Air tightness detecting and code spraying device used for dust collector

A technology of air tightness detection and vacuum cleaner, which is applied in measuring devices, liquid tightness measurement using liquid/vacuum degree, testing of machine/structural components, etc. Increase the production cost of the enterprise and other issues to achieve the effect of improving the effect of flexible coding, reducing the number of loading times, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

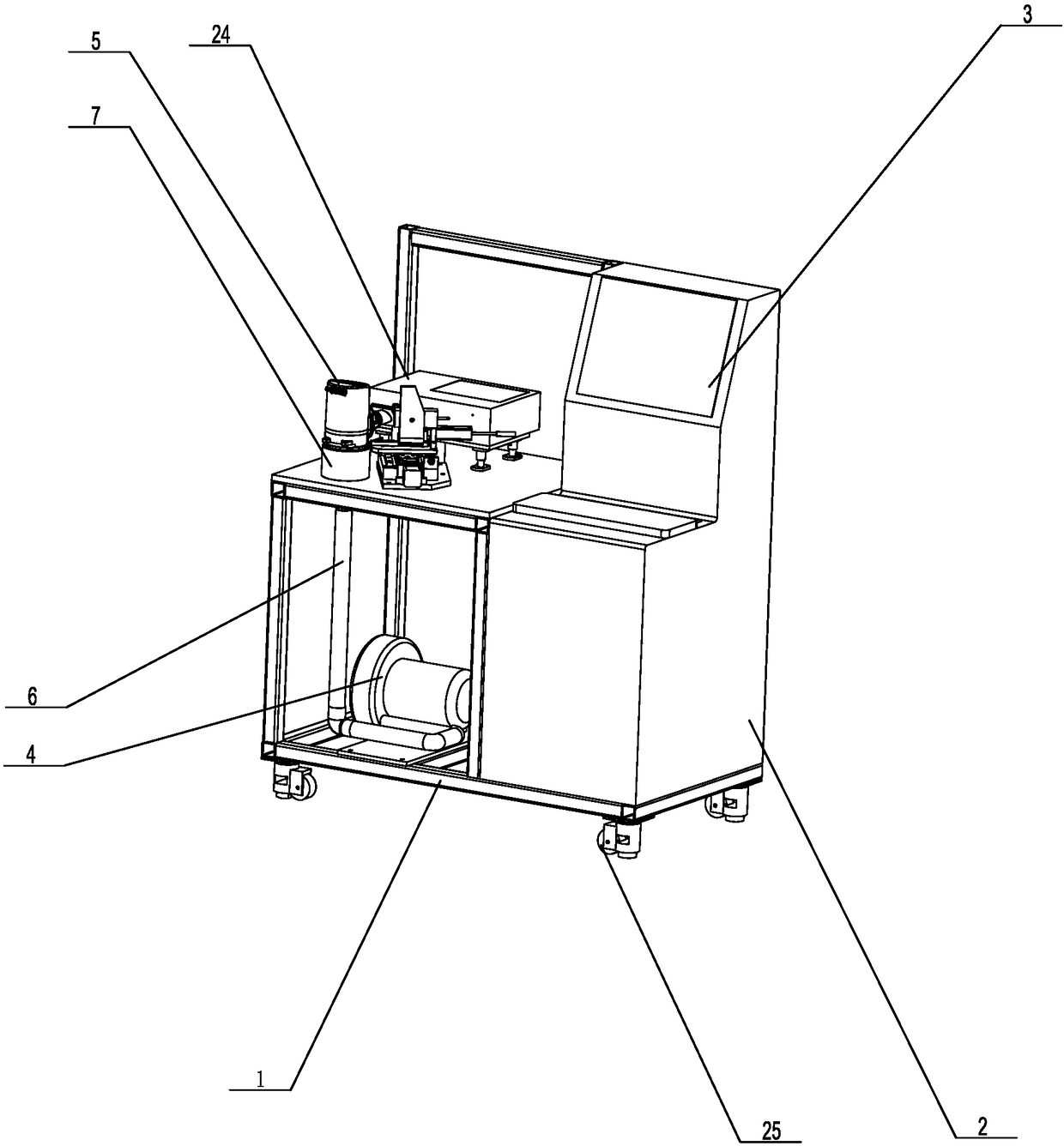

