Aspartate resin of novel structure, polyurea coating as well as preparation method and application of polyurea coating

A technology of aspartic acid ester and new structure, which is applied in the direction of polyurea/polyurethane coating, organic compound preparation, cyanide reaction preparation, etc., and can solve the problems that are not conducive to improving the hardness of the coating film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

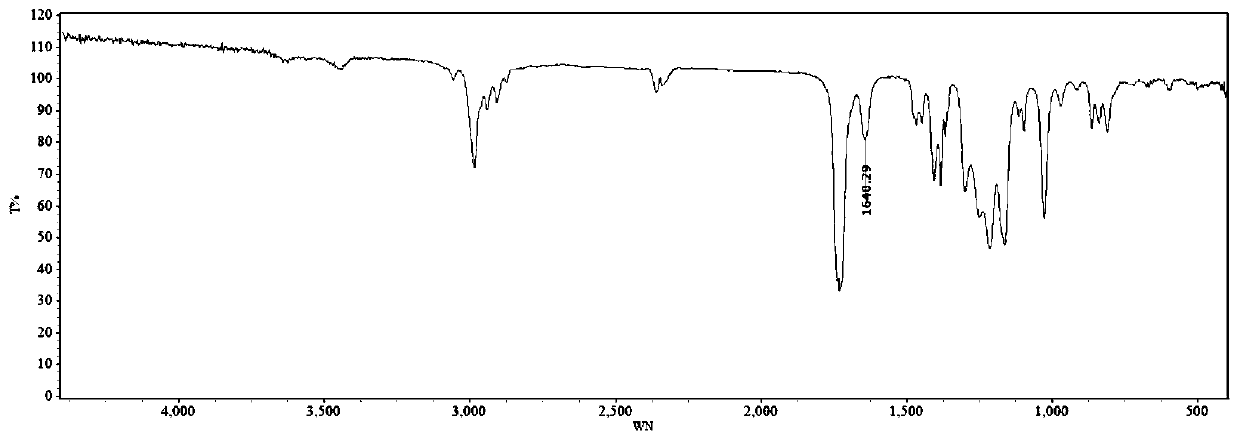

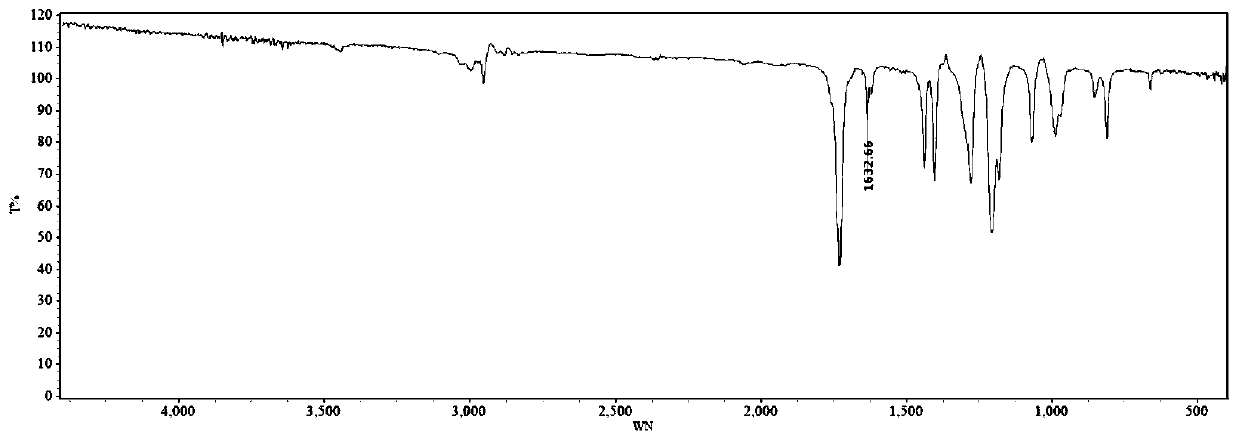

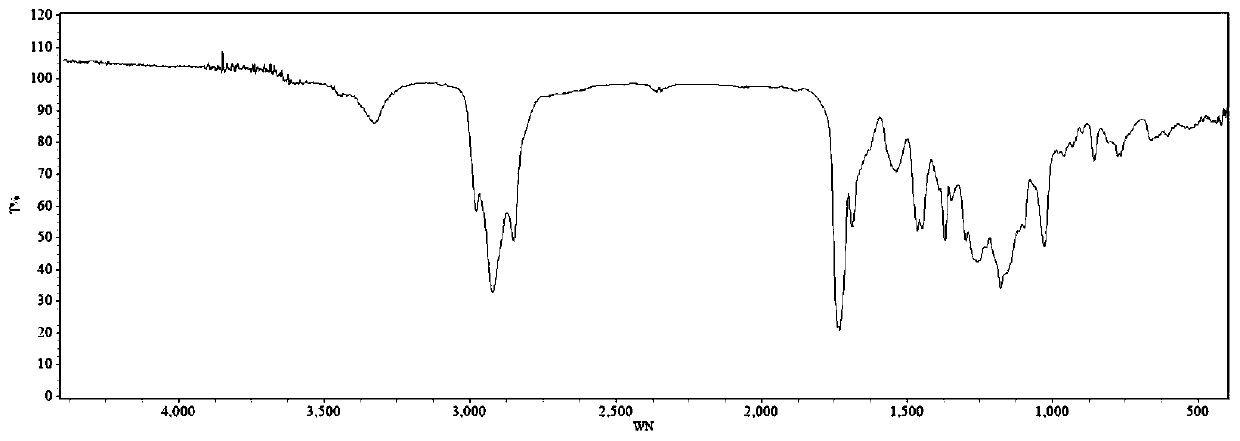

[0063] Preparation of Example 1E1

[0064] In a 500ml four-necked flask equipped with electric stirring, thermometer, dropping funnel, nitrogen conduit and reflux condenser respectively, add 0.5mol (105.2g) of 4,4'-diamino-dicyclohexylmethane, and then add 0.25 g2,4,6-tris(dimethylaminomethyl)phenol. Start stirring, blow nitrogen and slowly heat up to 40-45°C, start to drop 0.6mol (103.3g) diethyl maleate, control the temperature not to exceed 60°C and keep the dropwise addition within 30-40 minutes, and then React in the range of 60-65°C for 4 hours. Cool down to about 45°C, start to add 0.4mol (40.05g) methyl methacrylate dropwise, control the temperature not to exceed 60°C and keep the dropwise addition within 30-40 minutes. Then continue to react in the range of 60-65°C for 10 hours, cool down to 40°C and discharge to obtain the product E1. The product is a light yellow transparent liquid, and the conversion rate measured by the "iodination method" is 86% at this time, ...

Embodiment 2

[0067] The preparation of embodiment 2 E2

