Modified carbon fiber magnesite board prepared with industrial waste acid and preparation process thereof

A technology for industrial waste acid and preparation process, applied in the field of building materials, can solve the problems of complex preparation process, high dry shrinkage rate and wet expansion rate, increased production cost, etc., and achieves the effects of low cost, low water absorption rate, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

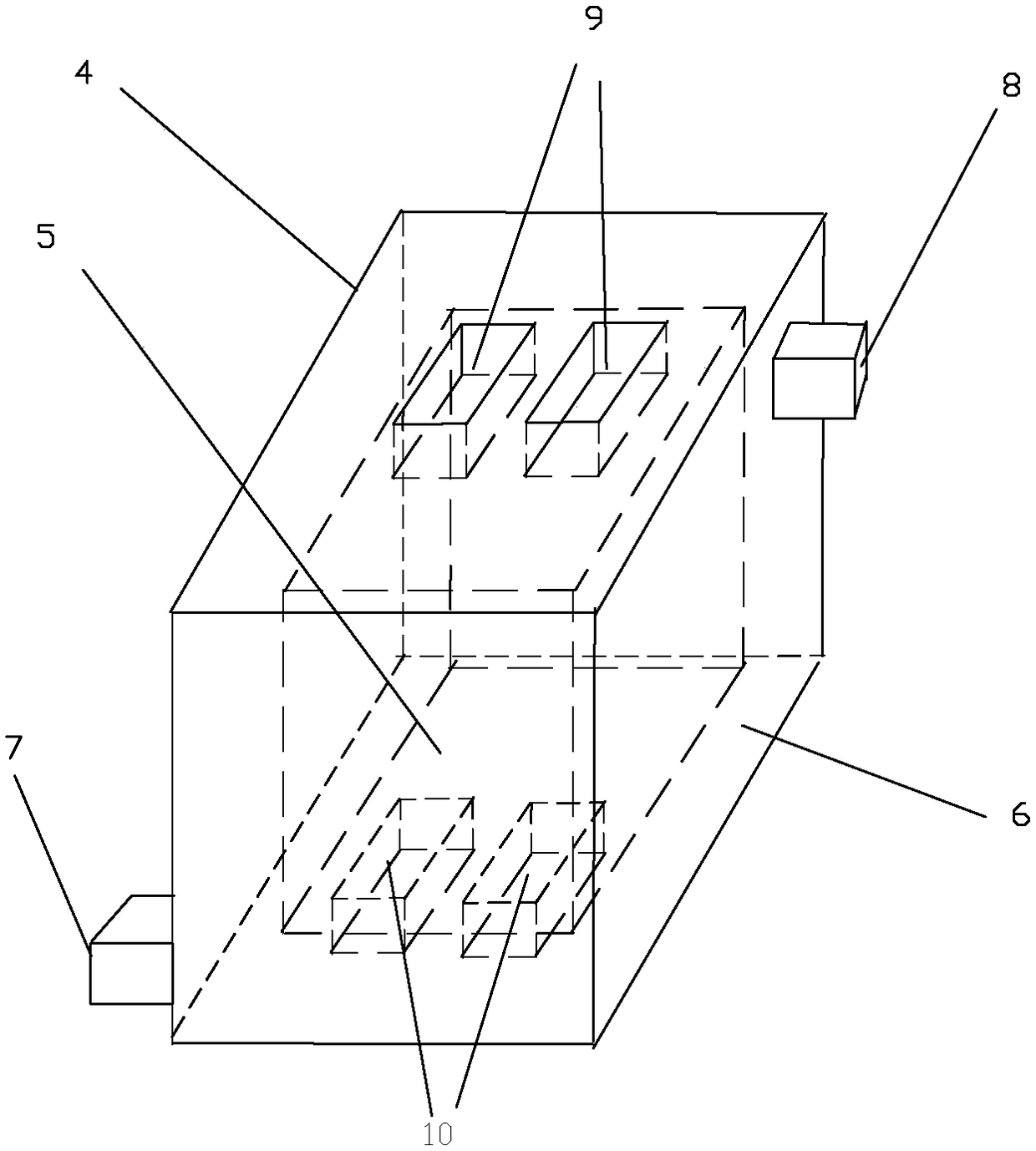

[0029] Depend on figure 2 As shown, a mixer, the mixer is a box structure, the mixer is provided with a mixer shell 4 and a mixing chamber 5, the mixer shell 4 and the mixing chamber 5 are box structures, and the mixing chamber 5 is located in the mixer shell 4 Inside; the inner wall of the mixer shell 4 and the outer wall of the mixing chamber 5 enclose a cooling water cavity 6, the cooling water cavity 6 and the mixing chamber 5 are not connected to each other; the side wall of the mixer shell 4 is provided with a water inlet 7 and a water outlet 8 , The water inlet 7 is lower than the water outlet 8; the top of the mixer housing 4 is provided with a feed inlet 9 communicating with the mixing chamber 5, and the bottom of the mixer housing 4 is provided with a material outlet 10 communicating with the mixing chamber 5.

