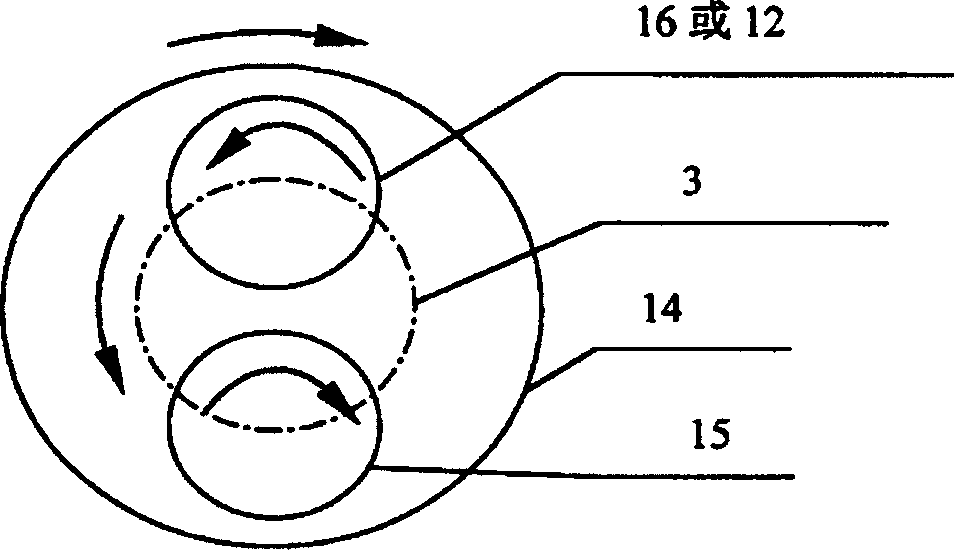

Continuous tea kneading machine

InactiveCN1362026AKneading quality is stableImprove work efficiencyPre-extraction tea treatmentSprocketEngineering

A continuous tea rubbing and twisting machine comprises motor, driving mechanism, planet wheel mechanism, rubbing and twisting device which sets a roller with spiral ridge bone on inside wall and is divided into rubbing and twisting zone with rubbing and twisting wheel as well as unblocking wheel, and strip twisting zone with strip twisting wheel. Both of the wheel of rubbing and twisting as wellas strip twisting wheel have spring rub hand, the shape of unblocking wheel is like of sprocket and there are two planet wheel mechanism on two sides of roller. The working principle is to utilize the revolution and the rotation of planet wheel mechanism to let the killing out of tea leaf ball in the roller rotated in reverse to the planet wheel break the leaf histocyte and finally form to a round strip shape along the main pulse by the acting force imposed from roller, rubbing and twisting wheel, strip twisting wheel and unblocking wheel.

Owner:HUAZHONG UNIV OF SCI & TECH

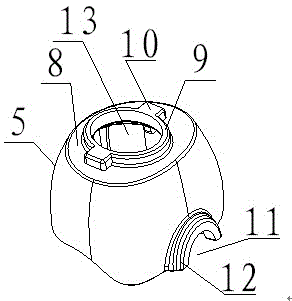

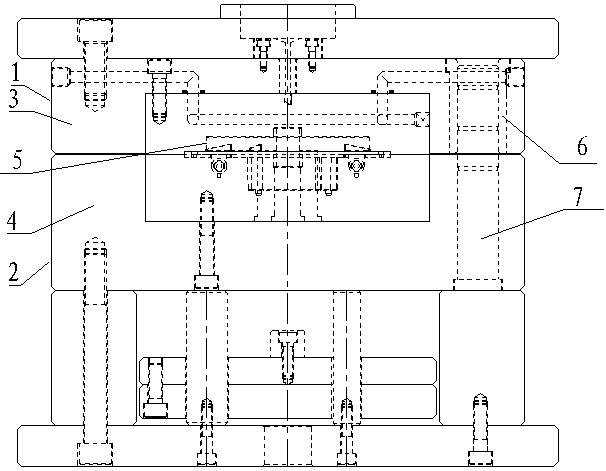

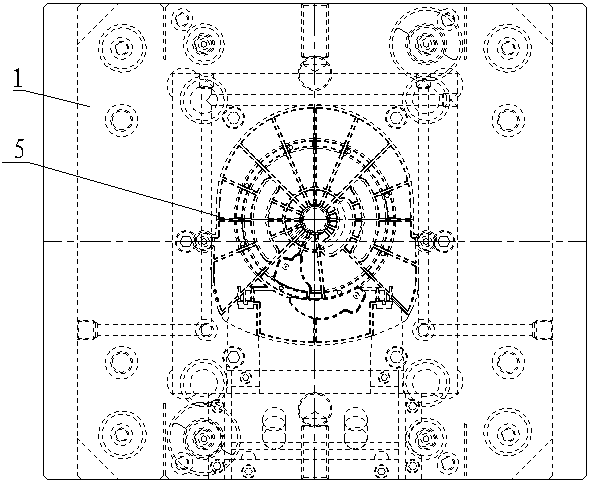

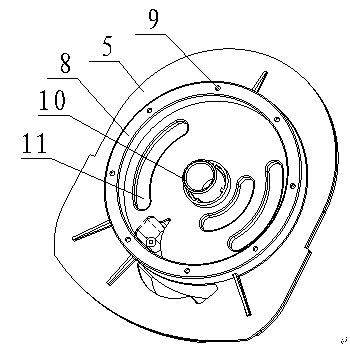

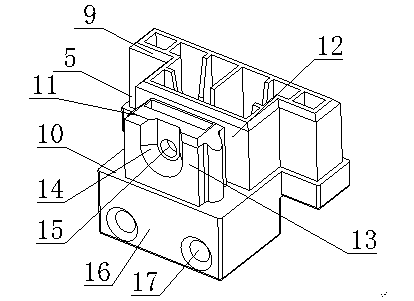

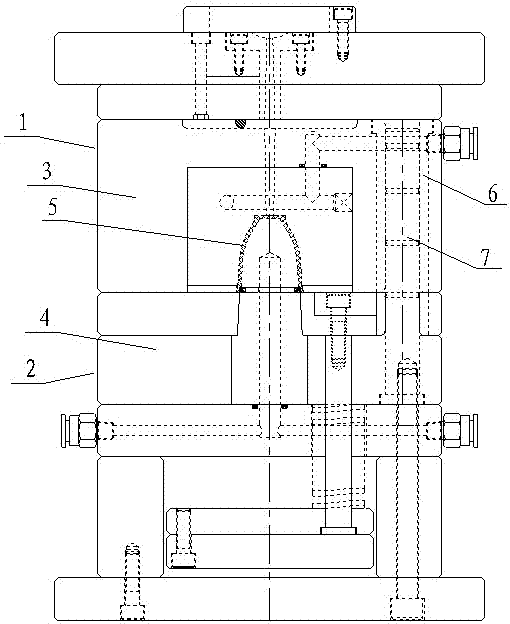

Molding plastic mold for software interface head

The invention discloses a molding plastic mold for a software interface head. The molding plastic mold disclosed herein comprises a fixed mold, a movable mold, a feed inlet and a cooling water channel, wherein a fixed template of the fixed mold is provided with a guide sleeve, a movable guide pillar is inserted in the guide sleeve, the guide pillar is fixed on a movable template of the movable mold, and the movable mold opens and closes by the guide pillar; the movable mold correspondingly occludes with the fixed mold to form two molding cavities, the two molding cavities are symmetrically arranged along the longitudinal axis of the movable mold, the molding cavity is a hollow frustum-shaped thin plate cavity, the bottom of the frustum-shaped thin plate cavity is an open-ended cavity, the top surface of the frustum-shaped thin plate cavity is provided with a pore cavity, the edge of the pore cavity is provided with an annular boss cavity, and the edge of the annular boss cavity is provided with connected rectangular table cavity. According to the invention, the production process can be simplified, manpower and material resources can be saved, the molding plastic mold disclosed herein is suitable for flow line production of products, the production cost is saved, and the production efficiency of the enterprise is raised.

Owner:SUZHOU WUZHONG ECONOMIC DEV ZONE BOYU MOLD PROCESSING FACTORY

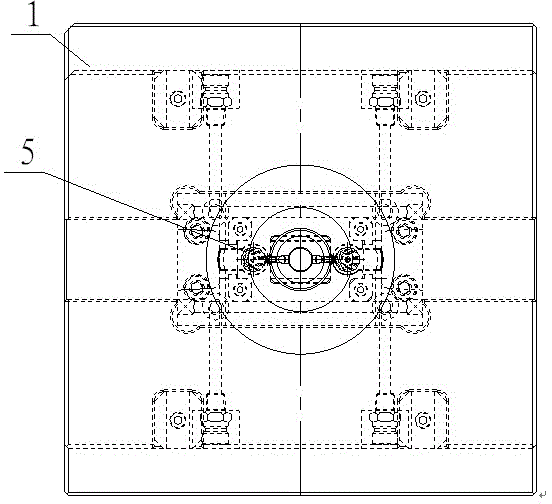

Base moulding plastic mould for electric room heater

The invention discloses a base moulding plastic mould for an electric room heater. The base moulding plastic mould of the electric room heater comprises a fixed die, a movable die, a feeding hole and a cooling water runner, wherein a fixed die plate of the fixed die is provided with a guide sleeve, a movable guide pillar is inserted into the guide sleeve, the guide pillar is fixed on a movable die plate of the movable die, and the movable die does open and close movement by virtue of the guide pillar; the movable die and the fixed die are correspondingly occluded into a moulding cavity, the moulding cavity is a thin plate cavity protruding upward, the front of the moulding cavity is provided with a circular boss cavity, eight screw mounting hole cavities are uniformly distributed on the circular boss cavity, the circular boss cavity is provided with one cylinder cavity at the center, the two sides of the cylinder cavity are provided with semicircle rotating sliding chute cavities, and multiple reinforcing rib cavities which are arranged in a radial shape from the center of the cylinder cavity to the outside are arranged at the concave surface side of the moulding cavity. By adopting the manner, a production process can be simplified and more human and material resources can be saved, so that the base moulding plastic mould disclosed by the invention is applicable to flow line production of a product, production cost is saved, and production efficiency of an enterprise is greatly improved.

Owner:苏州市吴中区木渎华利模具加工店

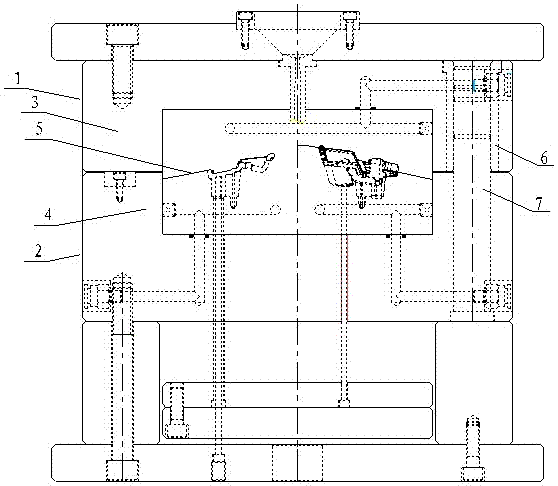

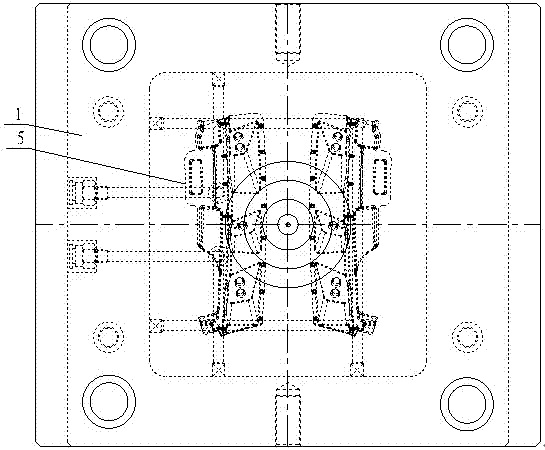

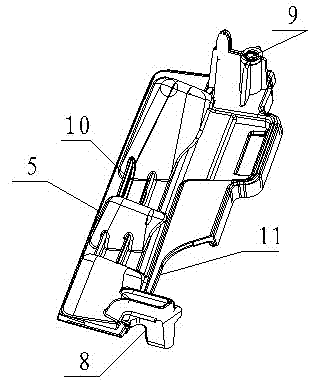

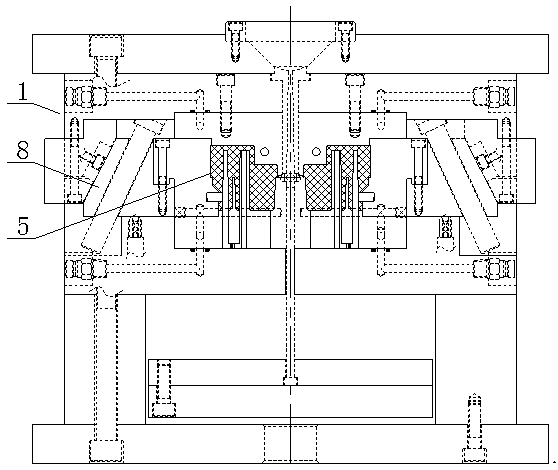

Plastic rubber mould for forming side supporting piece of automobile instrument desk

