Washing and drying integrated machine with front and rear double drying air inlets and control method thereof

An air inlet and post-drying technology, which is applied to washing machines with containers, washing machine control devices, washing devices, etc., can solve problems such as uneven drying degree, affecting drying effect, and low temperature of clothes, and achieve enhanced drying. Clothing effect, shortening drying time, uniform drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

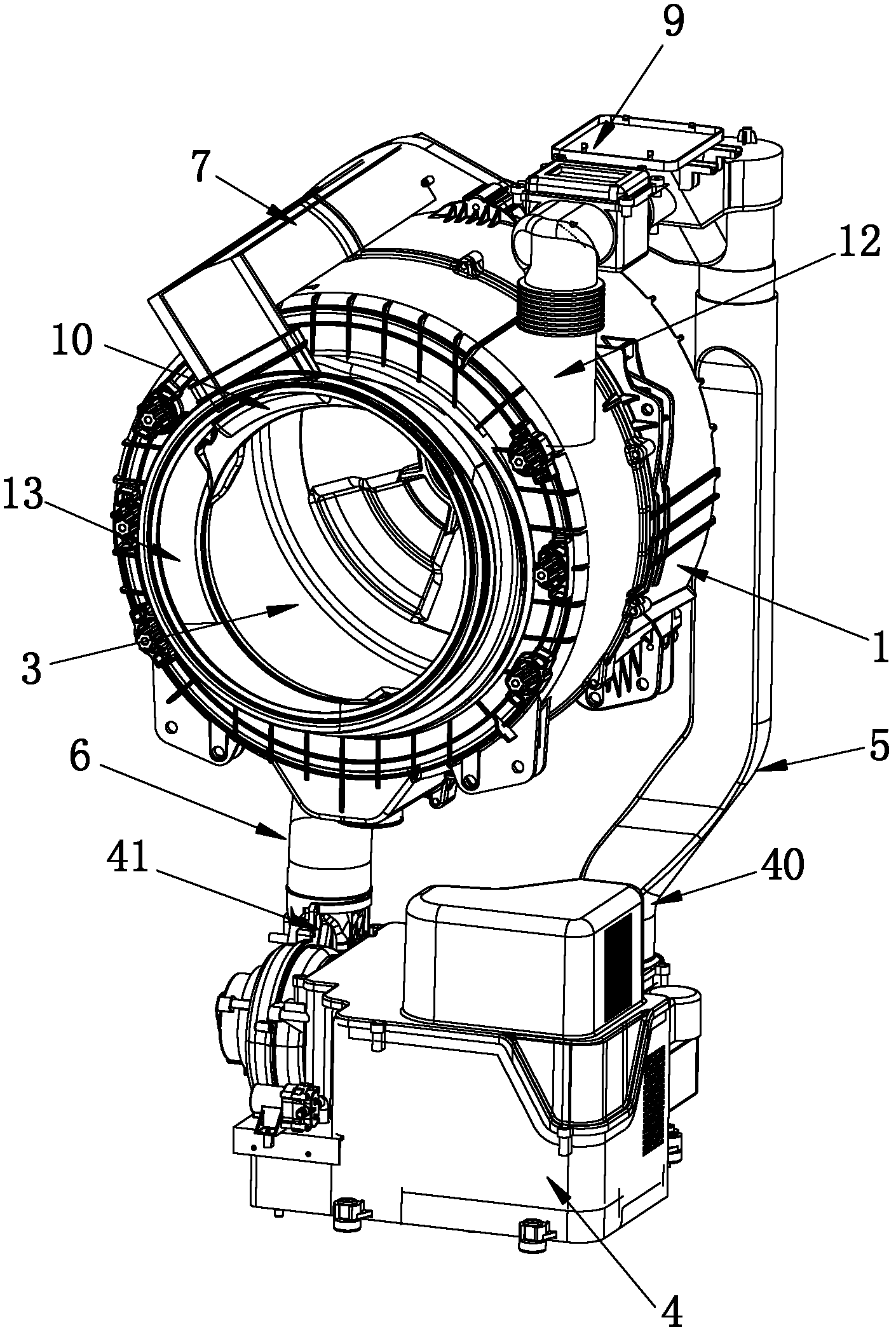

