Dyeing method for preventing color spots, hickie and flooding on cloth surface of thin type fabric

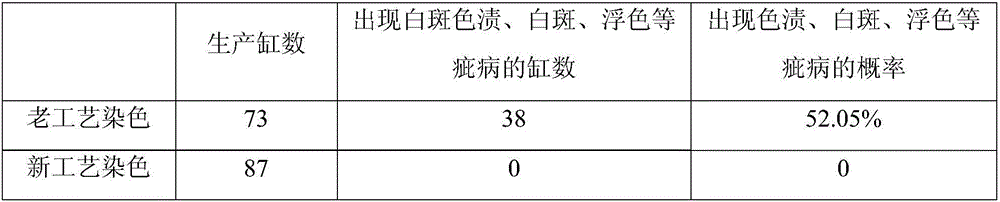

A dyeing method and fabric technology, applied in the field of fabric dyeing and finishing, can solve the problems of high oil content, white spot, floating color, etc., and achieve the effect of stable process, obvious dyeing effect and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A light and thin fabric 16kg: 30D / 36F semi-dull DTY constant force cotton wool composite cloth base material.

[0025] Dye in BRAZZOLI (U-shaped tank, S.p.A 20030, product name: AQUARIUS HT 50 (50Kg)) dyeing machine.

[0026] 1. Pre-treatment process: first open the fabric, then inject industrial soft water into the dyeing vat at a bath ratio of 1:15, put the polyester light and thin fabric into the BRAZZOLI vat, dilute the degreaser KIERALONF- in the attached vat MFB (BASF Chemical Co., Ltd.) 2g / L, injected into the dye vat, heated up to 90°C, kept warm for 30 minutes, then washed with water at 60°C for 10 minutes, and then washed with water at 40°C for 10 minutes to leave the vat. Dehydration, fabric arrangement, and high temperature presetting.

[0027] 2. Dyeing process: Add industrial soft water with a bath ratio of 1:15 into the BRAZZOLI (U-shaped cylinder S.p.A 20030, product name: AQUARIUS HT 50 (50Kg)) cylinder, put the pre-shaped fabric into it, first in the ...

Embodiment 2

[0032] Dye in BRAZZOLI (U-shaped tank, S.p.A 20030, product name: AQUARIUS HT 50 (50Kg)) dyeing machine.

[0033] A light and thin fabric 20kg: 50D / 72F full-dull polyester high-gauge cotton fleece.

[0034] 1. Pretreatment process: Since the cloth is in an open state after weaving, it can be directly put into the vat for production. Inject soft water for industrial use into the BRAZZOLI (U-shaped tank, S.p.A 20030, product name: AQUARIUS HT 50 (50Kg)) dyeing tank at a liquor ratio of 1:15, and put the above-mentioned light and thin polyester fabrics into the BRAZZOLI tank and the attached tank Dilute the degreasing agent KIERALONF-MFB (BASF Chemical Co., Ltd.) 2g / L, and inject it into the dyeing vat, raise the temperature to 90°C, keep it warm for 30 minutes, then wash it with water at 60°C for 10 minutes, and then wash it with water at 40°C for 10 minutes and leave the vat. Dehydration, fabric arrangement, and high temperature presetting.

[0035]2. Dyeing process: Add indu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com