Citric acid mixed ester production method

A production method and citric acid technology, applied in the field of plasticizers, can solve the problems of high synthesis temperature of octyl citrate, influence on market application of citrate ester, and high product color number, and achieve environmental friendliness, strong adaptability, and low catalyst cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

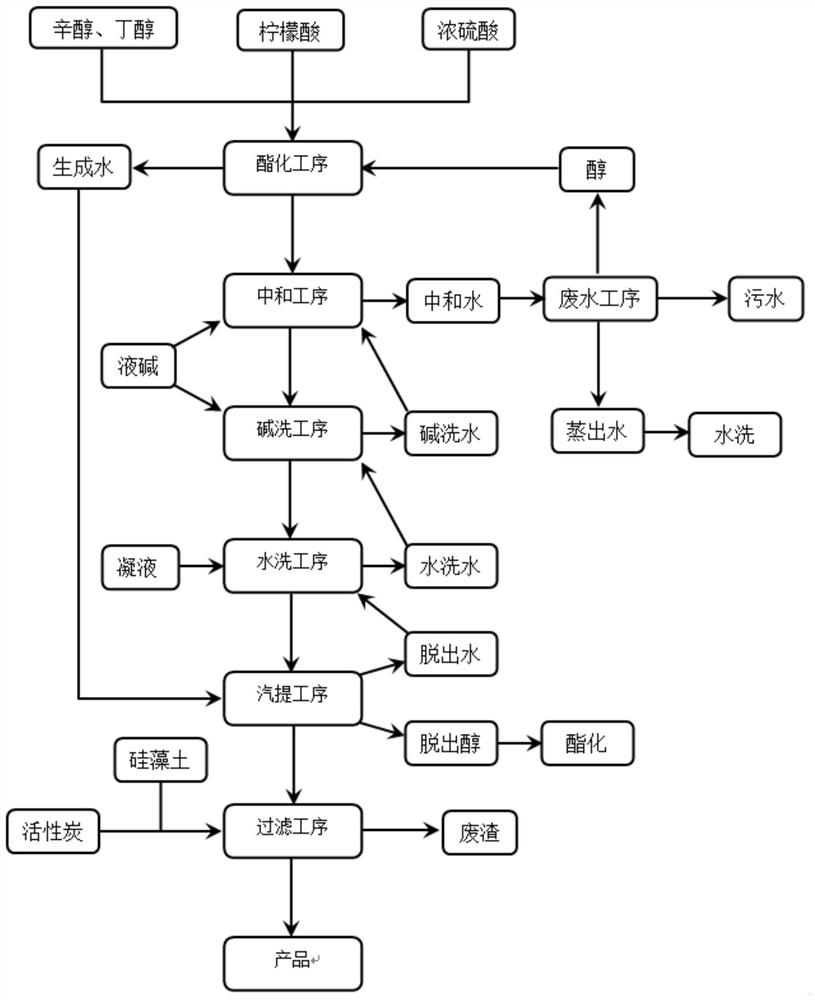

[0027] The production method of citric acid mixed ester comprises the following steps:

[0028] 1) Esterification process

[0029] The role of the esterification process is to complete the main reaction of the device and is a key process to control the conversion rate of raw materials. Add citric acid, butanol, octanol and catalyst to the reaction kettle, use concentrated sulfuric acid as the catalyst, carry out esterification according to the molar ratio of citric acid:alcohol (butanol+octanol) of 1:4.5, and the alcohol is excessive. The melting temperature is controlled within 145°C.

[0030] 2) Neutralization and washing process

[0031] Use lye to neutralize and remove sulfuric acid and incompletely esterified citric acid mono- and di-esters in the crude ester.

[0032] 3) Stripping process

[0033] The neutralized crude ester contains water, a small amount of low boiling matter and a certain amount of alcohol. In this process, the nitrogen protection vacuum stripping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com