The invention discloses a plastic rubber mould for forming a side supporting piece of an automobile instrument desk. The plastic rubber mould for forming a side supporting piece of an automobile instrument desk comprises a stationary mould, a movable mould, a feeding port and a cooling water passage, wherein a guide sleeve is installed on a stationary mould plate of the stationary mould, a movable guide pillar is inserted into the guide sleeve, the guide pillar is fixed on a movable mould plate of the movable mould, the movable mould makes open and close movement through the guide pillar, two four forming cavities are formed after the movable mould and the stationary mould are correspondingly engaged, and the two forming cavities are symmetrically arranged along the transverse axis of the movable mould plate; and a plurality of reinforcing rib cavities are distributed on the long-strip cavity bodies of the forming cavities, one end of each forming cavity is provided with an installing hook cavity, the other end of the forming cavity is provided with a screw installing hole cavity, and reinforcing rib cavities are arranged on both the installing hook cavity and the screw installing hole cavity. Via the above way, the side supporting piece of an automobile instrument desk can be quickly formed, two supporting pieces can be simultaneously machined, the production efficiency of the plastic rubber mould is increased, the rate of finished products is increased, the production cost is reduced, and the wasting of resources is avoided.

Owner:苏州市吴中区木渎华利模具加工店

Leechee color protecting and preserving method and leechee color protecting and preserving treatment solution

InactiveCN102018026AReduce dosageSimple and fast operationFruits/vegetable preservation by freezing/coolingOrganic acidO-Phosphoric Acid

The invention belongs to the field of preserving and relates to a leechee color protecting and preserving method. In the method, picked leechees are soaked in a hot acid solution for treating, and the adopted hot acid solution is prepared by mixing organic acid and inorganic acid, wherein the organic acid is citric acid or malic acid, the inorganic acid is hydrochloric acid or phosphoric acid, and the temperature during treating is maintained at 50-80 DEG C. The method can effectively maintain the red color of leechee peels so as to achieve the purposes of maintaining the fruit appearance, prolonging the storage period and the shelf life and reducing loss after picking. The invention has the advantages of simple and convenient process flow, simple and high-efficiency operation, obvious effect, and the like.

Owner:SOUTH CHINA AGRI UNIV

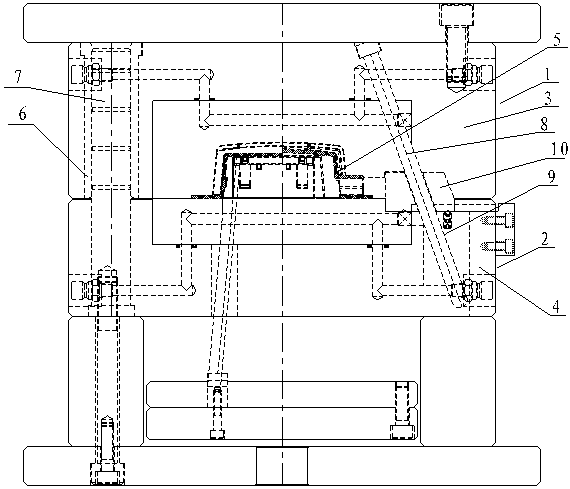

Molding plastic mold for automobile power supply module box

The invention discloses a molding plastic mold for an automobile power supply module box. The molding plastic mold for the automobile power supply module box comprises a fixed mold, a moving mold, a feed port and a cooling water flow passage, wherein a guide sleeve is mounted on a fixed mold plate of the fixed mold, a movable guide pole is inserted in the guide sleeve, the guide pole is fixed on a moving mold plate of the moving mold, and the moving mold can perform opening and closing motion through the guide pole; four molding cavities are formed after the moving mold and the fixed mold are correspondingly engaged, and the four molding cavities are symmetrically arranged like a rectangle; four oblique wedge block mechanisms are arranged on the moving mold, and each oblique wedge block mechanism corresponds to a molding cavity; and each molding cavity is provided with a T-shaped opening and is superimposed on a rectangular cubic cavity, and the cavity with the T-shaped opening and the rectangular cubic cavity are communicated. Through the way, the production process steps can be simplified, more manpower and material resources can be simultaneously saved, the molding plastic mold is suitable for production of products through an assembly line, the production cost is saved, and the production efficiency of an enterprise is greatly improved.

Owner:SUZHOU WUZHONG ECONOMIC DEV ZONE BOYU MOLD PROCESSING FACTORY

Plastic rubber mould for forming embedded box of refrigerator display screen

The invention discloses a plastic rubber mould for forming an embedded box of a refrigerator display screen. The plastic rubber mould for forming an embedded box of a refrigerator display screen comprises a stationary mould, a movable mould, a feeding port and a cooling water passage, wherein a guide sleeve is installed on a stationary mould plate of the stationary mould, a movable guide pillar is inserted into the guide sleeve, the guide pillar is fixed on a movable mould plate of the movable mould, the movable mould makes open and close movement through the guide pillar, and one forming cavity is formed after the movable mould and the stationary mould are correspondingly engaged; a movable oblique guide rod is also installed on the stationary mould plate of the stationary mould, the oblique guide rod is inserted into an oblique guide slot of the movable mould plate, an oblique sliding block is also sheathed on the oblique guide rod, and the oblique sliding block is movably connected with the movable mould plate; and the forming cavity is a semi-closed cavity with an upper opening and one side opening. Via the above way, the production procedure is simplified, so that actual production becomes more convenient and quicker, more labor and material resources are economized, the plastic rubber mould is applicable to the flow line production of products, the production cost is economized, and the production efficiency of an enterprise is greatly increased.

