Energy recovery system for preparing sponge iron by gasification of high-pressure pulverized coal and method thereof

An energy recovery and sponge iron technology, applied in furnace types, furnaces, shaft furnaces, etc., can solve the problems of low heating efficiency of reducing gas, low reduction efficiency of fine ore, and low life of heating tubes, etc. Small size and high gasification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

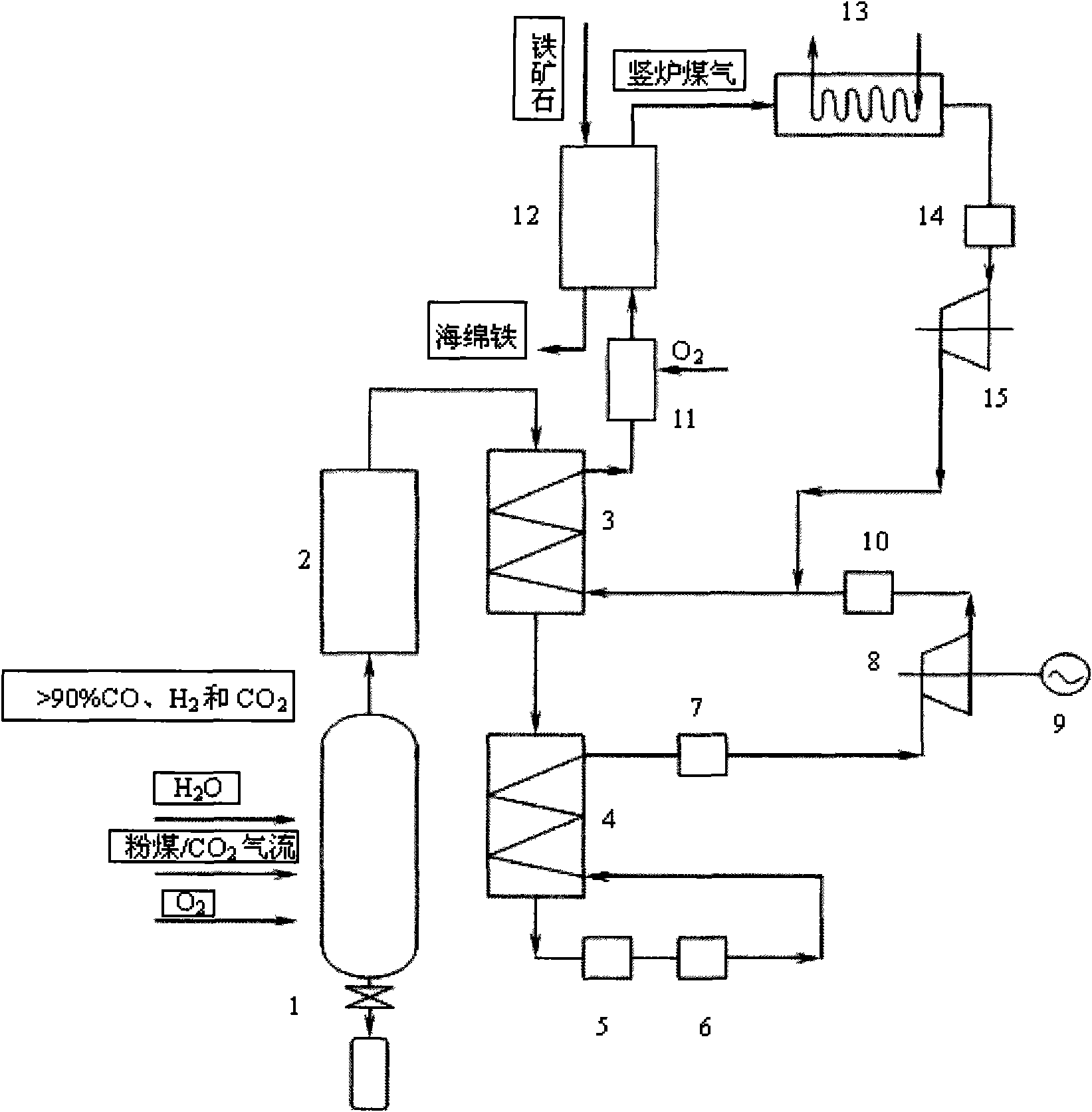

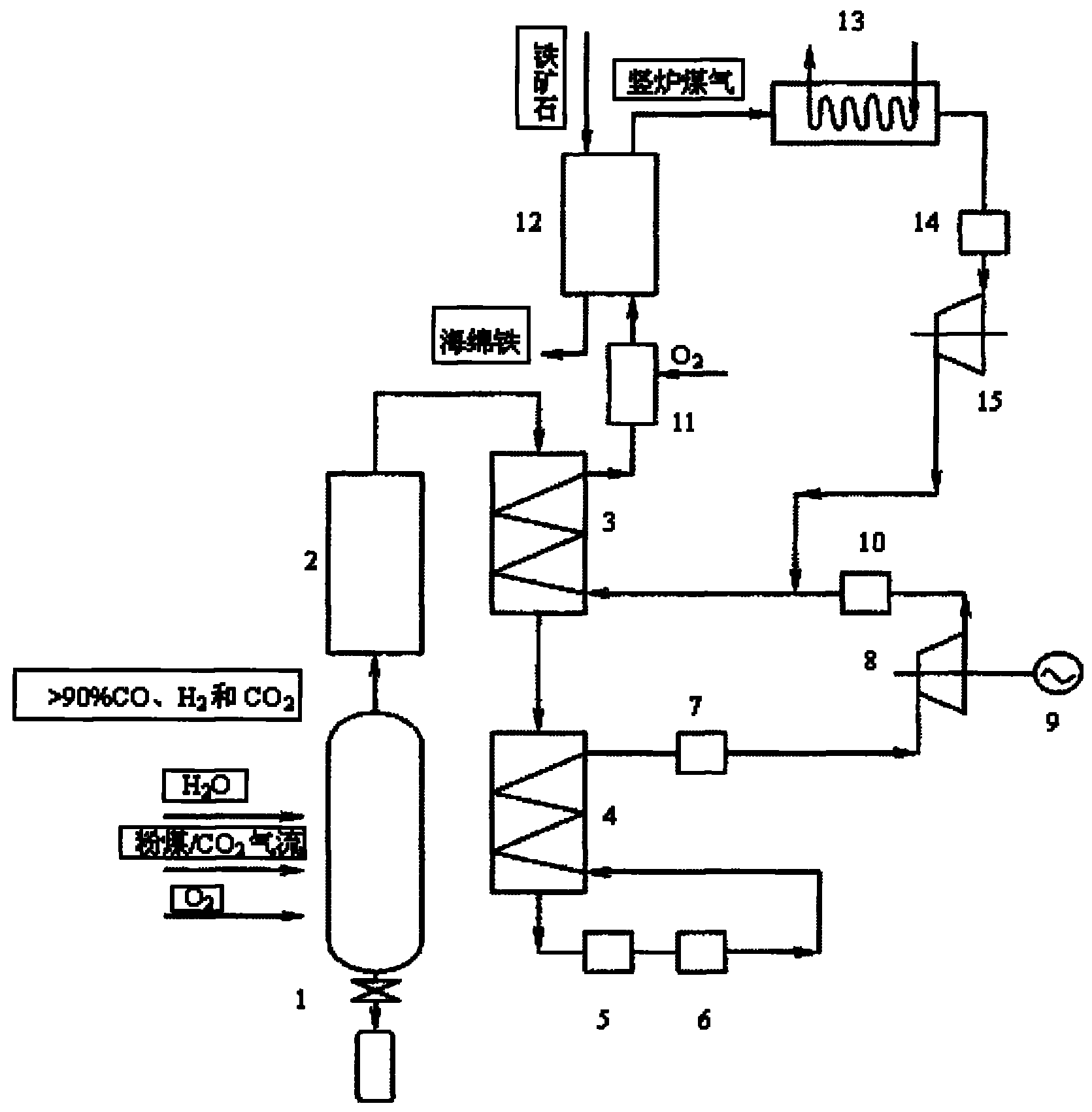

[0027] like figure 1 As shown, an energy recovery system for producing sponge iron by high-pressure pulverized coal gasification provided by the present invention includes a high-pressure pulverized coal gasifier 1, and a radiant crude gas cooling system with a water-cooled wall is connected in series on the high-pressure pulverized coal gasifier 1 2, secondary heat recovery device 3 and primary heat recovery device 4, dust collector 5 and desulfurization and denitrification equipment 6 are connected in series between the outlet of primary heat recovery device 4 and the heat recovery inlet, and primary heat recovery device 4 The reheating outlet of the boiler is sequentially connected to the CO conversion equipment 7, the gas turbine 8 and the first dehydration and CO removal 2 After the device 10 is connected to the heat recovery inlet of the secondary heat recovery device 3, a generator 9 is connected to the gas turbine 8, and a combustion chamber 11 and a shaft furnace 12 a...

