Device for curing packaging optoelectronic conversion modules based on coherent optical radiation and method thereof

A photoelectric conversion and coherent light technology, applied in the coupling of optical waveguides, etc., can solve the problem of low ability to penetrate plastic, and achieve the effect of reducing semi-finished products, good reliability and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

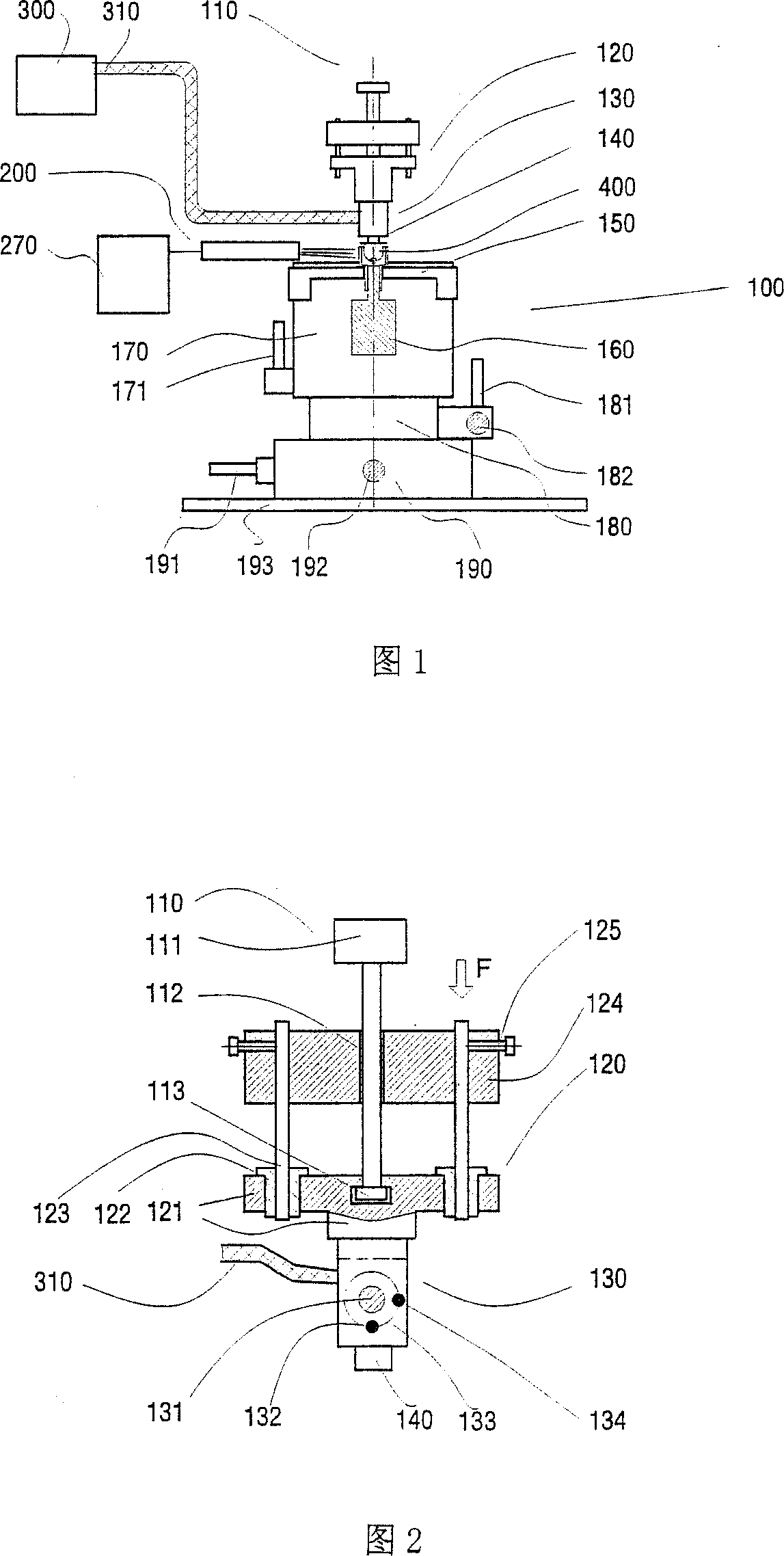

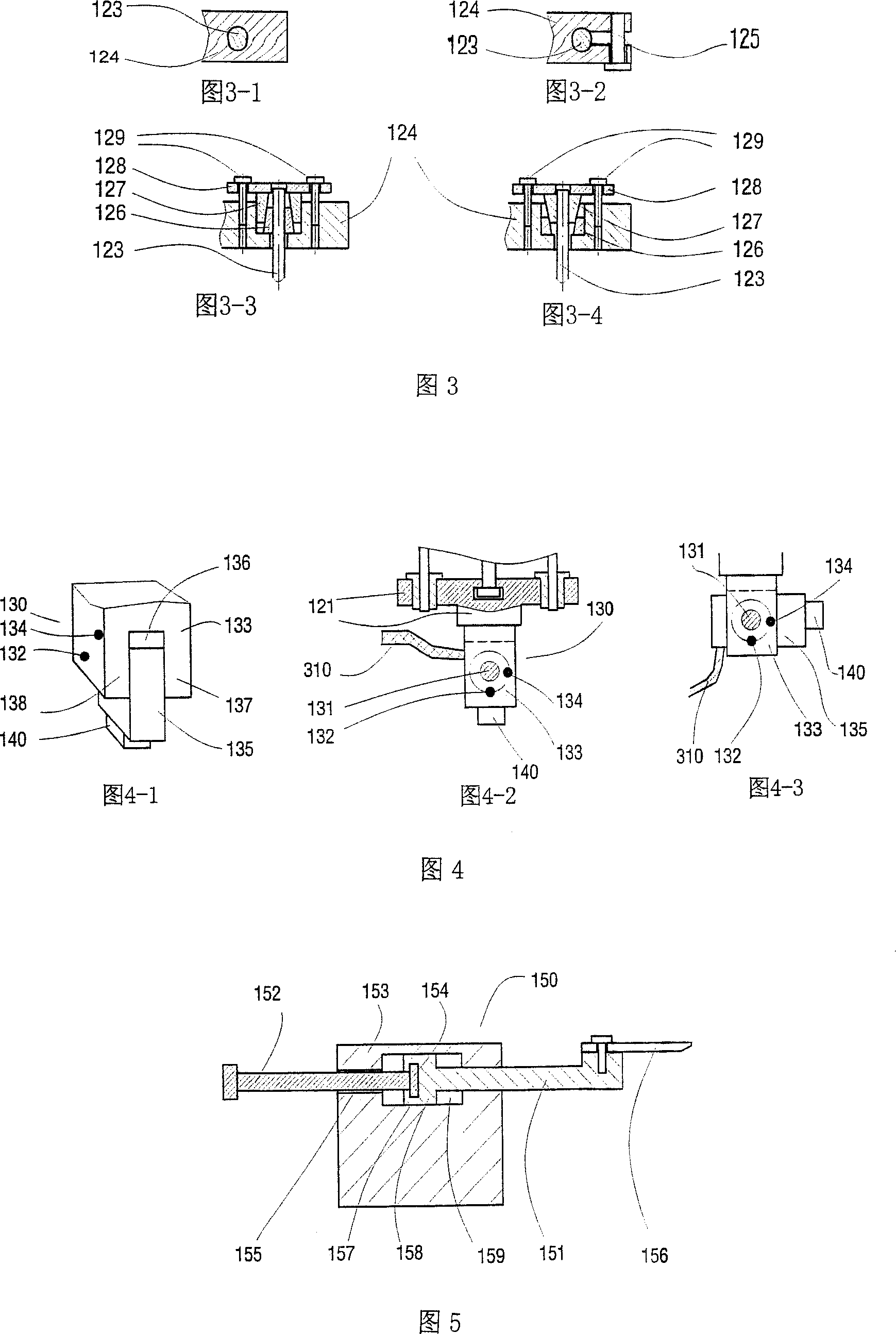

