Novel shoemaking part exposed burr processing technology

A processing technology and stubble technology, which is applied in the field of processing technology for exposed stubble of shoe-making components, can solve the problems of rough and unsightly appearance of finished products, and achieve the effects of improving appearance grade, bright leather stubble and delicate appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] A novel process for treating exposed stubble of shoe parts, comprising the following steps:

[0018] a. Singeing: singeing the exposed stubble of the cut leather parts, and cutting off the exposed leather fibers to achieve no stubble;

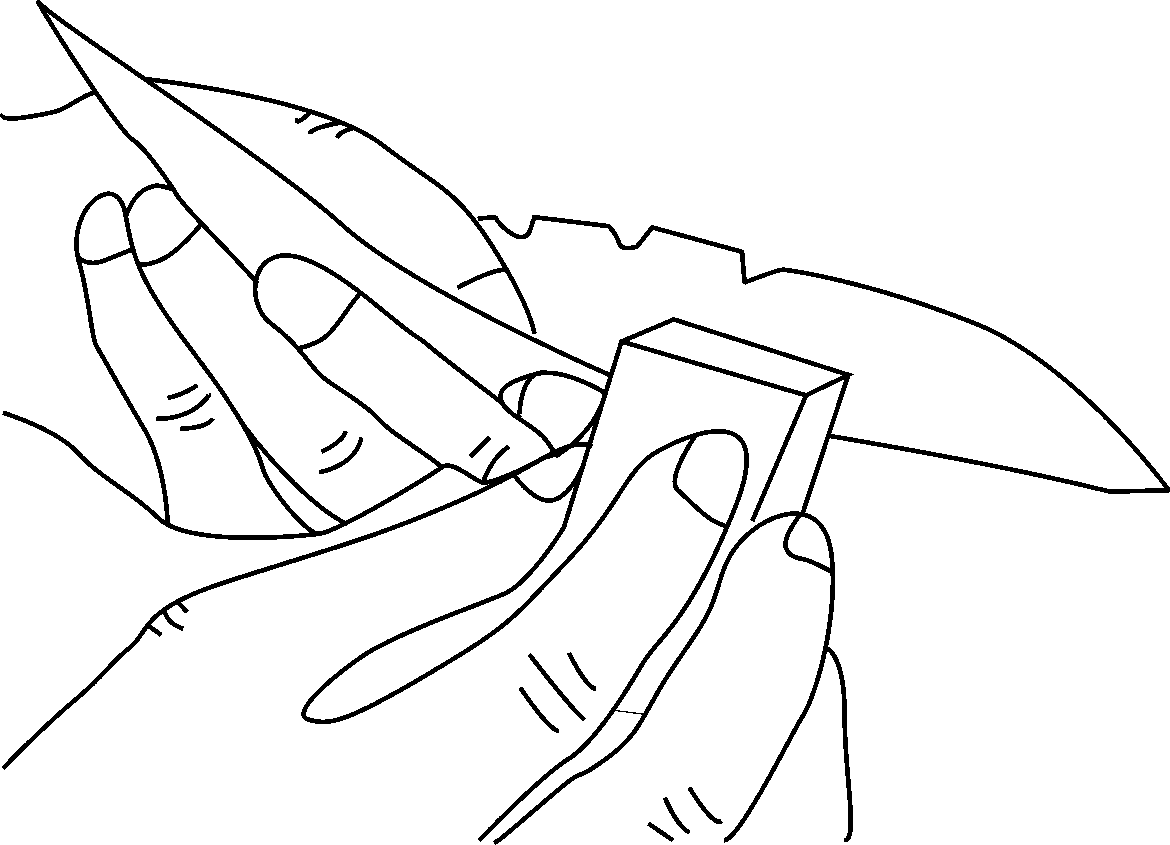

[0019] b. Apply beautifying agent: apply beautifying agent to the leather stubble, and paint evenly without accumulation; beautifying agent adopts hardener + dyeing agent. The operation method is as figure 1 shown.

