Front frameless glass refrigerator door and preparation method thereof

A refrigerator door, frameless technology, used in household refrigeration devices, lighting and heating equipment, household appliances, etc., can solve the problems of uncontrolled glass process temperature, poor color consistency of left and right borders, and high cost of raw material selection, and achieve appearance grades High, good aesthetic performance, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

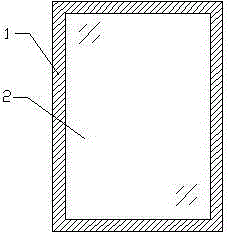

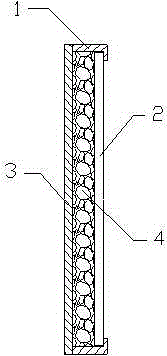

[0036] see image 3 and Figure 4 , the present invention relates to a front frameless glass refrigerator door, which includes a refrigerator door frame body 1, the front and back of the refrigerator door frame body 1 are respectively provided with a glass panel 2 and a door back panel 3, the refrigerator door A foam layer 4 is filled between the frame body 1 , the glass panel 2 and the door back panel 3 , and the glass panel 2 is laminated on the front of the refrigerator door frame body 1 .

[0037] The refrigerator door frame body 1 is injection molded, and the refrigerator door frame body 1 includes upper and lower end covers and left and right frames, and the upper and lower end covers and left and right frames are injection molded.

[0038] see Figure 5 , the refrigerator door frame body 1 is provided with transverse or longitudinal reinforcing ribs 5 .

[0039] see Figure 6 , a computer control panel 6 is arranged inside the refrigerator door frame body 1 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com