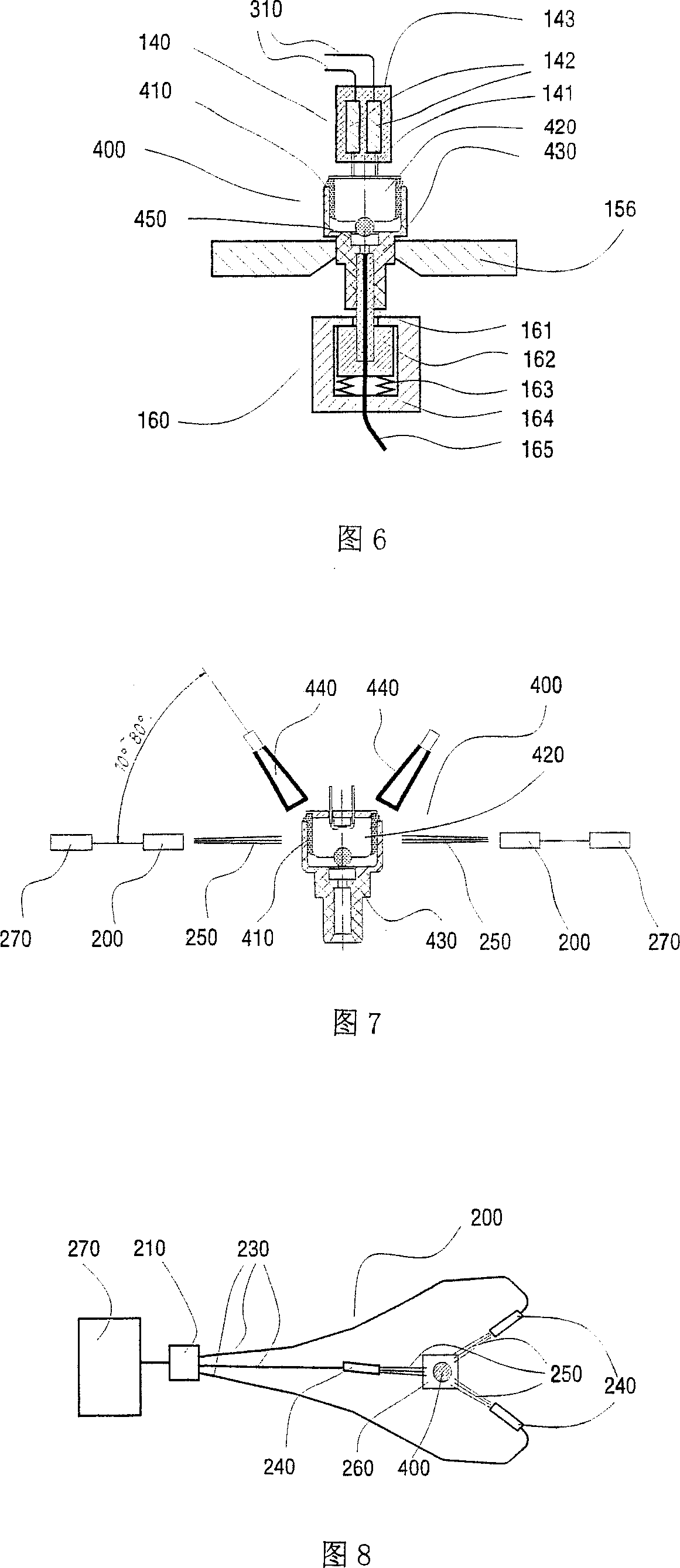

[0121] Further illustrate below in conjunction with accompanying drawing and embodiment:

[0122] 1. This equipment

[0123] 1. Coupling system(100)

[0124] 1) handle mechanism (110)

[0125] As shown in Figure 2, the structure of the handle mechanism (110) is composed of a rotary handle (111), a threaded pair (112), and a sliding head (113) connected in sequence from top to bottom.

[0126] The function of the handle mechanism (110) is to rotate and drive the guide mechanism (120).

[0127] 2) guide mechanism (120)

[0128] As shown in Fig. 2 and Fig. 3, the structure of the guide mechanism (120) is an upper base plate (124), a fastener (125), a thread pair (112), a guide slide bar (123), a shaft connected in sequence from top to bottom. Cover (122), lower base plate (121) form.

[0129]The function of the guiding mechanism (120) is to drive the multi-angle rotating structure (130) on the lower substrate (121) to move up and down under the guidance of the guiding slide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com