Self-suction type efficient stirring device

A stirring device and self-priming technology, applied in the field of new self-priming stirring devices, can solve the problems of easy deposition at the bottom of the reactor, weakening the rigidity and strength of the hollow shaft, and high critical speed of gas suction, saving equipment cost and operation. cost, avoid weakening of shaft strength and stiffness, optimize the effect of stirring power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

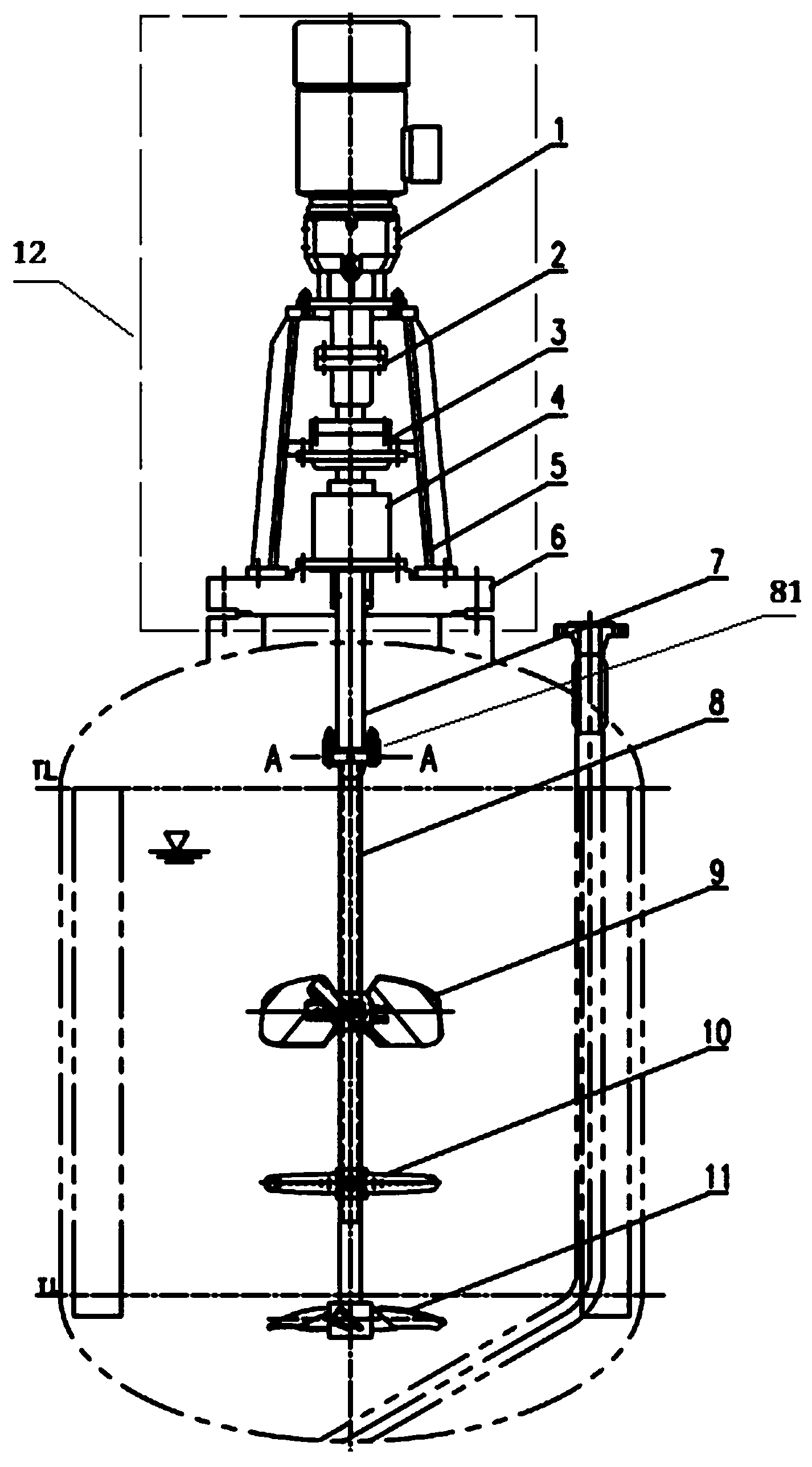

[0029] figure 1 Among them, a high-efficiency self-priming stirring device includes a driving device 12, and the driving device 12 includes a geared motor 1, a coupling 2 and a transmission shaft 7 connected to each other, and also includes a bearing box 3 for fixing and protecting, a machine Seal 4, frame 5 and install base plate 6.

