Interference-flash-point-free anti-dazzle glass, etching solution preparation method and production technology

A production process and non-interference technology, applied in non-interference flash point anti-glare glass, glass frosting etchant equipment, non-interference flash point anti-glare glass production process, can solve the problem of glass loss of anti-glare, affecting glass anti-glare Glare effect and other problems can be achieved to reduce the volatilization of acid mist, reduce the time of chemical polishing, and avoid the effect of excessive etching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

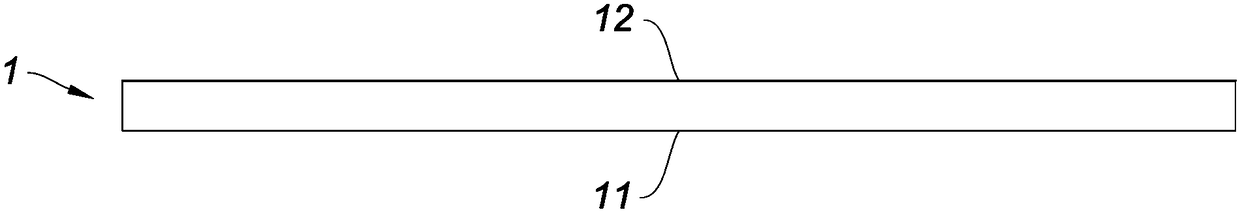

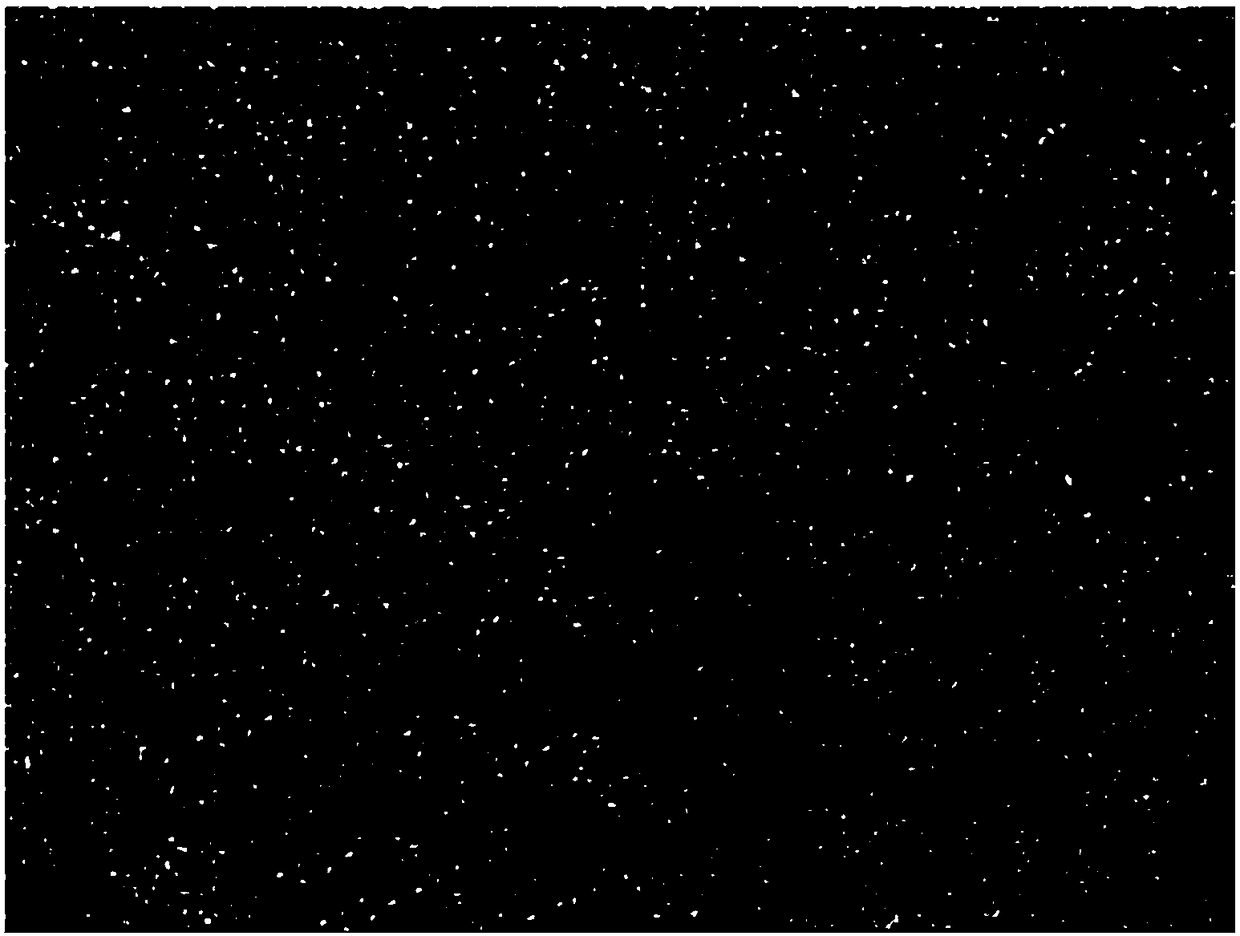

[0031] Such as figure 1 , figure 2 , image 3 As shown, the non-interference flash point anti-glare glass described in this embodiment includes a glass substrate 1, the glass substrate 1 has a light incident surface 11, and the light incident surface 11 is the side close to the display screen during application. The other side of the glass substrate 1 opposite to the light incident surface 11 is a light exit surface 12. The light exit surface 12 of the glass substrate 1 is a rough surface with a concave-convex structure formed by etching. The surface roughness of the light exit surface 12 is defined as follows : Ra is in the range of 0.06-0.18 μm, Rsm is in the range of 15-40 μm, Rz is in the range of 0.65-1.5 μm; the glossiness of the light exit surface 12 at an angle of 60° is in the range of 45-85 SGU. The transmittance of the glass substrate 1 is in the range of 83-94%. The haze of the glass substrate 1 is in the range of 5-19%. The clarity of the glass substrate 1 is...

Embodiment 11

[0045] This embodiment provides a method for preparing a glass frosting etching solution, and the preparation steps of the frosting etching solution are as follows:

[0046] Step 1: Stir and fuse 8 parts by weight of ammonium bifluoride, 2 parts of calcium fluoride, 3 parts of potassium chloride and 6 parts of water, then add 3 parts of potassium fluoride solution, and stir and mature for 4 hours;

[0047] Step 2: Pour the matured frosting etching solution obtained in step 1 into the liquid medicine tank equipped with horizontal spraying equipment, and use an acid-resistant pump to circulate and filter to make the frosting etching solution fully react, and then stir for 38 minutes;

[0048] Step 3: Filtration; the frosting etching solution obtained in step 2 is filtered with 80 mesh screen cloth in the tank, and the saturated crystals are isolated outside the extraction area of the acid-resistant pump, thereby obtaining the frosting etching solution with a pH value of 5.5. F...

Embodiment 12

[0052] The difference between this embodiment and Example 11 is that in step two of this embodiment, 9 parts by weight of ammonium bifluoride, 3 parts of sodium fluoride, 2 parts of calcium fluoride, 4 parts of potassium chloride and 6.5 parts of water Stir and fuse, then add 4 parts of potassium fluoride solution, and stir and mature for 5h.

[0053] The roughness parameters and optical characteristics of the glass etching surface etched by the frosting etching solution of this embodiment are those shown in Embodiment 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com