Production method for plastic product with customized pattern, plastic product and diaphragm

A technology for plastic products and customized patterns, which is applied in the production of plastic products with customized patterns, plastic products and diaphragms. It can solve the problems that the appearance patterns of home appliances cannot be customized, the patterns of diaphragms cannot be changed at will, and the spraying process is complicated, etc. problems, to achieve the effect of meeting the individual needs of the market, beautiful colors, and strong decorative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

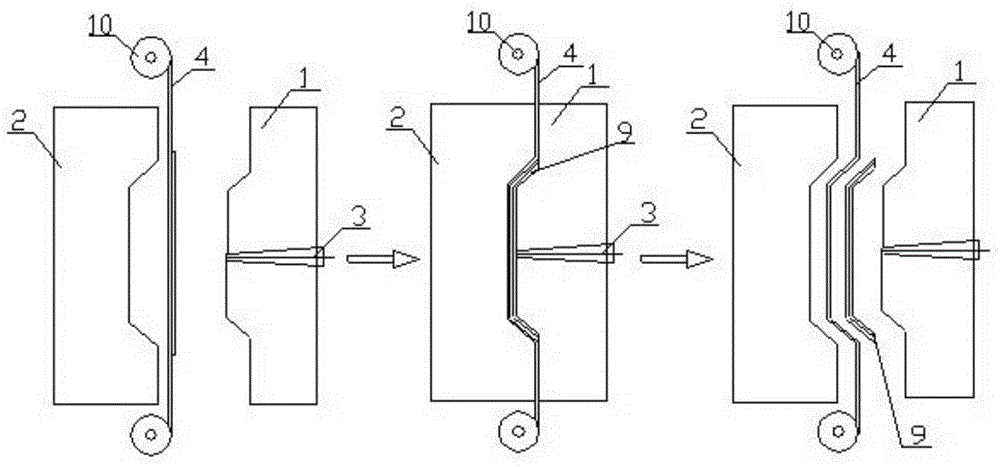

[0037] Such as figure 1 As shown, the present invention provides a method for producing plastic products with customized patterns, using a traditional injection molding machine and an injection mold. The injection mold includes a front mold 1 and a rear mold 2, and the front mold 1 and the rear mold 2 cooperate to form a cavity (not shown in the figure), the front mold 1 is provided with a glue inlet 3, and molten plastic enters the mold cavity through the runner and the glue inlet 3 after being injected from the injection molding machine, and finally forms a plastic product 9.

[0038] The method for producing plastic products with customized patterns specifically includes the following steps:

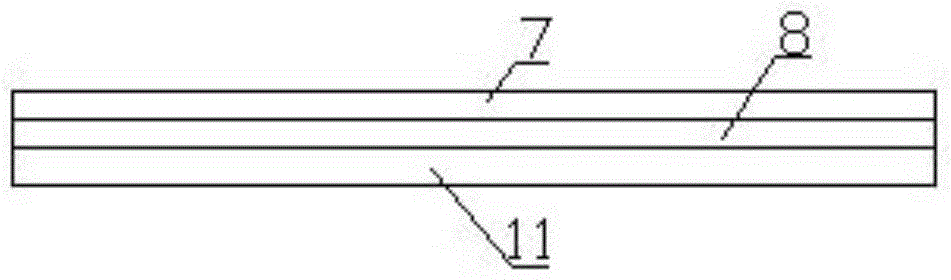

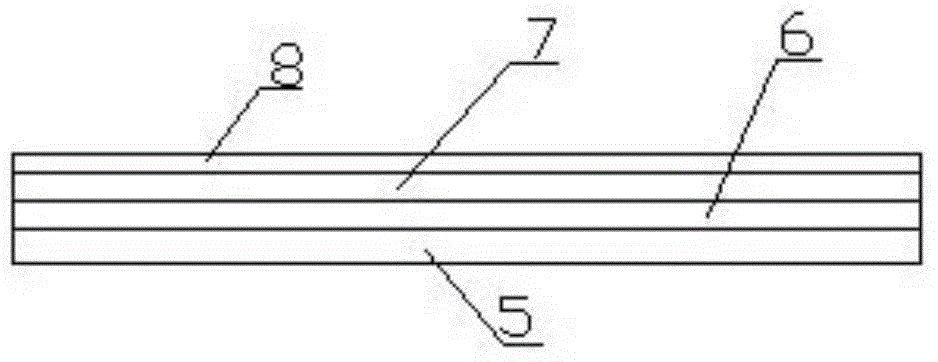

[0039] A0, prepare the base film 5 of the diaphragm 4, the base film 5 can be selected transparent or translucent PC, PE, PP, PET, PA, ABS film, etc.,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com