Continuous tea kneading machine

A kneading machine and tea technology, applied in the field of continuous tea kneading machine, can solve the problems of low efficiency, low efficiency, sacrifice of tea quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

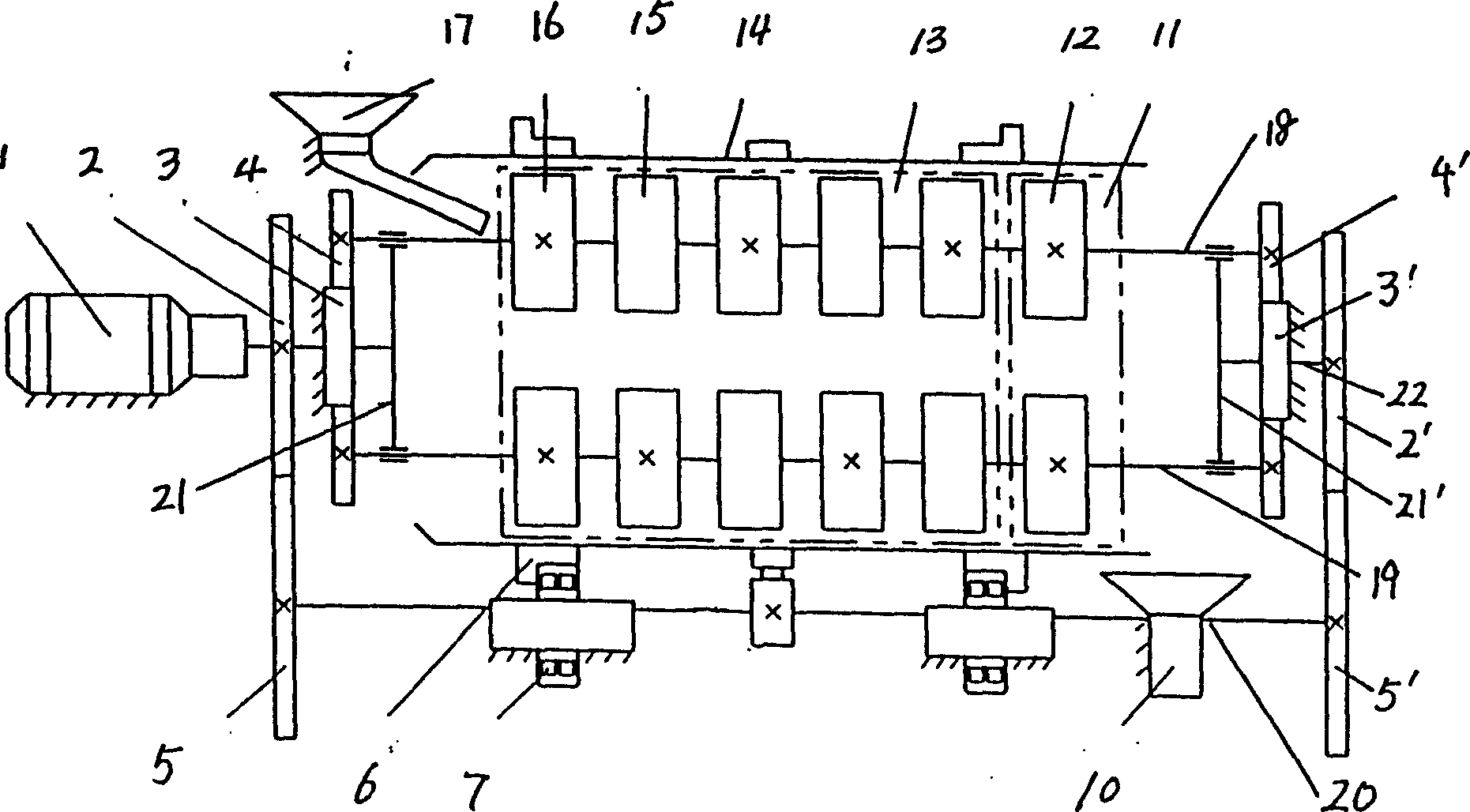

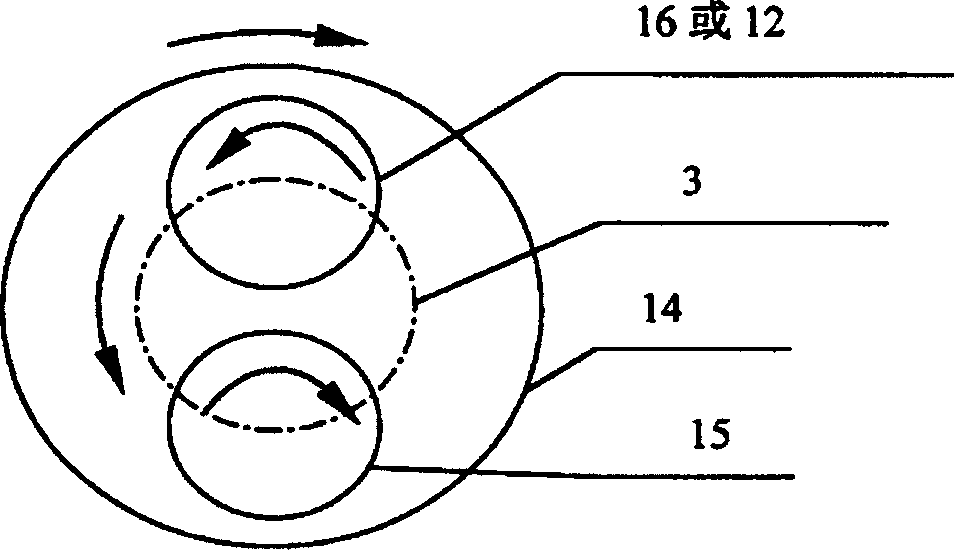

[0019] like figure 1 As shown, the present invention mainly comprises electric motor, transmission mechanism, roller device, planetary gear mechanism and forms. Described kneading device comprises an opening at both ends, and the inner wall is provided with the cylinder 14 of helical rib, and an opening of cylinder 14 is provided with upper hopper 17, and another opening is provided with lower hopper 10, and cylinder 14 both sides are provided with Two planetary gear mechanisms, the central wheel 3,3' of the planetary gear mechanism are fixed on the support, and the motor shaft and the fourth connecting shaft 22 pass through the center hole of the central wheel (3,3') respectively; the first connecting shaft 18 and The second connecting shaft 19 passes through the drum 14, and its two ends are fixedly connected with the planetary gears 4, 4' respectively; between the planetary gear mechanism on the side of the upper hopper and the motor 1, a first gear 2 and a second gear for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com