High-titanium blast furnace slag microcrystalline stone material and preparation method thereof

A high-titanium blast furnace slag and microcrystalline technology, which is applied in the field of stone manufacturing technology, can solve the problems of poor flatness, soil gray appearance and rough surface of microcrystalline stone, and achieve the effect of reducing glass viscosity, pure color and smooth surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

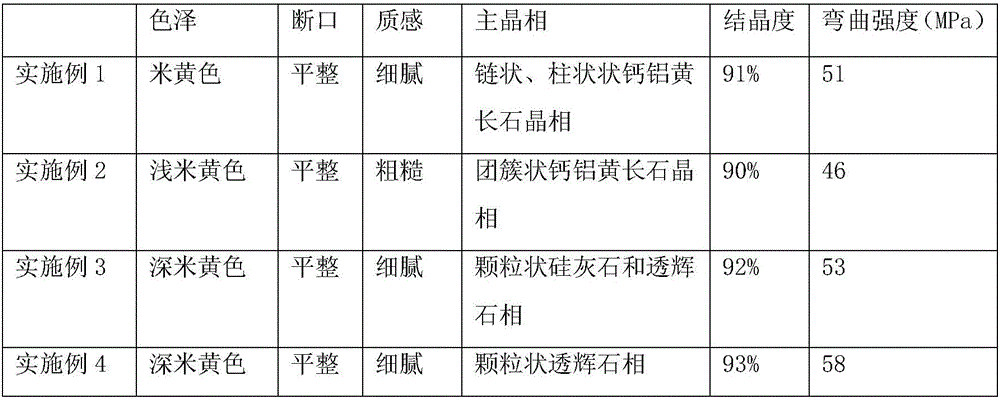

Examples

preparation example Construction

[0033] The invention provides a method for preparing high-titanium blast furnace slag microcrystalline stone, which comprises the following steps:

[0034] a. Combine 40-60 parts of high-titanium blast furnace slag with 24-37 parts of stabilizer, 5-8 parts of flux, 5-8 parts of crystal nucleus agent, 2-4 parts of crystallization accelerator, 1-3 parts of color regulator, 1-2 parts of reducing agent are mixed, melted, homogenized and clarified at 1480-1530° C. to obtain a mixed melt; the composition of the high-titanium blast furnace slag is: by weight percentage, calcium oxide is 20-27%, Titanium oxide is 19-22%, silicon dioxide is 20-27%, aluminum oxide is 14-15.8%, magnesium oxide is 3-9%, ferric oxide is 2.7-5.1%, and the rest is impurities ;

[0035] b. The glass melt forms a plate

[0036] When the temperature of the mixed melt in step a drops to 1250-1300°C, introduce a calender for rolling to form a plate;

[0037] c. Plate nucleation and crystallization treatment

...

Embodiment 1

[0047] Example 1 Preparation of high-titanium blast furnace slag microcrystalline stone by technical scheme of the present invention

[0048] Preparation of high-titanium blast furnace slag microcrystalline stone, the steps are as follows:

[0049]a, 40 parts by weight of high-titanium blast furnace water-quenched slag, 37 parts by weight of quartz sand, 8 parts by weight of sodium carbonate, 5.5 parts by weight of sphalerite, 2.5 parts by weight of sodium sulfate, 1 part by weight of zinc oxide, 4 parts by weight of ammonium dihydrogen phosphate, Mix 2 parts by weight of carbon powder evenly, and obtain a mixed melt at a temperature of 1530°C after 4-6 hours of melting, 2-3 hours of homogenization and 1-2 hours of clarification;

[0050] In this step, the upper limit of the crystallization temperature of the glass melt is 1170°C, T1=1380°C, T2=975°C, ΔT=T1-T2=1380°C-975°C=405°C.

[0051] b. The glass melt forms a plate

[0052] When the temperature of the mixed melt in step...

Embodiment 2

[0058] Example 2 Preparation of high-titanium blast furnace slag microcrystalline stone by technical scheme of the present invention

[0059] Preparation of high-titanium blast furnace slag microcrystalline stone, the steps are as follows:

[0060] a. Introduce 60 parts of high-titanium blast furnace molten slag into the glass melting furnace; then add 24 parts of quartz sand, 5 parts of sodium carbonate, 1 part of sphalerite, 4 parts of sodium sulfate, 2 parts of zinc oxide, and 3 parts of dihydrogen phosphate Mix 2 parts of ammonium and carbon powder evenly, and obtain a mixed melt at a temperature of 1480°C after 4-6 hours of melting, 2-3 hours of homogenization and 1-2 hours of clarification;

[0061] In this step, the upper limit of the crystallization temperature of the glass melt is 1175°C, T1=1375°C, T2=973°C, ΔT=T1-T2=1375°C-973°C=402°C.

[0062] b. The glass melt forms a plate

[0063] When the temperature of the mixed melt in step a drops to 1260°C, it is introduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com