Leather splitting device

A leather and segmentation technology, applied in leather punching/punching/cutting, raw hide/leather/fur manufacturing equipment, small raw hide/big raw hide/leather/fur treatment, etc., can solve problems such as low efficiency and labor, and achieve High efficiency, easy to use, and simple structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The best embodiment of the present invention will be further described in detail below.

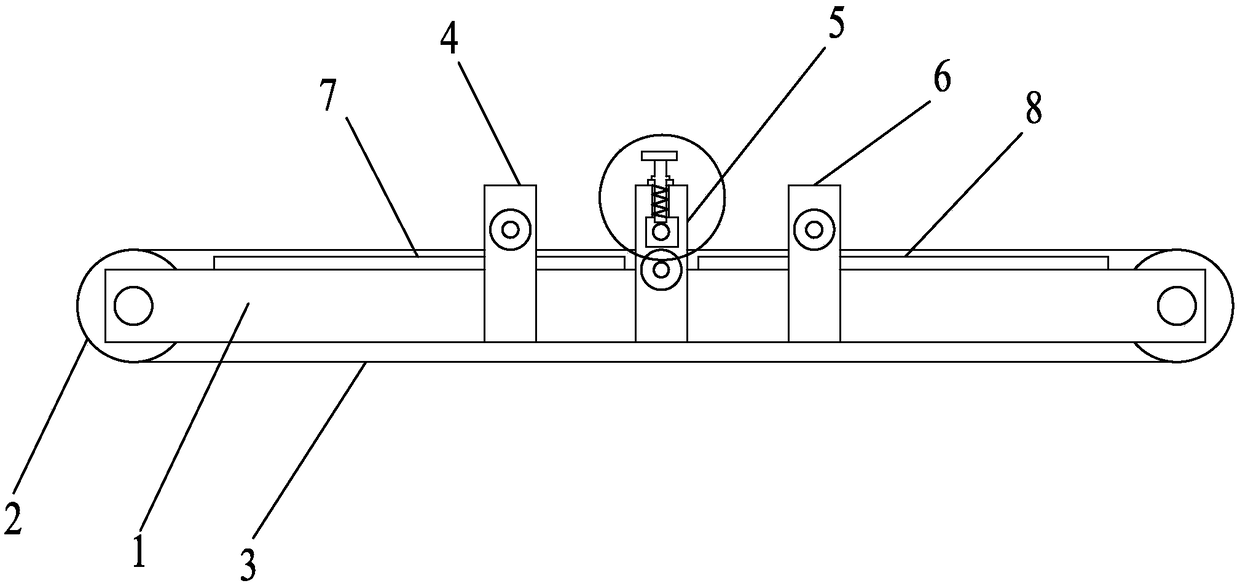

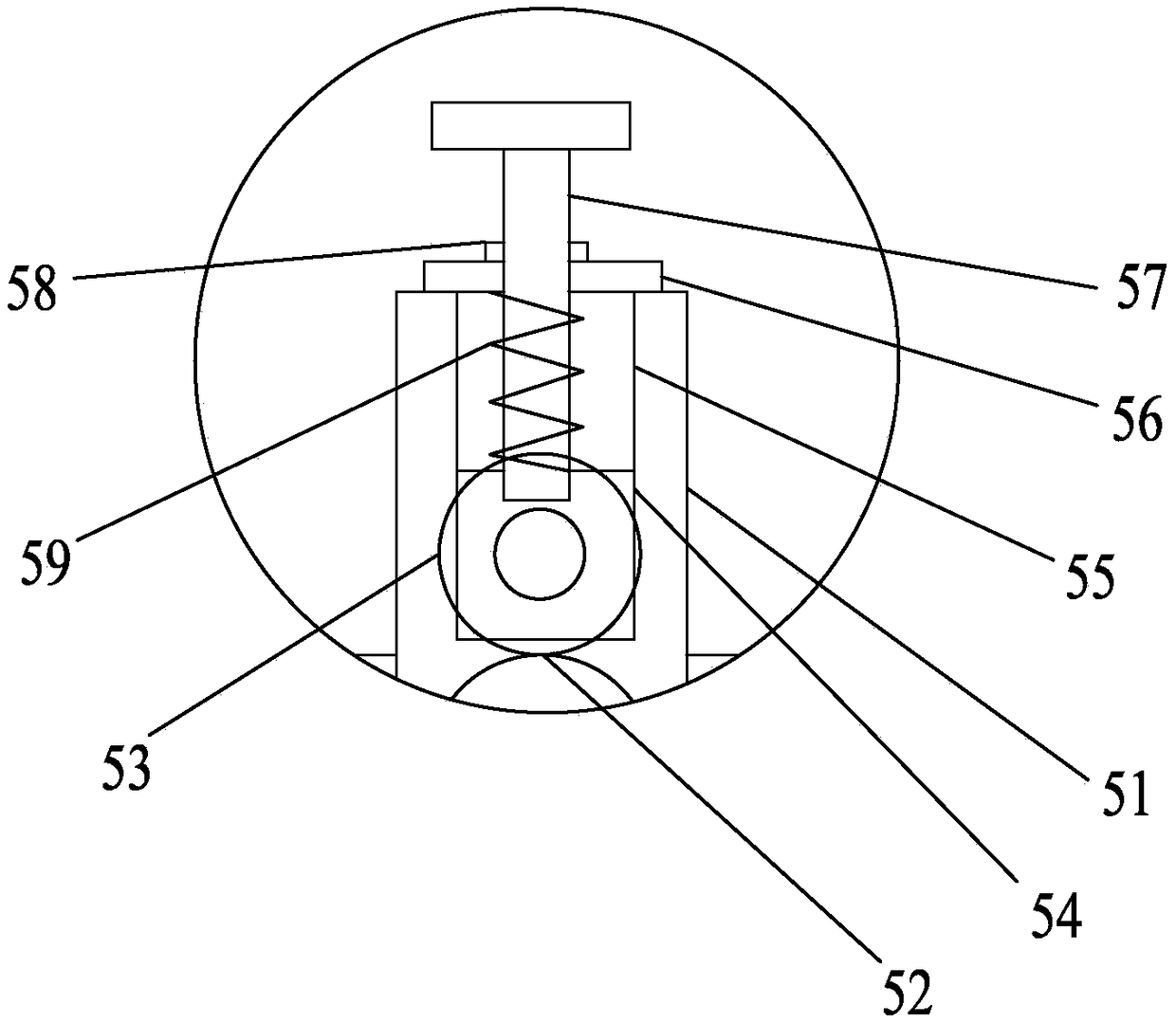

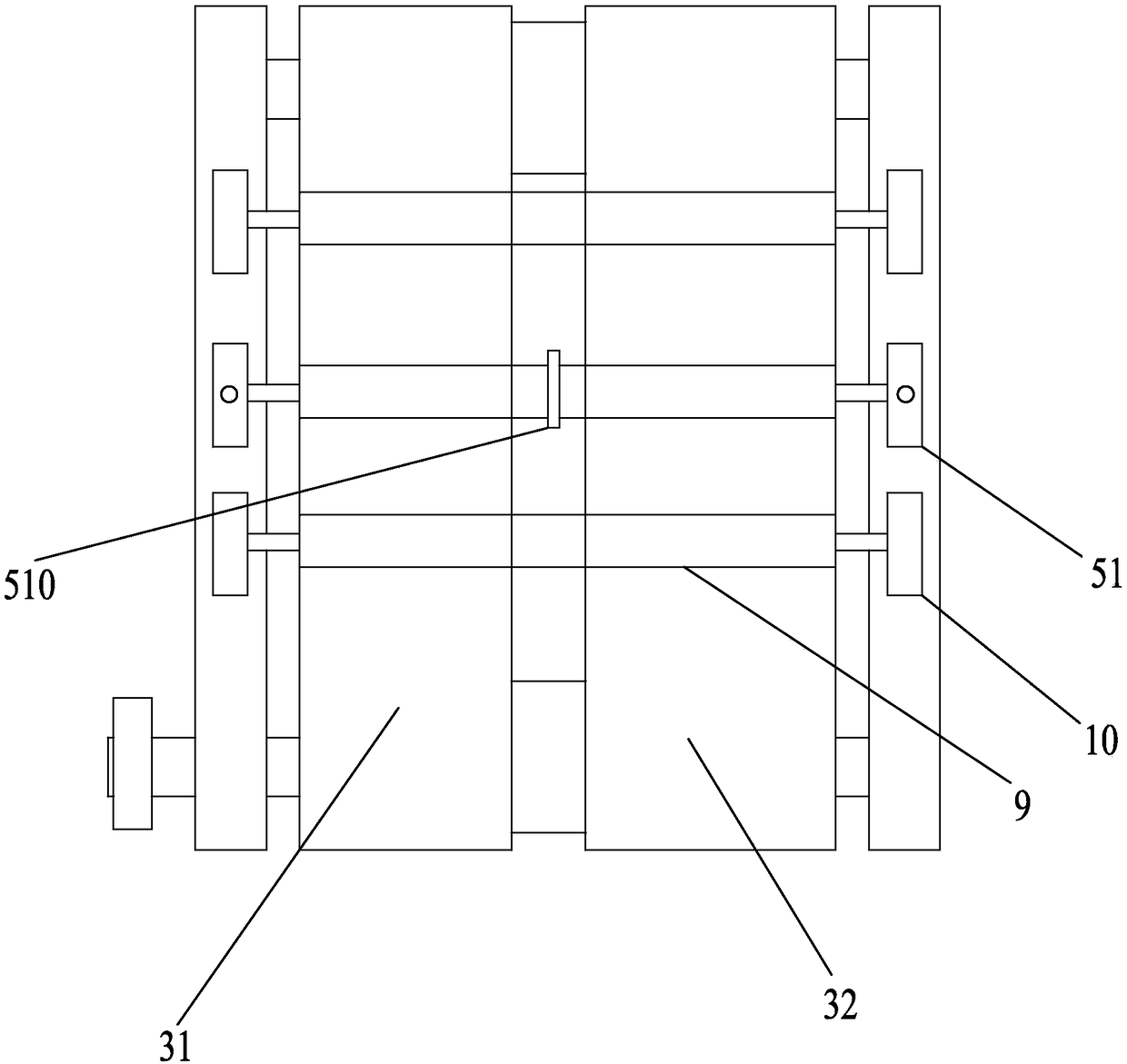

[0019] like Figure 1-4 As shown, in the embodiment of the present invention, the leather dividing device includes a frame body 1, a roller 2, a conveyor belt 3, a front pressing device 4, a dividing mechanism 5, a rear pressing device 6, a front pallet 7, and a rear pallet 8. Compression roller 9, side frame 10, rollers 2 are respectively fixed at both ends of the frame body 1, and a conveyor belt 3 is set on the rollers 2 for conveying leather. A dividing mechanism 5 is arranged horizontally on the frame body 1. 5 mainly includes splitting side frames 51, lower splitting shafts 52, and upper splitting shafts 53. The two splitting side frames 51 are relatively fixed on the frame body 1 respectively, and the upper splitting shaft 53 and the lower splitting shaft arranged up and down side by side are arranged between the two splitting side frames 51. Splitting shaft 52, the splitti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com