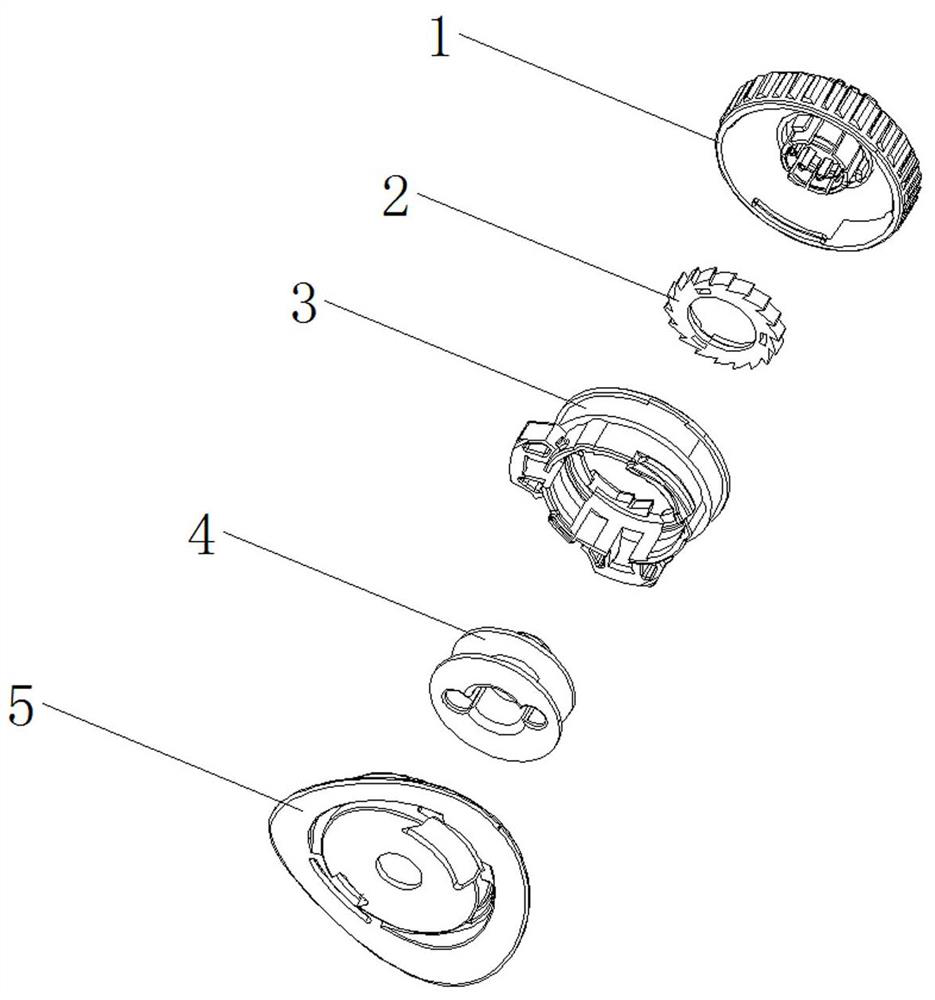

Knob device

A technology of knobs and wire wheels, which is applied to clothing, fastening objects, shoes, etc., can solve the problems that counterclockwise rotation cannot be prevented at any time, the wire wheel cannot rotate freely, and the degree of tightness is difficult to adjust, etc., to achieve sound Crisp and pleasing to the ear, improving the degree of recognition, and the effect of reasonable stress state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

