Waterborne woodware surface color modifier

A color repairing agent and woodware technology, which is applied in the field of water-based wood surface repairing agent, can solve the problems of organic preservatives, such as biological toxicity, poor adhesion of substrates, and fading of color repairing, and achieve effective antiseptic and bactericidal effects and outstanding adhesion , Avoid the effect of color correction and flowering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

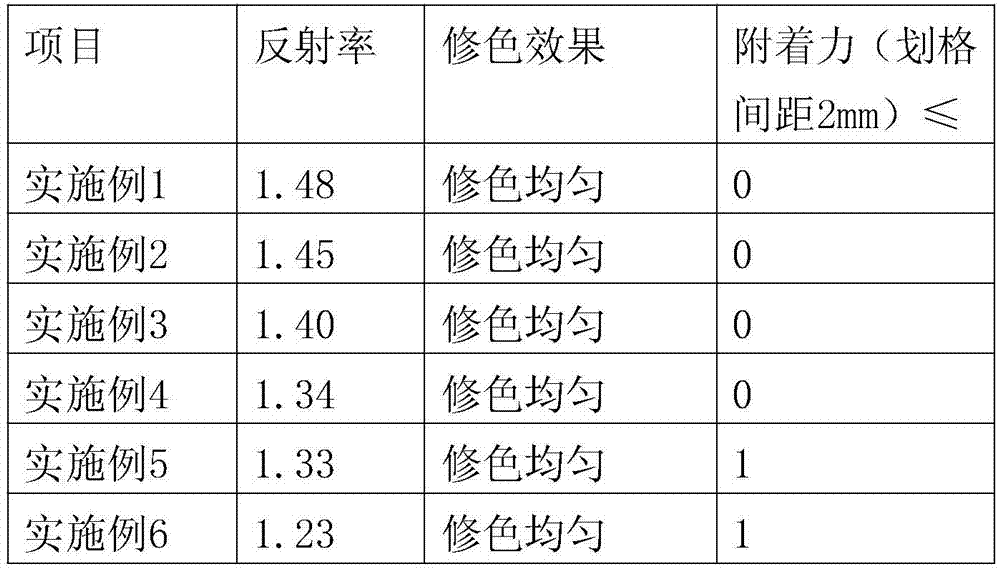

Examples

Embodiment 1

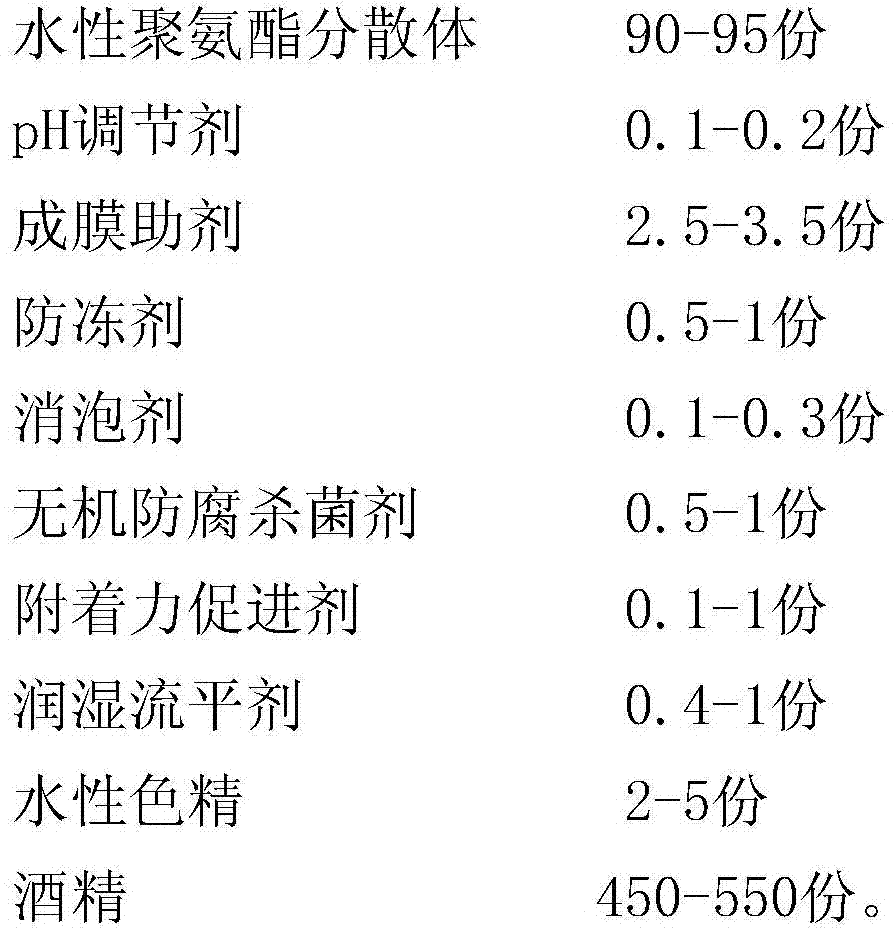

[0027] A water-based wood surface repair agent, mainly prepared from the following raw materials according to the following weight ratio:

[0028] 94.6 parts of water-based polyurethane dispersion, 0.1 part of pH regulator, 2.8 parts of film-forming aid, 0.8 part of antifreeze, 0.1 part of defoamer, 0.5 part of inorganic antiseptic and bactericide, 0.4 part of adhesion promoter, wetting and leveling agent 0.6 parts, 3 parts of water-based color essence, 400 parts of alcohol;

[0029] The concrete steps of this water-based wood surface repairing agent preparation are as follows:

[0030] (1) Select a suitable dispersing cylinder, first add 94.6 parts of water-based polyurethane dispersion, start the dispersing machine and adjust the rotating speed to 300 rpm, then add 0.1 part of pH regulator, 2.8 parts of film-forming aid, and 0.8 part of antifreeze, 0.1 part of defoamer, 0.5 part of inorganic antiseptic and bactericide, 0.4 part of adhesion promoter, 0.6 part of wetting and ...

Embodiment 2

[0034] A water-based wood surface repair agent, mainly prepared from the following raw materials according to the following weight ratio:

[0035] 94.6 parts of water-based polyurethane dispersion, 0.1 part of pH regulator, 2.8 parts of film-forming aid, 0.8 part of antifreeze, 0.1 part of defoamer, 0.5 part of inorganic antiseptic and bactericide, 0.4 part of adhesion promoter, 0.6 part of wetting and leveling agent parts, 3 parts of water-based color essence, 440 parts of alcohol;

[0036] The concrete steps of this water-based wood surface repairing agent preparation are as follows:

[0037] (1) Select a suitable dispersing tank, first add 94.6 parts of water-based polyurethane dispersion, start the dispersing machine to adjust the rotating speed to 500 rpm, then add 0.1 part of pH regulator, 2.8 parts of film-forming aid, and 0.8 part of antifreeze, 0.1 part of defoamer, 0.5 part of inorganic antiseptic and bactericide, 0.4 part of adhesion promoter, 0.6 part of wetting a...

Embodiment 3

[0041] A water-based wood surface repair agent, mainly prepared from the following raw materials according to the following weight ratio:

[0042] 94.6 parts of water-based polyurethane dispersion, 0.1 part of pH regulator, 2.8 parts of film-forming aid, 0.8 part of antifreeze, 0.1 part of defoamer, 0.5 part of inorganic antiseptic and bactericide, 0.4 part of adhesion promoter, 0.6 part of wetting and leveling agent parts, 3 parts of water-based color essence, 480 parts of alcohol;

[0043] The concrete steps of this water-based wood surface repairing agent preparation are as follows:

[0044] (1) Select a suitable dispersing cylinder, first add 94.6 parts of water-based polyurethane dispersion, start the dispersing machine and adjust the rotating speed to 300 rpm, then add 0.1 part of pH regulator, 2.8 parts of film-forming aid, and 0.8 part of antifreeze, 0.1 part of defoamer, 0.5 part of inorganic antiseptic and bactericide, 0.4 part of adhesion promoter, 0.6 part of wett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com