Owner:苏州市吴中区木渎华利模具加工店

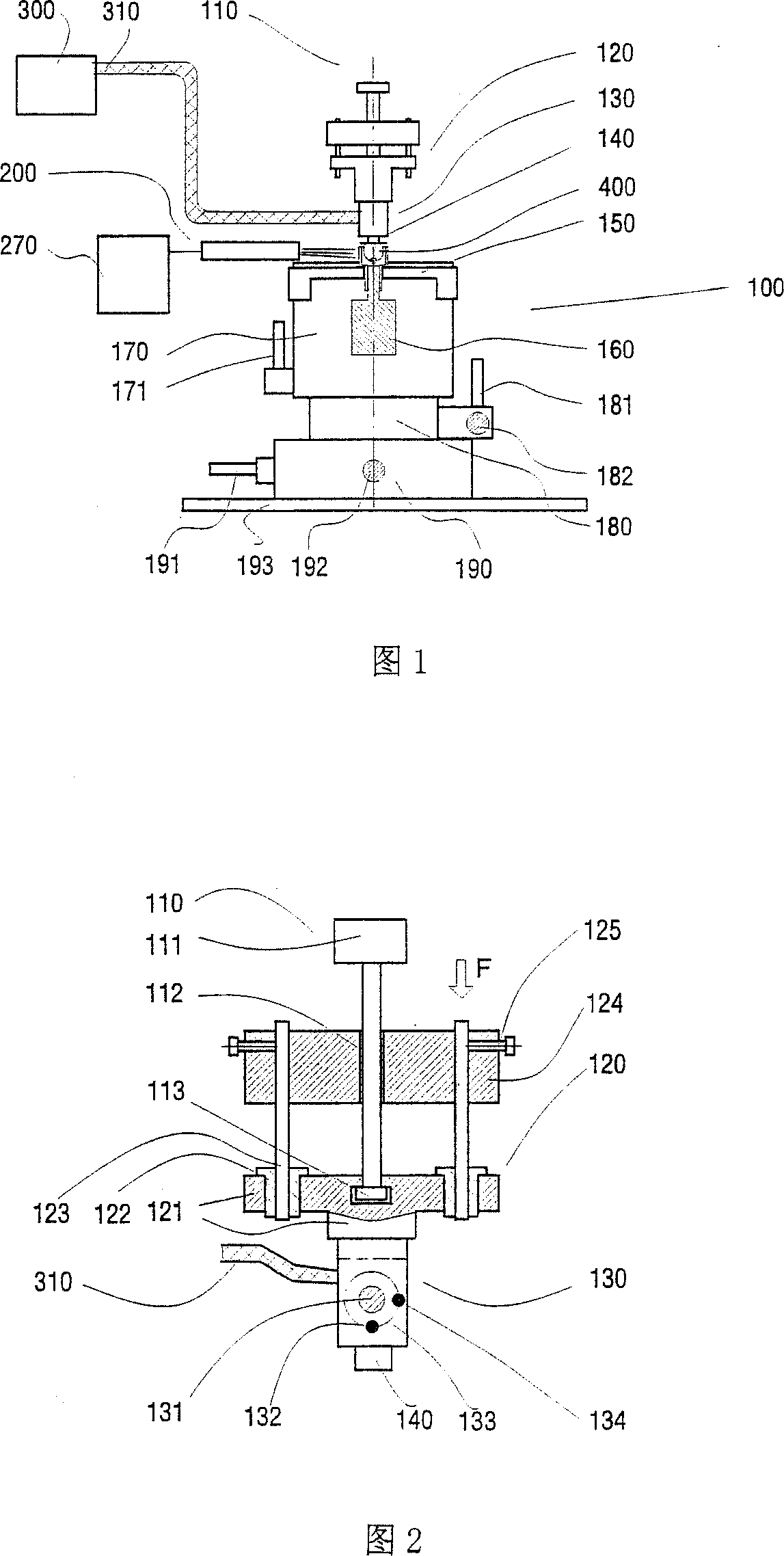

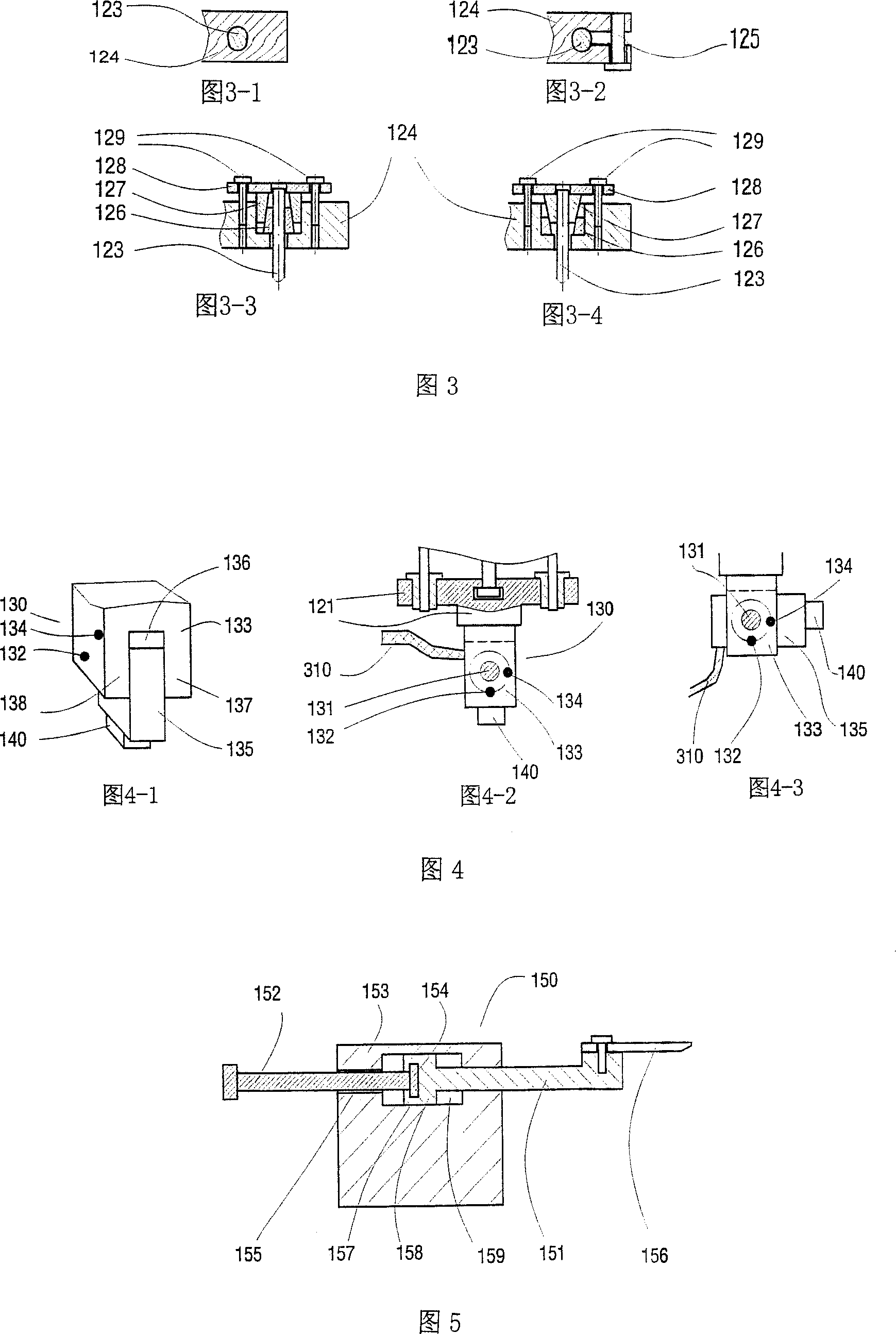

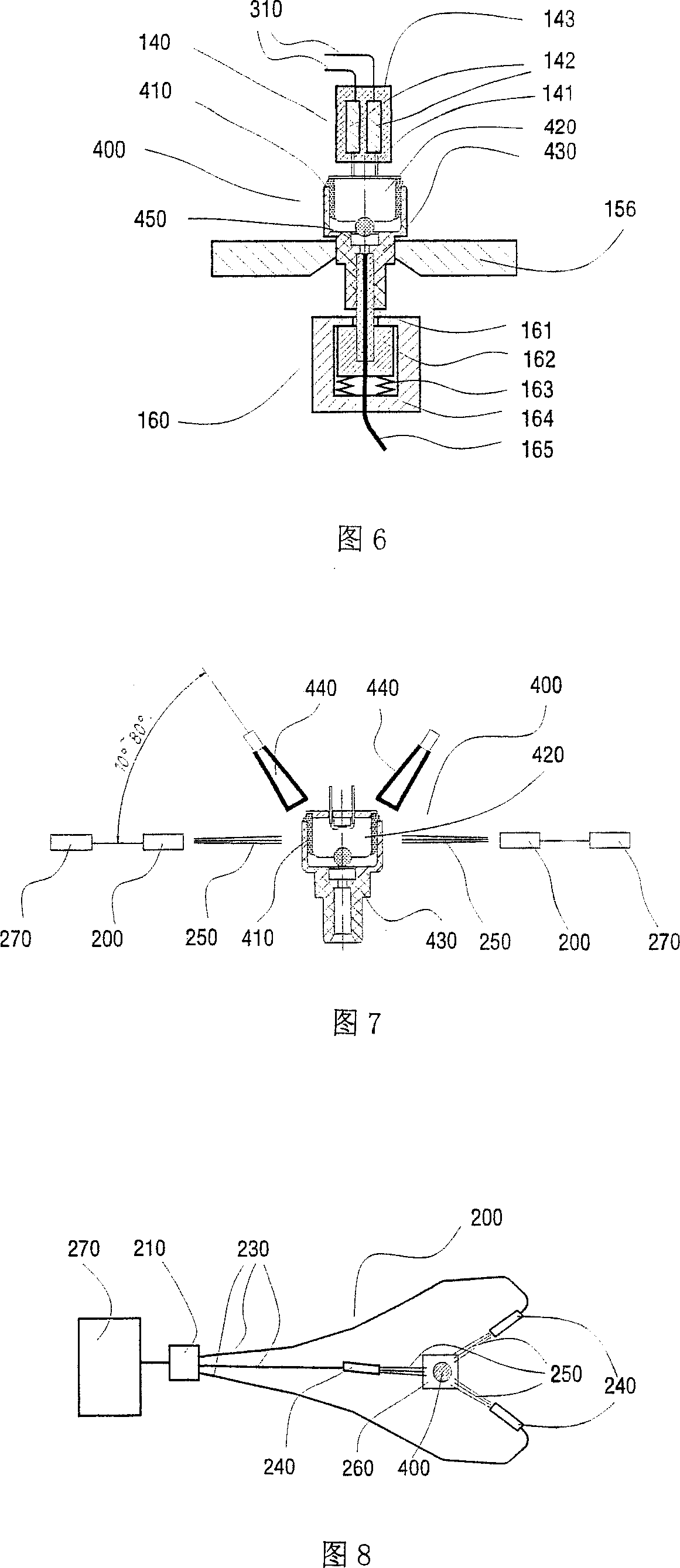

Device for curing packaging optoelectronic conversion modules based on coherent optical radiation and method thereof

ActiveCN101017226AAvoid vibrationReduce the displacement factorCoupling light guidesOptical radiationElectricity

This invention discloses one device and its method of fix sealing photo electricity conversion part based relative light radiation and to photo electricity conversion parts technique, which comprises couple system, light path device and circuit device, wherein, the couple system is to fix and clamp the conversion parts to realize fine adjust mechanic system; light path device is to emit the work position or light to be coupled optical system; circuit device is to provide electricity source, light source, receive and amplification signal display circuit.

Owner:WUHAN TELECOMM DEVICES

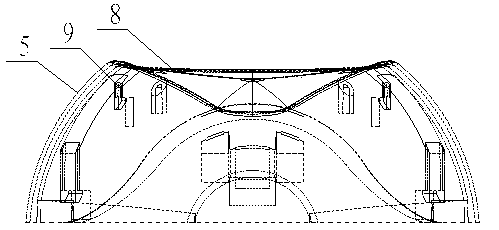

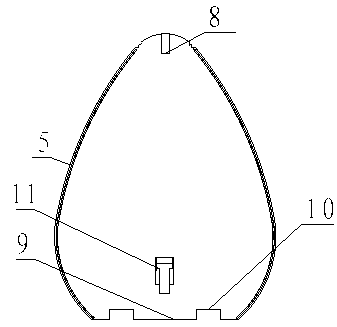

Acrylic mold for molding front shell of drop-shaped electric heater

The invention discloses an acrylic mold for molding a front shell of a drop-shaped electric heater. The acrylic mold for molding the front shell of the drop-shaped electric heater comprises a fixed die, a movable die, a feeding hole and a cooling water runner, wherein a guide sleeve is arranged on a fixed template of the fixed die; a movable guide post is inserted into the guide sleeve; the guide post is fixed on a movable template of the movable die; the movable die can do open and close movement through the guide post; the movable die and the fixed die form a forming cavity after being correspondingly meshed; the forming cavity is as follows: a drop-shaped front cover installing cavity is arranged in the middle of a drop-shaped frame type slab cavity, and six grab cavities for installing front cover are arranged at the surface of an inner cavity of the forming cavity. In the manner, the production process can be simplified; the actual production is relatively convenient and fast; the manpower and material resources are saved at the same time; the acrylic mold is suitable for the flow line production of products; and the production cost is saved, and the production efficiency of an enterprise is greatly improved.

Owner:苏州市吴中区木渎华利模具加工店

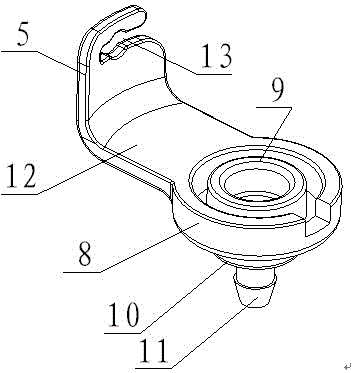

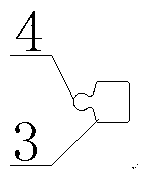

Molding plastic mold for automobile rotary connection buckle

The invention discloses a molding plastic mold for an automobile rotary connection buckle. The molding plastic mold disclosed herein comprises a fixed mold, a movable mold, a feed inlet and a cooling water channel, wherein a fixed template of the fixed mold is provided with a guide sleeve, a movable guide pillar is inserted in the guide sleeve, the guide pillar is fixed on a movable template of the movable mold, and the movable mold opens and closes by the guide pillar; the movable mold correspondingly occludes with the fixed mold to form two molding cavities, the two molding cavities are symmetrically arranged along the longitudinal axis of the movable mold, the molding cavity is characterized that the center of a disc-shaped cavity having a flanging cavity is provided with an annular boss cavity, the bottom of the disc-shaped cavity is provided with a circular truncated cone cavity, the circular truncated cone cavity is provided with a vertical rotary column cavity, and the center of the rotary column cavity is provided with a center pore cavity passing through the circular truncated cone cavity and the disc-shaped cavity. According to the invention, the production process can be simplified, manpower and material resources can be saved, the molding plastic mold disclosed herein is suitable for flow line production of products, the production cost is saved, and the production efficiency of the enterprise is raised.

