Patents

Literature

34results about How to "Shorten the lap length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

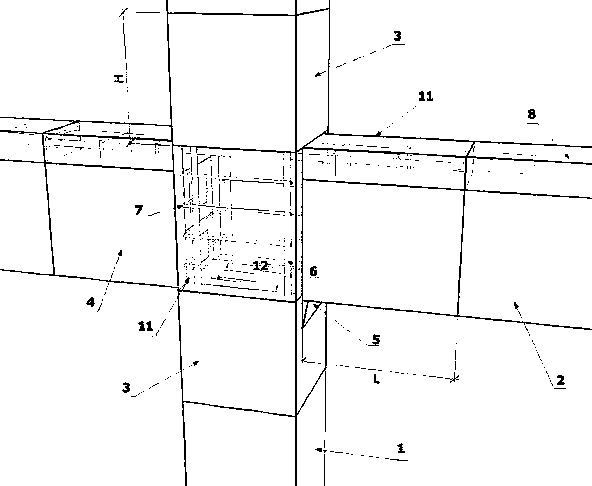

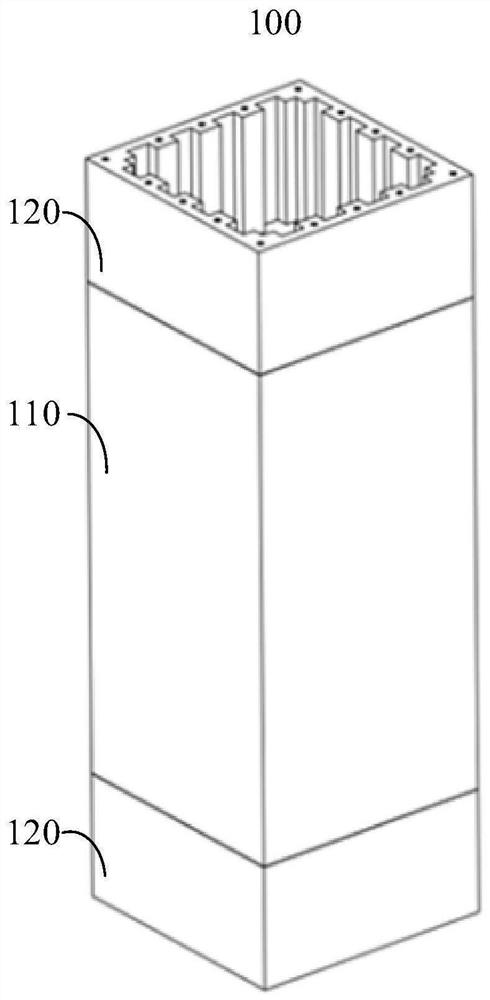

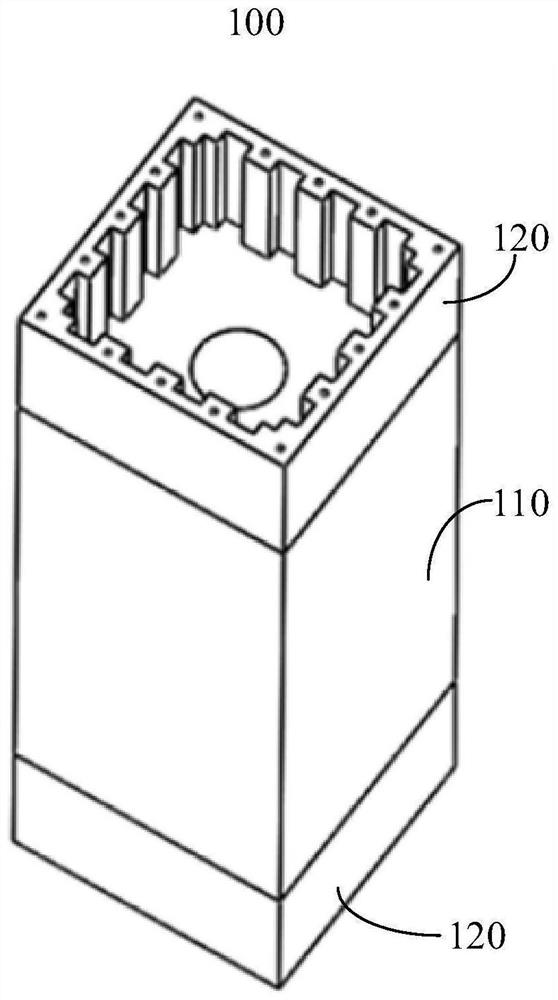

Assembly type reinforced concrete frame beam column joint and preparation method

InactiveCN106592759AShorten the lap lengthGuaranteed integrityBuilding constructionsReinforced concreteLap joint

