An injection mold for a product without a draft angle on the outer side of the edge of the side wall

An injection mold and outer side technology, applied in the field of injection molds, can solve the problems of high cost of injection molds, low molding efficiency, and complicated mold movements, and achieve the effects of high molding efficiency, increased mold costs, and improved appearance grades.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

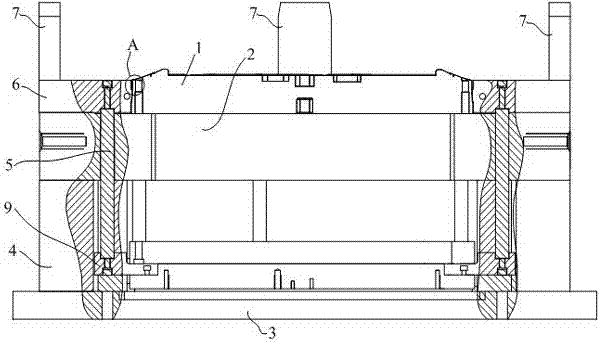

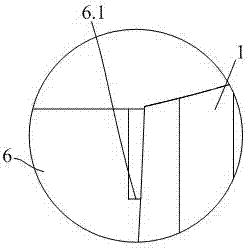

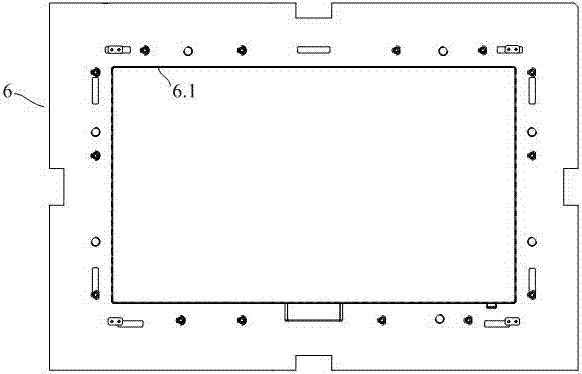

[0017] refer to figure 1 and figure 2 The injection mold shown includes a dynamic template and a static template. In this embodiment, the product stays on the movable template when the mold is opened, so figure 1 Only the structure diagram of the mold on the side of the dynamic formwork is given, and the structure of the mold on the side of the static formwork is the same as that of the prior art. Similar to the prior art, the movable template includes a core member and an ejection mechanism, the core member includes a core 1 and a core fixing plate 2, the core 1 is fixed on the core fixing plate 2, and the two can form an integral structure, Or in order to reduce the cost, the core 1 is embedded and fixed on the core fixing plate 2 in the form of mosaic; the ejector mechanism includes an ejector plate 3, a mold ejector pin 5 and an ejector plate 9, and the ejector plate 3 is paired with an ejector plate 9 Carry out limit; Between core fixed plate 2 and ejector plate 3 both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com