Owner:SUZHOU WUZHONG ECONOMIC DEV ZONE BOYU MOLD PROCESSING FACTORY

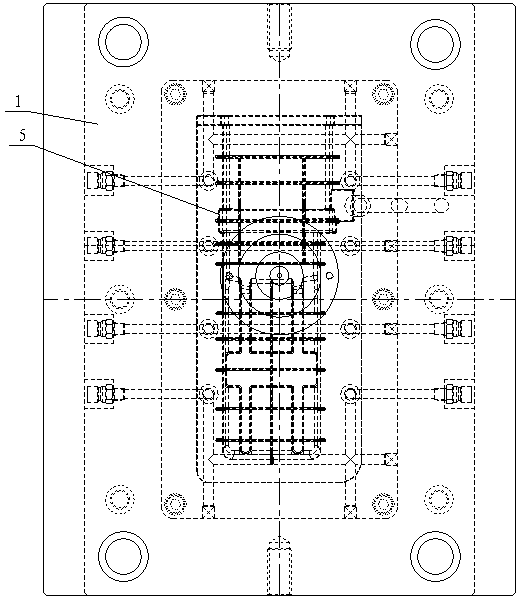

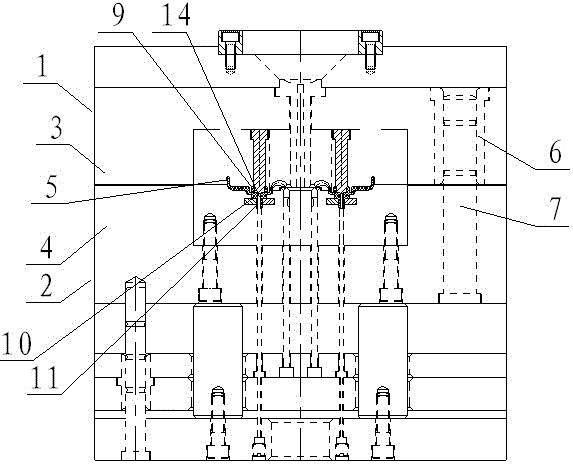

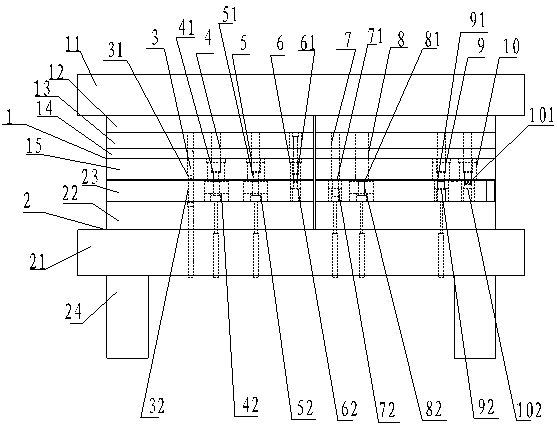

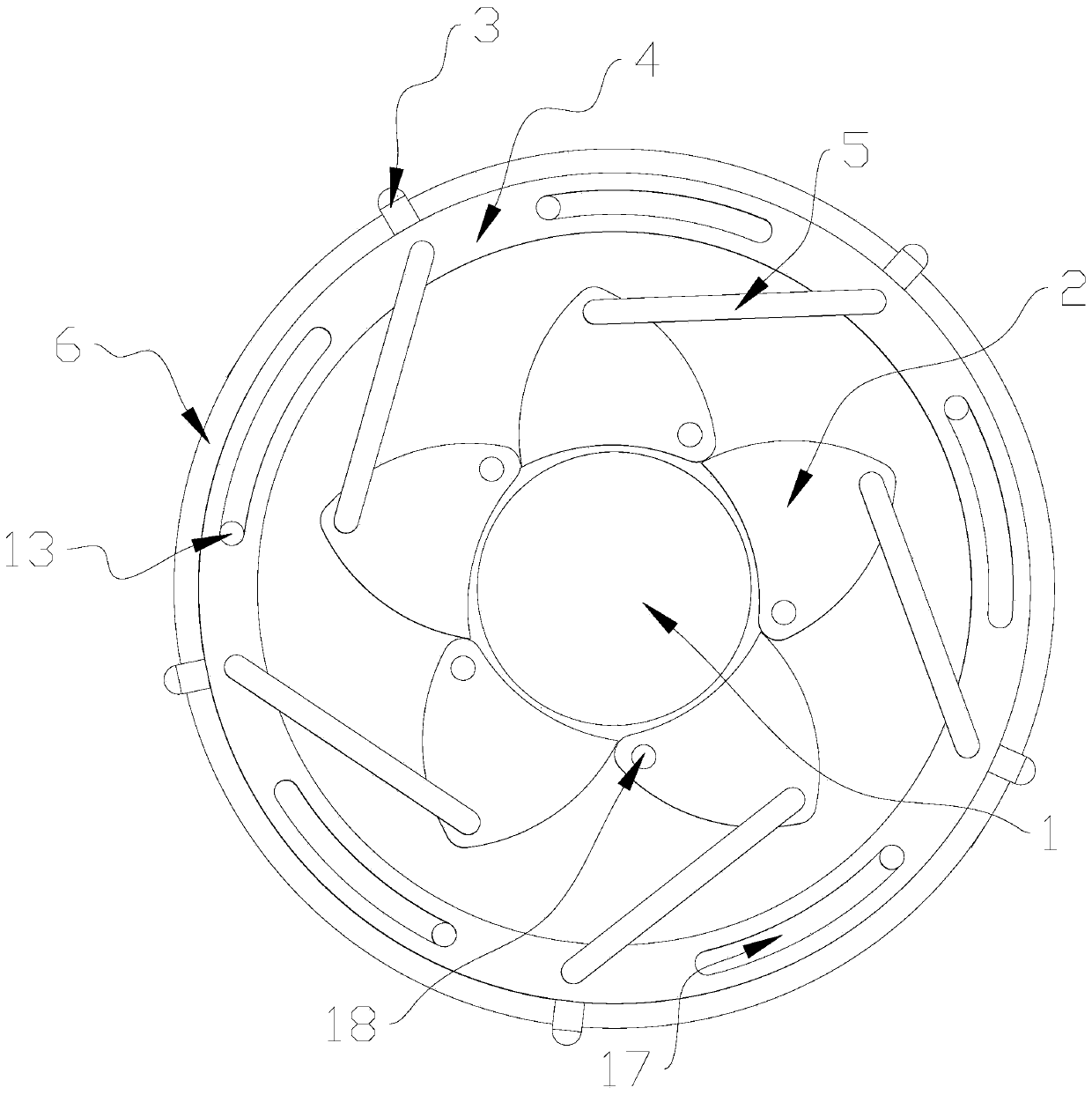

Mobile phone lens support frame continuous punching die

The invention discloses a mobile phone lens support frame continuous punching die. The mobile phone lens support frame continuous punching die conducts punch forming to products through an upper die, a lower die, a side hole punching die, an outer shape die-cutting die, a pre-molding stamp die, a middle hole thick die-cutting die, a scrap chopper die-cutting die, a fine molding stamp die, a half-cutting stamp die and a material discharge die-cutting die, wherein the upper die and the lower die are mutually meshed in a locating mode, and the side hole punching die, the outer shape die-cutting die, the pre-molding stamp die, the middle hole thick die-cutting die, the scrap chopper die-cutting die, the fine molding stamp die, the half-cutting stamp die and the material discharge die-cutting die are arranged between the upper die and the lower die. According to the mobile phone lens support frame continuous punching die, the production process is simplified, and thus actual production is enabled to be conducted conveniently and rapidly. At the same time, human and material resources are saved, the production cost is lowered, and the production efficiency of an enterprise is improved. The mobile phone lens support frame continuous punching die is suitable for flow line production of products.

