Vulcanizing machine with linkage tipping bucket function

A vulcanizing machine and functional technology, applied in the rubber field, can solve the problems of inaccurate control of feeding time, manual feeding, and deterioration of rubber product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

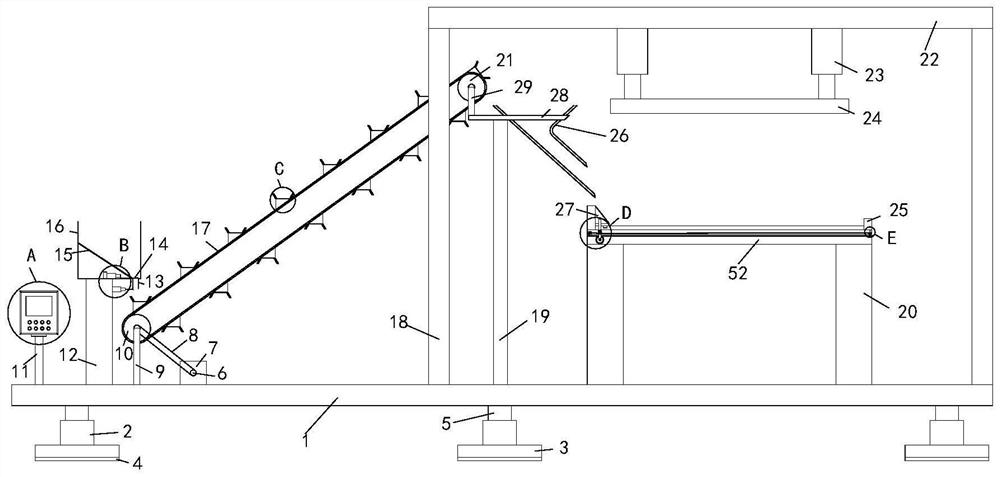

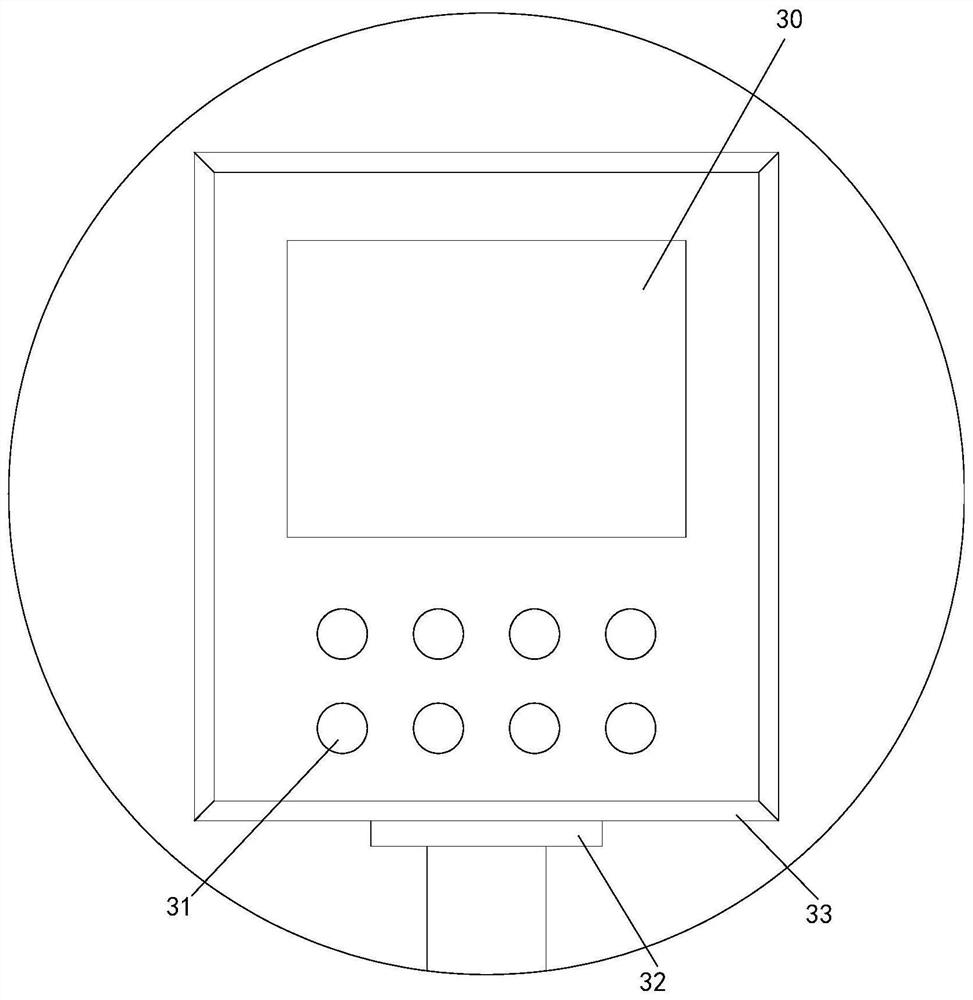

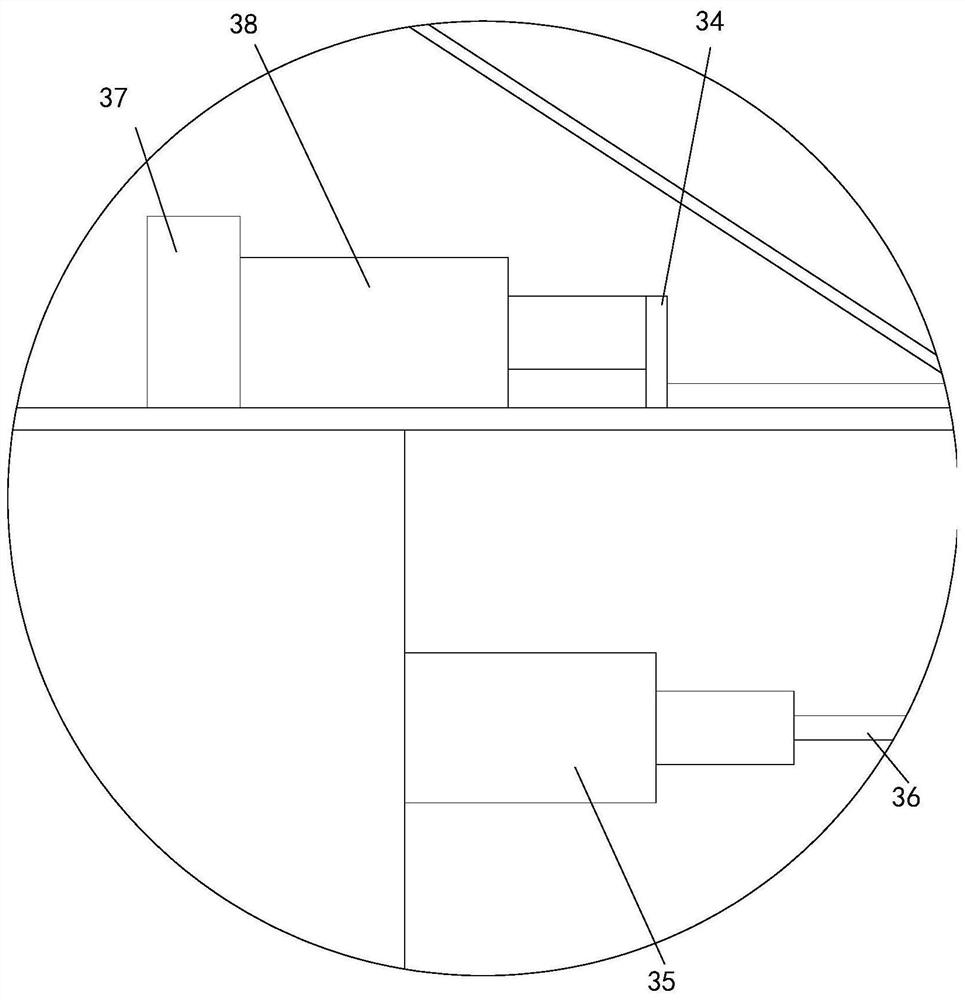

[0024] see Figure 1-6 , the present invention provides a technical solution: a vulcanizing machine with a linkage tipping function, including a chassis 1, the bottom of the chassis 1 is evenly arranged with leveling screws 5, and the outer peripheral walls of each leveling screw 5 are fitted with Leveling nut 2, the left side of the top of the chassis 1 is provided with a pole two 11, and the top of the pole two 11 is provided with a control box 33 through a rotating shaft 32, the top of the chassis 1 is provided with a column one 12, and the top of the column one 12 A hopper 16 is provided, and the inner bottom wall of the hopper 16 is provided with a baffle plate 1 37, and the right end of the baffle plate 37 is provided with a telescopic rod 3 38, and the right end of the telescopic rod 3 38 is provided with a connecting plate 34, and the right end of the connecting plate 34 is provided with a connecting plate 34. Cut-off plate one 14 is arranged, the bottom right side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com