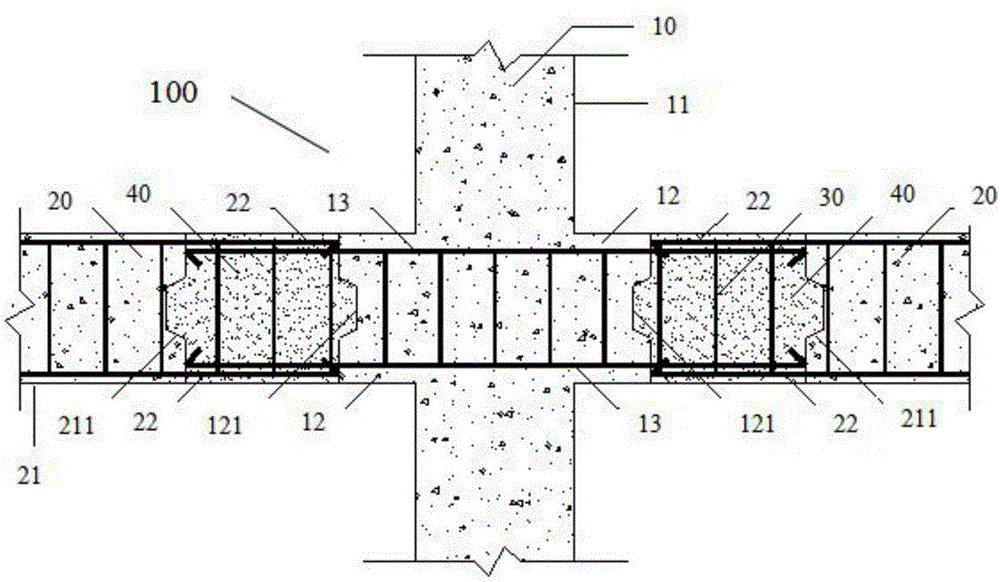

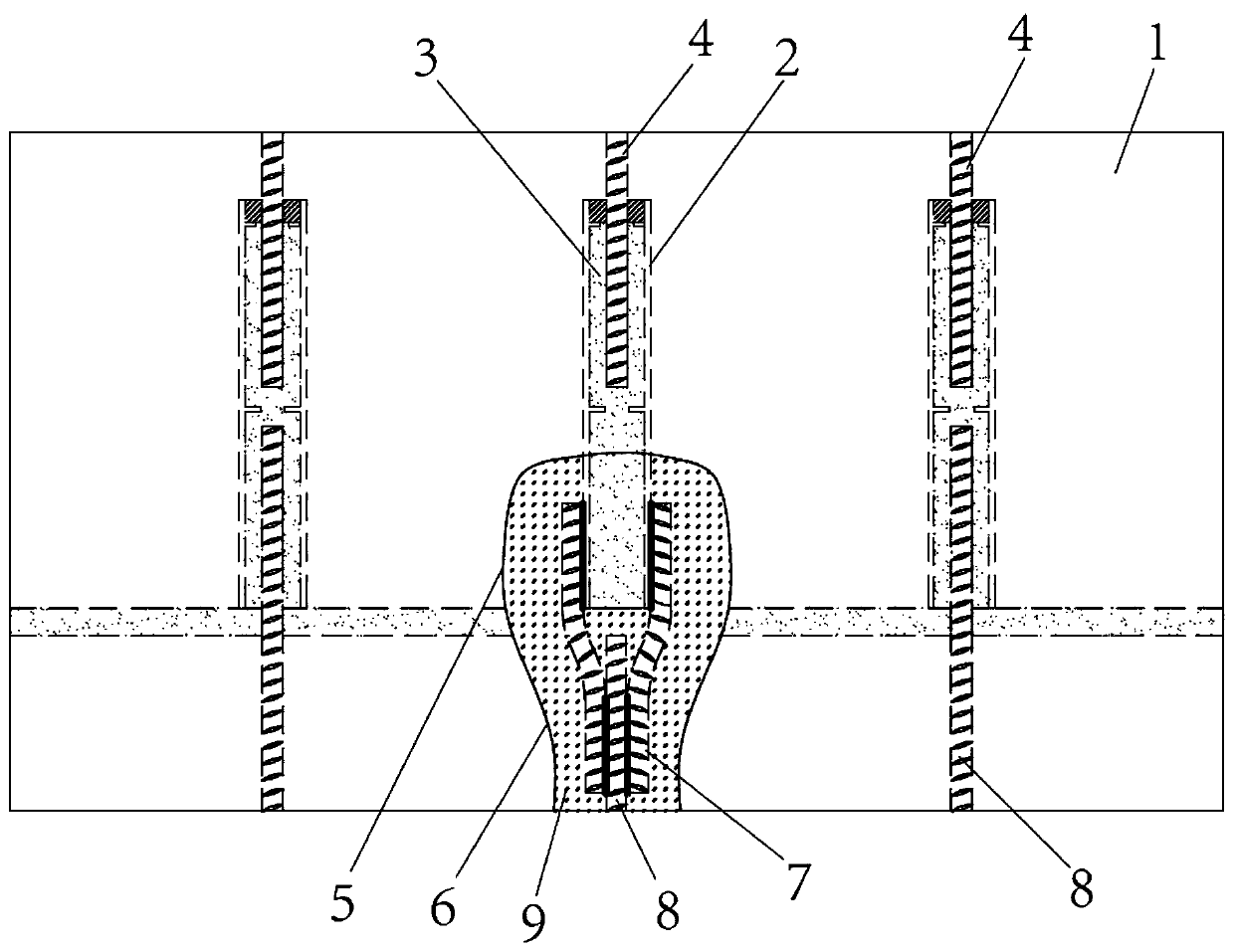

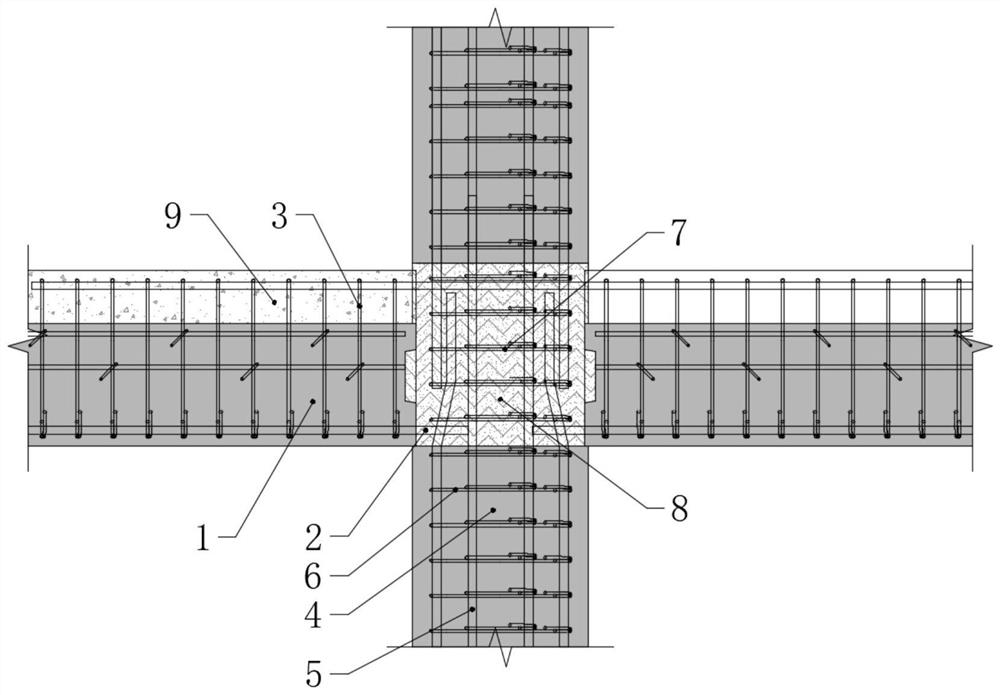

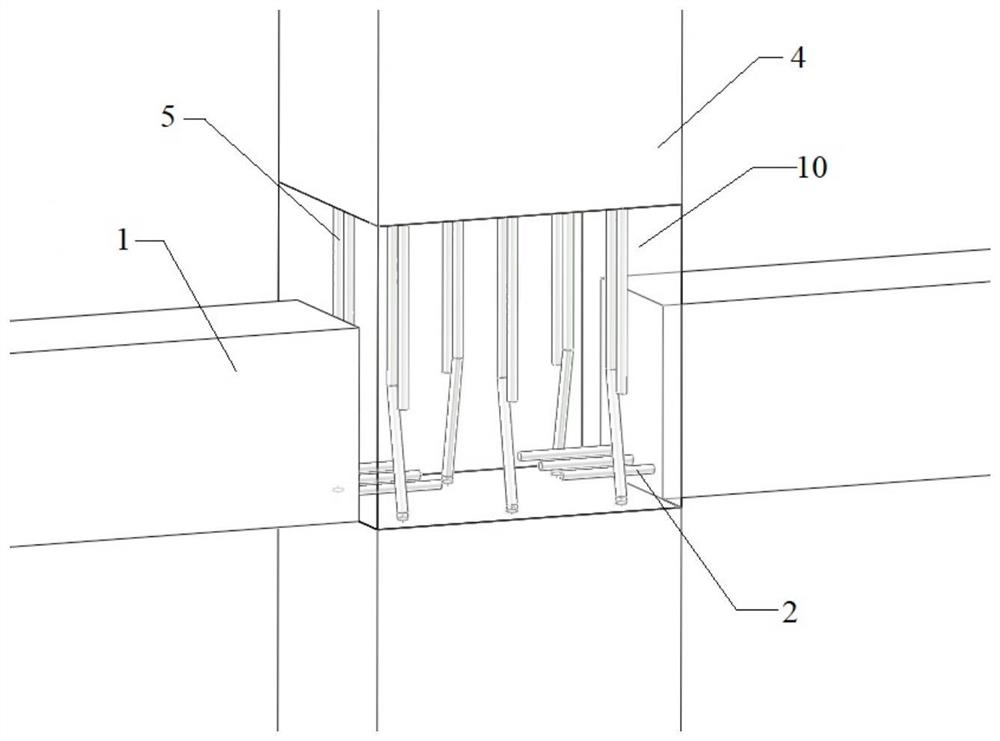

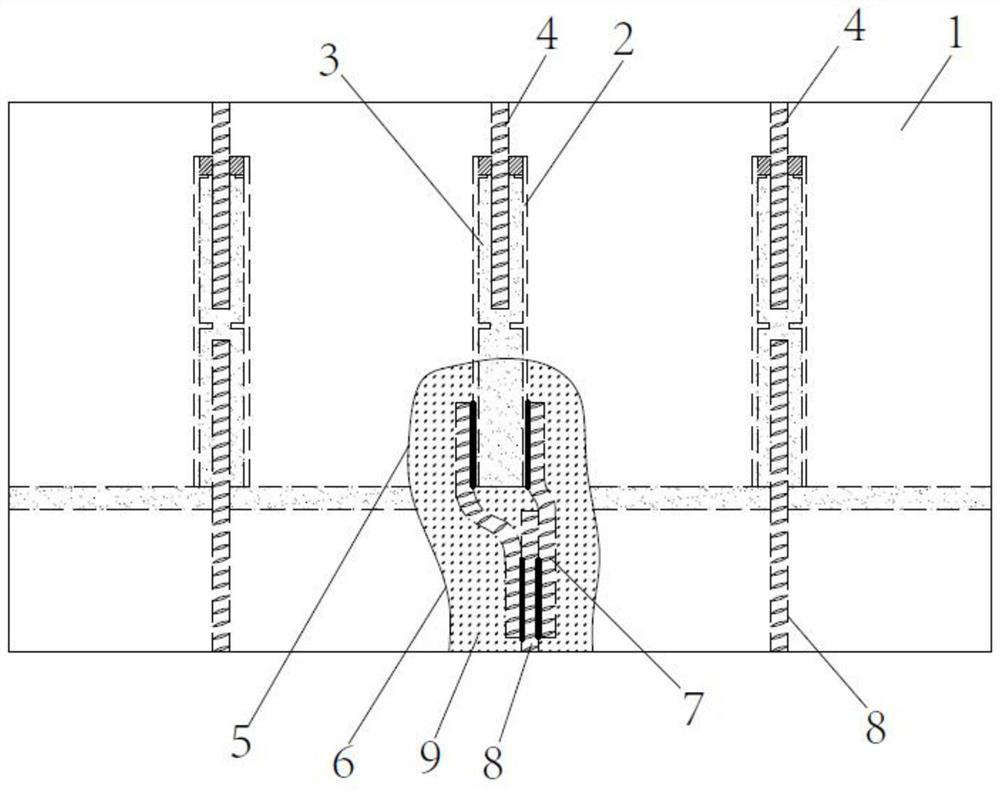

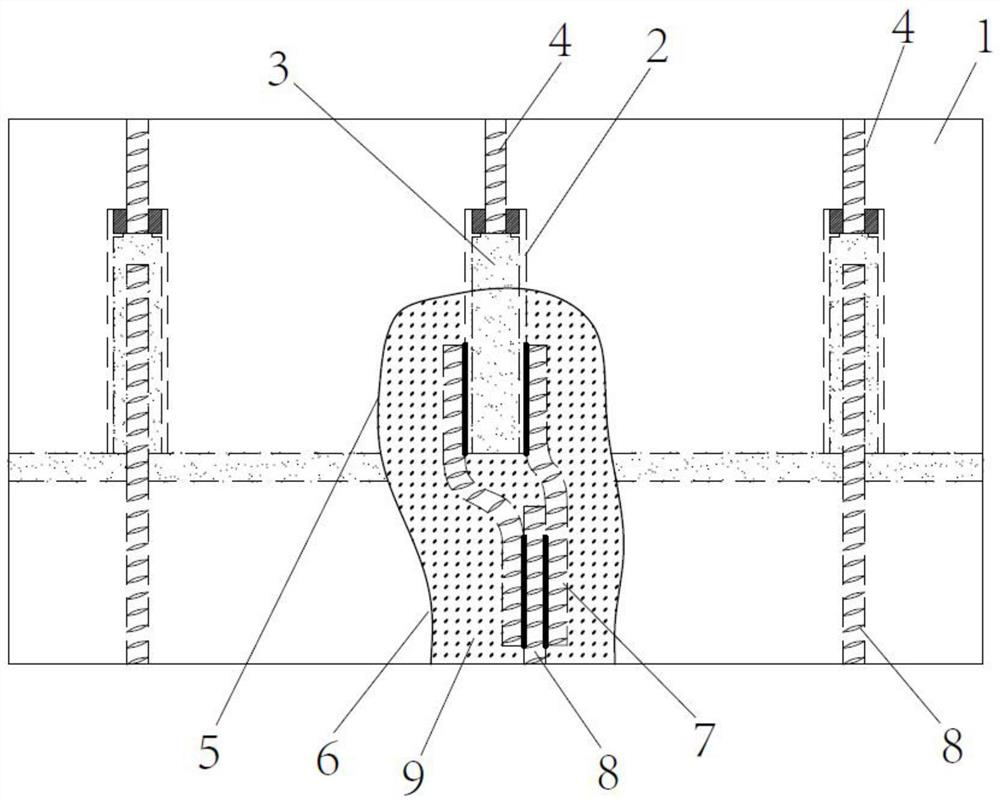

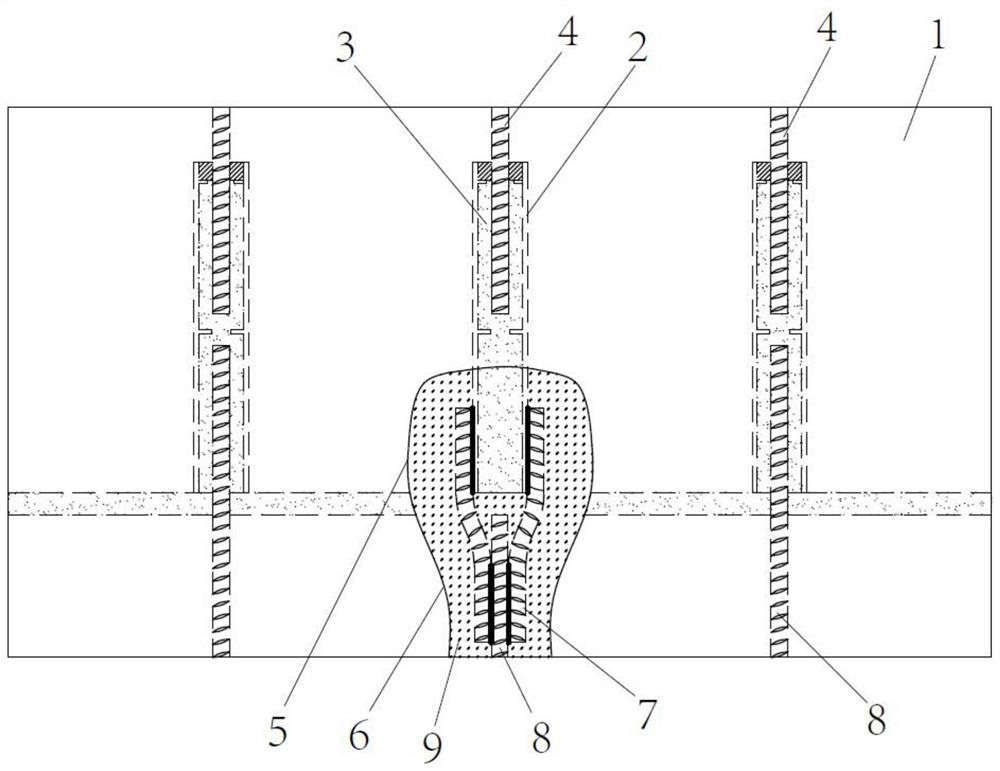

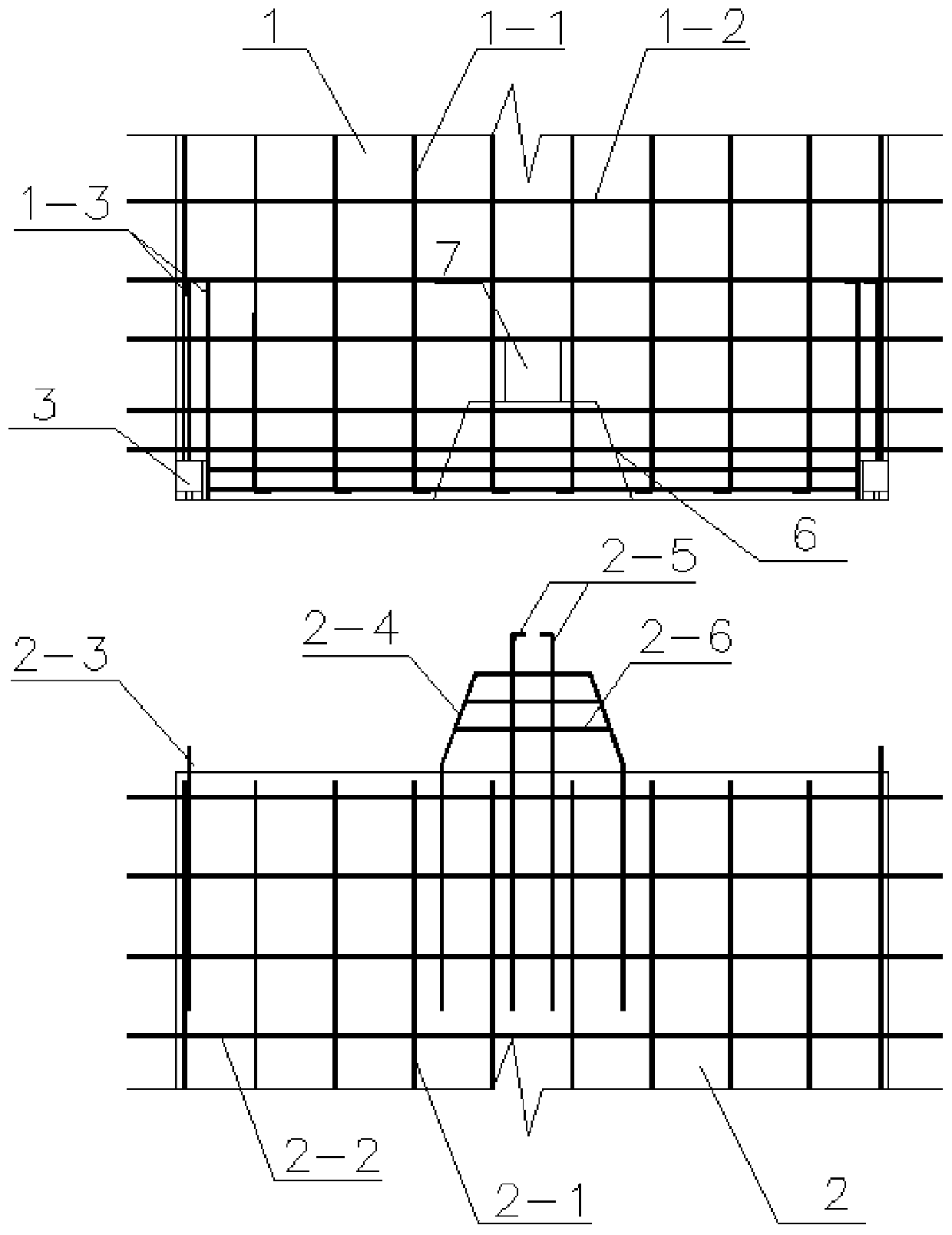

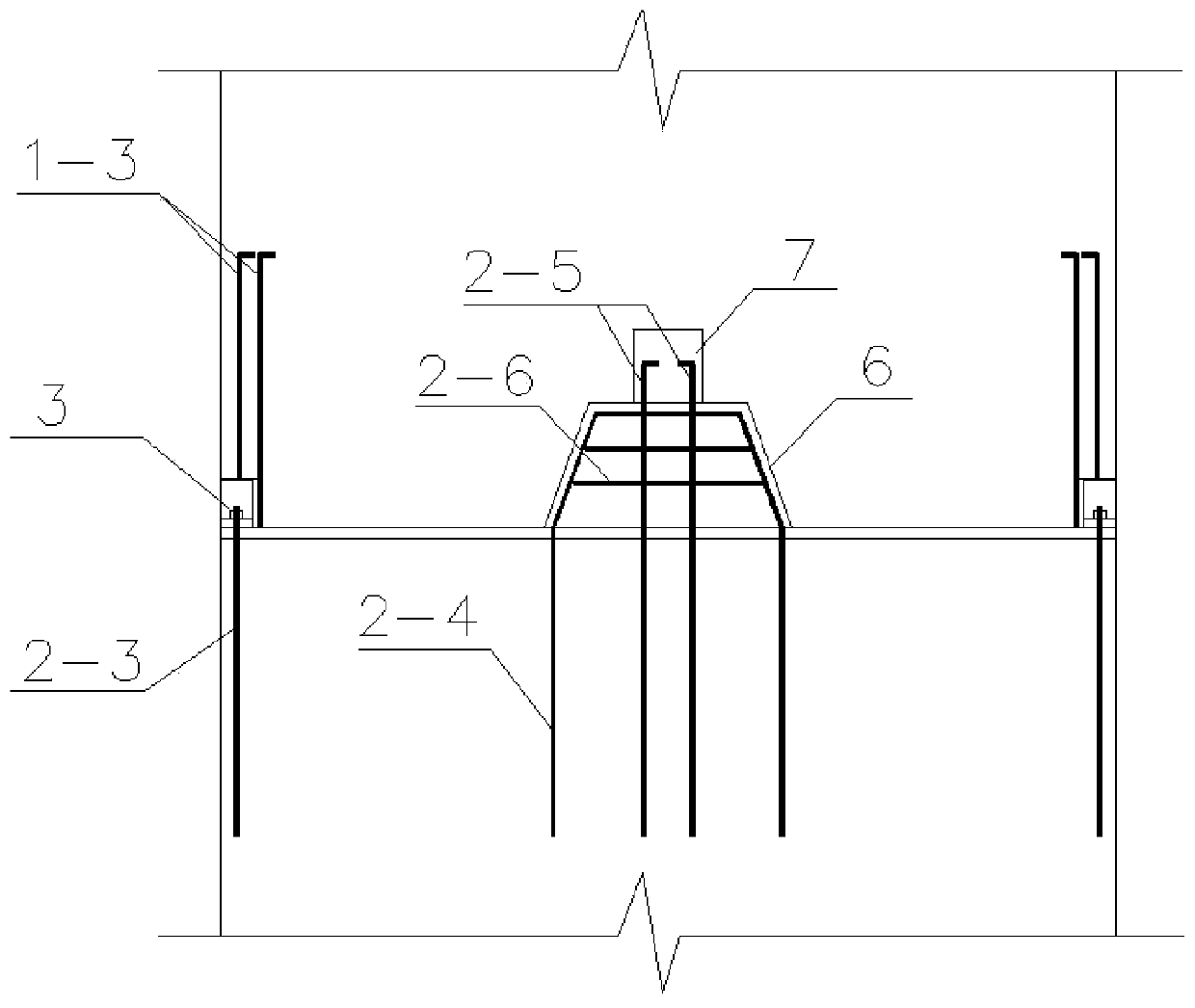

The invention provides an assembly type reinforced concrete frame beam column joint. The assembly type reinforced concrete frame beam column joint is characterized by comprising a prefabricated column and a prefabricated beam, wherein the prefabricated column is provided with a prefabricated column body, an extension section and at least one pair of column lap joint longitudinal ribs; the extension section is arranged in the center of the prefabricated column body and extends to the two sides; each pair of column lap joint longitudinal ribs are arranged in the extension section, penetrate through the whole extension section and extend out from the two ends of the extension section; the prefabricated beam is provided with a prefabricated beam body and at least one pair of prefabricated beam longitudinal ribs arranged on the prefabricated beam body; one ends of each pair of prefabricated beam longitudinal ribs extend out from the end, close to the prefabricated column, of the prefabricated beam body; the prefabricated column and the prefabricated beam are connected through a plurality of stirrups and ultra-high performance concrete; and the column lap joint longitudinal ribs and the prefabricated beam longitudinal ribs are fixed through the multiple stirrups according to a certain interval.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

