Color repairing composition and preparation method and application thereof

A composition and color-repairing technology, applied in coatings, polyurea/polyurethane coatings, fire-retardant coatings, etc., can solve problems such as harming human health, increasing safety hazards, and being prone to fires, achieving no environmental pollution and reducing emissions , the effect of good color development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] Another aspect of the present invention also provides a preparation method of the color-correcting composition, comprising the steps of: (1) stirring the water-based polyurethane resin at a stirring speed of 400-600 r / min.

[0027] In step (1), the water-based polyurethane resin is added into a container, such as a reaction kettle, and the stirring is started. The stirring is, for example, 400r / min, 500r / min, 600r / min.

[0028] The preparation method of the color-correcting composition of the present invention also includes the step of: (2) adding the cosolvent, the wetting agent, the defoamer, the bactericide and the water, and continuing to stir The color correcting composition is prepared.

[0029] In step (2), the co-solvent, the wetting agent, the defoamer, the bactericide and the water are slowly added in sequence.

[0030] The present invention also provides a water-based color-correcting agent comprising the above-mentioned color-correcting composition. Based...

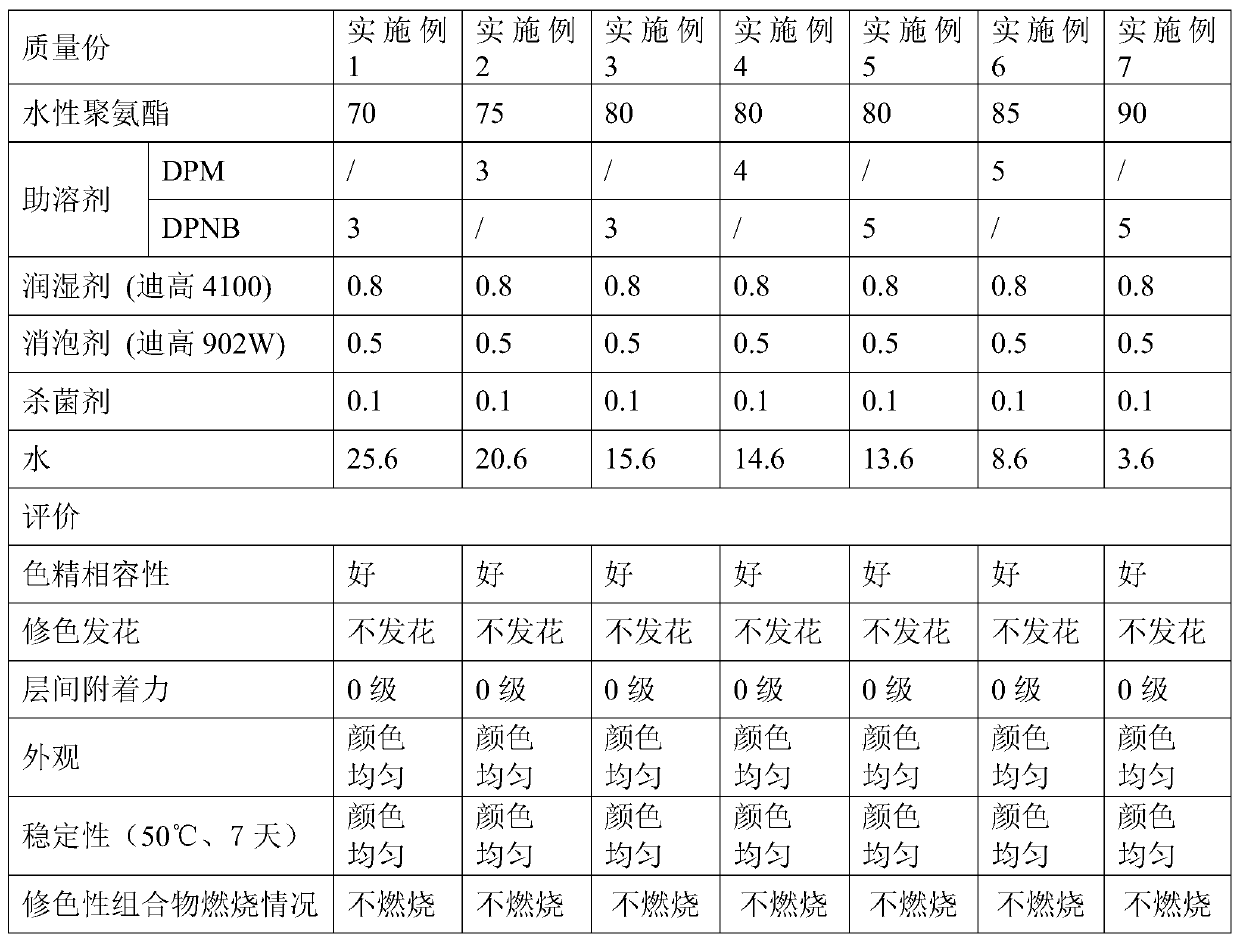

Embodiment 1

[0033] Weigh 70g of water-based polyurethane and add it to the reaction kettle, turn on the stirring speed of 400r / min, and stir; to the reaction kettle, add 3g DPNB, 0.8g Digao 4100, 0.5g Digao 902W, 0.1g of the sterilization agent and 25.6g of the remaining water, and continued to stir for 30 minutes to prepare a color-correcting composition 1. The specific ratio and test performance are shown in Table 1.

Embodiment 2

[0035] Weigh 75g of water-based polyurethane and add it to the reaction kettle, turn on the stirring speed of 400r / min, and stir; in the reaction kettle, add 3g DPM, 0.8g Digao 4100, 0.5g Digao 902W, 0.1g of the sterilizing agent and 20.6g of remaining water, and continued to stir for 30 minutes to prepare color-correcting composition 2. See Table 1 for the specific ratio and test performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| minimum film forming temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com