Owner:SUZHOU WUZHONG ECONOMIC DEV ZONE BOYU MOLD PROCESSING FACTORY

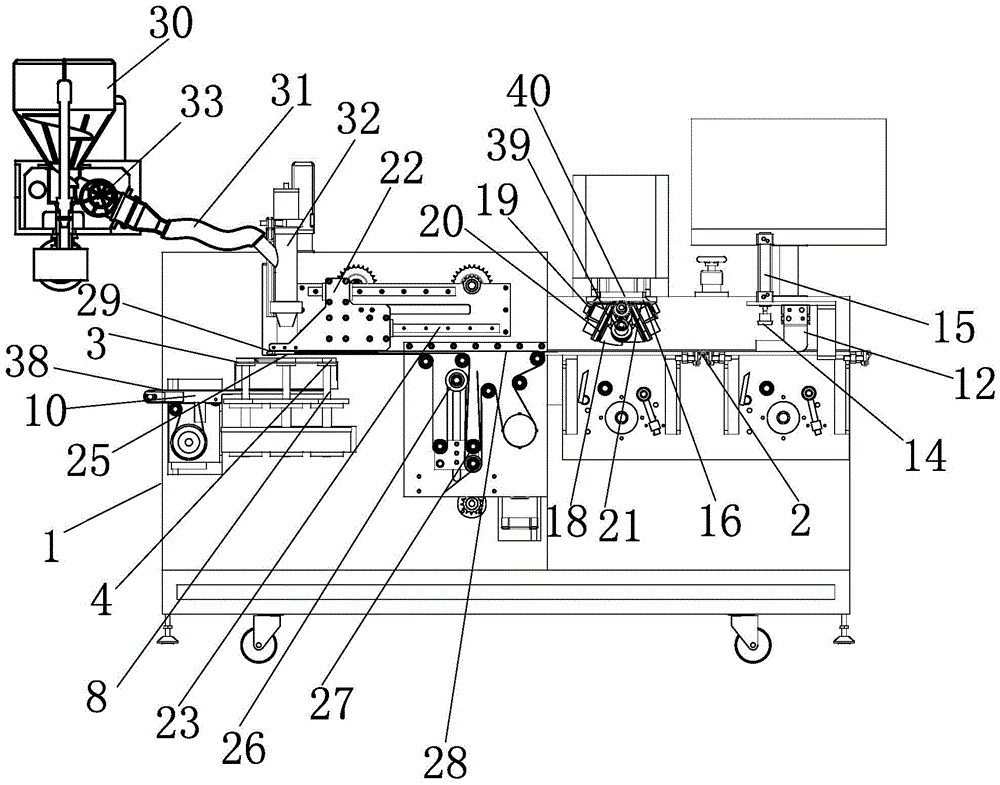

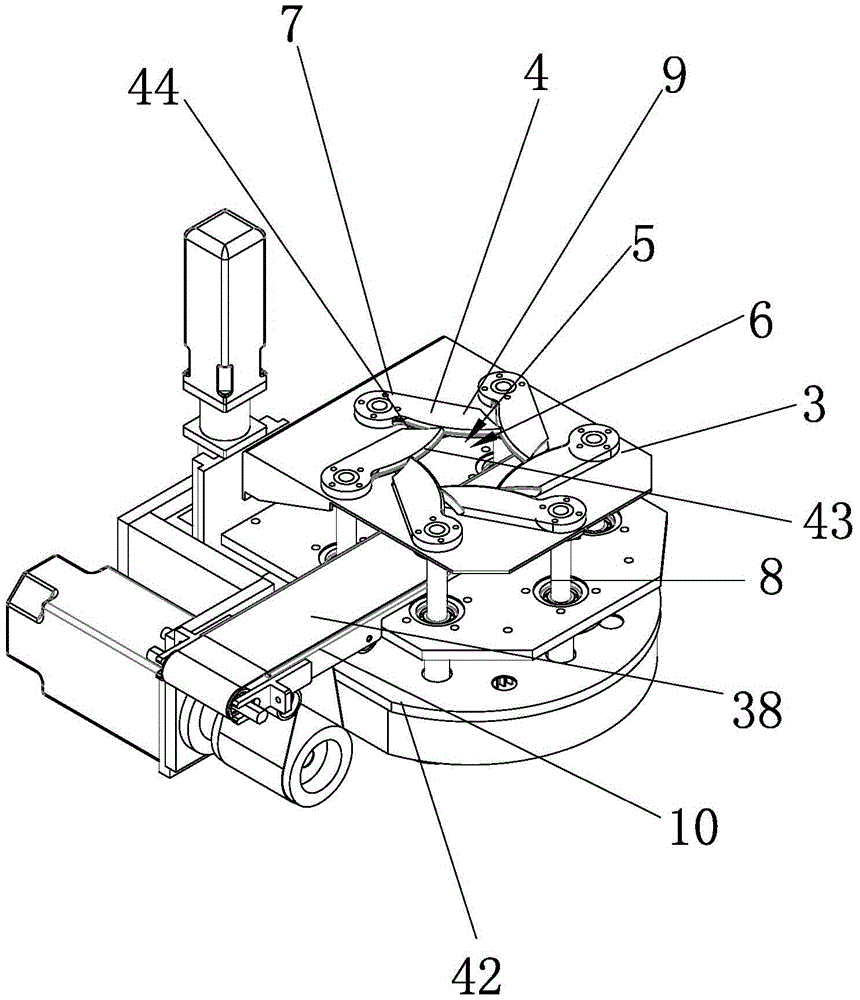

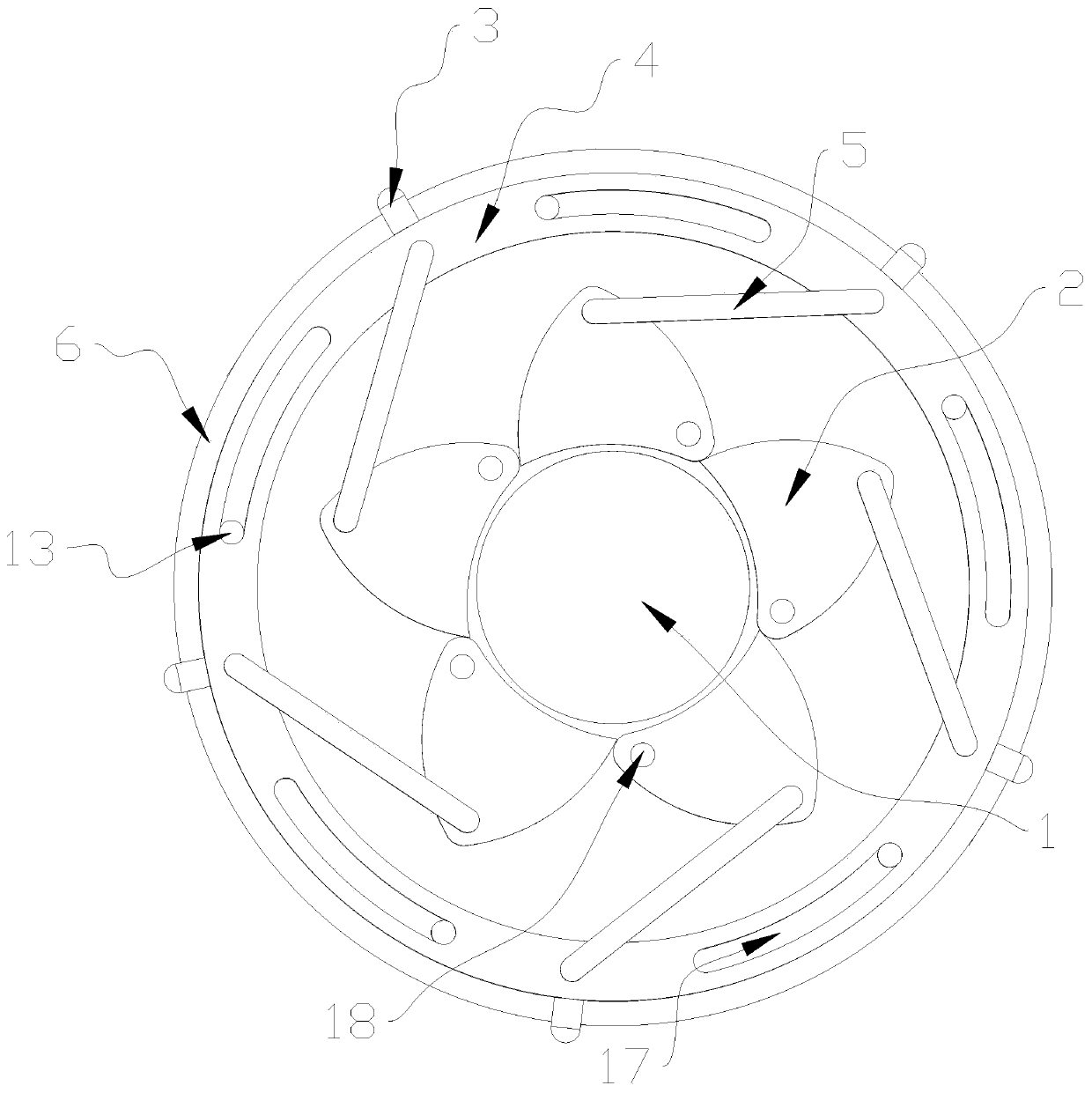

Food stuffing filling machine

PendingCN105104464ACompact structureHigh degree of automationDough processingEngineeringConveyor belt

The invention provides a food stuffing filling machine, belongs to the technical field of food processing machinery, and aims at solving the problems that the automation degree of the existing food stuffing filling production equipment is low and the like. The food stuffing filling machine comprises a rack, a conveyor belt which is arranged according to a processing flow direction, and a rounding device for enabling dough to form a cylinder shape, a rolling device, a wrapper storing device, a stuffing filling device and a covering and forming device which are arranged sequentially along the conveyor belt, wherein the covering and forming device comprises a fixed seat, a plurality of covering fingers and a first driving mechanism; each covering finger is rotationally connected to the fixed seat through a first rotary shaft; the first rotary shafts are arrayed at equal distances along a circumference; a covering clamping opening is formed in the center of each covering finger; and the first driving mechanism is used for driving the covering fingers to rotate by taking the corresponding first rotary shafts as central shafts so that the covering clamping openings are expanded and retracted. The food stuffing filling machine has high production efficiency; and a whole process does not need manual work so that the food stuffing filling machine is suitable for flow line production of foods.

Owner:金华市喜加达智能设备有限公司

Moulding plastic mould used for surface cover of cleaning machine

The invention discloses a moulding plastic mould used for a surface cover of a cleaning machine. The moulding plastic mould used for the surface cover of the cleaning machine comprises a fixed die, a movable die, a feeding hole and a cooling water runner, wherein a fixed die plate of the fixed die is provided with a guide sleeve, a movable guide pillar is inserted into the guide sleeve, the guide pillar is fixed on a movable die plate of the movable die, and the movable die does open and close movement by virtue of the guide pillar; and the movable die and the fixed die are correspondingly occluded to form one moulding cavity, the moulding cavity is a square box-like cavity, one side cavity of the square box-like moulding cavity is extended upward into a large-cambered-surface side cavity, the other side cavity of the square box-like moulding cavity opposite to the large-cambered-surface side cavity is a small-cambered-surface side cavity, the rest side cavities of the square box-like moulding cavity are straight side cavities, and the upper edge of the small-cambered-surface side cavity is provided with two hinge mounting cavities. By adopting the manner, a production process can be simplified and more human and material resources can be saved, so that the moulding plastic mould disclosed by the invention is applicable to flow line production of a product, production cost is saved, and production efficiency of an enterprise is greatly improved.

Owner:苏州市吴中区木渎华利模具加工店

Plastic rubber forming mold of inner cap of cosmetic bottle

The invention discloses a plastic rubber forming mold of an inner cap of a cosmetic bottle. The plastic rubber forming mold of the inner cap of the cosmetic bottle comprises a fixed mold, a movable mold, a feeding port and a cooling water flow channel, wherein a fixed template of the fixed mold is provided with a guide sleeve in which a movable guide post is inserted; the guide post is fixed on a movable template of the movable mold; the movable mold is opened or closed through the guide post; the movable mold and the fixed mold are correspondingly engaged to form two forming cavities which are symmetrically arranged along an axial line of the movable template; the forming cavities with open upper openings are conversely frustum-shaped; the upper openings of the forming cavities are approximately elliptic; two ends of the elliptic upper openings are short straight sides; the circular arc sides of the upper openings are provided with clamping groove cavities; the lower openings of the forming molds are sealed ends; and the surfaces of the sealed ends are elliptic. Through the way mentioned above, the plastic rubber forming mold of the inner cap of the cosmetic bottle, disclosed by the invention, has the advantages of molding the inner cap of the cosmetic bottle rapidly, improving production efficiency of the plastic rubber mold as the inner caps of two bottles can be processed, improving a rate of finished products, lowering production cost and avoiding resource waste.

Owner:苏州市吴中区木渎华利模具加工店

Plastic forming die for inner upper covers of eye cream bottles

Owner:苏州市吴中区木渎华利模具加工店

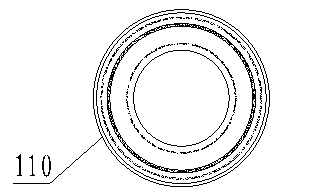

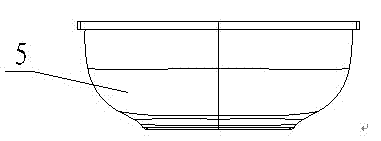

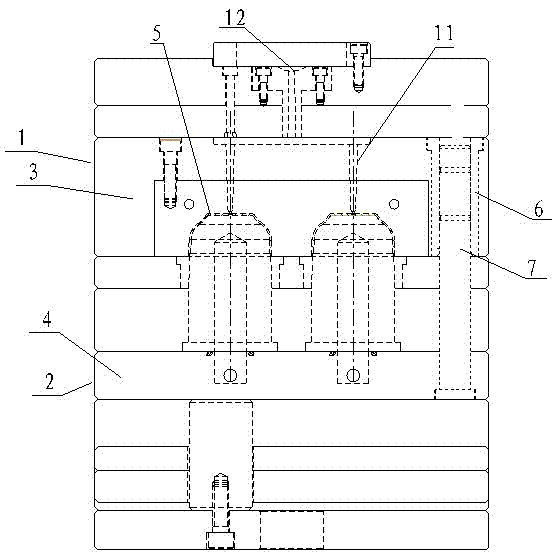

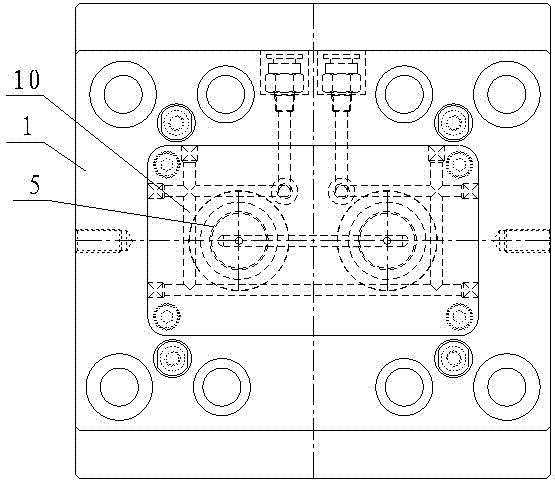

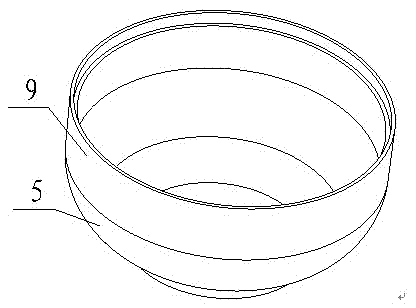

Plastic rubber mould for forming inner container of eye cream bottle

The invention discloses a plastic rubber mould for forming an inner container of an eye cream bottle. The plastic rubber mould for forming an inner container of an eye cream bottle comprises a stationary mould, a movable mould, a feeding port and a cooling water passage, wherein a guide sleeve is installed on a stationary mould plate of the stationary mould, a movable guide pillar is inserted into the guide sleeve, the guide pillar is fixed on a movable mould plate of the movable mould, and the movable mould makes open and close movement through the guide pillar; two forming cavities are formed after the movable mould and the stationary mould are correspondingly engaged, the two forming cavities are symmetrically arranged along the longitudinal axis of the movable mould plate, the upper openings of the forming cavities are in the shape of open bowels, and the cavity walls at the upper openings of the forming cavities are in the shape of vertical cylinders; the rectangular cooling water passage surrounding the forming cavities is arranged in the stationary mould; and both the two forming cavities are provided with independent feeding branch passages, and the feeding branch passages are communicated with the feeding port. Via the above way, the production procedure is simplified, so that actual production becomes more convenient and quicker, more labor and material resources are economized, the plastic rubber mould is applicable to the flow line production of products, the production cost is economized, and the production efficiency of an enterprise is greatly increased.

Owner:苏州市吴中区木渎华利模具加工店

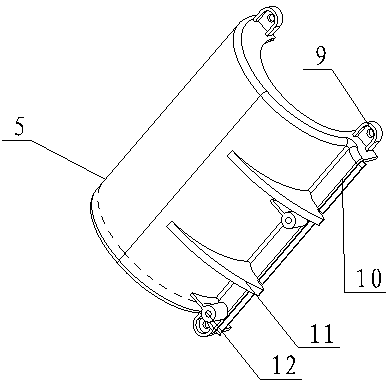

Wind drum left and right piece moulding plastic mould for electric room heater

The invention discloses a wind drum left and right piece moulding plastic mould for an electric room heater. The wind drum left and right piece moulding plastic mould for the electric room heater comprises a fixed die, a movable die, a feeding hole and a cooling water runner, wherein a fixed die plate of the fixed die is provided with a guide sleeve, a movable guide pillar is inserted into the guide sleeve, the guide pillar is fixed on a movable die plate of the movable die, the movable die does open and close movement by virtue of the guide pillar; the movable die and the fixed die are correspondingly occluded to form a wind drum left piece moulding cavity and a wind drum right piece moulding cavity, and the wind drum left piece moulding cavity and the wind drum right piece moulding cavity are symmetrically arranged along a lateral axis of the movable die plate; and the wind drum left piece moulding cavity is a semicircle cambered surface cavity three corners of which are respectively provided with screw connecting hitching leg cavities parallel to an axial section of an arc, and one straight edge of the wind drum left piece moulding cavity is provided with a splicing vertical side cavity. By adopting the manner, a production process can be simplified and more human and material resources can be saved, so that the wind drum left and right piece moulding plastic mould disclosed by the invention is applicable to flow line production of a product, production cost is saved, and production efficiency of an enterprise is greatly improved.