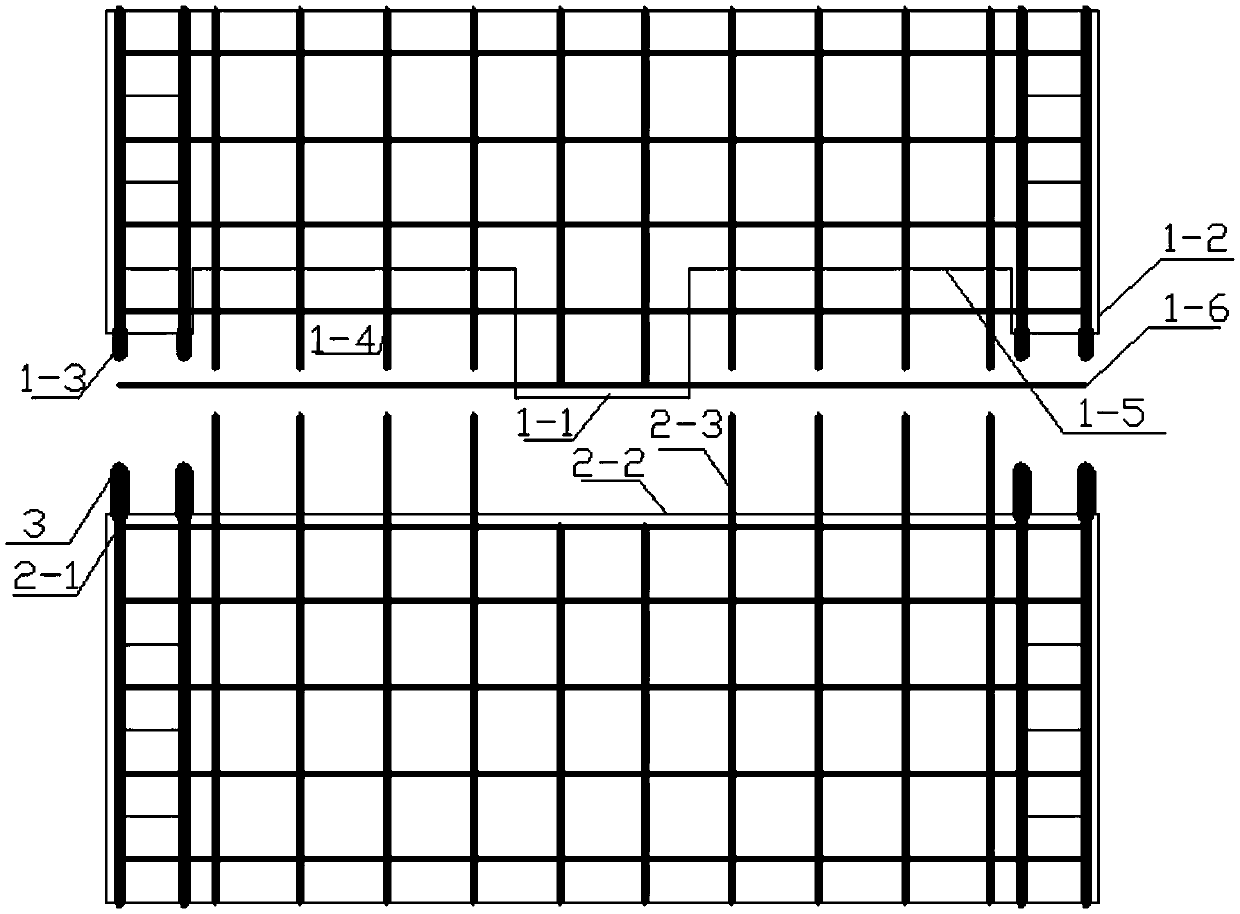

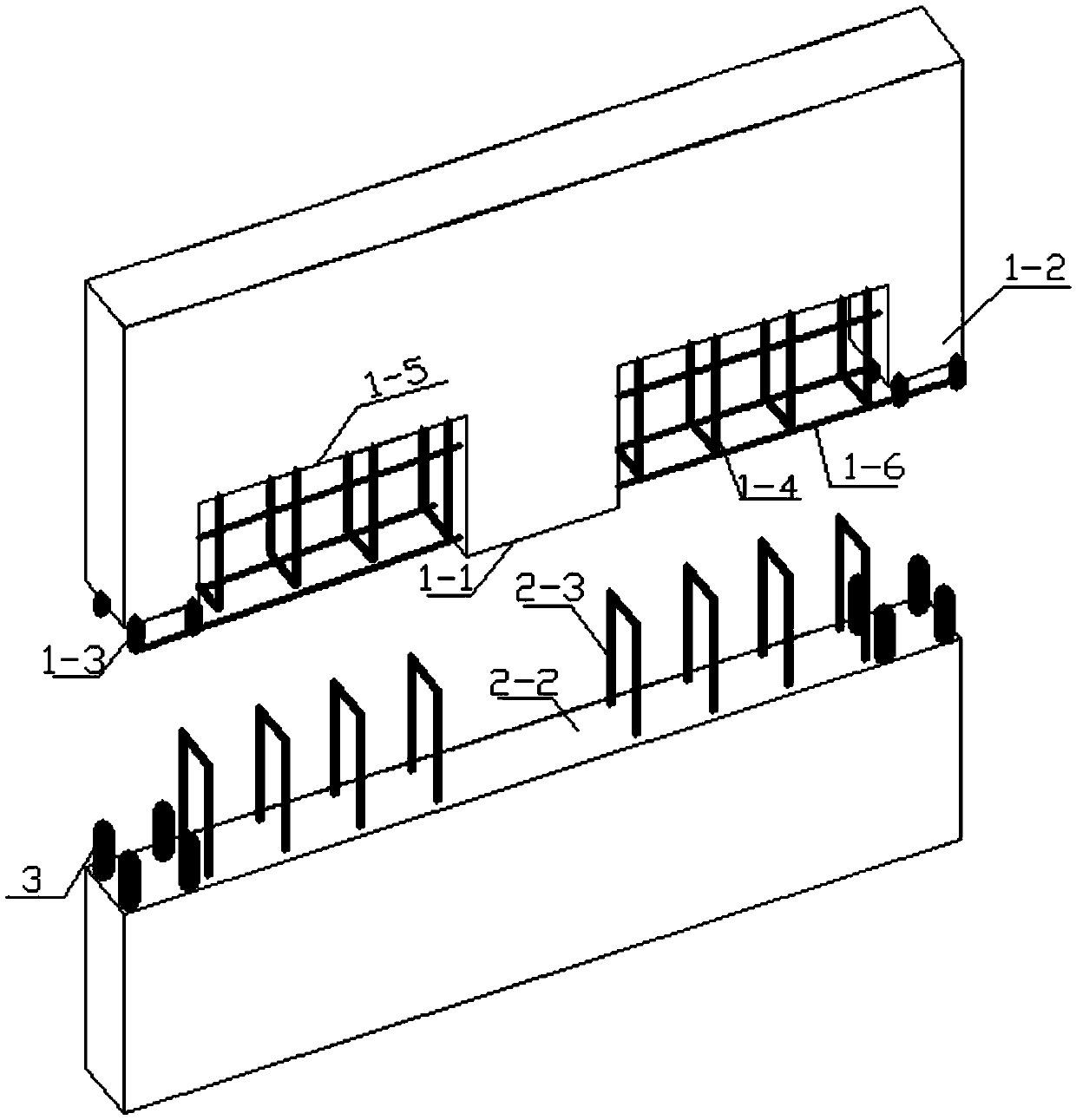

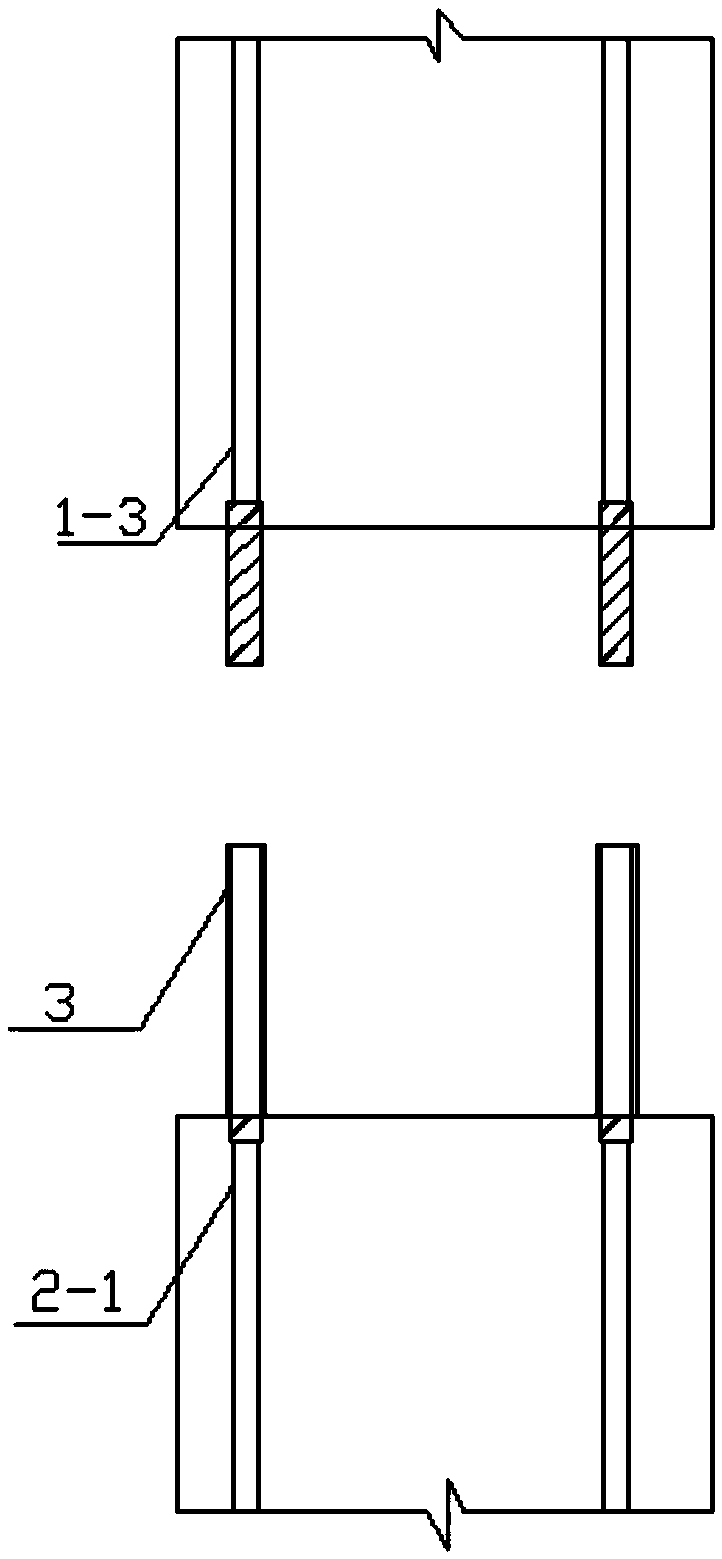

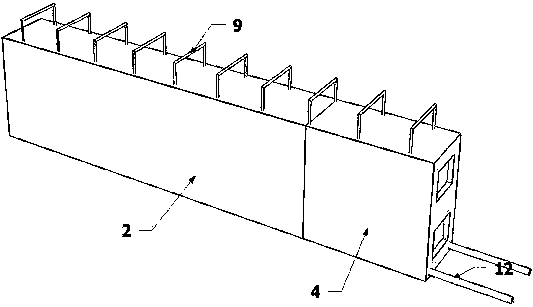

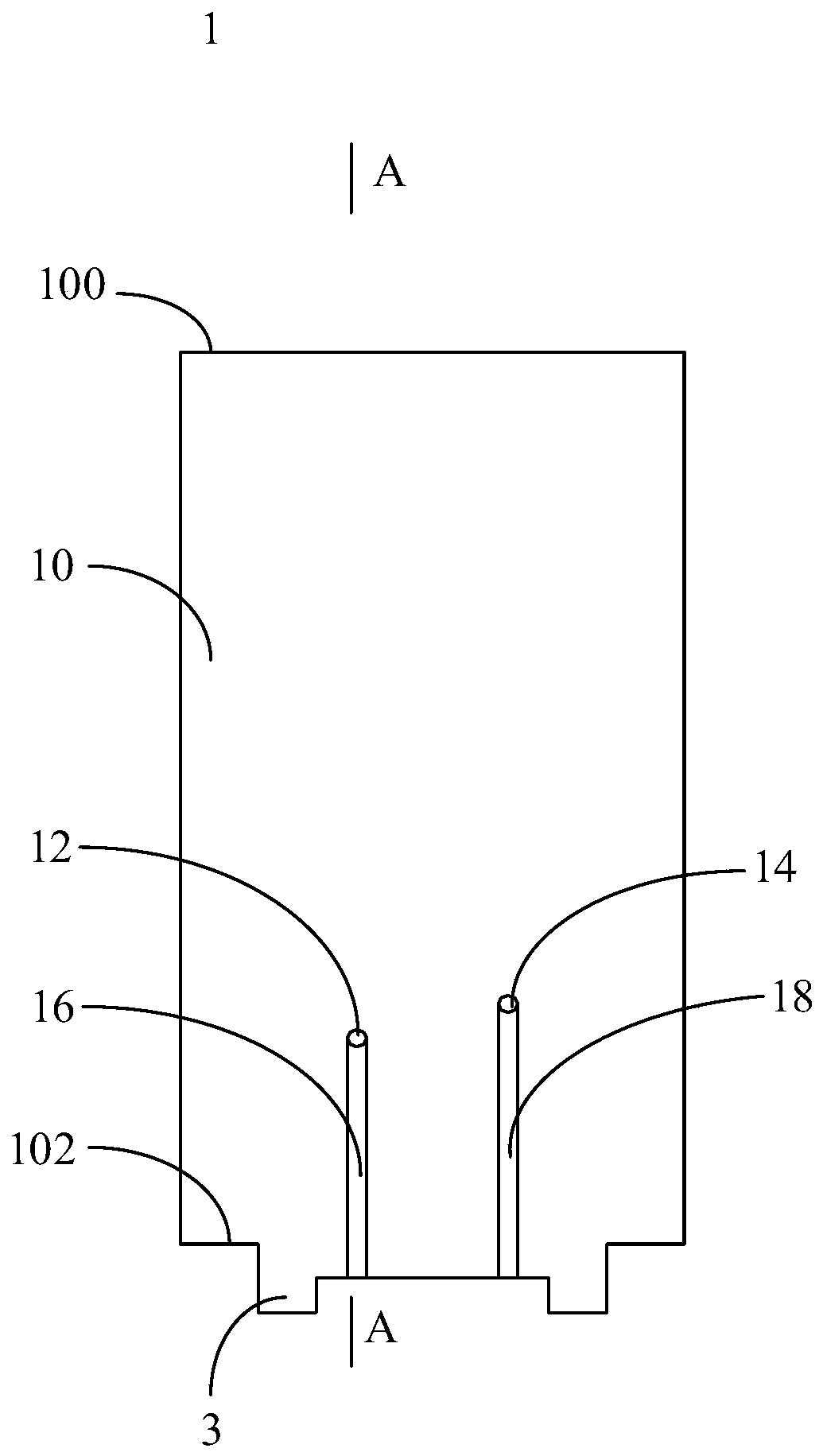

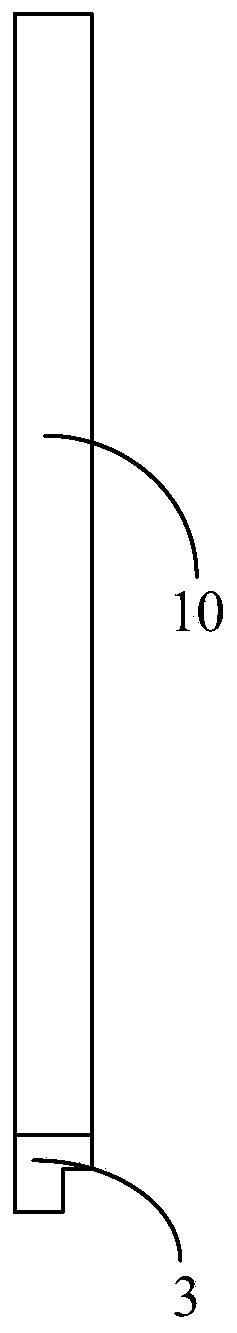

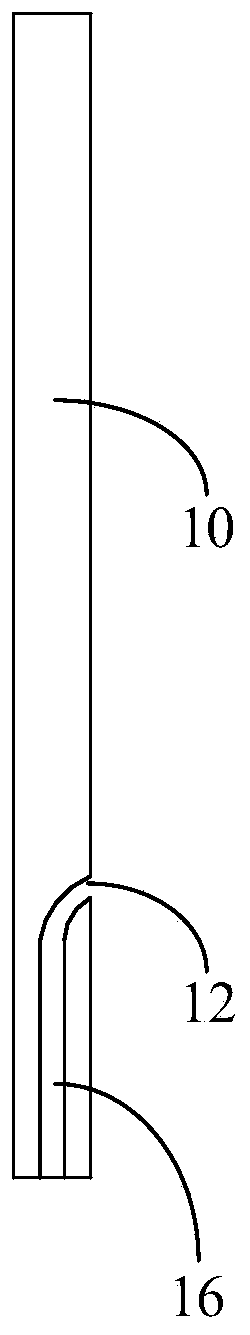

Assembled type shear wall upper-layer and lower-layer combined connection structure

The invention discloses an assembled type shear wall upper-layer and lower-layer combined connection structure which comprises an upper-layer prefabricated wall and a lower-layer prefabricated wall which are connected in a butted mode. When the upper-layer prefabricated wall and the lower-layer prefabricated wall are connected in the butted mode, a downward-protruding supporting structure of the upper-layer prefabricated wall is supported on the lower-layer prefabricated wall, structural longitudinal ribs of an embedded column of the upper-layer prefabricated wall and structural longitudinal ribs of an embedded column of the lower-layer prefabricated wall are opposite in a one-to-one mode and are connected mechanically, the structural longitudinal ribs I of the upper-layer prefabricated wall and the structural longitudinal ribs II of the lower-layer prefabricated wall are connected in an overlapped mode, and the upper-layer prefabricated wall and the lower-layer prefabricated wall are connected at the joint through a cast-in-place concrete structure. The combined connection way combined with the cast-in-place concrete structure is formed through mechanical connection, steel bar splicing and concrete spraying, the wall prefabrication technology is simpler, on-site construction is more convenient and rapider, and the workpiece manufacturing cost and the construction cost can be reduced.

