Gas-supply apparatus and gas-supply method for realizing efficient transferring and storage and precise metering of gas in double-stage gas-storage cylinder

A gas supply device and gas storage bottle technology, applied in the field of continuous extrusion molding of microporous plastics, can solve problems affecting production stability, waste, and reduced gas delivery efficiency, and achieve efficient and stable dump delivery, accurate measurement, and improved The effect of gas utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

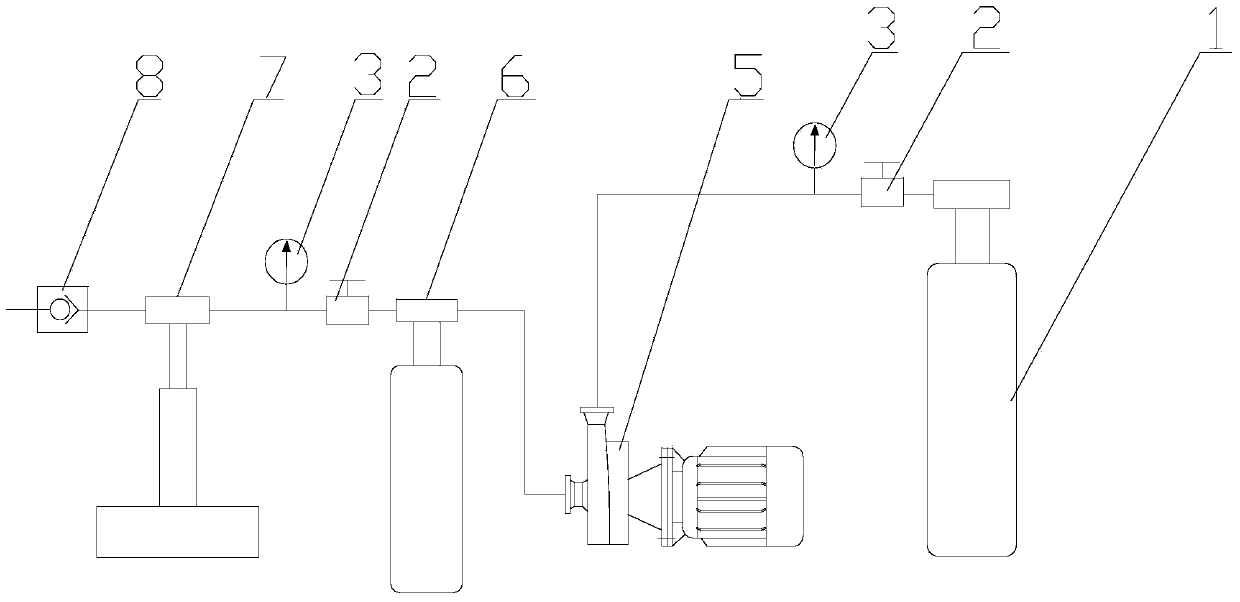

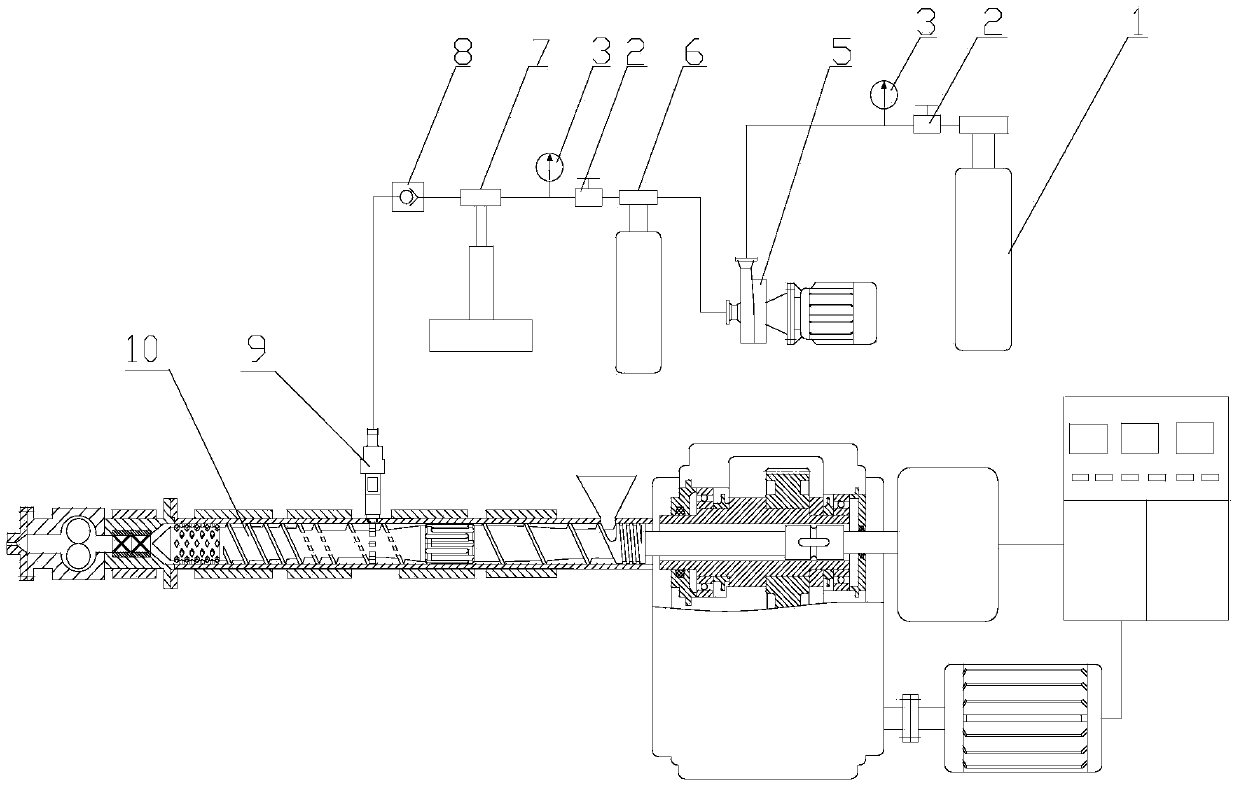

[0025] In this embodiment, a two-stage gas storage cylinder is efficiently transferred to an accurate metering gas supply device, such as figure 1 As shown, it includes a first gas storage bottle 1, a booster pump 5, a second gas storage bottle 6 and a high-pressure plunger pump 7 connected in sequence, and an air valve 2 is provided on the pipeline connected to the first gas storage bottle and the booster pump. A gas valve 2 and a pressure gauge 3 are also arranged on the pipeline connected with the pressure gauge 3, the second gas cylinder and the high-pressure plunger pump, and a check valve 8 is provided at the outlet end of the high-pressure plunger pump.

[0026] In this embodiment, a two-stage gas storage cylinder is efficiently transferred and accurately metered to supply gas through the above-mentioned device. First, the gas in the first gas storage cylinder is transferred to the second gas storage cylinder through a booster pump, The pump improves the gas utilization...

Embodiment 2

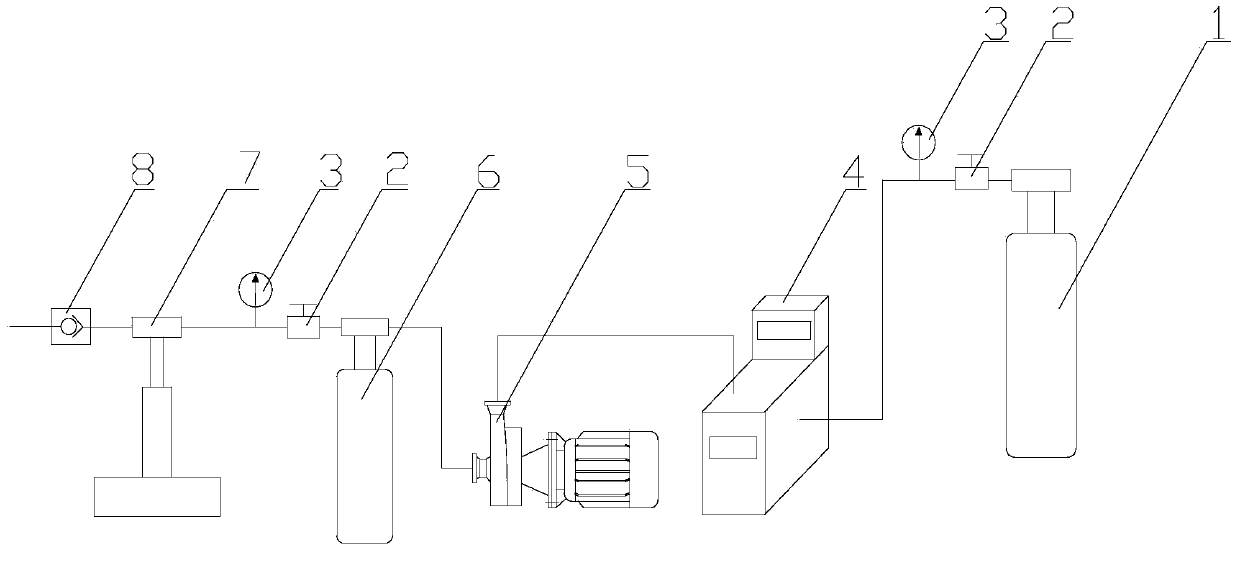

