High-gloss, flame-retarding and heat-resistance ABS alloy and preparation method thereof

An alloy and heat-resistant technology, which is applied in the field of high-gloss flame-retardant and heat-resistant ABS alloy and its preparation, can solve problems affecting gloss and achieve low cost, high heat distortion temperature, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

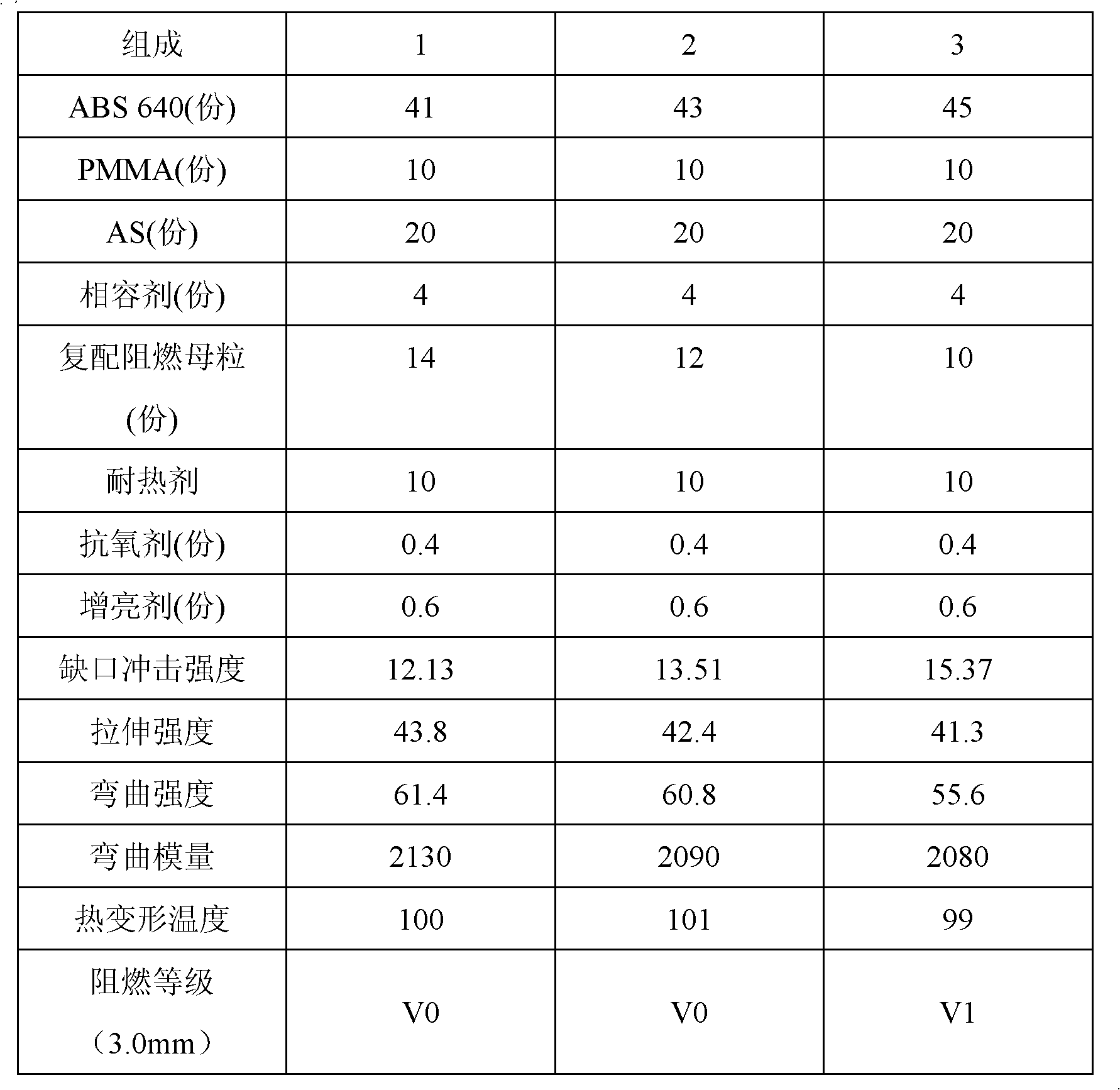

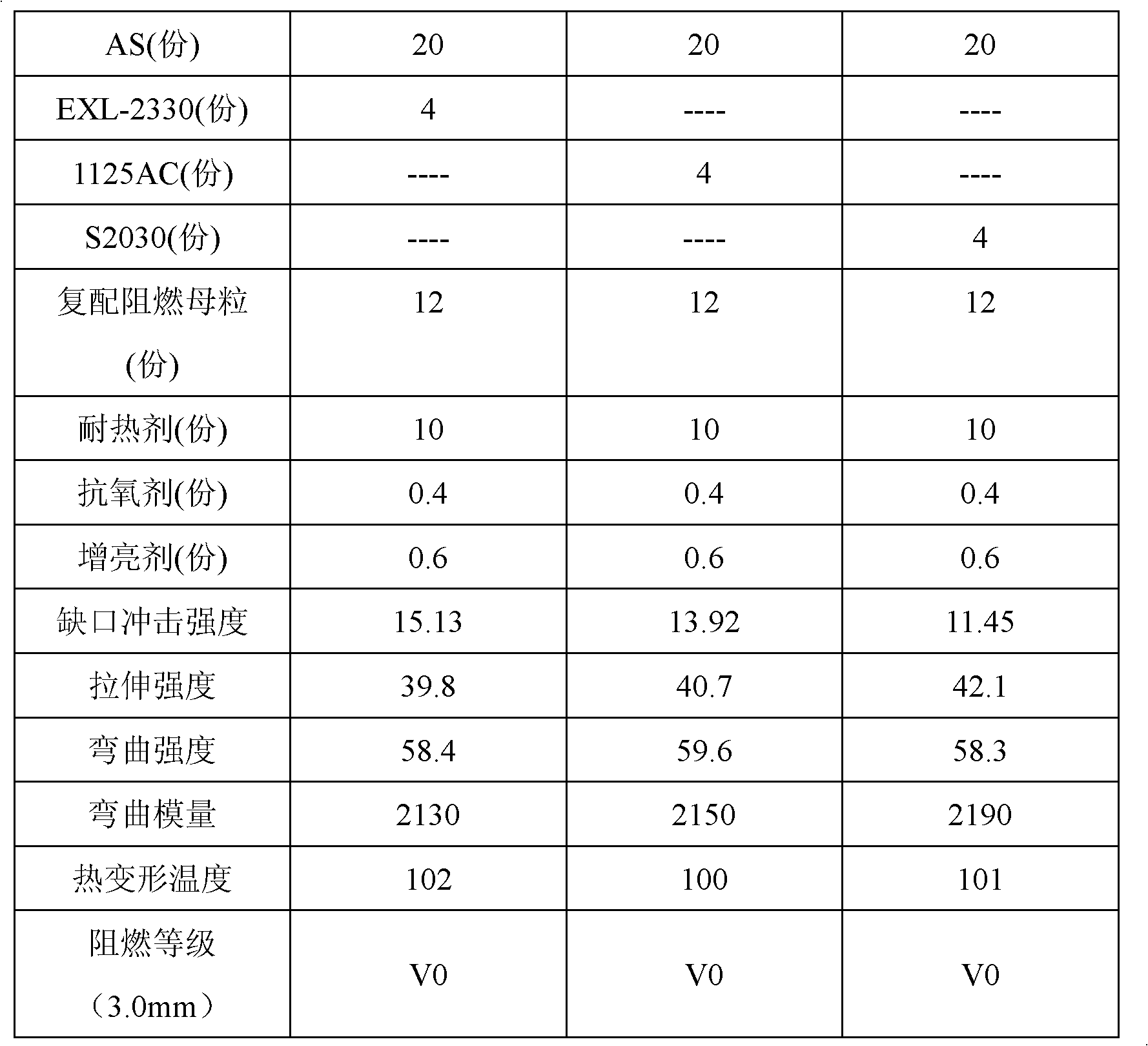

Embodiment 1

[0039] According to the weight ratio, ABS 640 is 45 parts, PMMA is 10 parts, AS is 20 parts, compatibilizer is 4 parts, and compound flame retardant masterbatch is 14 parts. The ratio of ABS resin, brominated flame retardant, synergistic flame retardant, silane coupling agent, and grafted polar siloxane in the intercombined flame retardant is 30:52:14:2:2. The effective flame retardant is polymerized antimonate, 10 parts of heat-resistant agent, 0.2 part of antioxidant 1010, 0.2 part of antioxidant 168, and 0.6 part of brightening agent. The mixed material is put into the hopper of the twin-screw extruder, melted and blended, extruded and granulated to form a composite material.

Embodiment 2

[0041] According to the weight ratio, ABS 640 is 45 parts, PMMA is 10 parts, AS is 20 parts, compatibilizer is 4 parts, and the compound flame retardant masterbatch is 12 parts. Among the flame retardants, ABS resin, brominated flame retardant The ratio of agent, synergistic flame retardant, silane coupling agent, and grafted polar