Trackpad and manufacturing method thereof

A manufacturing method and touchpad technology, which is applied in the fields of instruments, computing, and electrical digital data processing, etc., can solve the problems of touchpad touch and poor gloss, and achieve the effects of ensuring gloss, improving performance, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

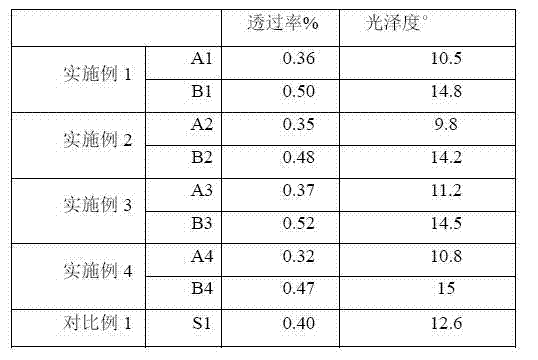

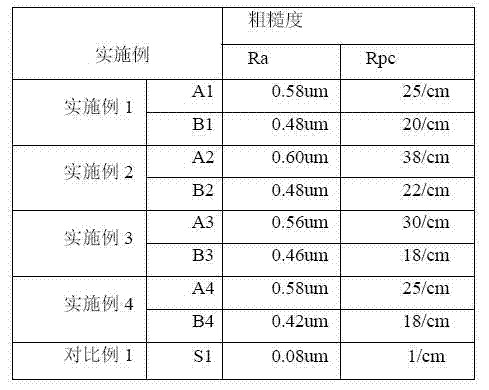

Examples

Embodiment 1

[0040] This embodiment 1 is used to illustrate the manufacturing method of the touch panel and the obtained touch panel;

[0041] Step 1. Provide a glass substrate and make a screen printing screen; apply photosensitive glue on a 120-mesh monofilament polyester screen, the angle of the squeegee is 75°, and the travel angle is 45°, and the screen printing screen is obtained after coating;

[0042] Step 2, using the above-mentioned screen printing screen to print etching ink on the glass substrate, the etching ink includes 50 parts by weight of ammonium bifluoride, 15 parts by weight of calcium sulfate, 5 parts by weight of barium sulfate, and 10 parts by weight of hydrochloric acid and 20 parts by weight of water; the distance between the screen printing screen plate and the glass substrate is 3mm, and the travel speed is 20 / min. After printing, place it for 8 minutes, then use clear water to clean the etching ink on the surface of the glass substrate, and then dry it A glass s...

Embodiment 2

[0045] This embodiment 2 is used to illustrate the manufacturing method of the touch panel and the obtained touch panel;

[0046] Step 1. Provide a glass base material and make a screen printing screen; apply photosensitive glue on a 150-mesh monofilament polyester screen, the angle of the squeegee is 55°, and the travel angle is 65°, and the screen printing screen is obtained after coating;

[0047] Step 2, using the above-mentioned screen printing screen to print etching ink on the glass substrate, the etching ink includes 45 parts by weight of ammonium bifluoride, 10 parts by weight of calcium sulfate, 8 parts by weight of barium sulfate, and 15 parts by weight of hydrochloric acid and 22 parts by weight of water; the distance between the screen printing screen plate and the glass substrate is 2mm, and the travel speed is 25 / min. After printing, place it for 10min, then use clear water to clean the etching ink on the surface of the glass substrate, and then dry it A glass s...

Embodiment 3

[0050] This embodiment 3 is used to illustrate the manufacturing method of the touch panel and the obtained touch panel;

[0051] Step 1. Provide a glass substrate and make a screen printing screen; apply photosensitive glue on a 120-mesh monofilament polyester screen, the angle of the squeegee is 65°, and the travel angle is 50°, and the screen printing screen is obtained after coating;

[0052] Step 2, using the above-mentioned screen printing screen to print etching ink on the glass substrate, the etching ink includes 40 parts by weight of ammonium bifluoride, 10 parts by weight of calcium sulfate, 10 parts by weight of barium sulfate, and 15 parts by weight of hydrochloric acid and 25 parts by weight of water; the distance between the screen printing screen plate and the glass substrate is 4mm, and the speed of travel is 30 / min. After printing, place it for 8 minutes, then use clear water to clean the etching ink on the surface of the glass substrate, and then dry it A gla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com