Multi-cylinder engine cylinder hole ceramization clamp, device and method

A multi-cylinder engine, ceramic technology, applied in the direction of anodic oxidation, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problem of low cylinder bore roundness and cylindricity accuracy, poor cylinder bore surface roughness, and cylinder bore roundness , cylindricity accuracy has not been improved, etc., to achieve the effect of improving product quality, satisfying cylindricity, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

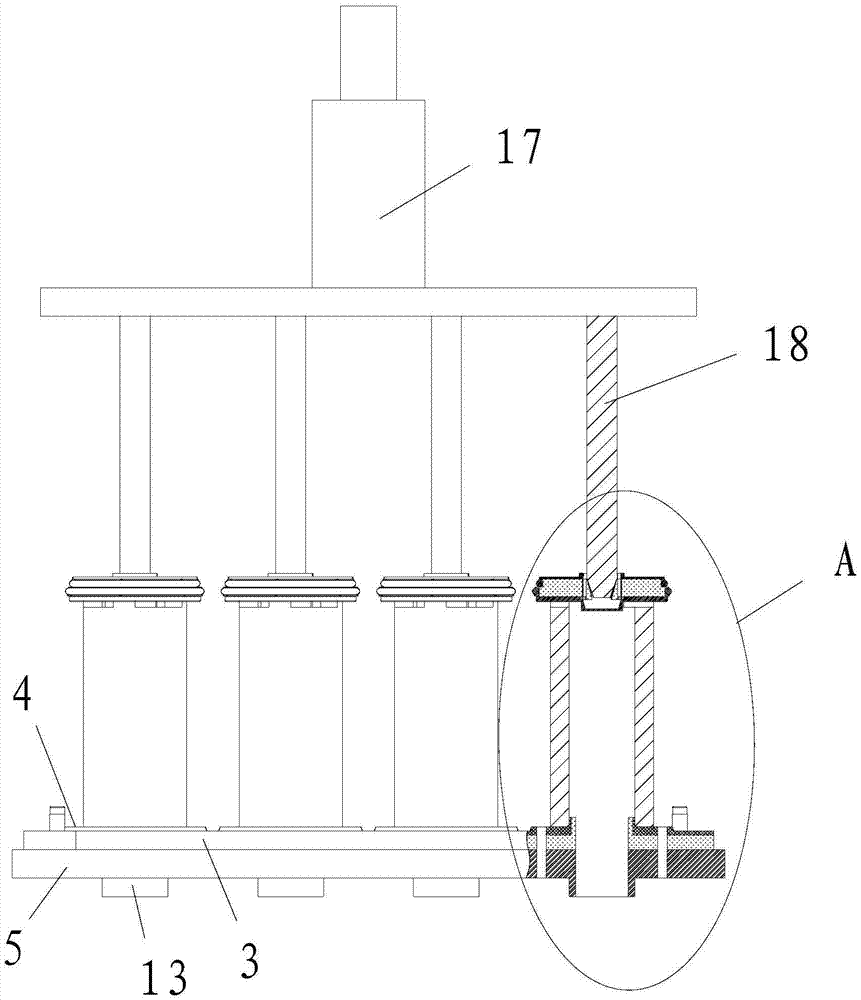

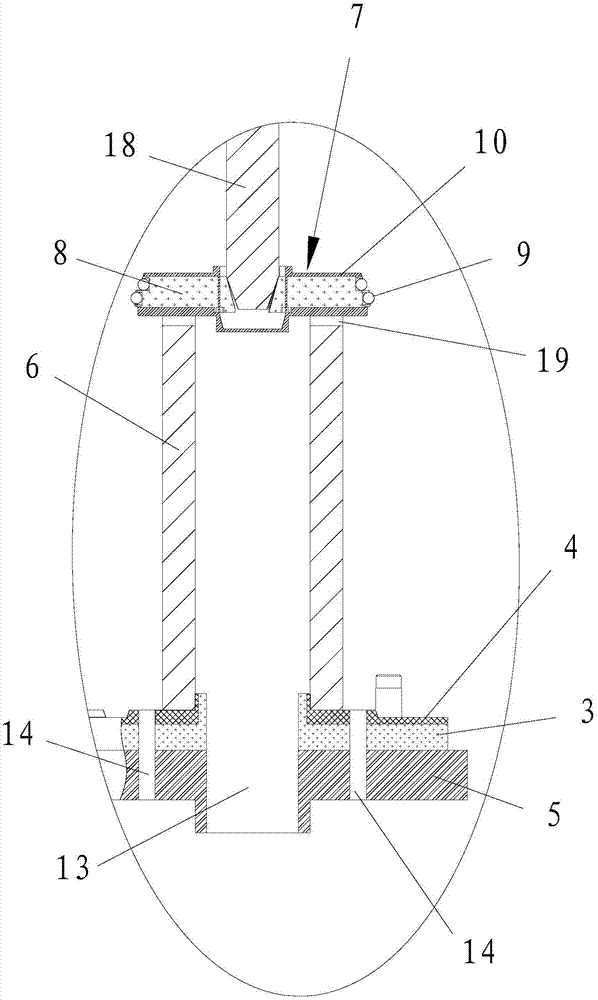

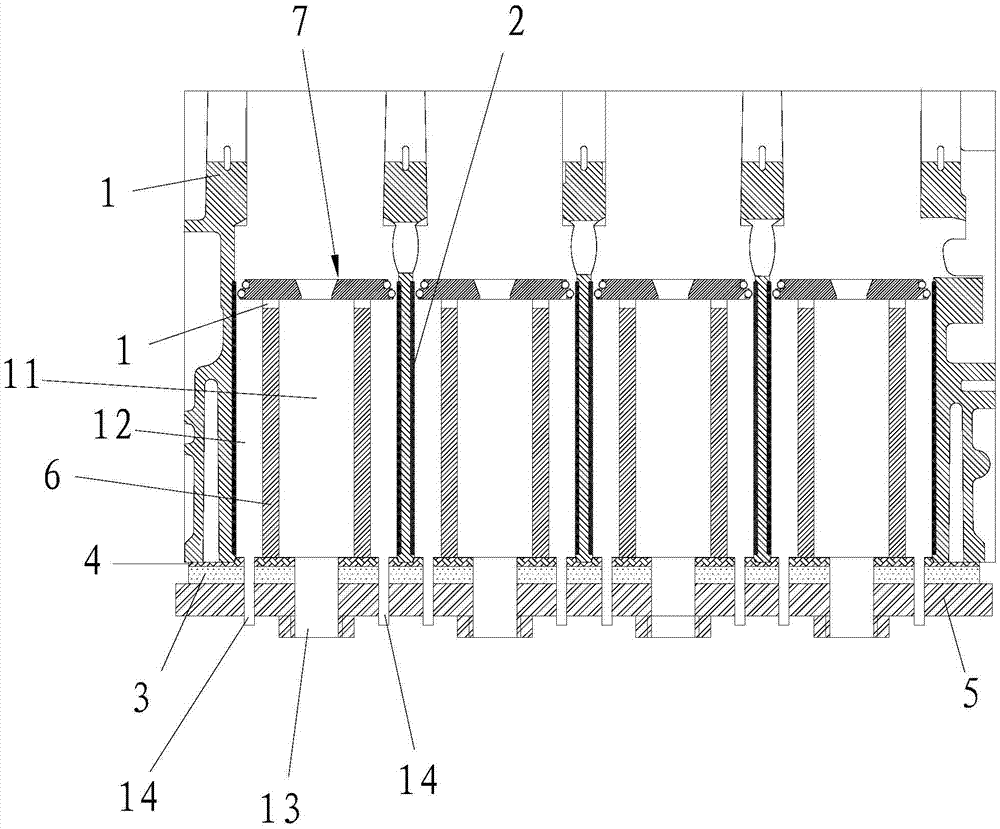

[0037] This embodiment relates to a fixture for ceramicizing cylinder bores of a multi-cylinder engine, consisting of figure 1 , figure 2 and combine image 3 As shown, the multi-cylinder engine cylinder hole ceramization fixture includes a bottom plate 5, and a cylinder hole top sealing plate 4 fixedly connected to the bottom plate 5, and an insulating plate is also sandwiched between the bottom plate 5 and the cylinder hole top sealing plate 4. 3. The insulating plate 3 can realize electrical insulation between the bottom plate 5 and the cylinder block 1 of the multi-cylinder engine, so as to avoid electric leakage. The multi-cylinder engine cylinder hole ceramization fixture also includes a cylinder hole bottom sealing plate 7 arranged above the cylinder hole top sealing plate 5, and the quantity is corresponding to the number of cylinder holes 2 on the multi-cylinder engine cylinder block 1, and setting In the cylinder hole 2, the cathode electrolysis part 6 is press-fi...

Embodiment 2