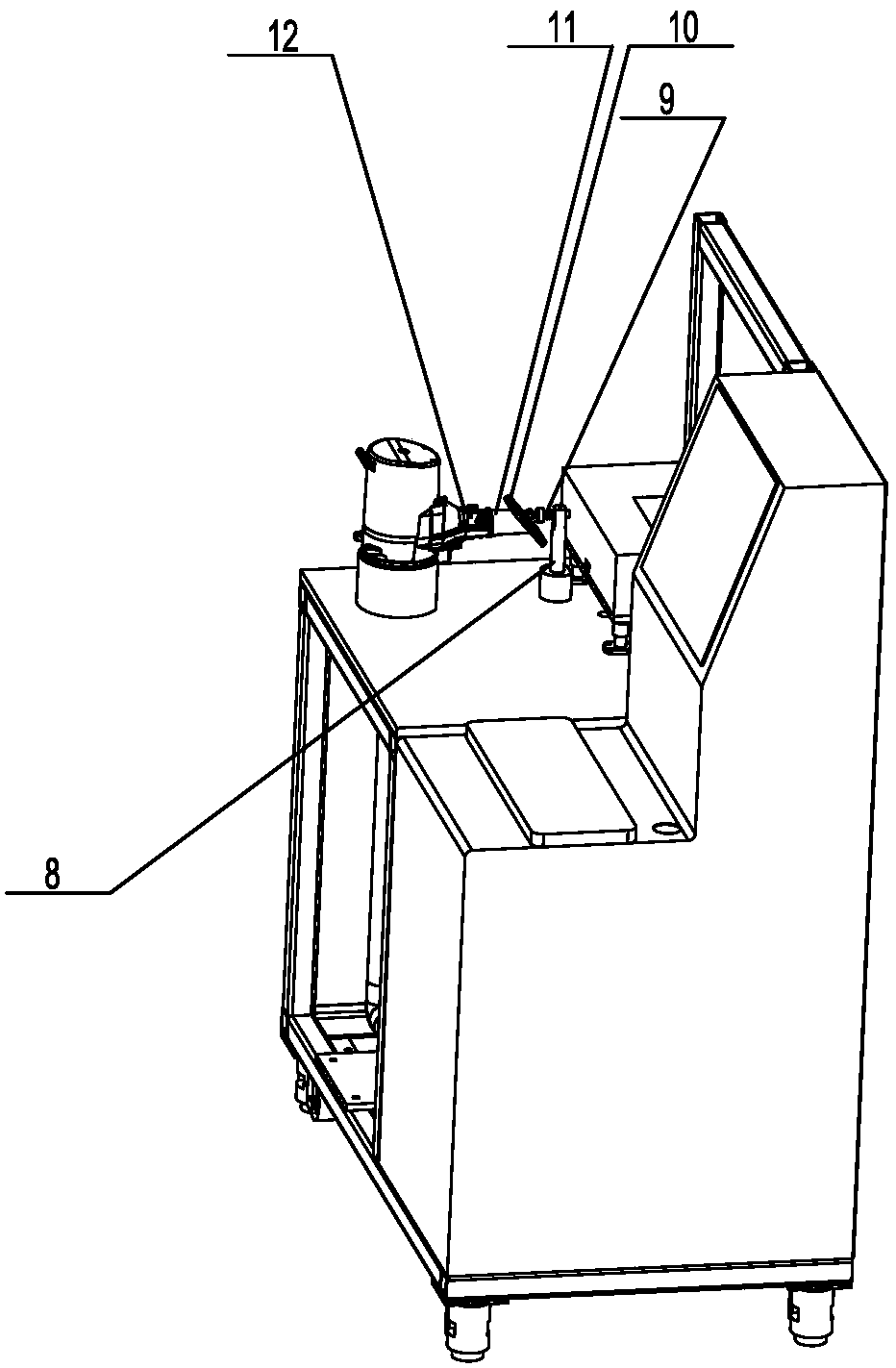

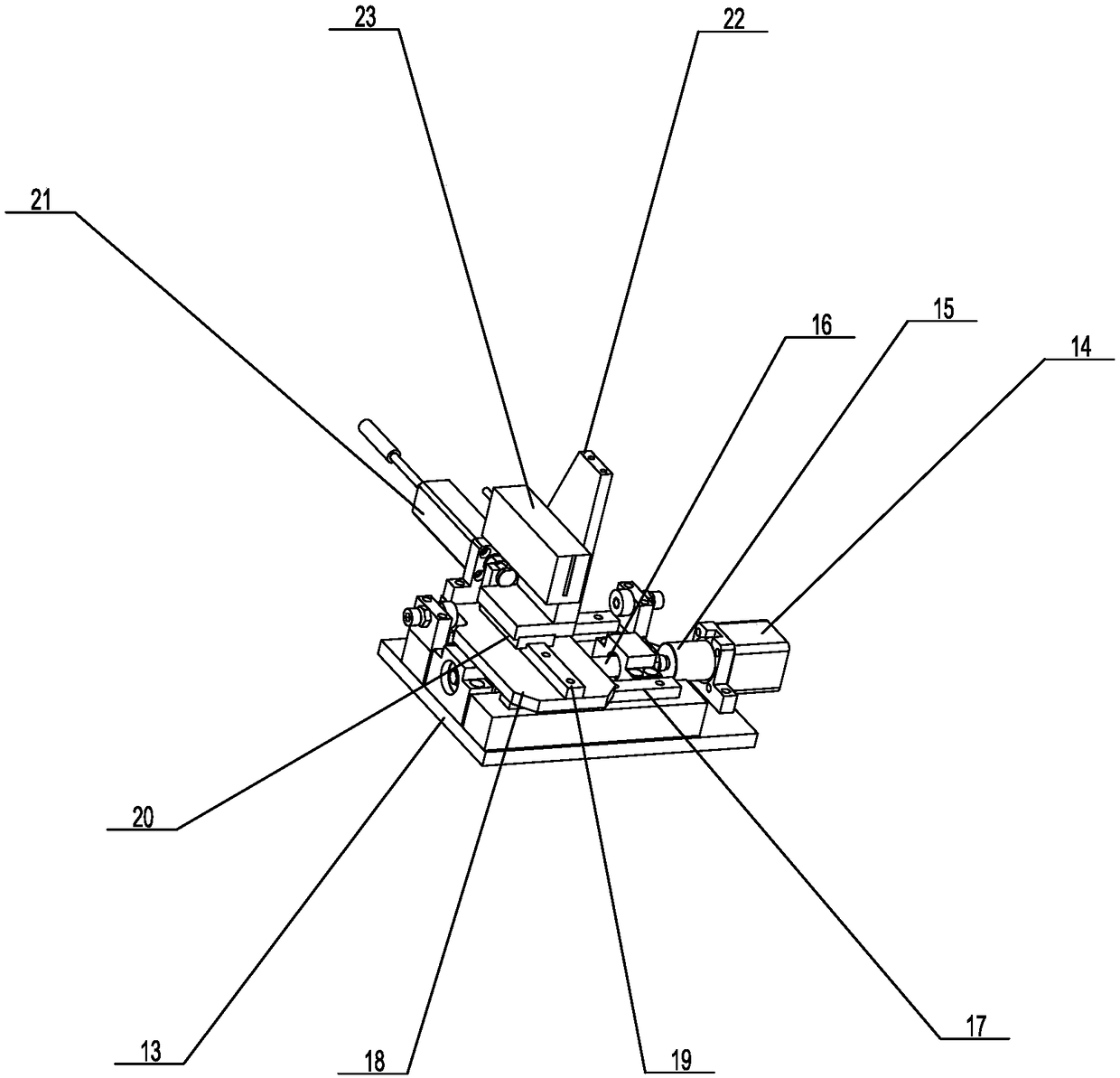

[0018] Such as figure 1 A specific embodiment of the present invention is proposed as shown, the air tightness detection and coding device for vacuum cleaners, including a frame 1, a main control box 2 is provided on one side of the frame 1, and a main control box 2 is arranged on the main control box 2. There is a display screen 3 electrically connected to it; the other side of the frame 1 is provided with an air tightness detection mechanism and a coding mechanism, and in this embodiment, the other side of the frame 1 is set as upper and lower layers, The airtight mechanism includes an air extractor 4 located at the lower end of the frame 1, the air extractor 4 is provided with a gas pipe 6 detachably connected to the sealed housing 5 of the vacuum cleaner, and the upper end of the frame 1 is provided with a The housing base 7, the sealing housing 5 is detachably installed on the housing base 7, the air pipe 6 extends vertically upwards from the lower end of the frame 1 to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com