Punch for internal high pressure forming

An internal high pressure, body technology, applied to the field of internal high pressure forming devices, can solve the problems of easy instability and wrinkling, complex structure, no support, etc., and achieve the effects of being conducive to stable forming, simple overall structure, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described in further detail below:

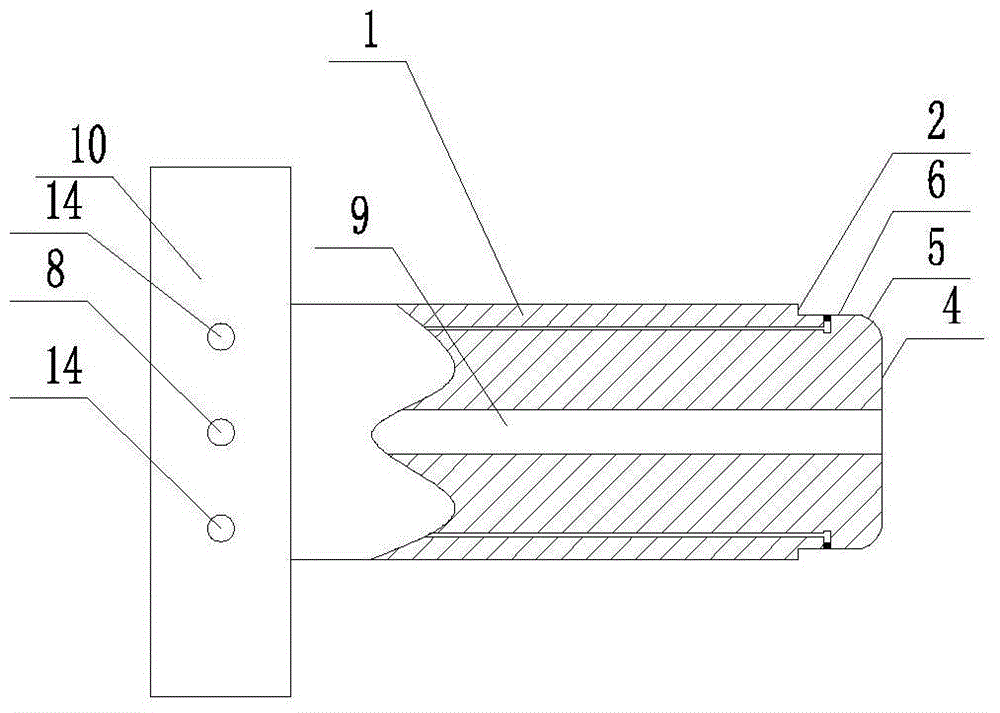

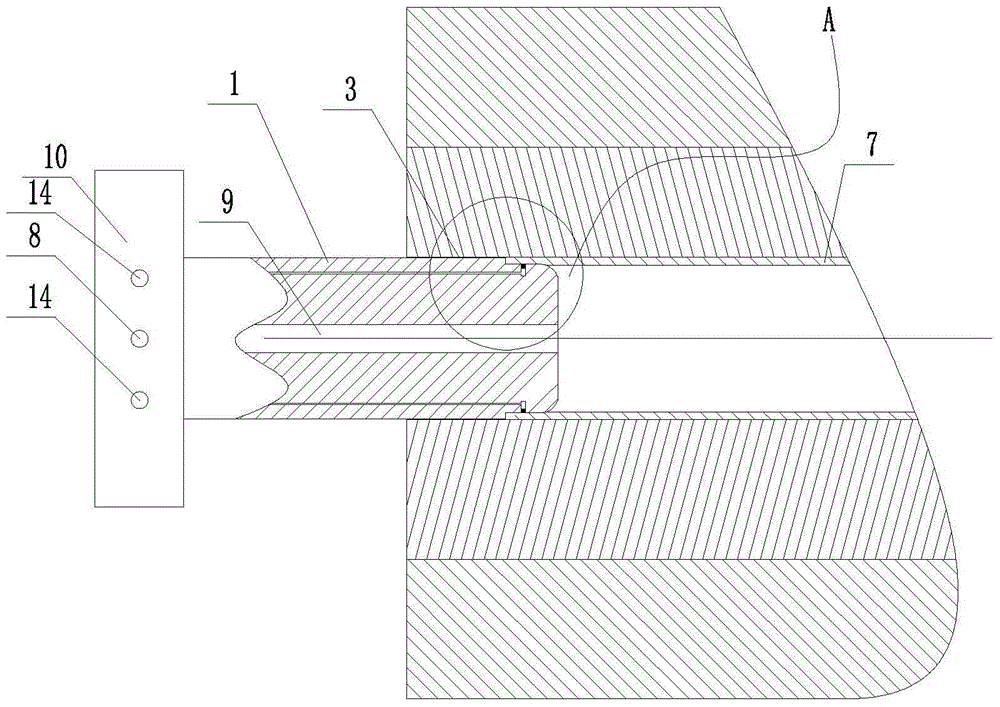

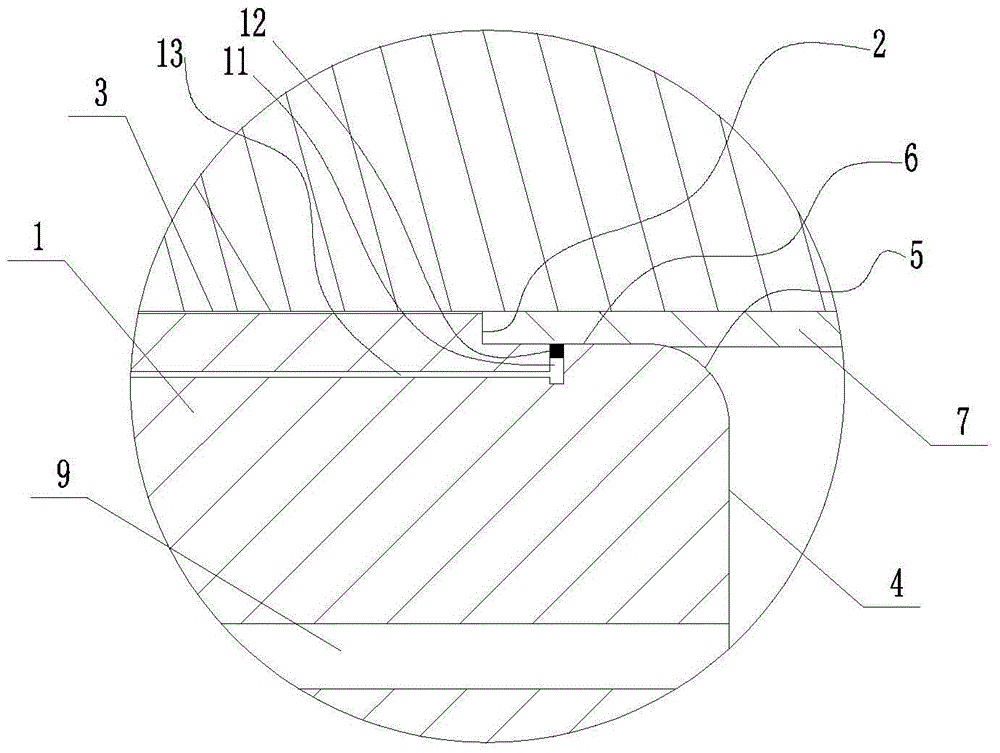

[0014] The punch for internal high pressure forming of the present invention includes a body 1, at least one end of the body 1 is a cylinder, and the one end is provided with an annular plane 2, and the annular plane 2 divides the one end into left and right parts, and the left part is used to communicate with The punch inlet and outlet holes 3 of the mold for internal high pressure forming are clearance fit, the right part includes the end face 4 of the one end, and the right part is a guide section 5 and a sealing section 6 in sequence from right to left along the axial direction, and the sealing section 6 is used to communicate with The processed pipe fitting 7 formed by internal high pressure has an interference fit, and the guide section 5 is a rounded transition part provided between the side of the right part and the end surface 4 .

[0015] An annular groove 11 is provided on the sealing section 6 of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com