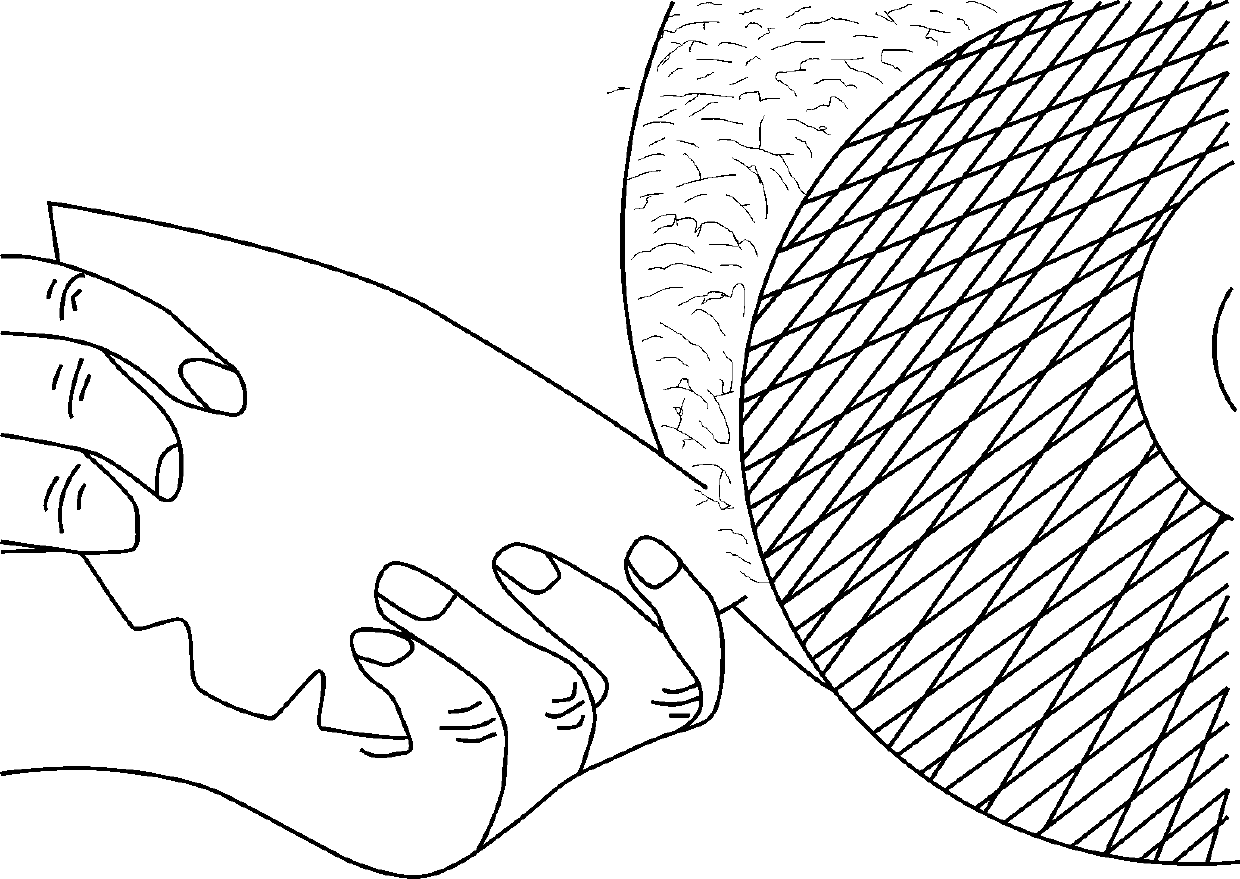

[0020] c. Polishing and waxing: Use a hair wheel with polishing wax to polish and wax the painted leather stubble. The operation method is as figure 2 shown.

[0021] The hardener is made by mixing epoxy resin and acetone, and the dyeing agent is made by mixing polyamide resin, dye, acetone and cycloethylene.

[0022] The waxing speed of the polishing wheel is 1300-1500 revolutions per minute, and the polishing and waxing speed of the stubble is 600 revolutions per minute.

[0023] The finished product produced by thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com