Double-end grinding machine for single-face machining

A double-end grinder and single-sided technology, which is applied in the field of mechanical processing, can solve the problems of low processing efficiency, achieve the effects of improving processing efficiency, high yield, and ensuring single-sided precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

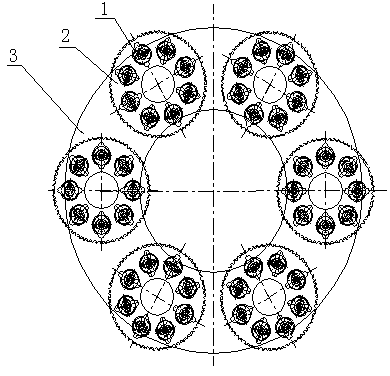

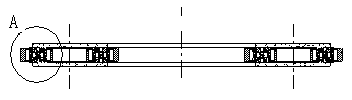

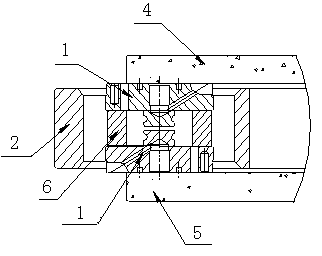

[0011] The structure of the processing part of the double-end grinding machine for single-sided processing of the present invention is as follows: Figure 1-3 As shown, the processing part is provided with two layers of grinding wheels 3, a belt box 2 is installed between the upper grinding wheel 4 and the lower grinding wheel 5, and the belt tray 2 is provided with at least one workpiece 1 placement area, the upper grinding wheel 4 and the lower grinding wheel 5 The workpiece 1 to be processed is installed into the workpiece 1 placement area with the tray 2 through the backing ring 6. The upper grinding wheel 4 and the lower grinding wheel 5 are CBN grinding wheels, and the two planes of the part are processed at the same time, so as to achieve a high consistency of thickness. Dimensional and high-precision flatness and parallelism. In order to meet the single-side processing, a special belt tray and backing ring are designed, which not only meet the accuracy requirements of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com