Polyacrylate emulsion printing paste adhesion preventer and preparation method thereof

A technology of polyacrylate emulsion and anti-adhesive agent, which is applied in the field of screen printing, can solve the problems of reduced anti-adhesive effect, narrow application range, easy to break, etc., and achieve improved color fastness to rubbing, wide application range, and rapid dispersion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A polyacrylate emulsion printing paste has been prepared, and the anti-sticking agent is added according to the following steps:

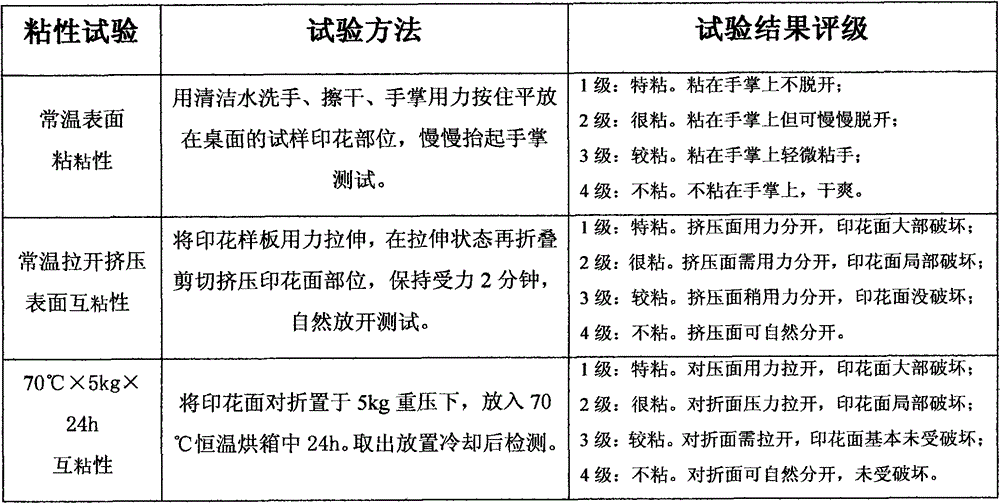

[0044] 1. According to the method in Table 1, it is judged that the viscosity of the printed product of the printing paste is grade 3.

[0045] 2. Select the anti-sticking agent composed of paraffin oil, mineral oil and silicone oil. The mass ratio is 6:3:1.

[0046] 3. Mix paraffin oil, mineral oil, and silicone oil in a mass ratio of 6:3:1, and mechanically stir to form a uniform mixture;

[0047] 4. While stirring the printing glue, slowly add the anti-sticking agent prepared according to step 3, whose quality is equivalent to 3.0% of the printing glue, and continue stirring until the glue is evenly mixed.

Embodiment 2

[0061] A polyacrylate emulsion printing paste has been prepared, and the anti-sticking agent is added according to the following steps:

[0062] 1. According to the method in Table 1, it is judged that the viscosity of the printed product of the printing paste is 2-level viscosity.

[0063] 2. Select the anti-adhesive agent composed of paraffin wax, paraffin oil, stearate and silicone oil.

[0064] 3. Mix paraffin, paraffin oil, stearate and silicone oil in a ratio of 2:6:1:1 by weight, and stir mechanically to form a uniform mixture;

[0065] 4. While stirring the printing glue, slowly add the anti-sticking agent prepared according to step 3, whose mass is equivalent to 4.0% of the printing glue mass, and continue stirring until the glue is evenly mixed.

Embodiment 3

[0079] A polyacrylate emulsion printing paste has been prepared, and the anti-sticking agent is added according to the following steps:

[0080] 1. According to the method in Table 1, it is judged that the viscosity of the printed product of the printing glue is a grade 1 viscosity, especially the viscosity is obvious under high temperature and pressure load;

[0081] 2. Select the anti-adhesive agent composed of paraffin wax, paraffin oil, mineral oil, PE wax, and high-grade fatty acid ester.

[0082] 3. Mix paraffin wax, paraffin oil, mineral oil, PE wax, and high-grade fatty acid esters in a weight ratio of 2:4:2:1.5:0.5, and mechanically stir to form a uniform mixture;

[0083] 4. While stirring the printing glue, slowly add the anti-sticking agent prepared according to step 3, whose mass is equivalent to 6.0% of the printing glue mass, and continue stirring until the glue is evenly mixed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com