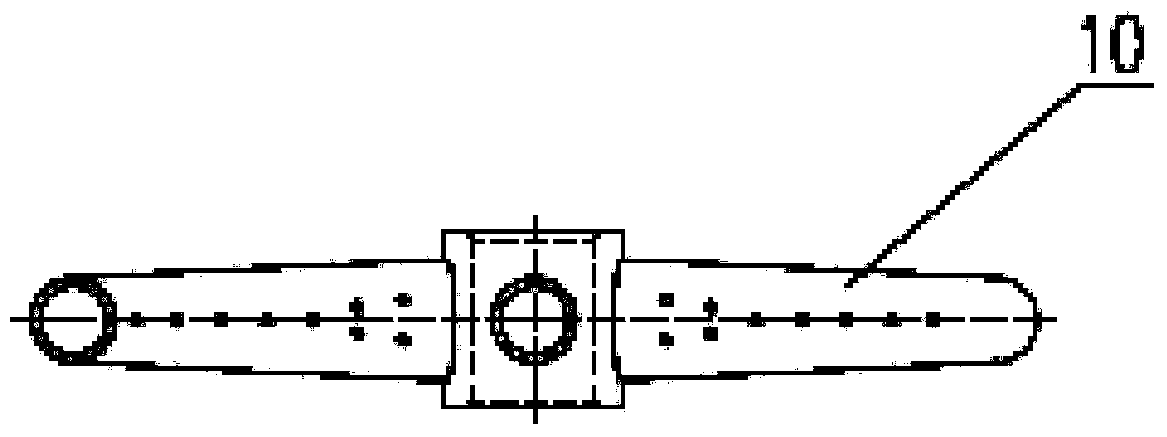

[0030] The driving device 12 is connected to and drives the hollow stirring shaft 8. The hollow stirring shaft 8 is sequentially provided with an upper auxiliary stirring paddle 9, a self-priming stirring paddle 10, a lower auxiliary stirring paddle 11, a self-priming variable-diameter tubular stirring paddle 11 and a hollow stirring paddle. The shafts 8 are fixed and communicate with each other.

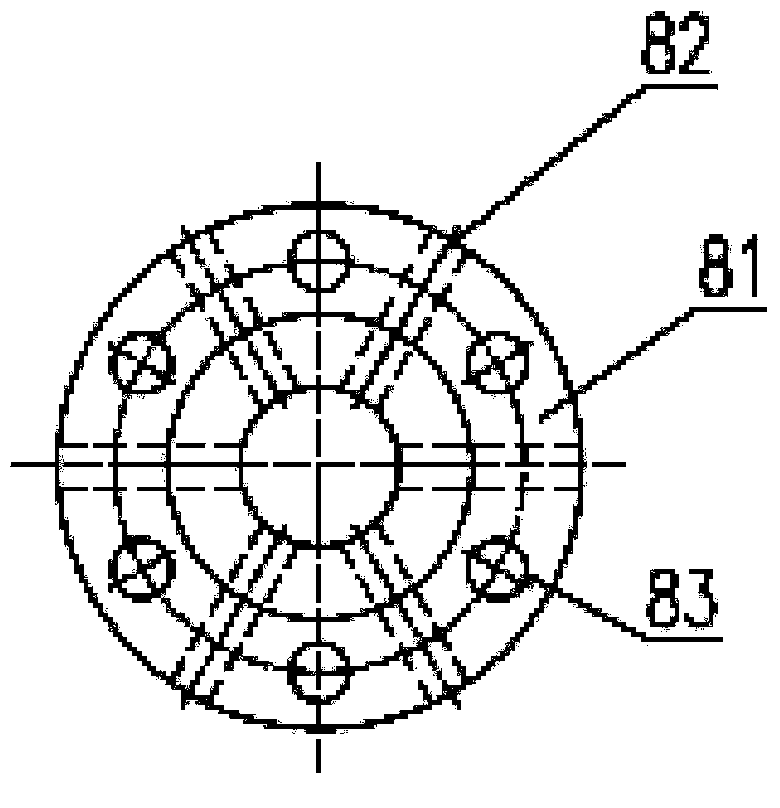

[0031] In the present invention, the hollow stirring shaft 8 is welded with a coupling flange 81, such as figure 2 As shown, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com