A kind of preparation method and product of milk silky fiber earphone wire

A technology of earphone cable and milk silk, which is used in cable/conductor manufacturing, conductors, insulated cables, etc., can solve the problems of insufficient color fastness and monotonous color of outer quilt, and achieve improved appearance, bright colors, normal temperature and high temperature color. Good fastness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing a milk silky fiber earphone cable, comprising the steps of:

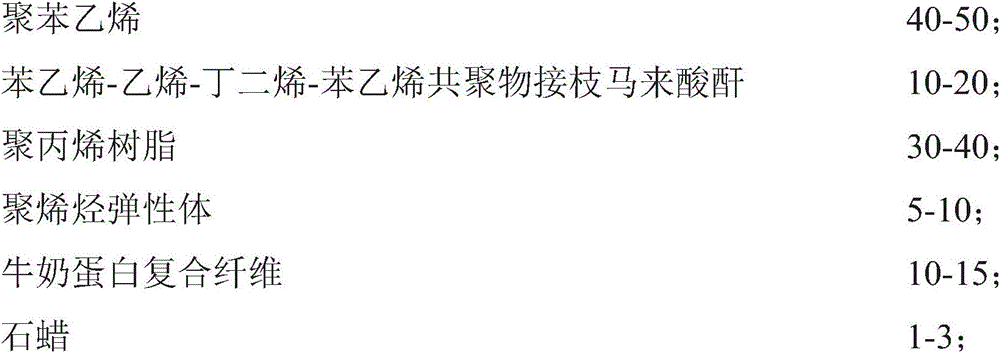

[0031] 1) Weigh the components in the following weight ratios:

[0032]

[0033]

[0034] Wherein, the milk protein composite fiber comprises the following preparation steps:

[0035] 1.1) Fiber pretreatment: adding sodium hydroxide solution to the fiber, soaking at room temperature, filtering, and rinsing;

[0036] 1.2) Reduction of fiber: adding the cotton fiber treated in step 1.1) into sodium periodate solution, stirring for reaction, filtering, and rinsing to obtain modified fiber;

[0037] 1.3) Preparation of milk protein liquid: configure sodium hydroxide solution, add olive oil to the sodium hydroxide solution, stir at room temperature, mix well, then add milk, stir at room temperature, heat to boiling and stir, then lower to room temperature Stir, mix thoroughly, filter to remove solids, and obtain milk protein liquid;

[0038] 1.4) Add the modified fiber prepared in s...

Embodiment 2

[0051] A method for preparing a milk silky fiber earphone cable, comprising the steps of:

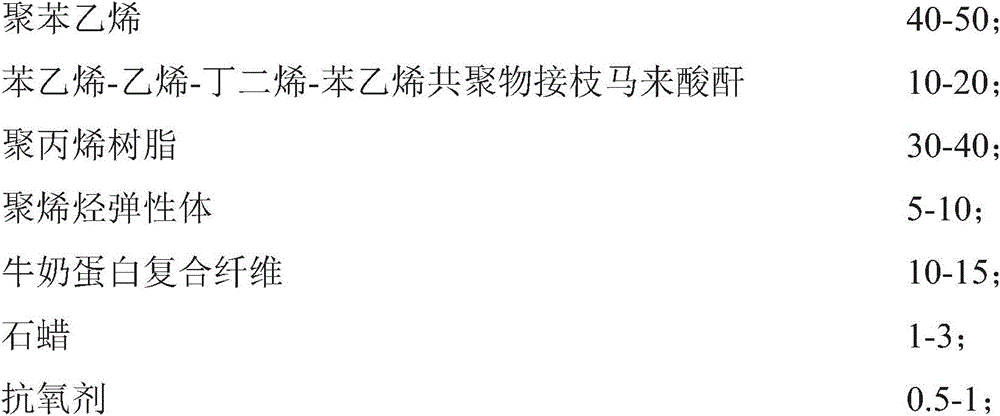

[0052] 1) Weigh the components in the following weight ratios:

[0053]

[0054] Wherein, the milk protein composite fiber comprises the following preparation steps:

[0055] 1.1) Fiber pretreatment: adding sodium hydroxide solution to the fiber, soaking at room temperature, filtering, and rinsing;

[0056] 1.2) Reduction of fiber: adding the cotton fiber treated in step 1.1) into sodium periodate solution, stirring for reaction, filtering, and rinsing to obtain modified fiber;

[0057] 1.3) Preparation of milk protein liquid: configure sodium hydroxide solution, add olive oil to the sodium hydroxide solution, stir at room temperature, mix thoroughly, then add milk, stir at room temperature, heat to boiling and stir, then lower to room temperature Stir, mix thoroughly, filter to remove solids, and obtain milk protein liquid;

[0058] 1.4) Add the modified fiber prepared in step 1....

Embodiment 3

[0068] Embodiment 3 is basically the same as Embodiment 2, and its difference is:

[0069] A method for preparing a milk silky fiber earphone cable, comprising the steps of:

[0070] 1) Weigh the components in the following weight ratios:

[0071]

[0072]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com