Method for preparing three-dimensional ordered macroporous material by using water-soluble colloidal crystal as template

A water-soluble colloid, three-dimensional ordered technology, applied in climate sustainability, sustainable manufacturing/processing, silica, etc., to achieve good gloss and chemical structure, size uniformity, maintain gloss and chemical structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

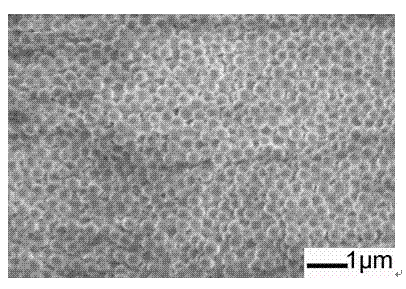

[0047] Preparation of three-dimensional ordered macroporous cross-linked polyacrylonitrile with a pore size of about 300 nm

[0048] (1) Preparation of 300nm water-soluble polyacrylamide colloidal crystal template

[0049] Add 2.6923g (5.98% of the total mass percentage of the material) AM and 2.6923g (5.98% of the total mass of the material) of PVP into the three-necked bottle, and then add 20mL (20g of 44.45% of the total mass of the material) distilled water and 25mL (19.5g accounts for 43.34% of the total mass of the material) tert-butanol, bubble argon into the solution, heat to 75°C in a water bath or oil bath, react under the protection of argon, and stir until the solution is heated to 75°C ℃ and the system is stable, add the initiator 0.1122g (accounting for 0.25% of the total mass percentage of the material) AIBN into the three-necked flask, the stirring speed is 80r / min, the temperature is controlled at about 75℃, stop the reaction after 7h, and the obtained milk T...

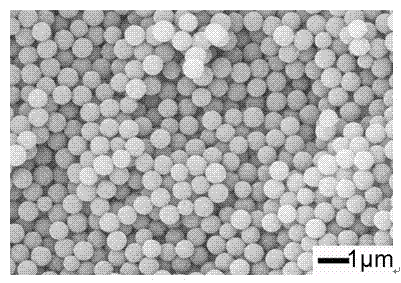

Embodiment 2

[0054] Preparation of Three-Dimensional Ordered Crosslinked Polystyrene with Pore Size About 500nm

[0055] (1) Preparation of 500nm water-soluble polyacrylamide colloidal crystal template

[0056] Add 5.0804g (10% of the total mass percentage of the material) AM and 3.0482g (6% of the total mass of the material) of PVP into the three-necked bottle, and then add 15mL (15g of 29.53% of the total mass of the material) distilled water and 35mL (27.65g accounts for 54.42% of the total mass of the material) ethanol, bubbles argon into the solution, heats it to 75°C in a water bath or an oil bath, reacts under the protection of argon, and stirs until the solution is heated to 75°C and When the system is stable, add the initiator 0.0254g (0.05% of the total mass percentage of the material) AIBN into the three-necked flask, the stirring speed is 70r / min, the temperature is controlled at about 75°C, stop the reaction after 7h, and the obtained emulsion Removed, centrifuged at 3000r / mi...

Embodiment 3

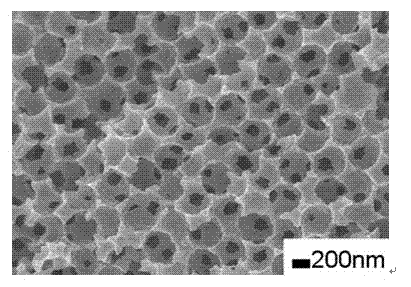

[0061] Preparation of Three-Dimensional Ordered Macroporous Polymethylmethacrylate with Pore Size About 200nm

[0062] (1) Preparation of 200nm water-soluble polyacrylamide colloidal crystal template

[0063] Add 24g (20mL water, 24.4892% of the total mass percentage of 4g AM of the material) acrylamide aqueous solution and 5.8g (5.9182% of the total mass of the material) of Span80, 5.8g (5.9182% of the total mass of the material) in the three-necked flask Tween80, then add 80mL (62.4g accounted for 63.6718% of the total mass of the material) cyclohexane, bubble argon into the solution, heat to 30 ° C, react under the protection of argon, and stir, when the system is stable 0.0025g of the initiator ammonium persulfate (0.0026% of the total mass of the material) was added to the three-necked flask, the timing was started, the reaction was stopped after 5h, the obtained emulsion was removed, centrifuged at 3000r / min or naturally settled to obtain a monodisperse Polyacrylamide c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com