Owner:苏州市吴中区木渎华利模具加工店

Low-temperature resistant UV (Ultraviolet)-curable coating material and preparation method thereof

InactiveCN103788863AImprove wear resistanceImprove adhesionPolyurea/polyurethane coatingsEpoxy resin coatingsDispersityKetone

The invention relates to a low-temperature resistant UV (Ultraviolet)-curable coating material. The low-temperature resistant UV-curable coating material is prepared from the following raw materials in parts by weight: 40-45 parts of polyurethane acrylate prepolymer, 14-18 parts of epoxy acrylate, 5-7 parts of hydroxypropyl methacrylate, 8-12 parts of meerschaum powder, 3-5 parts of linoleic acid, 4-6 parts of dioctyl phthalate, 4-8 parts of methyl ethyl ketone, 1-2 parts of benzil dimethyl ketal, 10-14 parts of maleic anhydride, 3-6 parts of ammonium polyphosphate and 4-5 parts of auxiliaries. The UV coating material disclosed by the invention has high wear resistance, high adhesive power, high flexibility, high peeling strength, excellent low-temperature resistance and outstanding optical properties and weatherability; through adding the meerschaum powder, the shrinking percentage is lowered, a coating is difficult to crack, and the flame retardance is improved; the coating material further has the characteristics of low content of VOC (Volatile Organic Compounds), good decorative effect, high curing speed, easiness in construction, being suitable for assembly line production and the like, and can be applied to the decoration of base materials, such as plastics, woodenware, metals and the like; due to the auxiliaries, the dispersity of the coating material is improved, the leveling property is good, and a coating layer is smooth and bright.

