Cooking fume recirculation type energy-saving gas stove

A gas stove and recirculation technology, which is applied in the field of gas stoves, can solve the problems of high harmful gas content and low thermal efficiency, and achieve the effects of low production cost, reduced oil fume emissions, and improved gas utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

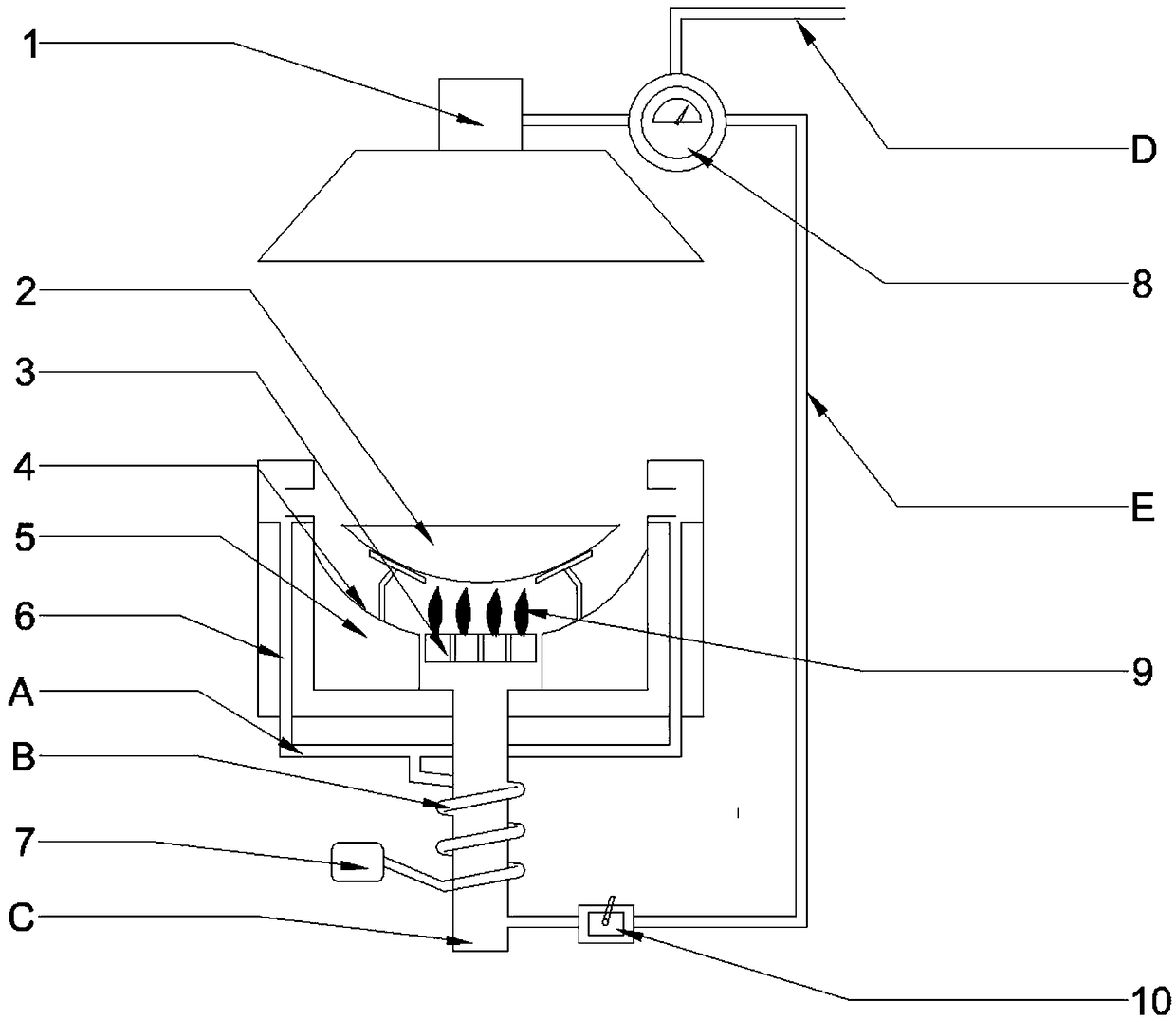

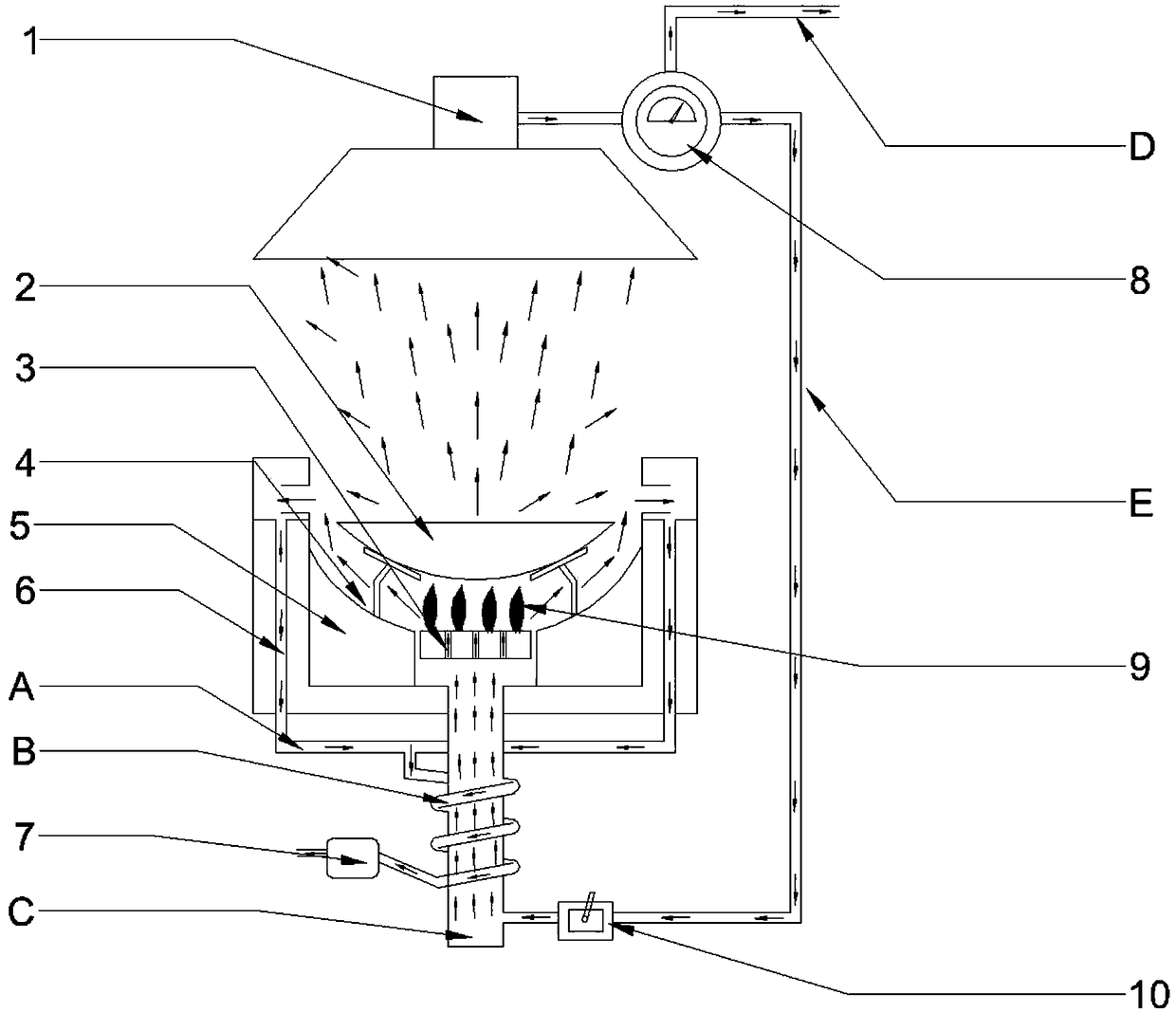

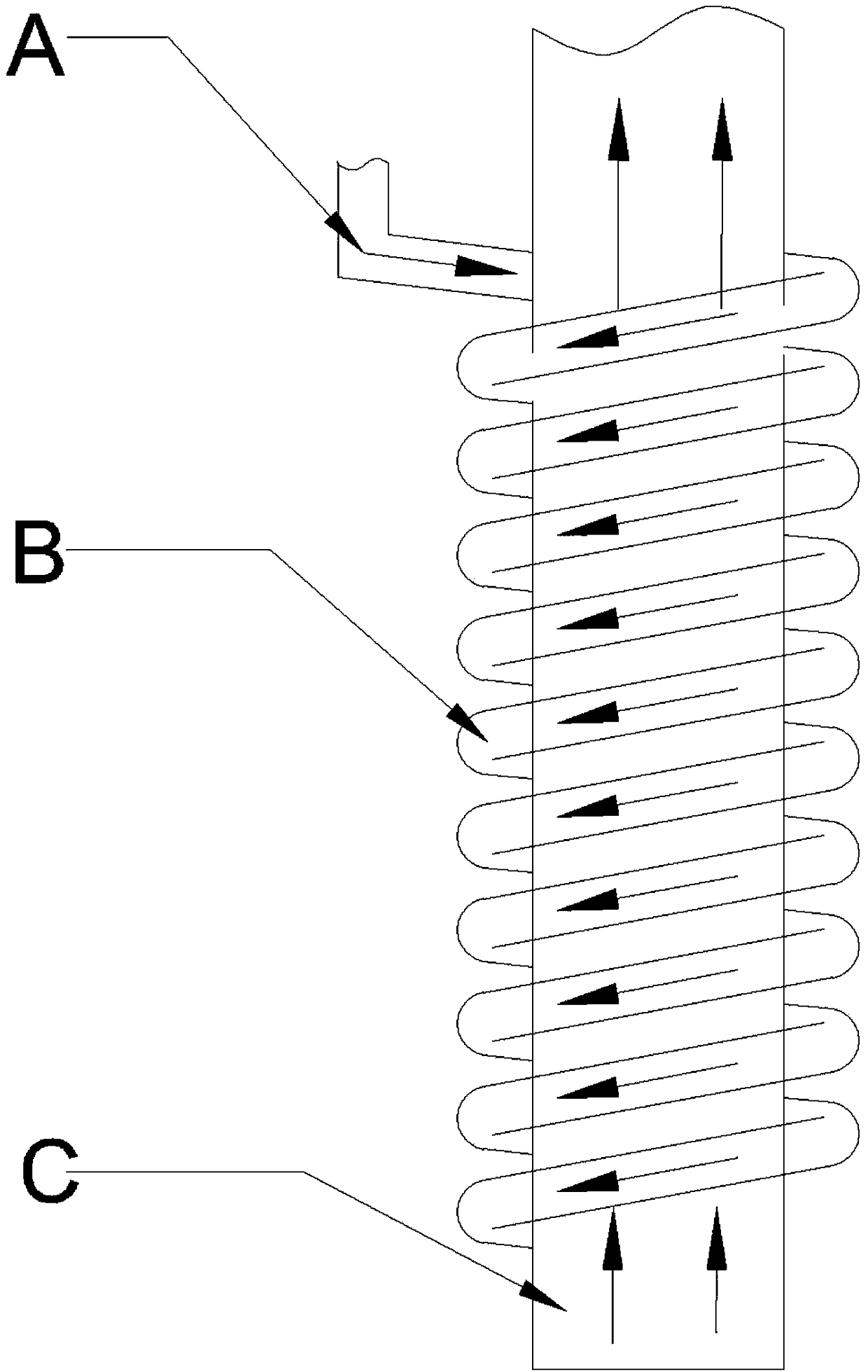

[0016] An oil fume recirculation energy-saving gas stove device of the present invention, such as figure 1 As shown, it includes a stove base 5, a burner 3, a range hood 1, a negative pressure pump 7, an oil fume automatic detection control valve 8, and a safety valve 10; the stove base 5 is a cylindrical structure, and its upper part is a concave spherical surface structure, the surface of the concave spherical surface is coated with a radiation heat dissipation paint coating 4, and a hollow annular insulation layer 6 is provided on the stove base 5; the burner 3 is placed in the center of the concave spherical surface, and its lower part is connected with gas and Air premixing pipe C, a spiral preheating pipe B is wound outside the gas and air premixing pipe C; one end of the preheating pipe B is connected to the negative pressure pump 10, and the other end passes through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com