Quick-change discharging machine

A technology for discharging machines and materials, applied in loading/unloading, containers, packaging, etc., which can solve problems such as spillage and long time spent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

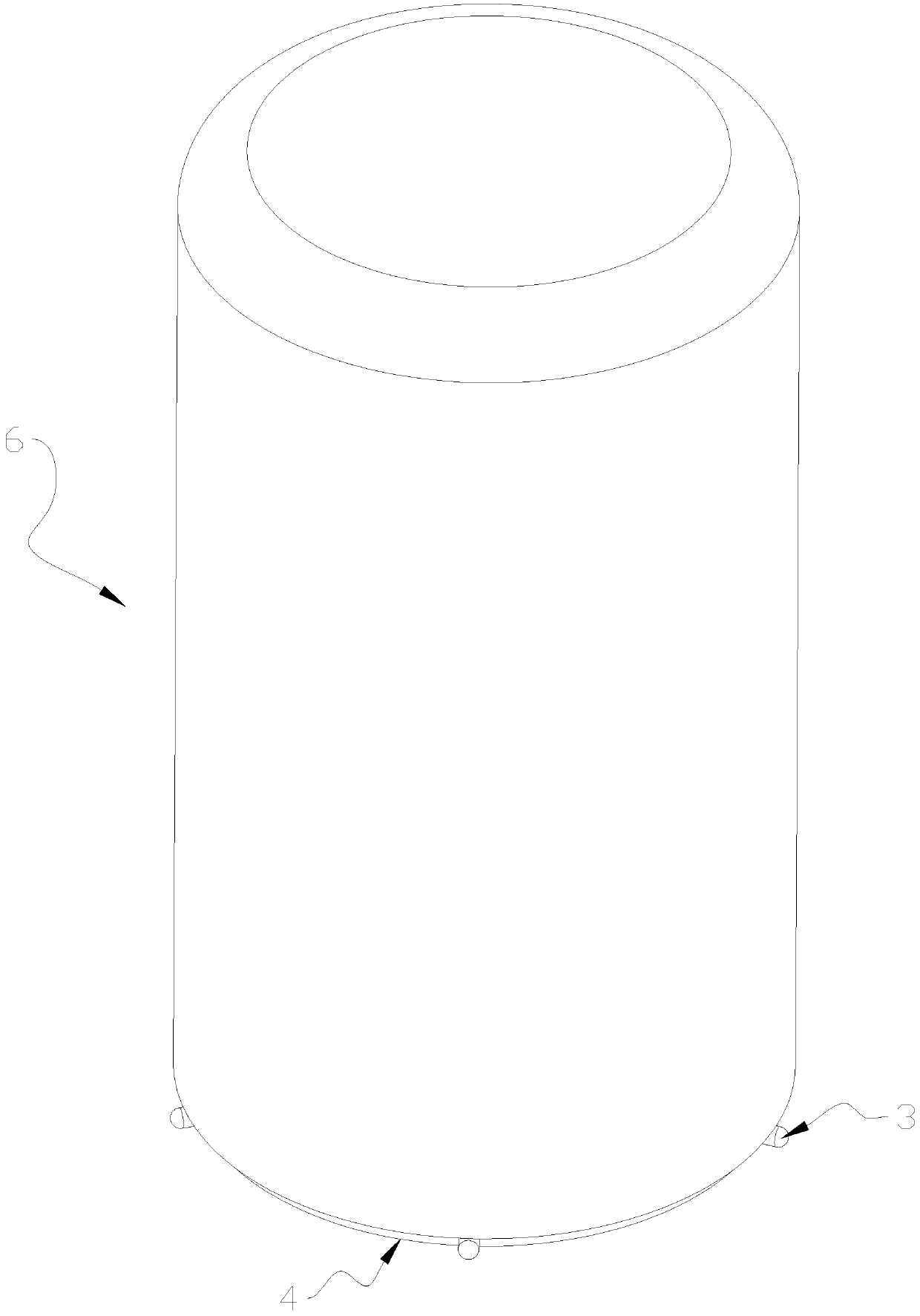

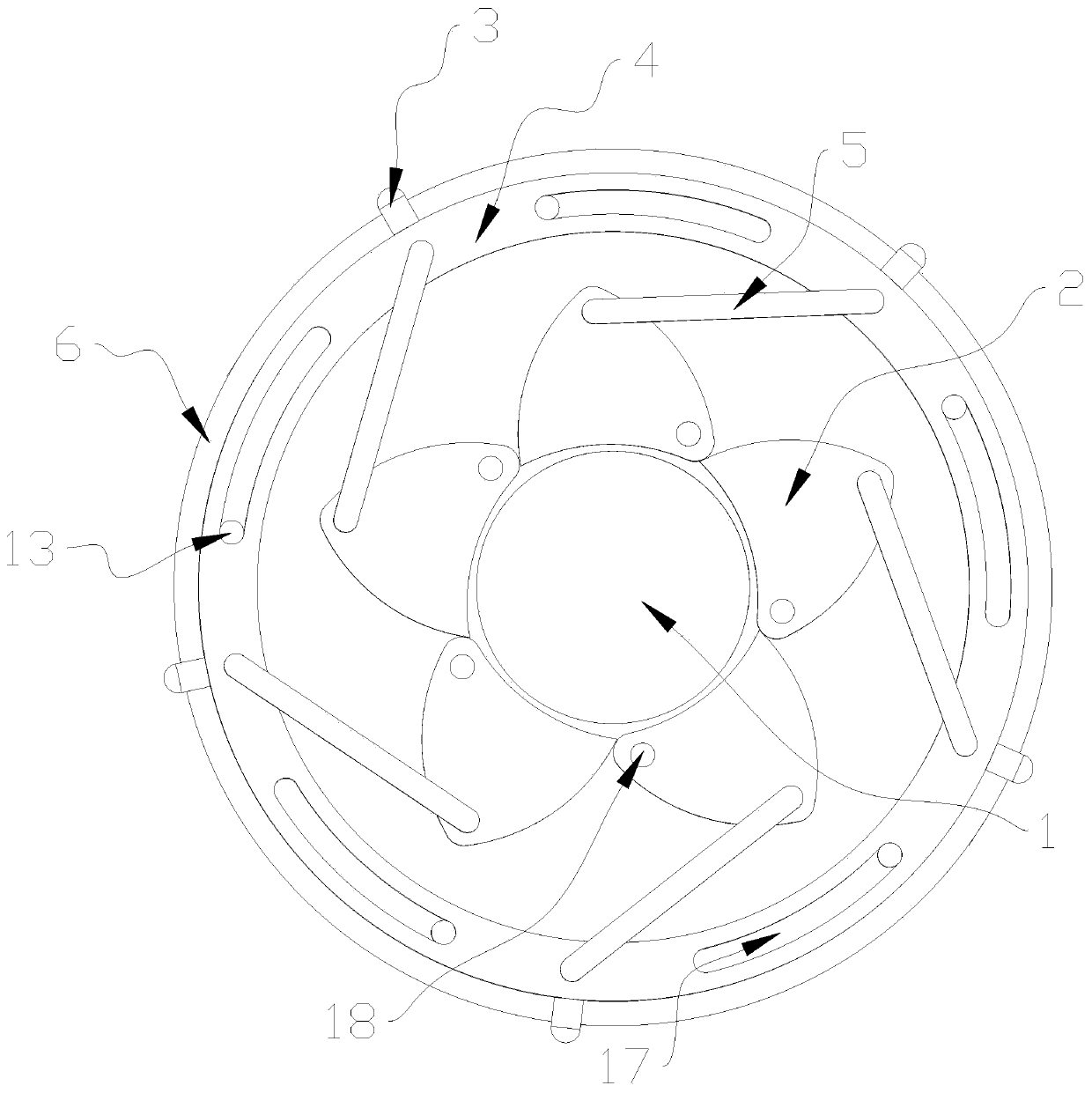

