High-performance waterborne double-component epoxy resin with relatively high solid content and preparation method

A water-based two-component, solid content technology, applied in epoxy resin coatings, anti-corrosion coatings, coatings, etc., to achieve the effects of reducing VOC emissions, reducing production costs, and improving feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The content of each component is as follows:

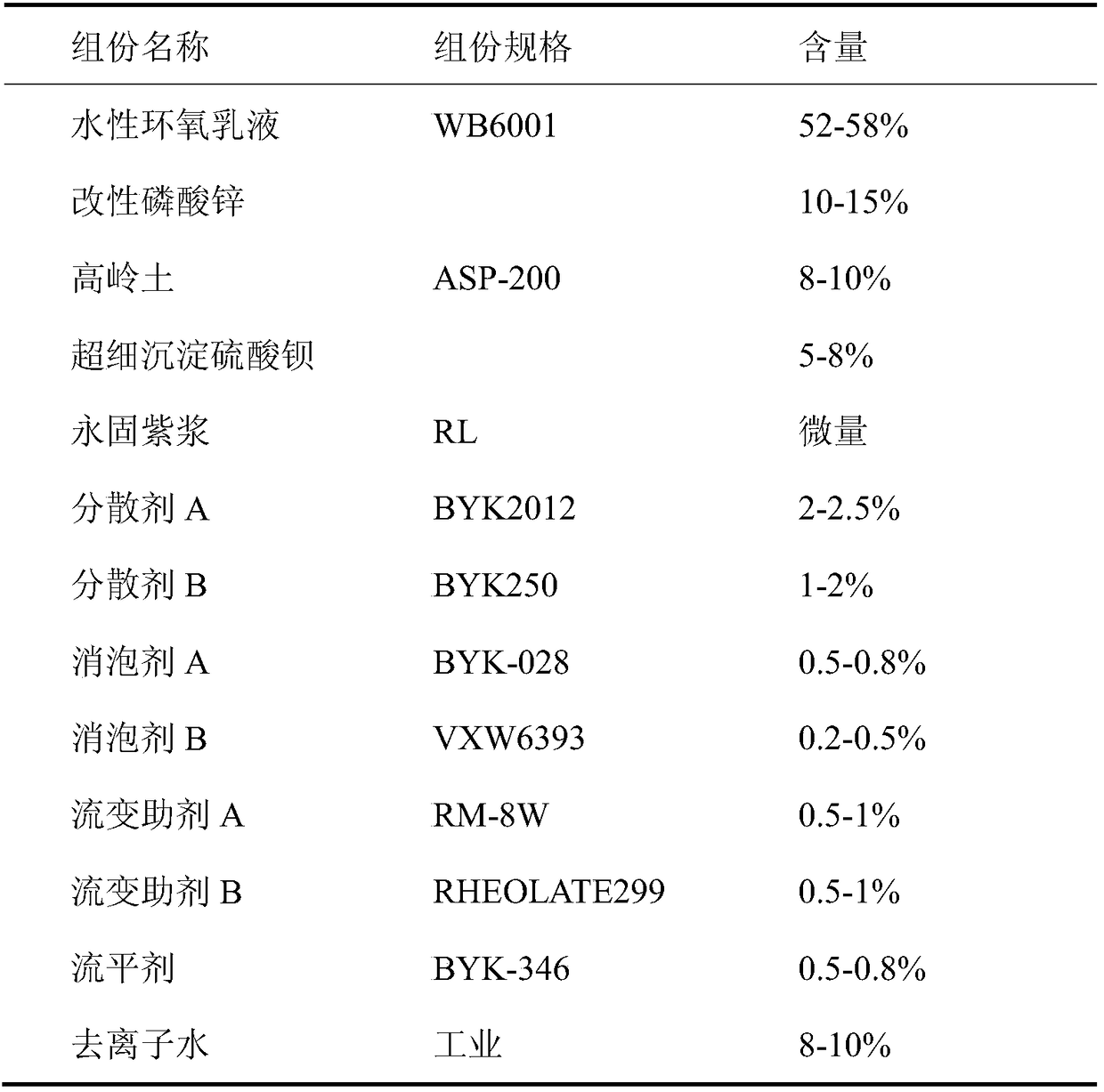

[0023] 1. The composition and weight percentage of component A are:

[0024]

[0025] 2. The composition and weight percentage of component B are:

[0026]

[0027] Its preparation method is as follows:

[0028] 1) Preparation of component A: Add deionized water to WB6001 water-based epoxy emulsion, stir evenly, control the speed at 400r / min, slowly add defoamer A (dilute with an equal amount of water), dispersant A and dispersant Agent B, stir evenly, control the speed at 400r / min, then add anti-rust filler modified zinc phosphate, kaolin and ultra-fine precipitated barium sulfate, stir well, control the stirring speed at 500-600r / min, stir for 30min and grind to fineness When the temperature reaches 30um, the grinding temperature is controlled to not exceed 50°C during the grinding process. If the temperature is too high, the machine will be shut down first, and the temperature of the grinding body will be reduced...

Embodiment 2

[0033] The content of each component is as follows:

[0034] 1. The composition and weight percentage of component A are:

[0035]

[0036]

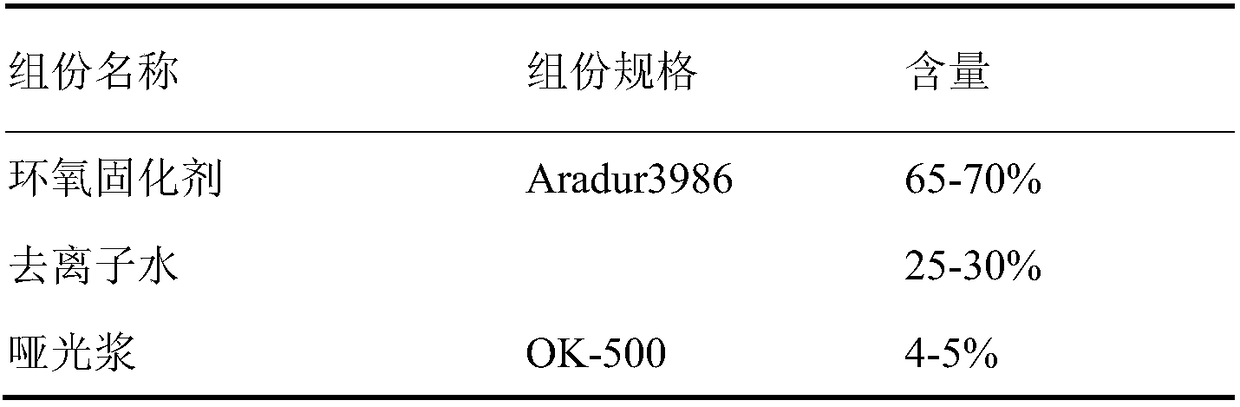

[0037] 2. The composition and weight percentage of component B are:

[0038]

[0039] The preparation method is the same as in Example 1.

[0040] Influence on product performance: The film thickness will be appropriately increased by 2-4 microns, but the original paint is easy to sink, the storage performance will be deteriorated, and the fineness will become coarser; at the same time, the salt spray will be affected by a certain amount, which will reduce 10-20%, and the chemical resistance will be reduced. Will be worse, especially water resistance will be reduced by 5-8%

Embodiment 3

[0042] The content of each component is as follows:

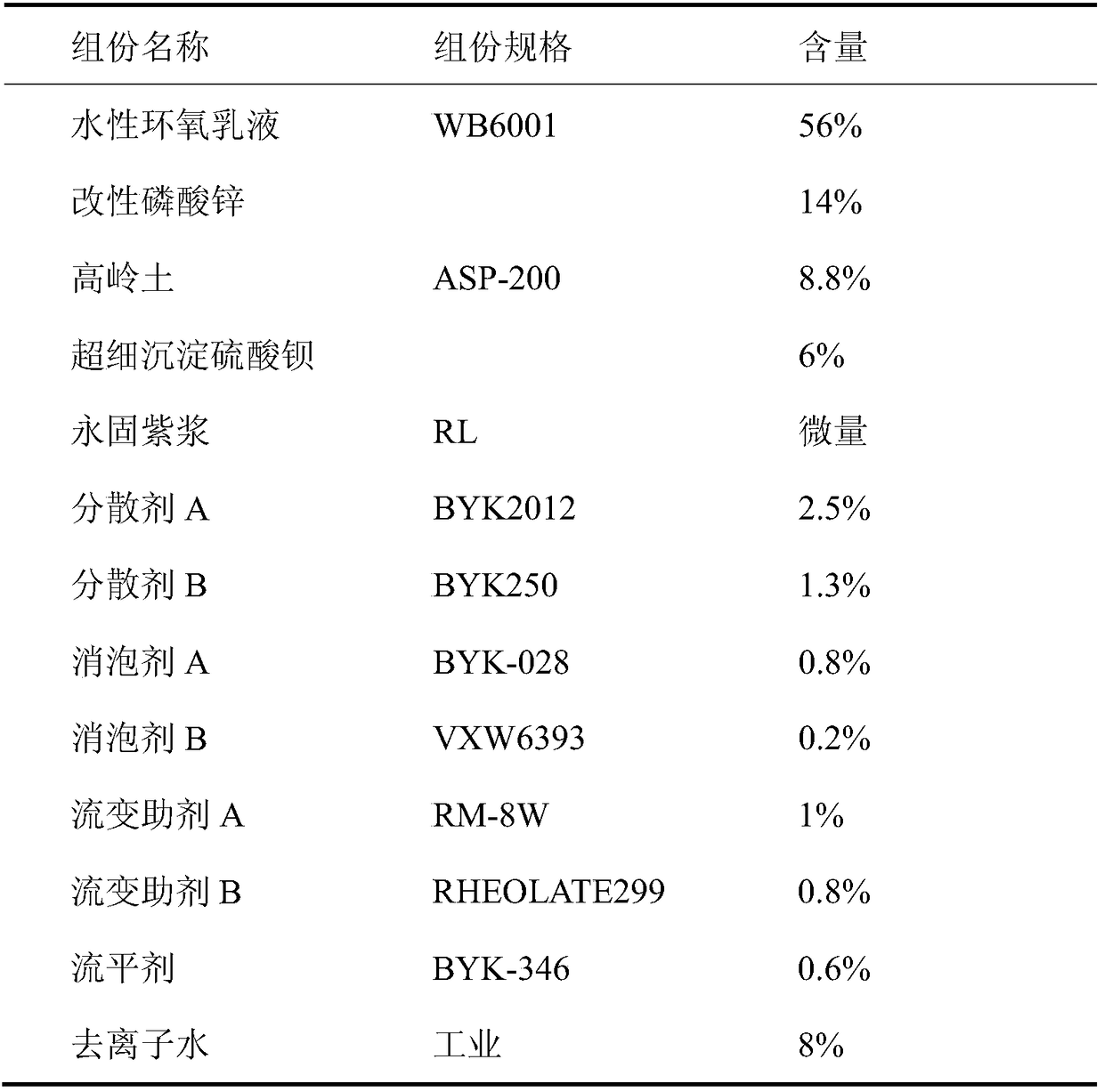

[0043] 1. The composition and weight percentage of component A are:

[0044]

[0045] 2. The composition and weight percentage of component B are:

[0046]

[0047] The preparation method is the same as in Example 1.

[0048] The influence of product performance: easy to sag, difficult to apply film, dryness is slowed down appropriately, surface drying will be prolonged for 5-10 minutes, gloss is high, and salt spray resistance is reduced by 5-10%.

[0049] The invention also provides a coating method of a water-based two-component epoxy coating with high performance and high construction solid content, which includes ensuring that the surface of the workpiece is oil-free and dust-free→spraying→drying. This method is easy to operate, and it is easy to apply a film by spraying. It is similar to the conventional spraying method. Because the paint film itself is matte, it can also be operated when the humidity is too h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com