Owner:WUHU BAOYI AMUSEMENT EQUIP

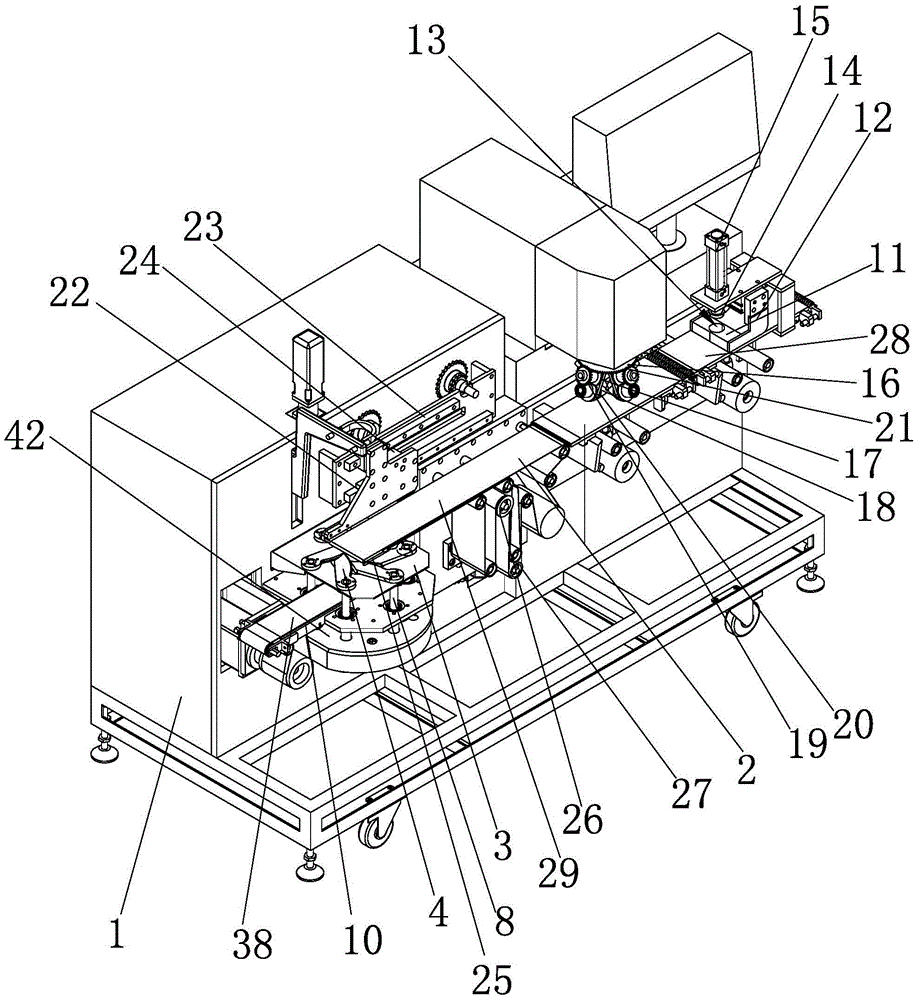

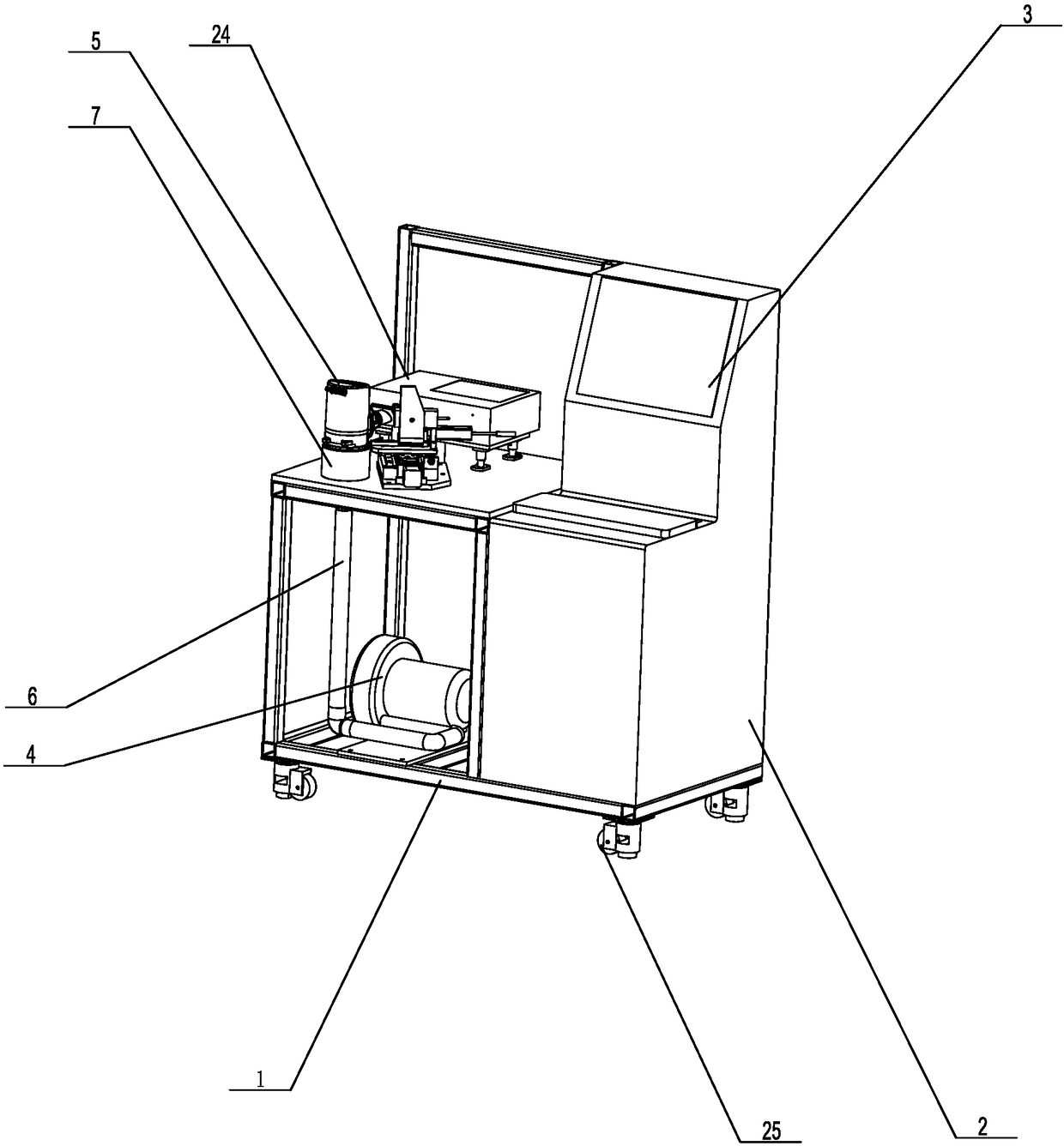

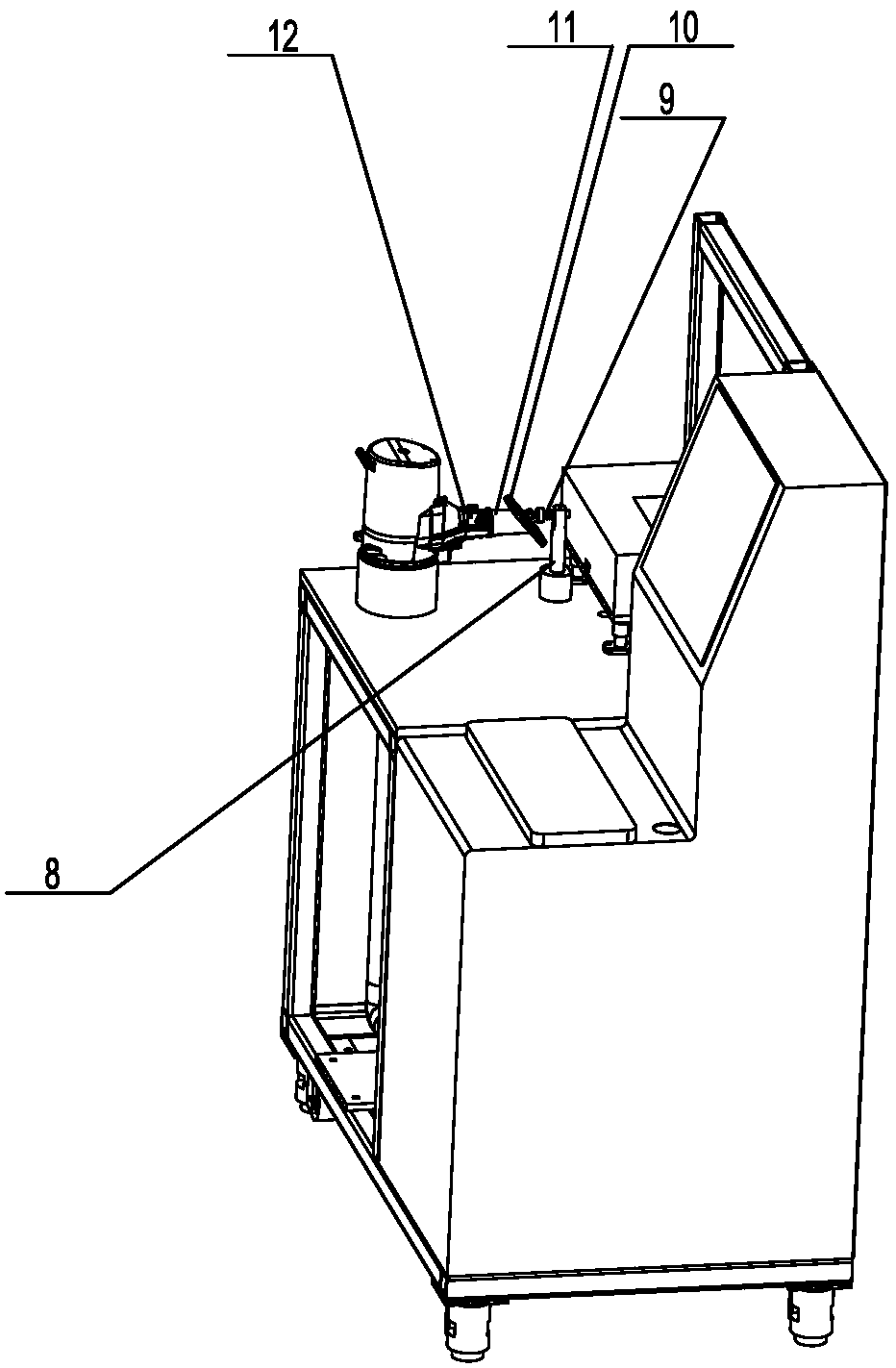

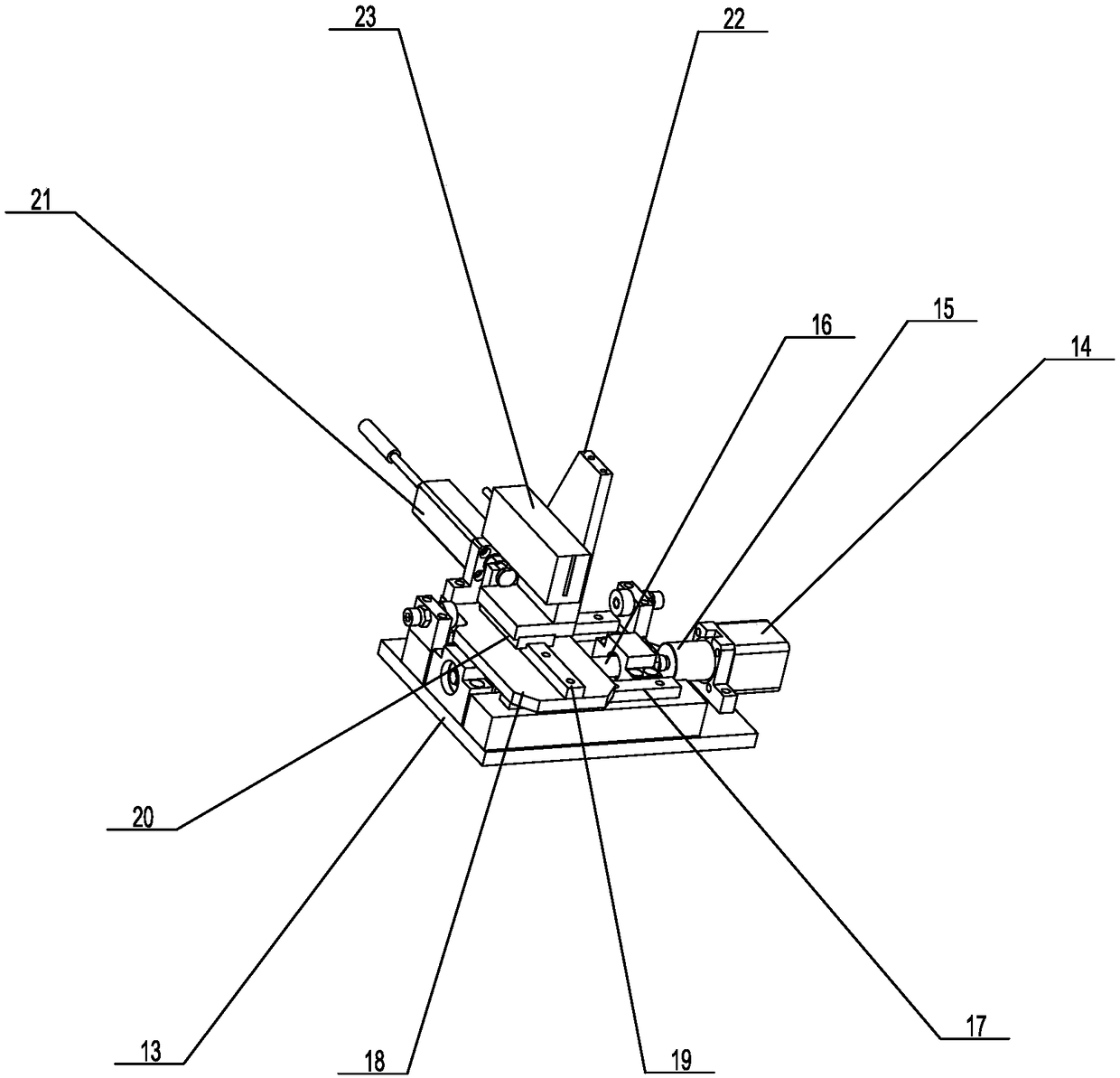

Air tightness detecting and code spraying device used for dust collector

PendingCN108088633ASimple structureEasy to implementMeasurement of fluid loss/gain rateAssembly lineEngineering

The invention discloses an air tightness detecting and code spraying device used for a dust collector. The device comprises a rack, and a main control box and a display screen are arranged on one sideof the rack; an air tightness detecting mechanism and a code spraying mechanism are arranged on the other side of the rack, and the air tightness mechanism comprises an air exhauster, an air pipe, asealed shell, a fixed stand column, a connecting rod, a wind shield, a ventilating hard pipe and a ventilating hose; the code spraying mechanism comprises an X-axis motor, a ball screw, two X-axis guide rails, a movable plate, a Y-axis slide rail, a sliding block, an air cylinder and a code spraying device body. The device integrates air tightness detecting and code spraying, can perform code spraying after air tightness detection, reduces loading frequency, and is high in working efficiency. The air tightness detecting mechanism of the device is simple in structure, easy to realize and low inmanufacturing cost; the code spraying mechanism can flexibly and accurately move to perform code spraying, and therefore the device is good in practicability, greatly improves production efficiency for enterprises, and is suitable for assembly line production of the enterprises.

Owner:QINZHOU UNIV

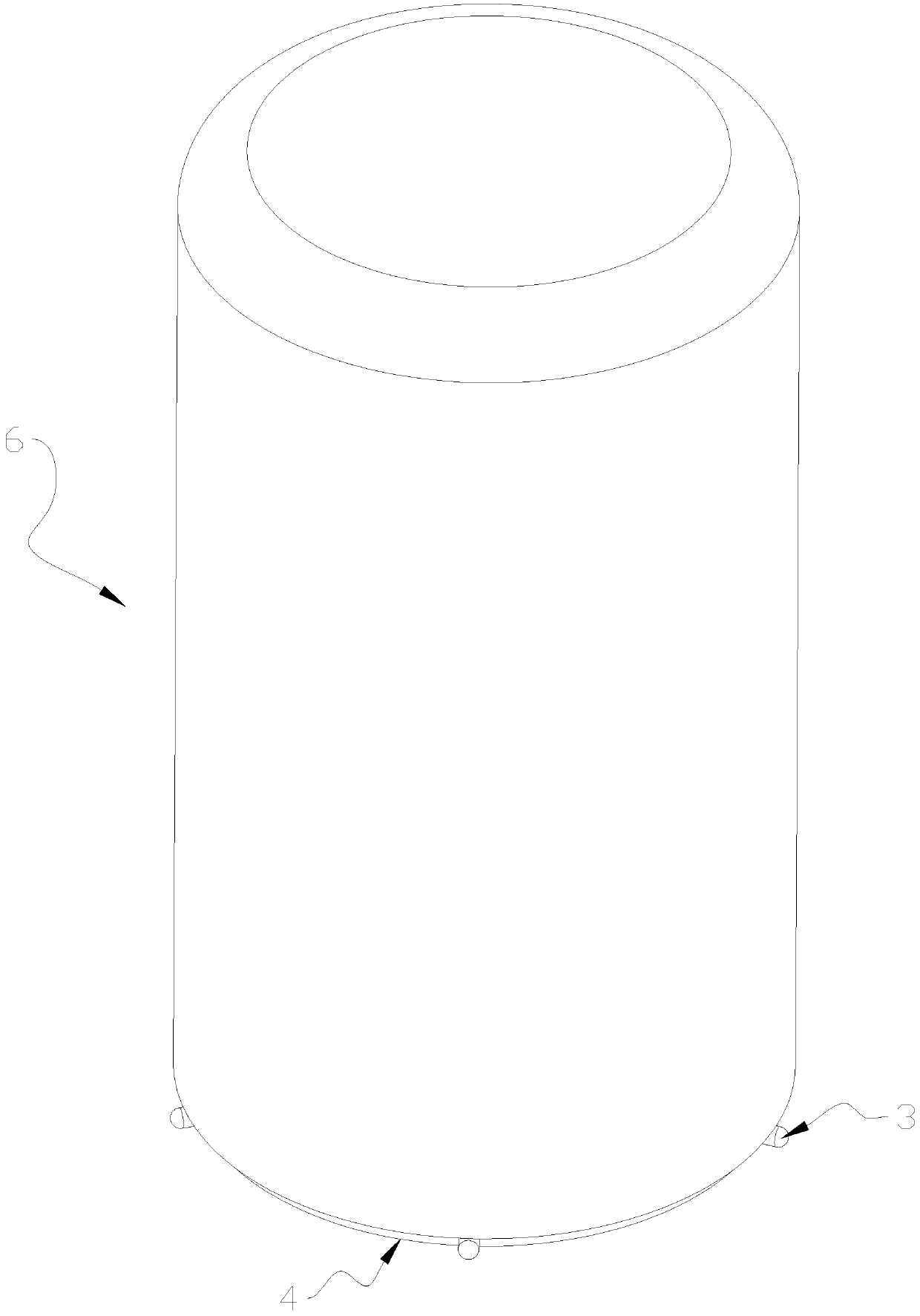

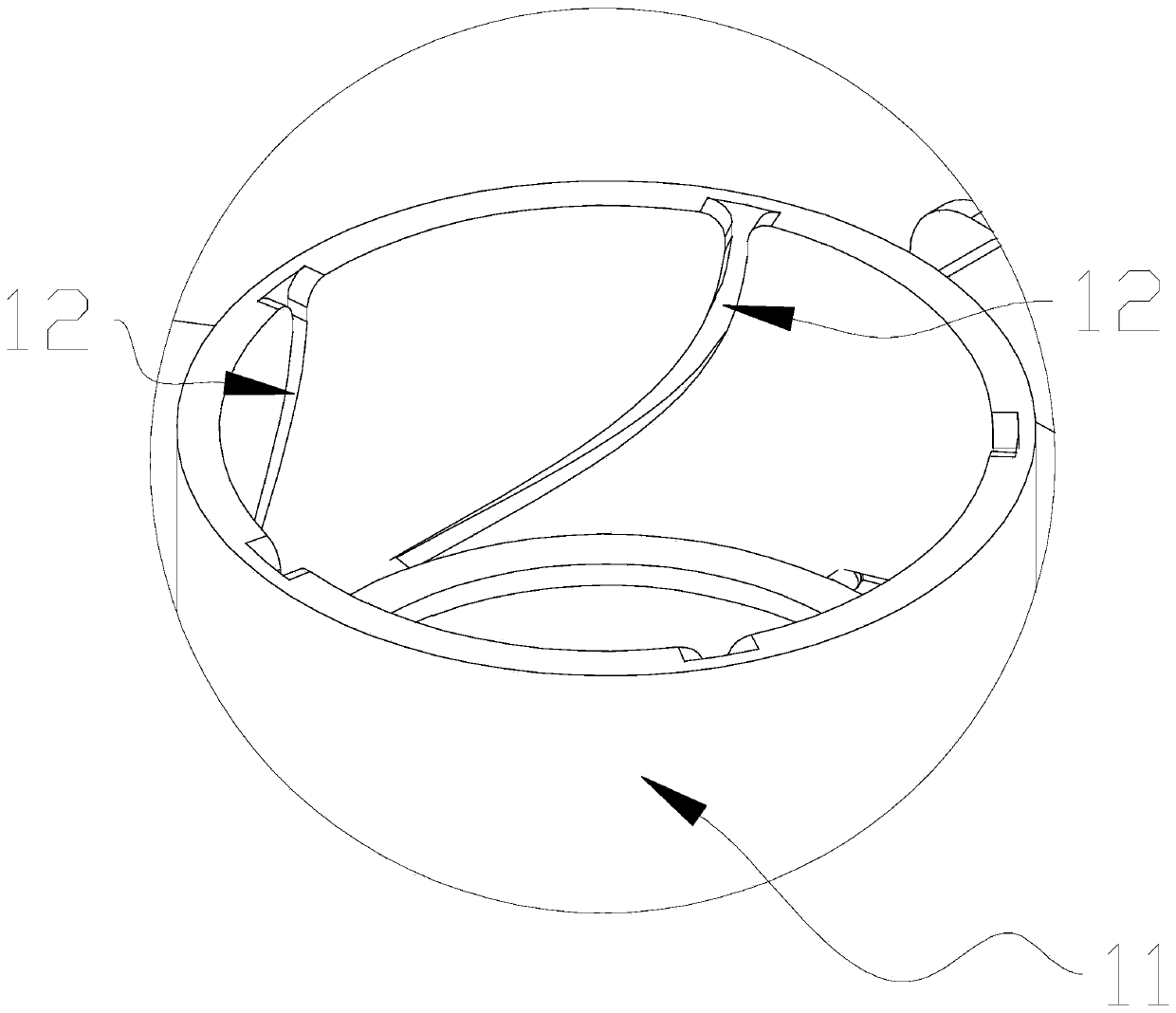

Quick-change discharging machine

PendingCN110844385ARealize can opening and unloadingSimple processLarge containersLoading/unloadingEngineeringElectrical and Electronics engineering

A quick-change discharging machine comprises a feeding port, a discharging driving mechanism and a discharging port. Materials added through the feeding port are driven by the discharging driving mechanism to the discharging port to be discharged. A discharging base matched with a storage tank is arranged at the feeding port. The storage tank is provided with a cover body at the open end and an operation part used for opening the cover body. The operation part laterally protrudes to the outer side wall of the open end and is operated to bypass the open end to circumferentially rotate to open the cover. The discharging base can automatically open the storage tank. An opening in the top of the discharging base is larger than the open end of the storage tank so as to accommodate the open endof the storage tank and to rotate around a spindle of the storage tank. A downward guide groove is formed in the top surface of the inner side wall of the discharging base and allows the operation part of the storage tank to sink therein and move downwards from the top surface. The guide groove is obliquely formed and thus has a circumferential component.