Owner:TIANJIN UNIV

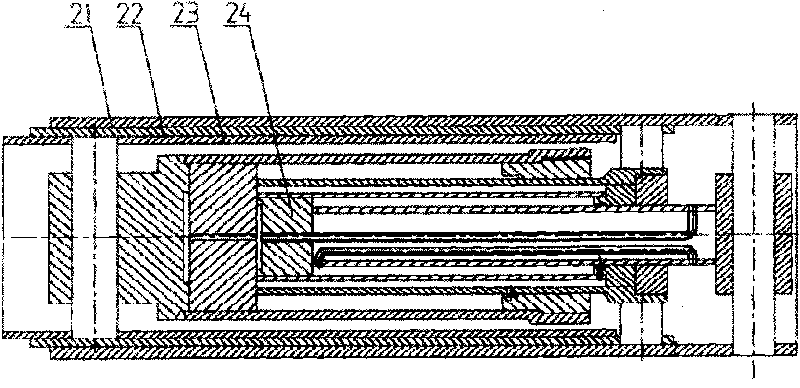

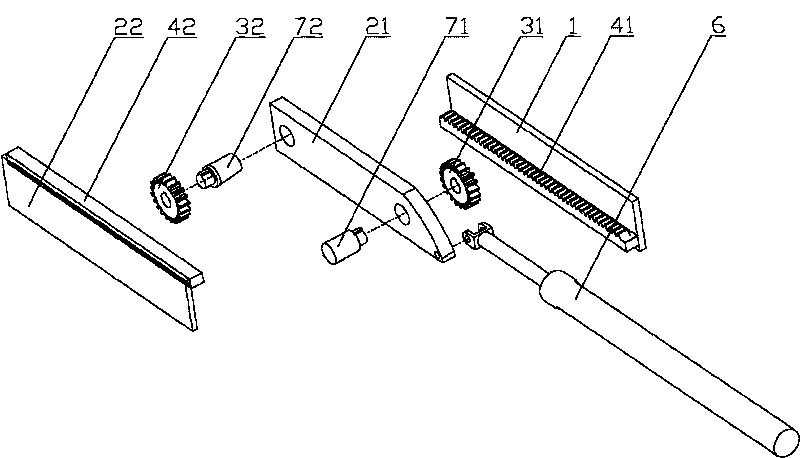

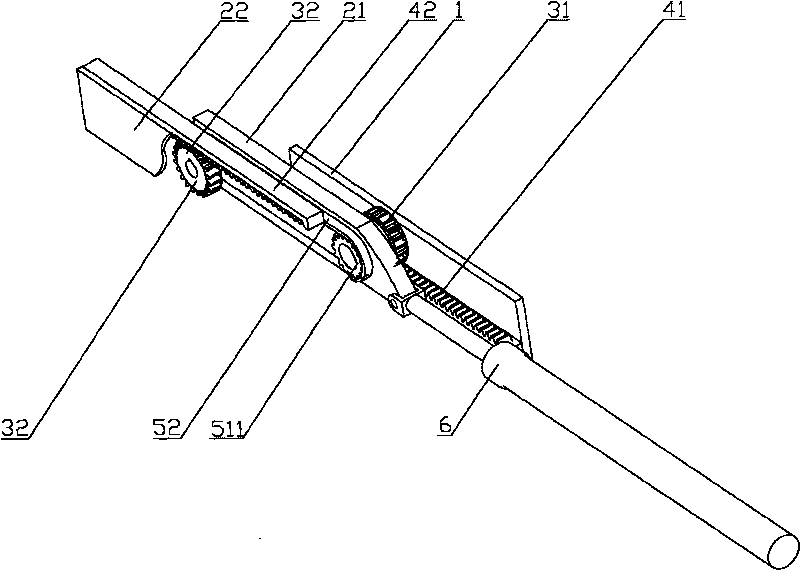

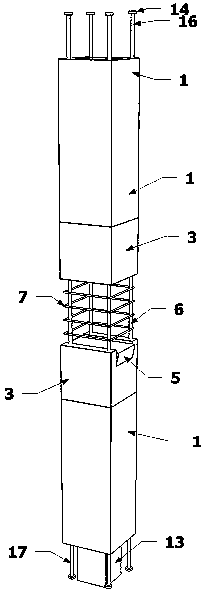

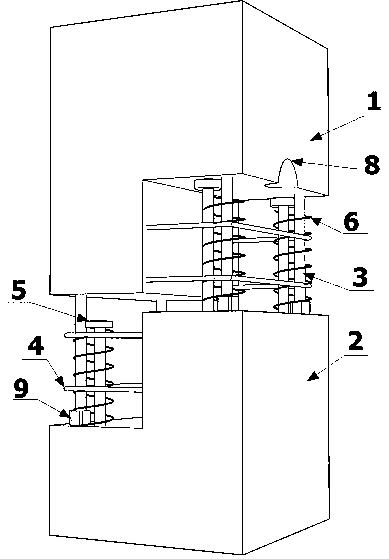

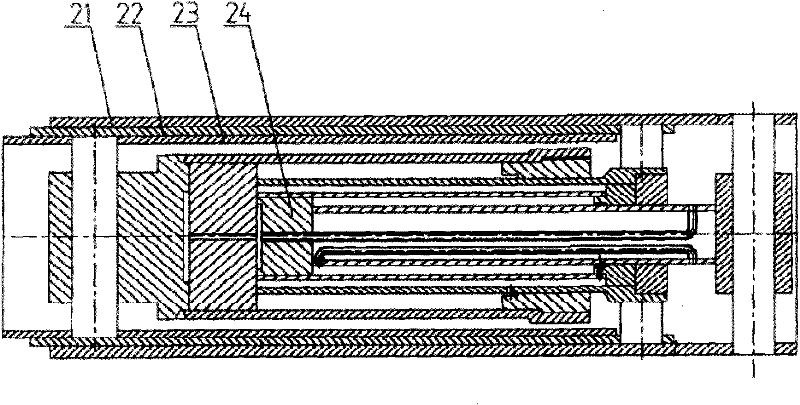

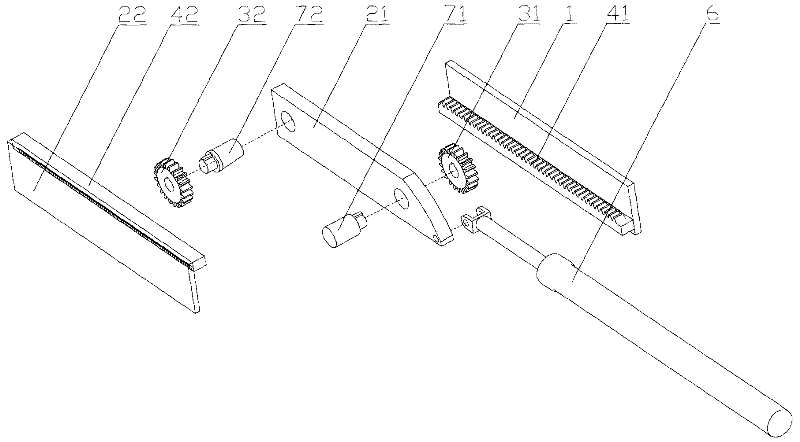

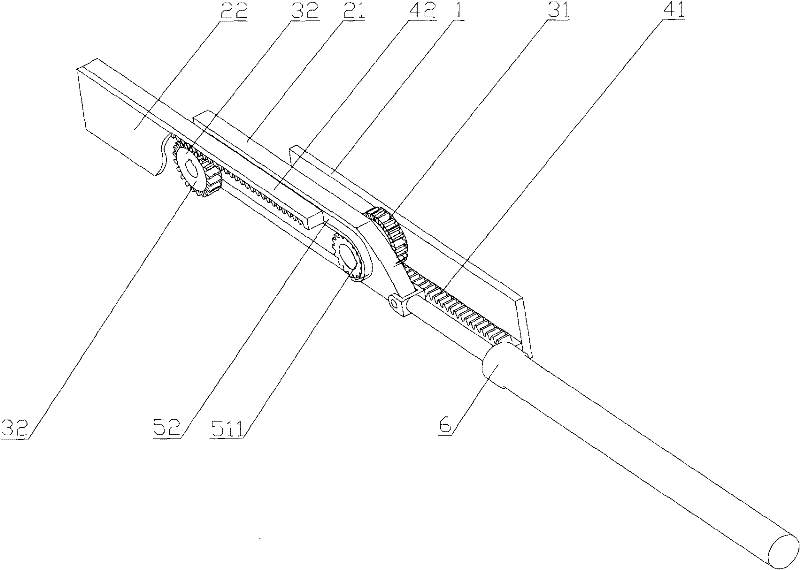

Movable type engineering machine and support leg device thereof

InactiveCN101698407AHigh transmission reliabilityIncrease total elongationVehicle fittings for liftingBuilding material handlingGear wheelMovable type

The invention discloses a support leg device used for a movable type engineering machine, comprising a fixed support leg box (1), wherein a first movable support leg (21) arranged on the fixed support leg box (1) is provided with a first gear (31), and the fixed support leg box (1) is provided with a first rack (41) meshed with the first gear (31); the first movable support leg (21) is provided with a second gear (32), and a second movable support leg (22) arranged on the first movable support leg (21) is provided with a second rack (42) meshed with the second gear (32); and the first gear (31) is linked with the second gear (32) under the action of a connecting part, and the first movable support leg (21) and the second movable support leg (22) move towards the same direction. By adopting a rack and pinion pair, the support leg device can be stretched, has simpler structure and simplifies the processing technique. The invention also discloses the movable type engineering machine including the support leg device.

Owner:SANY AUTOMOBILE MFG CO LTD

Fiber sheet concrete bidirectional laminated slab close-splicing connection structure and implementation method

The invention provides a fiber sheet concrete bidirectional laminated slab close-splicing connection structure and an implementation method. The fiber sheet concrete bidirectional laminated slab close-splicing connection structure comprises a strip-shaped fiber sheet, prefabricated concrete bottom plates, a post-pouring concrete laminated layer, plate bottom longitudinal force bearing bars and a laminated surface additional bar, wherein the strip-shaped fiber sheet is connected to a slab joint between two spliced prefabricated concrete bottom plates and is located on the lower surfaces of theprefabricated concrete bottom plates; the plate bottom longitudinal force bearing bars are provided with bended end parts and the bended end parts are anchored into the post-pouring concrete laminatedlayer; and the laminated surface additional bar is arranged on the upper surfaces of the prefabricated concrete bottom plates and stretches across the slab joint, and is connected with the bended endparts of the plate bottom longitudinal force bearing bars. According to the fiber sheet concrete bidirectional laminated slab close-splicing connection structure and the implementation method, the strip-shaped fiber sheet is bonded to the lower surface of the slab joint between the prefabricated concrete bottom plates, the tensile stress on the section of the slab joint can be complementally borne, the section bearing capacity can be effectively improved, and thus the integrality of a floor system can be improved.