[0044] This embodiment relates to a multi-cylinder engine cylinder bore ceramic device, such as Figure 4 As shown in , it includes an electrolyte tank 16 and a power supply 15, and also includes a multi-cylinder engine cylinder bore ceramization fixture as described in Embodiment 1, and the multi-cylinder engine cylinder block 1 is clamped on the multi-cylinder engine cylinder bore ceramization fixture , the electrolyte tank 16 forms a liquid inlet passage through the liquid inlet 14 and the liquid inlet chamber 12, and the electrolyte tank 16 is also connected with the liquid outlet 13 to form a liquid outlet passage. Through the liquid inlet passage and the liquid outlet passage, the The electrolyte containing electrolyte in the electrolyte tank 16 continuously enters the liquid inlet chamber 12 . The positive pole of the power supply 15 is electrically connected to the cylinder block 1 of the multi-cylinder engine, and the negative pole of the power supply 15 is electrical...

Embodiment 3

[0047] This embodiment relates to a multi-cylinder engine cylinder bore ceramization method, the method comprises the multi-cylinder engine cylinder block 1 clamped in the multi-cylinder engine cylinder bore ceramization device as described in the second embodiment of the multi-cylinder engine cylinder The ceramicization process has been performed on the hole ceramicization jig. In addition, the multi-cylinder engine cylinder hole ceramization method further includes the step of honing the cylinder hole 2 after the ceramization treatment, and the honing step uses a rough honing to remove the 15-20 μm allowance in the diameter direction of the cylinder hole 2 Finally, a fine honing is also carried out to remove the diameter of 5-10 μm in the diameter direction of the cylinder bore 2.

[0048] Specifically, the multi-cylinder engine cylinder bore ceramization treatment steps in this embodiment include:

[0049] (1) Carry out rough boring and fine boring on the inner wall of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cylindricity | aaaaa | aaaaa |

| Roundness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com