Comprehensive color modifier used for double-face leather and comprehensive color modifying process for double-face leather

A technology of color repairing agent and fur leather, which is applied in the field of leather processing and processing, and can solve problems such as poor fullness, difficulty in balancing color and feel, and whitening of color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

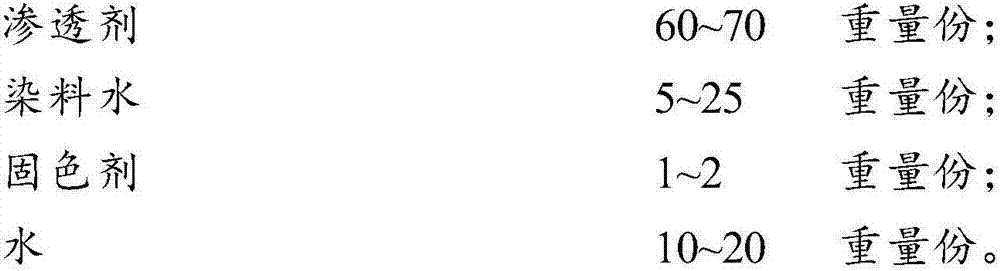

Method used

Image

Examples

Embodiment 1

[0112] camel color repair

[0113] Isopropanol: 800

[0114] Water: 200

[0115] Dark Brown Dye Water: 15

[0116] Yellow Dye Water: 3

[0117] Orange Dye Water: 0.5

[0118] Make a uniform solution according to the above formula, spray 2 times on the spraying machine with 8 guns and 8 grids, pump pressure 1.0, the spraying amount is 7g / sf, and dry at 60°C.

[0119] Color enhancer ratio:

[0120] Water: 1000

[0121] Fatliquor 358:15

[0122] Penetrant 0240:50

[0123] Fatliquor LB: 10

[0124] Make a uniform solution according to the above formula, 4 guns and 6 grids, spray once on the spraying machine with a pump pressure of 1.0, the spraying amount is 3g / sf, and dry at 50°C. At last, obtain the fur leather after comprehensive color correction.

[0125] The wool leather prepared in Example 1 of the present invention was tested, and the color fastness to dry rubbing was increased from 3.5 to 4.0, and the color fastness to wet rubbing was 2.0. Through visual observa...

Embodiment 2

[0127] Isopropanol: 800

[0128] Water: 200

[0129] Scarlet Dye Water: 15

[0130] Pink Dye Water: 2

[0131] Make a uniform solution according to the above formula, spray 2 times on the spraying machine with 8 guns and 7 grids, pump pressure 1.0, the spraying amount is 6.5g / sf, and dry at 60°C.

[0132] Color enhancer ratio:

[0133] Water: 1000

[0134] Fatliquor 358:35

[0135] Penetrant 0240:50

[0136] Fatliquor LB: 25

[0137] Make a uniform solution according to the above formula, spray it once on the spraying machine with 4 guns and 6 grids, pump pressure 1.0, the spraying amount is 3g / sf, and dry at 50°C. At last, obtain the fur leather after comprehensive color correction.

[0138] The wool leather prepared in Example 2 of the present invention was tested, and the color fastness to dry rubbing was increased from 2.5 to 3.5, and the color fastness to wet rubbing was increased from 1.5 to 2.0. Through visual observation, it can be found that the treated fur l...

Embodiment 3

[0139] Example 3: Blackboard white hair color correction

[0140] Dye ratio:

[0141] Isopropanol: 800

[0142] Water: 200

[0143] Black Dye Water: 400

[0144] Fixing agent Sellafix-E: 10

[0145] Make a uniform solution according to the above formula, roll it once with a 24L coarse roller of a roller coater, the roller coating amount is 20g / sf, dry at 45°C, and then use a 32L fine roller for three times, the roller coating amount is 10g / sf, and hang it to dry loose smell. 4 guns and 15 grids spray water, the temperature of the drying tunnel is at room temperature, let it stand for 2 hours, and then arrange 10 pressure vertical pulls to soften, and then stretch the board to obtain a semi-finished product.

[0146] The semi-finished product obtained in the above steps is used for color correction with a comprehensive color correction agent.

[0147] Color correction agent ratio:

[0148] Water: 500

[0149] Isopropanol: 300

[0150] 0240:200

[0151] Black Dye Water: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com