Embodiment 2

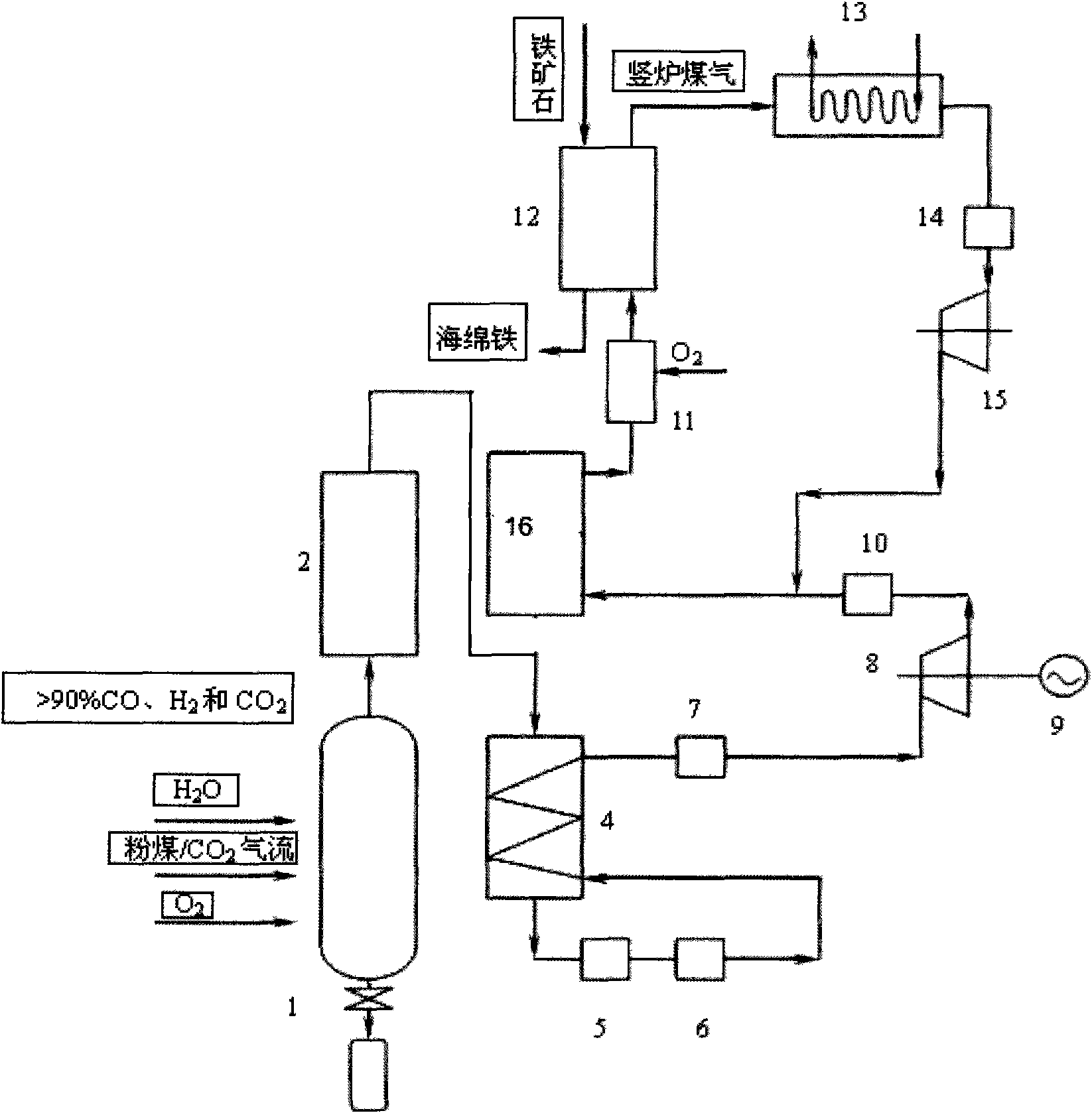

[0035] like figure 2 As shown, the system used in this embodiment includes a high-pressure pulverized coal gasifier 1, and a radiant crude gas cooler 2 with a water-cooled wall and a first-stage heat recovery device 4 are connected in series on the high-pressure pulverized coal gasifier 1. Between the outlet of the heat recovery device 4 and the heat recovery inlet, there are dust collectors 5 and desulfurization and denitrification equipment 6 in series, and the heat recovery outlet of the primary heat recovery device 4 is connected to the CO conversion equipment 7, the gas turbine 8 and the first dehydration equipment in sequence. and deCO 2 The device 10 is connected to the inlet of the heating device 16, the generator 9 is connected to the gas turbine 8, the combustion chamber 11 and the shaft furnace 12 are connected to the outlet of the heating device 16 in sequence, and the gas outlet of the shaft furnace 12 is connected to the waste heat Boiler 13, second dehydration...

Embodiment 3

[0043] The system in this embodiment is the same as that in Embodiment 2. The difference between the steps in this embodiment and Embodiment 2 is that the heating temperature of the heating device described in step 4 is 200°. Other steps are identical with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com