Deep sea culture platform and manufacturing method thereof

A platform and deep-sea technology, applied in the field of deep-sea aquaculture platform and its production, can solve the problems of installation of power supply device, short service life, installation of monitoring system in cages, etc., save manpower and material resources, improve wind and wave resistance, and simple production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

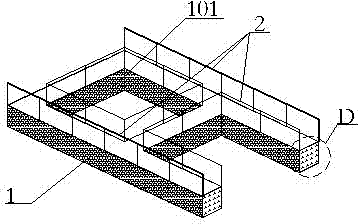

[0029] Combine below Figure 1-Figure 8 The specific implementation of the present invention is further described, but the technical solution of the present invention is not limited to the content described here.

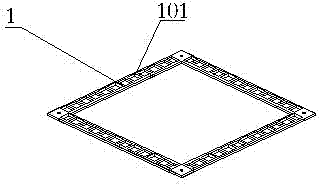

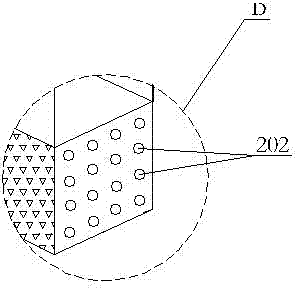

[0030] A deep-sea aquaculture platform includes a closed platform frame 1 floating on the water surface, a large net 6 is arranged in the platform frame 1, and the platform frame 1 includes multiple layers fixed in parallel at a distance of 5 to 50 cm. The anticorrosive and mothproof bamboo 202 or wood in the platform frame 1 further includes the mixed lightweight aggregate concrete poured in the platform frame 1, and the density of the mixed lightweight aggregate concrete is 400-970 kg / cubic meter.

[0031] The mixed lightweight aggregate concrete is made by mixing rice husk, woven bag silk or polypropylene fiber, construction glue, early strength agent, polystyrene foam particles, water and cement, and the weight ratio of each component is:

[0032] 100 parts cement, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com