[0029] In this embodiment, a two-stage gas storage cylinder is efficiently transferred to an accurate metering gas supply device, such as image 3 As shown, compared with Embodiment 1, the difference is that a low-temperature cooling circulation pump 4 is provided on the pipeline connecting the first gas cylinder 1 and the booster pump 5 . The gas in the first gas storage bottle is cooled and liquefied by the low-temperature cooling circulation pump, and then sent into the second gas storage bottle by the booster pump, thereby improving the transfer efficiency and utilization rate of the gas.

[0030] Through the above-mentioned device, a two-stage gas storage bottle can be efficiently transferred and accurately metered to supply gas. First, the gas in the first gas storage bottle is cooled and liquefied by the low-temperature cooling circulation pump, and then sent to the second gas storage by the booster pump. In the bottle, use the booster pump to increase the gas utilizati...

Embodiment 3

[0032] In this embodiment, a two-stage gas storage cylinder is efficiently transferred to an accurate metering gas supply device, such as Figure 4 As shown, compared with Embodiment 1, the difference is that a low-temperature cooling circulation pump 4 is provided on the pipeline connecting the second gas cylinder 6 and the high-pressure plunger pump 7 . The gas in the second gas storage cylinder is cooled and liquefied by the low-temperature cooling circulation pump, and then sent out by the check valve after passing through the high-pressure plunger pump, thereby improving the transfer efficiency of the gas.

[0033] Through the above-mentioned device, a two-stage gas storage cylinder can be efficiently transferred to an accurate metering gas supply method. First, the gas in the first gas storage cylinder is transferred to the second gas storage cylinder through the booster pump, and the booster pump is used to increase the gas supply. The utilization rate of the gas in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com