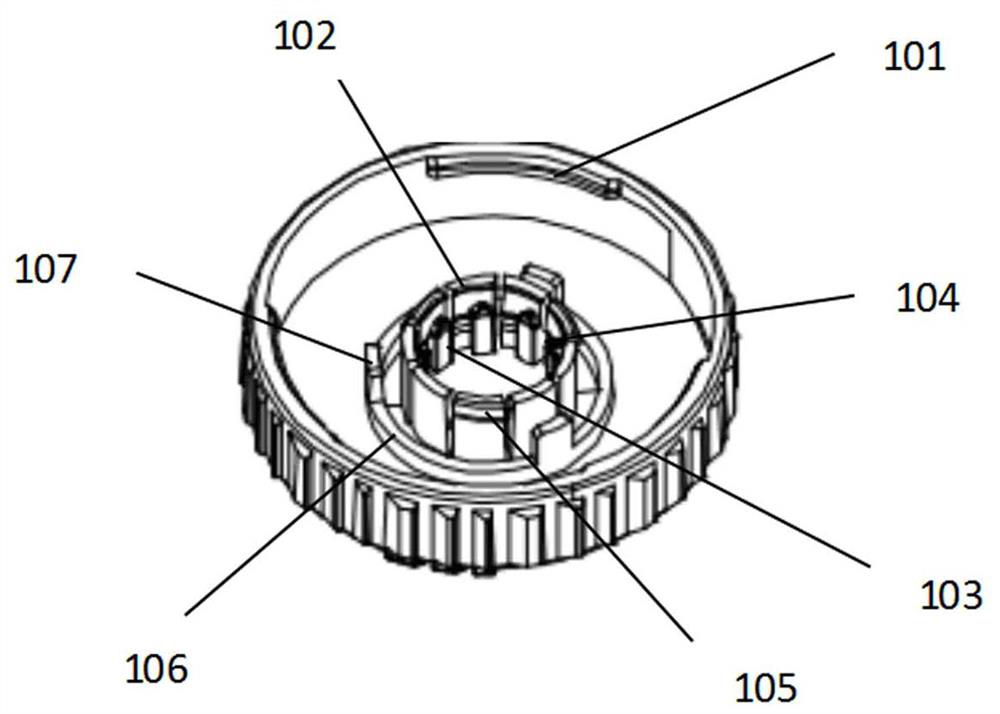

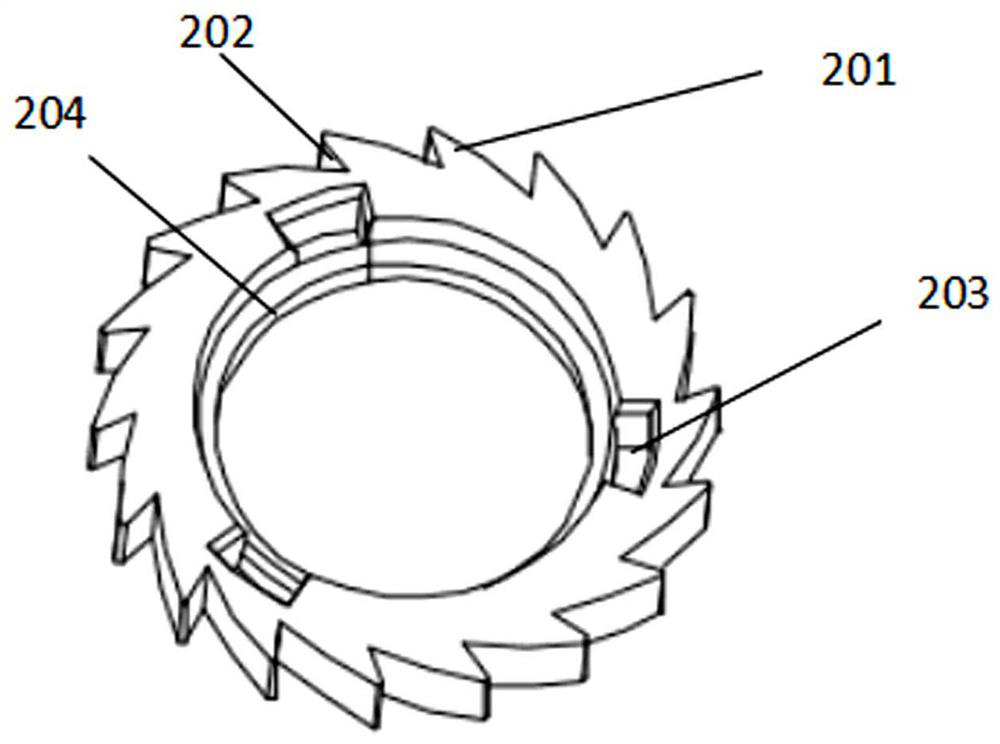

[0057] Tighten the shoelaces, press the knob 1 assembly slightly toward the base 5, and when you hear a "click", the knob 1 is in a combined state with the ratchet wheel compartment 3 and the wire wheel 4. During this process, the wire wheel 4 The protruding structure 403 is pressed into the concave structure 104 in the knob 1, the central circular bone structure 102 of the knob 1 is combined with the annular bone structure 401 of the wire wheel 4, and the load on the circular bone structure 102 Muscle 1 103 intersects with load 2 402 on the wire wheel, and the locking teeth 201 on the ratchet ring 2 and the ratchet teeth 302 on the ratchet wheel bin 3 are also in meshing state. Turn the knob clockwise, and the ratchet ring 2 The latch tooth 201 on the ratchet wheel bin 3 can cross the ratchet tooth 302 on the ratchet wheel bin 3, but in the ratchet wheel bin 3, there is always a ratchet tooth end surface position 303 of the ratchet tooth 302 facing the ratchet ring 2. The pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com