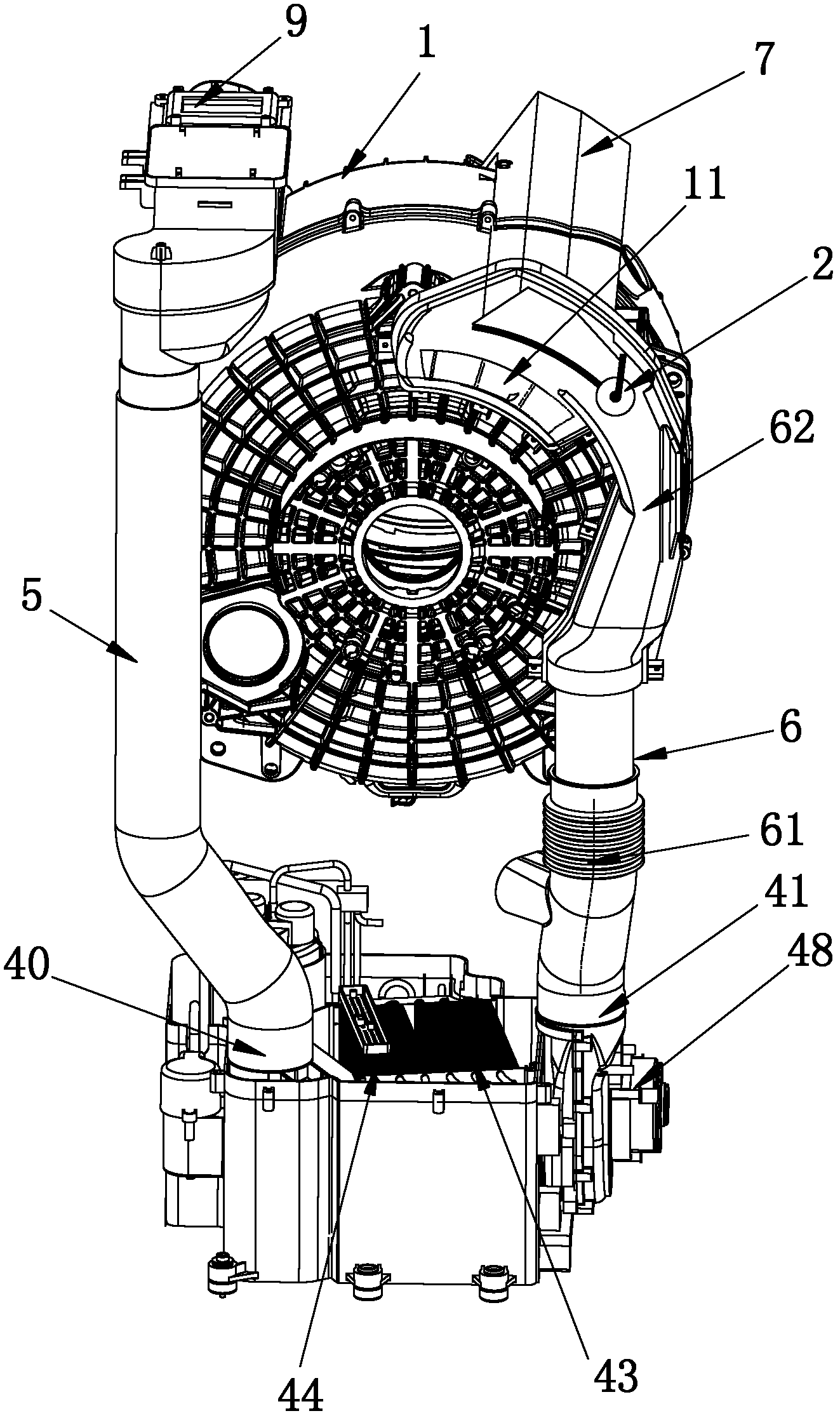

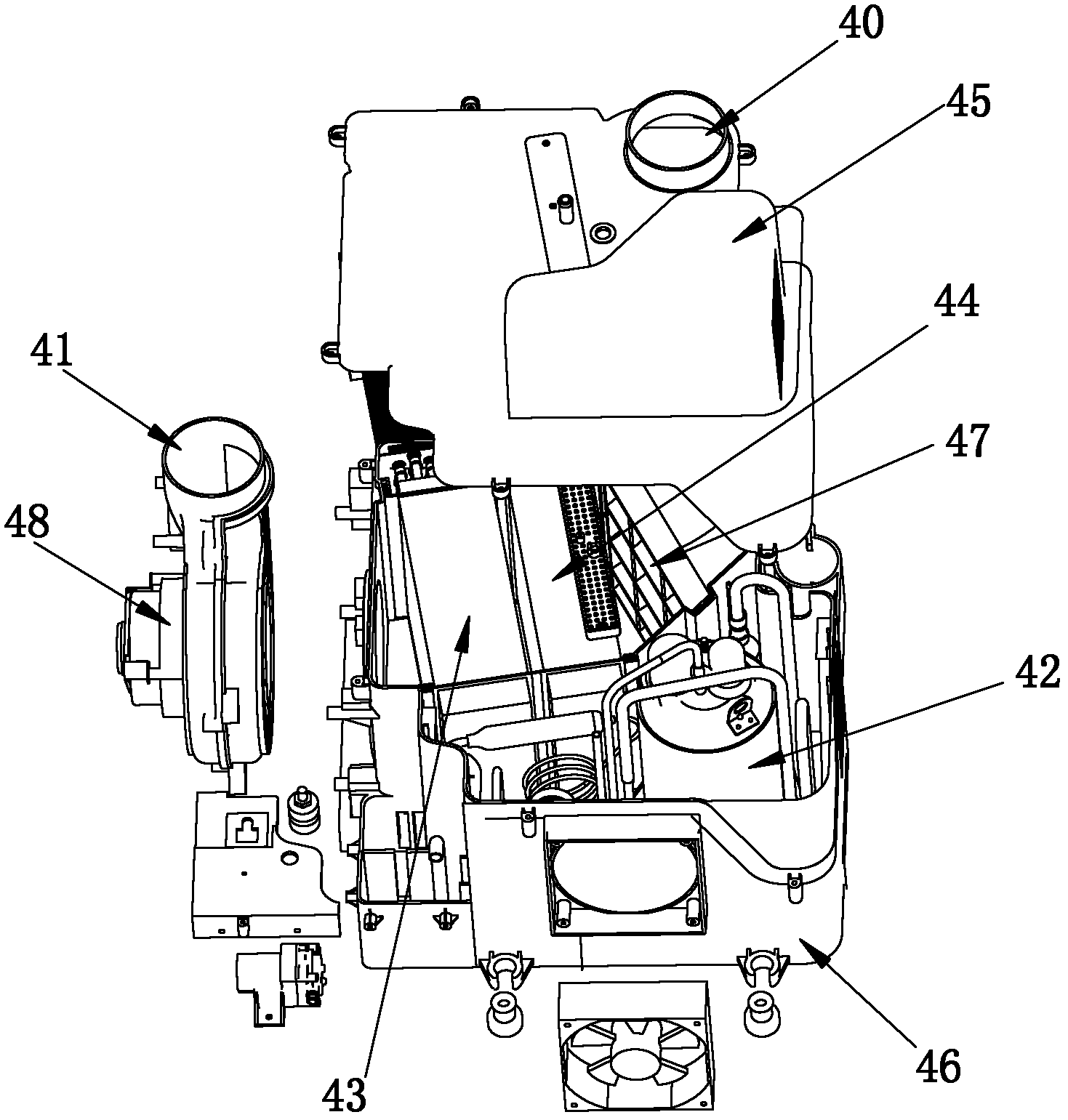

[0041] Such as Figure 1 to Figure 7 As shown, the all-in-one washing and drying machine according to the present invention includes a casing, an outer cylinder 1 disposed inside the casing, an inner cylinder 3 rotatably disposed inside the outer cylinder, and a heat pump system 4 for drying clothes. The heat pump system 4 described above includes a heat pump air inlet 40 and a heat pump air outlet 41, a front drying air inlet 10 and a rear drying air inlet 11 are respectively provided at the front and rear of the outer cylinder 1, and a There is a drying air outlet 12, the drying air outlet 12 communicates with the heat pump air inlet 40 through the air inlet duct 5, the heat pump air outlet 41 communicates with the rear drying air inlet 11 through the air supply duct 6, and the front drying air inlet 10 A second air duct 7 is provided between the air supply duct 6, and the second air duct 7 is closely attached to the outer wall of the outer cylinder 1 and is integrally forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com