[0068] In a 500ml four-necked flask equipped with electric stirring, thermometer, dropping funnel, nitrogen conduit and reflux condenser respectively, add 0.5mol (105.2g) of 4,4'-diamino-dicyclohexylmethane, and then add 0.27 g2,4,6-tris(dimethylaminomethyl)phenol. Start stirring, blow nitrogen and slowly heat up to 40-45°C, start to drop 0.6mol (103.3g) diethyl maleate, control the temperature not to exceed 60°C and keep the dropwise addition within 30-40 minutes, and then React in the range of 60-65°C for 4 hours. Cool down to about 45°C, start to add 0.4mol (45.7g) ethyl methacrylate dropwise, control the temperature not to exceed 60°C and keep the dropwise addition within 30-40 minutes. Then continue to react in the range of 60-65°C for 10 hours, cool down to 40°C and discharge to obtain product E2. The product is a light yellow transparent liquid, and the conversion rate measured by the "iodination method" is 84% at this ti...

Embodiment 3

[0071] The preparation of embodiment 3 E3

[0072]In a 500ml four-necked flask equipped with electric stirring, thermometer, dropping funnel, nitrogen conduit and reflux condenser respectively, add 0.5mol (105.2g) of 4,4'-diamino-dicyclohexylmethane, and then add 0.25 g2,4,6-tris(dimethylaminomethyl)phenol. Start stirring, blow nitrogen and slowly heat up to 40-45°C, start to drop 0.6mol (103.3g) diethyl maleate, control the temperature not to exceed 60°C and keep the dropwise addition within 30-40 minutes, and then React in the range of 60-65°C for 4 hours. Cool down to about 45°C, start to add 0.4mol (40.0g) ethyl acrylate dropwise, control the temperature not to exceed 60°C and keep the dropwise addition within 30-40 minutes. Then continue to react in the range of 60-65°C for 10 hours, cool down to 40°C and discharge to obtain the product E3. The product is a light yellow transparent liquid, and the conversion rate measured by the "iodination method" is 86% at this time,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com