[0030] When in use, the cooling water is introduced from the water inlet 7 and discharged from the water outlet 8, and the temperature of the reactants in t...

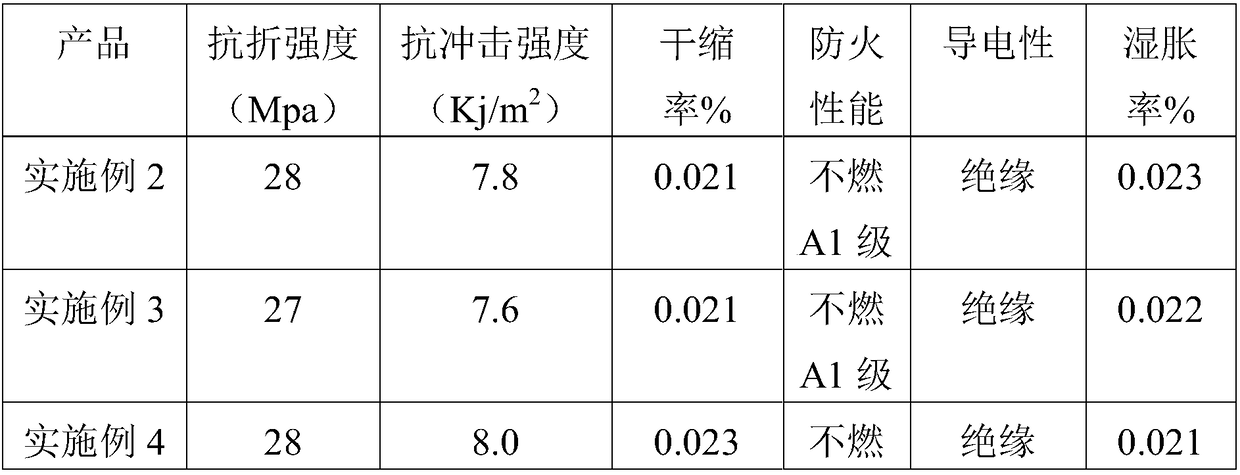

Embodiment 2

[0033] a) by parts by weight, take by weighing 0.6 parts of surface oxidation-treated carbon fibers, 40 parts of sawdust, 160 parts of magnesium oxide powder, and 580 parts of industrial waste sulfuric acid with a concentration of 8%;

[0034] b) by figure 2 Shown, carry out in the mixing machine of embodiment 1, pass into cooling water from water inlet 7, cooling water flows out from water outlet 8, stirring tool is a stirring cage, injects in mixing chamber 5 from feed inlet 9 while stirring Step a) weighed 580 parts of industrial waste sulfuric acid with a concentration of 8%; 0.6 parts of surface oxidation-treated carbon fibers weighed in step a) and 160 parts of magnesium oxide powder weighed, mixed and stirred for 1 hour, Slowly add the above industrial waste sulfuric acid, keep stirring, control the size of the cooling water flow, when the reaction temperature is 50°C<T<65°C, reduce the cooling water flow, add 40 parts of sawdust weighed in step a), stir evenly, When ...

Embodiment 3

[0042] a) by parts by weight, take by weighing 2.0 parts of surface oxidation-treated carbon fibers, 50 parts of sawdust, 180 parts of magnesium oxide powder, and 700 parts of industrial waste hydrochloric acid with a concentration of 16%;

[0043] b) by figure 2Shown, carry out in the mixing machine of embodiment 1, pass into cooling water from water inlet 7, cooling water flows out from water outlet 8, stirring tool is a stirring cage, injects in mixing chamber 5 from feed inlet 9 while stirring Step a) weighed 700 parts of 16% industrial waste hydrochloric acid; mixed and stirred 2.0 parts of surface oxidation-treated carbon fiber and 180 parts of magnesium oxide powder weighed in step a), and the mixing time was 1.5 hours , slowly add to the above industrial waste hydrochloric acid, keep stirring, control the size of the cooling water flow, when the reaction temperature is 50°C<T<65°C, reduce the cooling water flow, add 50 parts of sawdust weighed in step a), and stir eve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com