siloxane is 30:52:14:2:2, and the synergistic flame retardant used is a mixture of polymerized antimonate and zinc borate , wherein the ratio of polyantimonate and zinc borate is 1:1. The heat-resistant agent is 10 parts, the antioxidant 1010 is 0.2 parts, the antioxidant 168 is 0.2 parts, and the brightening agent is 0.6 parts. The mixed material is put into the hopper of the twin-screw extruder, melted and blended, extruded and granulated to form a composite material.

Embodiment 3

[0043] According to the weight ratio, ABS 640 is 45 parts, PMMA is 10 parts, AS is 20 parts, compatibilizer is 4 parts, and the compound flame retardant masterbatch is 10 parts. Among the flame retardants, ABS resin, brominated flame retardant The ratio of agent, synergistic flame retardant, silane coupling agent, and grafted polar siloxane is 30:52:14:2:2. The synergistic flame retardant used is antimony trioxide, heat-resistant agent 10 parts, 0.2 parts of antioxidant 1010, 0.2 parts of antioxidant 168, and 0.6 parts of brightener. The mixed material is put into the hopper of the twin-screw extruder, melted and blended, extruded and granulated to form a composite material.

[0044] Performance Testing:

[0045] Tensile strength is tested according to ASTM-638 standard.

[0046]Flexural strength and flexural modulus are tested according to ASTM-790 standard.

[0047] The Charpy notched impact strength is tested according to ASTM-D256 standard.

[0048] Combustibility (ver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com