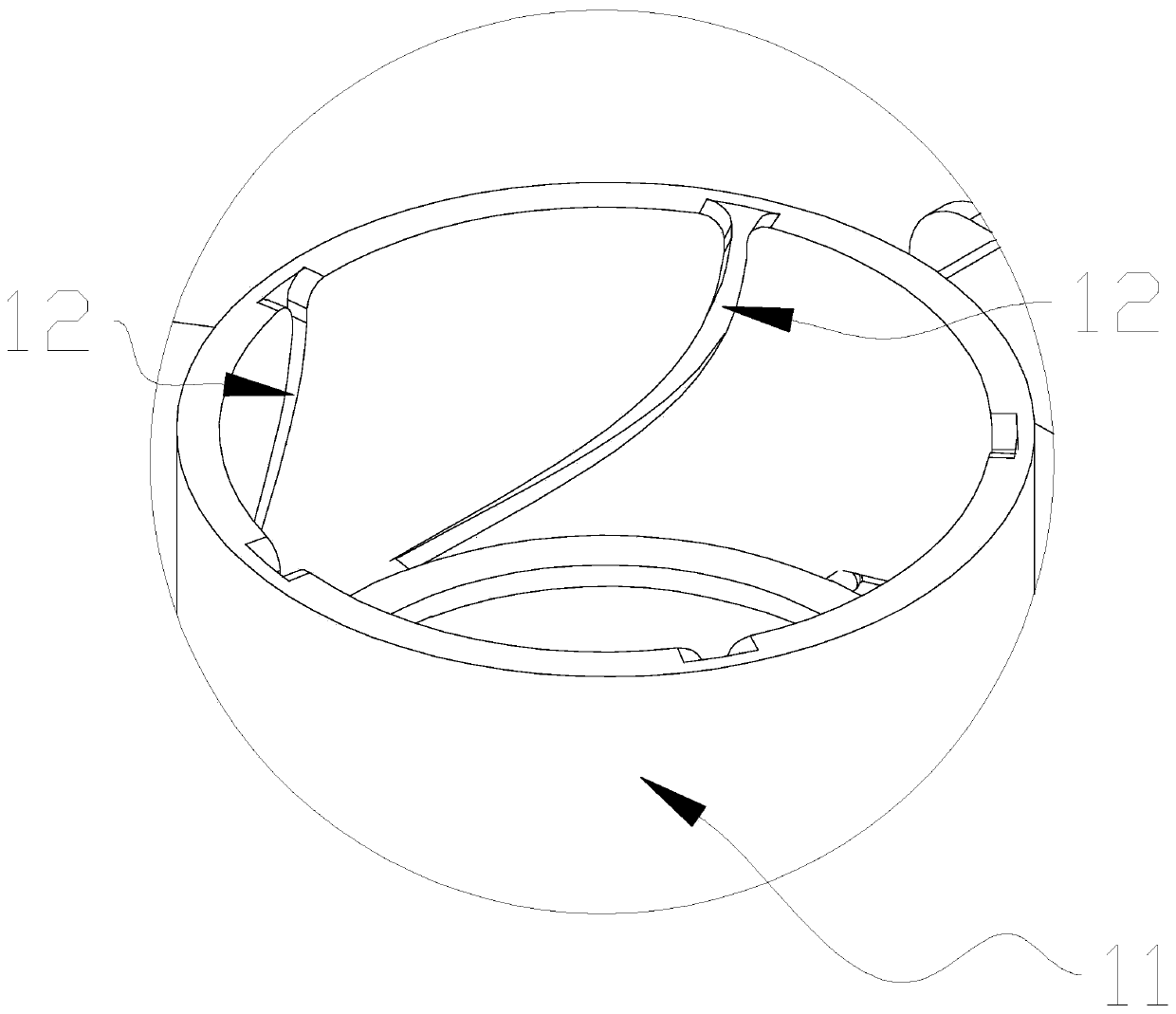

[0021] Such as Figure 1~2 As shown, the storage tank 6 is a cylindrical tank body of equal diameter, and its bottom is an open end, and a circular discharge port 1 is provided on the circular bottom wall of the open end, and the center of the circle of the discharge port 1 and the bottom The centers of the walls coincide. Five position-limiting protrusions 13 are arranged in the circumferential direction of the bottom wall, and the position-limiting protrusions 13 are located on the same circle, and the center of the circle coincides with the center of the circle of the bottom wall. The bottom wall also includes a ring-shaped rotating ring 4, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com