Manufacturing method of wedge joint board

A manufacturing method and technology of finger-jointed boards, which are applied in the manufacture of tools, the joining of wooden veneers, and wood processing appliances, etc., can solve the problems of easy drying shrinkage and deformation of eucalyptus, so as to change the chemical and physical properties and reduce the moisture absorption performance , The effect of small material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

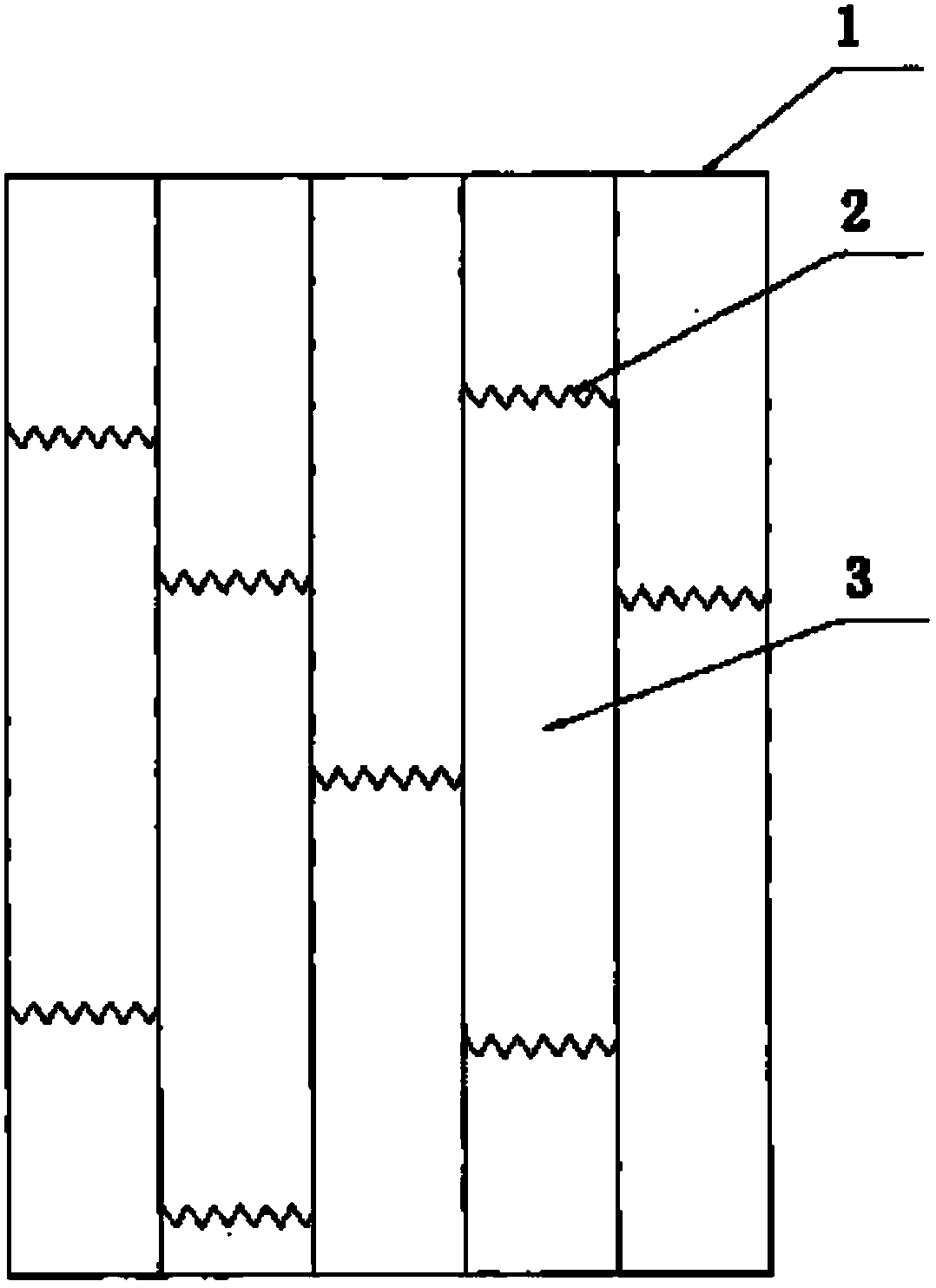

[0053] Control attached figure 1 , the finger-jointed board is composed of a plurality of finger-joined wood chips 3 which are mutually finger-joined. The finger-jointed wood chips 3 can be of various specifications and sizes, and the eucalyptus sawn timber after carbonization and moisture resurgence are sawed in different ways according to product requirements. The finger-jointed wood chip 3 is a cuboid wood block, equal in width and thickness, and has finger-shaped teeth 2 on the two short sides of the finger-joined wood chip 3, and the tooth shape of the finger-shaped teeth 2 on each finger-joined wood chip 3 is exactly the same , so two pieces of finger-jointed wood 3 can be fully engaged. A plurality of finger-joined wood chips 3 are joined to form a finger-joined strip 1, and then the finger-joined strips 1 are glued in parallel to form a finger-joined board.

[0054] Its preparation method comprises the following steps:

[0055] A. Log sawing: Cut the log into 1-2m l...

Embodiment 2

[0074] Control attached figure 1 , the finger-jointed board is composed of a plurality of finger-joined wood chips 3 which are mutually finger-joined. The finger-jointed wood chips 3 can be of various specifications and sizes, and the eucalyptus sawn timber after carbonization and moisture resurgence are sawed in different ways according to product requirements. The finger-jointed wood chip 3 is a cuboid wood block, equal in width and thickness, and has finger-shaped teeth 2 on the two short sides of the finger-joined wood chip 3, and the tooth shape of the finger-shaped teeth 2 on each finger-joined wood chip 3 is exactly the same , so two pieces of finger-jointed wood 3 can be fully engaged. A plurality of finger-joined wood chips 3 are joined to form a finger-joined strip 1, and then the finger-joined strips 1 are glued in parallel to form a finger-joined board.

[0075] The concrete steps of manufacturing this finger joint board are:

[0076] A. Log sawing: Cut the log ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com