Owner:GUANGZHOU FUGANG WANJIA INTELLIGENT TECH CO LTD

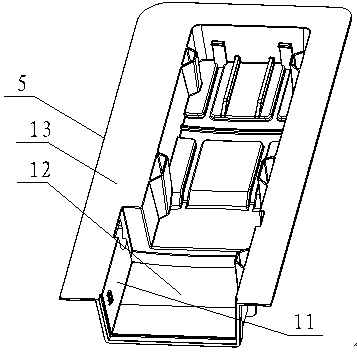

Moulding plastic mould for upper cover of foundation bottle

The invention discloses a moulding plastic mould for an upper cover of a foundation bottle. The moulding plastic mould for the upper cover of the foundation bottle comprises a fixed die, a movable die, a feeding hole and a cooling water runner, wherein a fixed die plate of the fixed plate is provided with a guide sleeve, a movable guide pillar is inserted into the guide sleeve, the guide pillar is fixed on the movable die plate of the movable die, and the movable die does open and close development by virtue of the guide pillar; the movable die and the fixed die are corresponding occluded to form two moulding cavities, the two moulding cavities are symmetrically distributed along a lateral axis of the movable die plate, each moulding cavity is a square box-like cavity the upper end face of which is provided with openings, four sides of each moulding cavity are cambered surfaces protruding outward, the inner wall of the side of each moulding cavity is provided with two symmetrical side clamping and hooking cavities, and the side clamping and hooking cavities are arranged at the inner edge of the opening on the upper end face of each moulding cavity. By adopting the manner, a production process can be simplified, the actual production is more convenient and efficient and more human and material resources can be saved, so that the base moulding plastic mould disclosed by the invention is applicable to flow line production of a product, production cost is saved, and production efficiency of an enterprise is greatly improved.

Owner:苏州市吴中区木渎华利模具加工店

Upper male die of punching die of front frame fastener of liquid crystal display

The invention discloses an upper male die of a punching die of a front frame fastener of a liquid crystal display. The upper male die of the punching die of the front frame fastener of the liquid crystal display is an upright body which has a specially-shaped cross section, and the lower end of the upright body is a diagonal plane; and the cross section of the upper male die is leftwards convex, the convex part of the cross section is circular, and all connecting parts of the cross section are of circular arc transition. Due to adoption of the mode, the production procedures are simplified, the actual production is enabled to be more convenient and rapider, and meanwhile, more manpower and material resources can be saved; and the upper male die disclosed by the invention is suitable for flow line production of products and has the advantages of saving the production cost and greatly improving the production efficiency of enterprises.

Owner:SUZHOU WUZHONG ECONOMIC DEV ZONE BOYU MOLD PROCESSING FACTORY

Continuous tea kneading machine

InactiveCN1168389CKneading quality is stableImprove work efficiencyPre-extraction tea treatmentSprocketEngineering

Owner:HUAZHONG UNIV OF SCI & TECH

Discharging base

The invention relates to a discharging base. The discharging base is characterized in that a storage tank can be automatically opened, a cover body and an operation part used for operating and openingthe cover body are arranged at an opening end of the storage tank, the operation part laterally protrudes to exceed an outer side wall of the opening end, the operation part rotates around the circumference of the opening end to open the cover when being operated, a top opening of the discharging base is larger than the opening end of the storage tank so that the opening end of the storage tank can be contained to sink into the discharging base and rotate around a main shaft of the storage tank, a descending guide groove is formed on an inner side wall of the discharging base from a top faceso that the operation part of the storage tank can sink into the discharging base from the top face, and the guide groove is obliquely formed and has a circumferential component. The discharging baseis advantaged in that the discharging base is used in cooperation with the storage tank, tank opening discharging can be achieved while the storage tank is installed on the discharging base, the process is simple and convenient, the time is saved, and the discharging base is suitable for assembly line type production.

Owner:GUANGZHOU FUGANG WANJIA INTELLIGENT TECH CO LTD

Blanking plug housing injection mould

The invention discloses a blanking plug housing injection mould; a guide hole is disposed on a fixed mould plate of a fixed mould; a movable guide post is inserted in the guide hole; the guide post is fixed on a movable mould plate of the movable mould; the movable mould performs opening-closing movement through the guide post; a positioning clamping groove is disposed on the movable mould plate; a removable mould core is mounted on the movable mould plate; the removable mould core is clamped in the positioning clamping groove; two moulding cavities are formed by corresponding engaging of the movable mould with the fixed mould; the two moulding cavities are symmetrically arranged along the fixed mould plate transverse axis; the moulding cavities are hollow, long cylindrical cavities; two sets of waist-shaped holes are distributed on the outer cavity wall of each long cylindrical cavity; each set of the waist-shaped holes comprises three holes which are evenly distributed on the outer cavity wall. With the above mode, the production procedure is simplified; actual production is more convenient and efficient; more human and material resources are saved; the injection mould is suitable for product flow line production; the production cost is saved; and the enterprise production efficiency is greatly improved.

Owner:WUZHONG DISTRICT MUDU KUAIBIN MOLD PROCESSING FACTORY

Plastic mold for molding baffle of water-drop-shaped electric heater

The invention discloses a plastic mold for molding a baffle of a water-drop-shaped electric heater. The plastic mold comprises a fixed mold, a movable mold, a feeding hole and a cooling water flow channel, wherein a guide sleeve is installed on a fixed mold plate of the fixed mold; a movable guide pillar is inserted in the guide sleeve and is fixed on a movable mold plate of the movable mold; the movable mold does open and close movements via the guide pillar; the movable mold and the fixed mold form a molding cavity after occluding correspondingly; the molding cavity is a water-drop-shaped plane sheet cavity; a small locating bayonet cavity is arranged in the position, close to the top arc, at the upper end of the molding cavity; a straight-sided cavity is arranged at the lower end of the molding cavity; two rectangular locating bayonet cavities with downward openings are arranged on the straight-sided cavity; and a fixed clamp hook cavity is arranged in the position, close to the middle position between the two rectangular locating bayonet cavities, on the plane of the molding cavity. The plastic mold has the beneficial effects that the plastic mold can simply the production processes and simultaneously save more human and material resources, is suitable for assembly line production of the products, saves the production cost and greatly improves the production efficiency of the enterprises.

Owner:苏州市吴中区木渎华利模具加工店

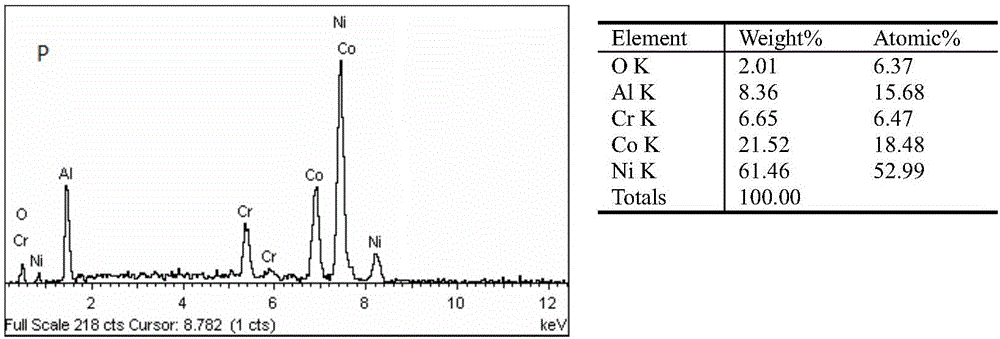

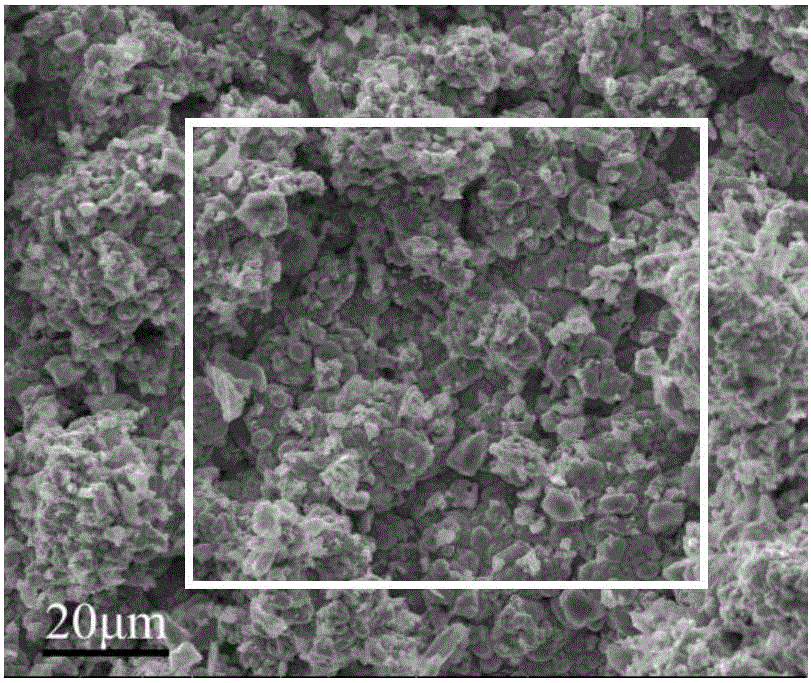

Nickel-cobalt/chromium-aluminum/yttrium oxide plating and composite electroplating method thereof

The invention relates to a (Ni-Co) / CrAl / Y2O3 plating and a composite electroplating method thereof. The composite electroplating method comprises the following steps that CrAl / Y2O3 alloy powder is prepared, specifically, CrAl alloy powder and Y2O3 powder are mixed with the weight ratio being 80-120:1, then ball milling is conducted, and the CrAl / Y2O3 alloy powder is obtained; and the plating is prepared, specifically, a substrate is taken for composite electroplating, then periodic reverse pulse current is adopted for electroplating, and the (Ni-Co) / CrAl / Y2O3 plating is obtained, wherein composite electroplating comprises the substep that the CrAl / Y2O3 alloy powder is added into electroplate liquid with the adding amount being 20-50 g / L. The (Ni-Co) / CrAl / Y2O3 plating prepared through the composite electroplating method is delicate in crystal, good in binding force, compact, smooth, low in void ratio, good in toughness, high temperature oxidation resistance and hot corrosion resistance and low in production cost.

Owner:GUANGZHOU SPECIAL PRESSURE EQUIP INSPECTION & RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com