Owner:SHANGHAI INST OF TECH

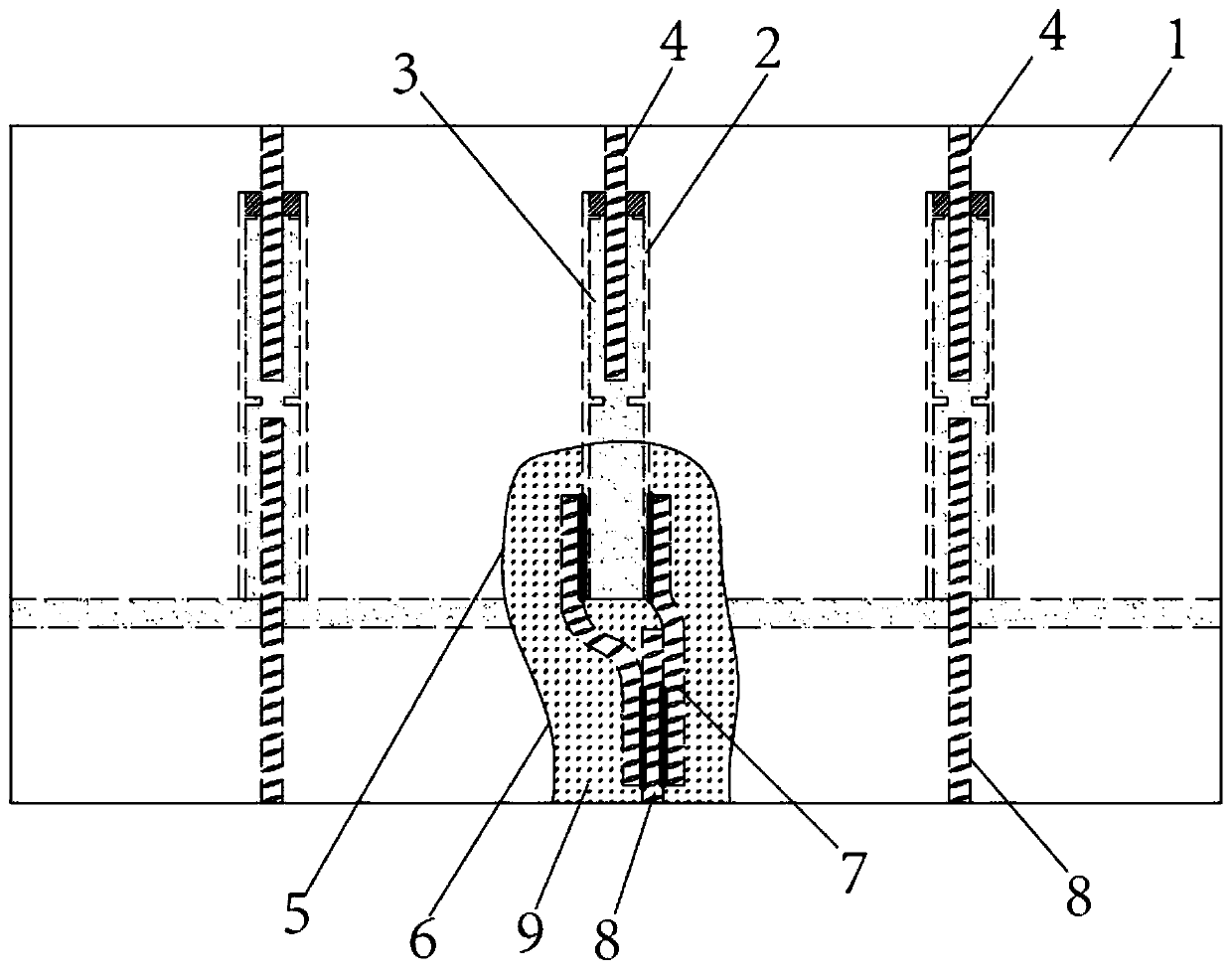

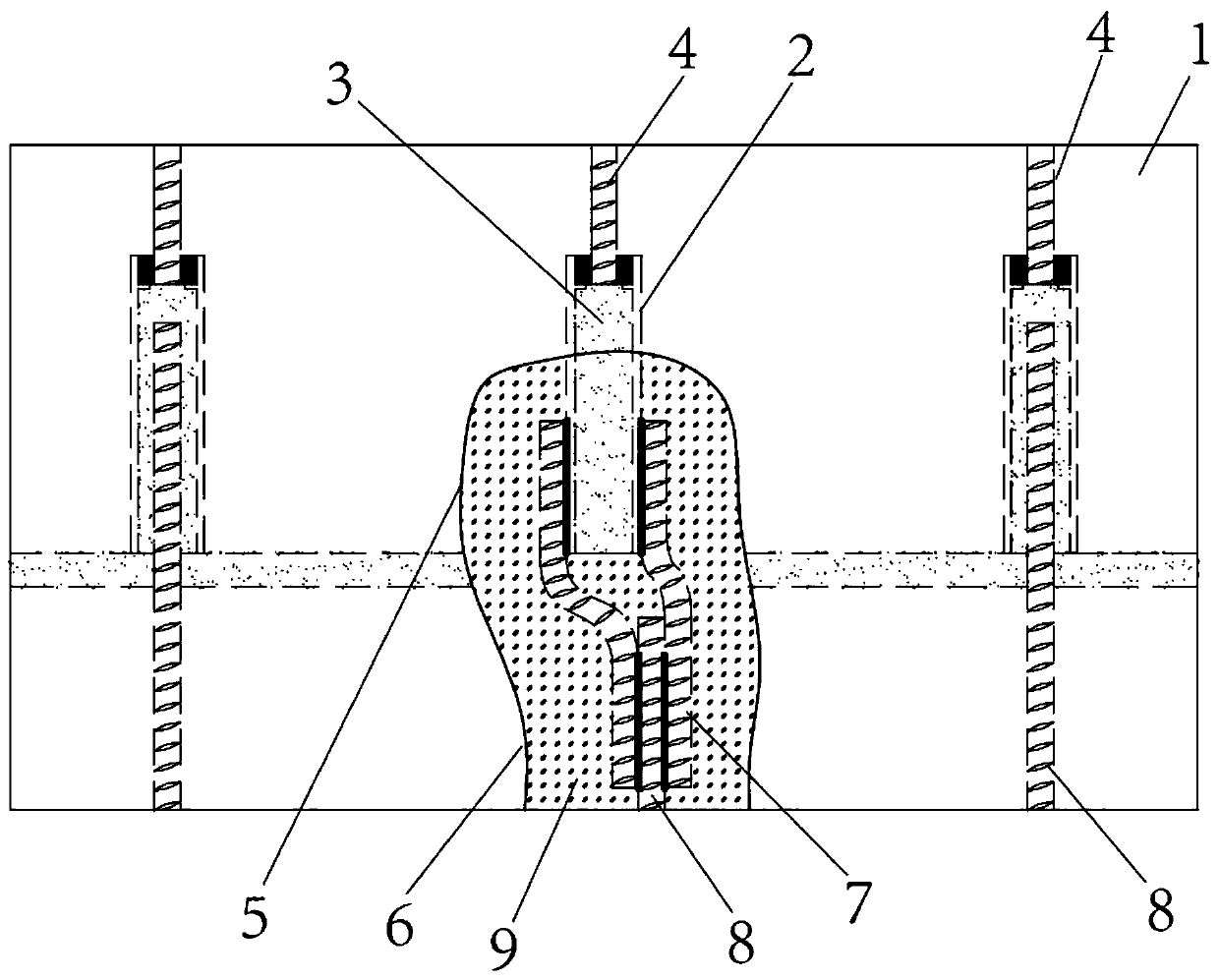

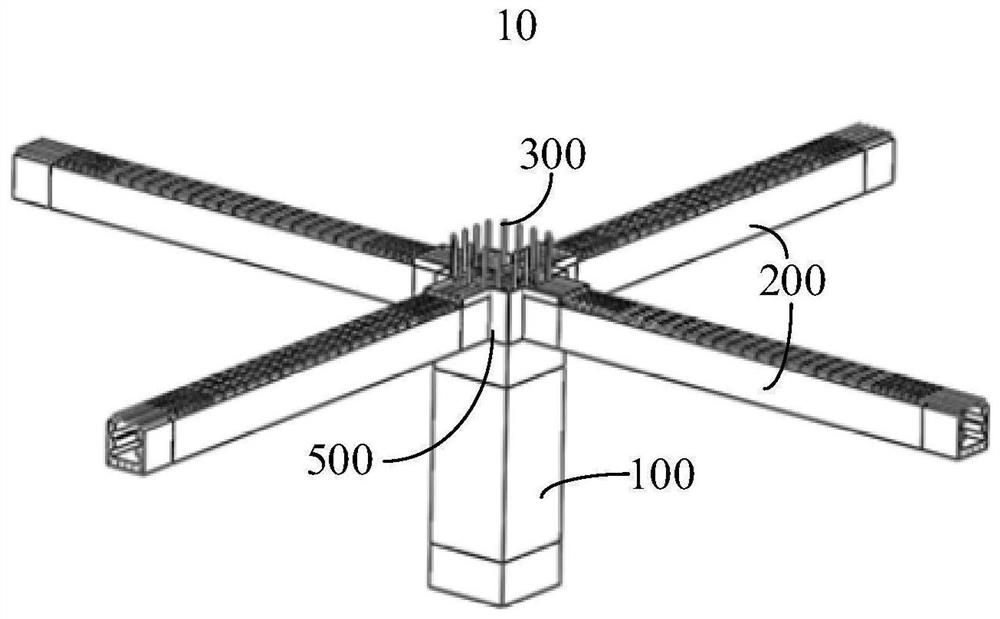

High-strength and high-ductility concrete fabricated frame structure system and connecting system thereof

PendingCN108035438AHigh tensile strengthTensile strain hardening highArched girdersPortal framesReinforced concrete columnRebar

The invention provides a high-strength and high-ductility concrete fabricated frame structure system and a connecting system thereof. According to the high-strength and high-ductility concrete fabricated frame structure system, a column longitudinal bar penetrates through the upper end and the lower end of a concrete prefabricated column to form an upper prefabricated column longitudinal bar and alower prefabricated column longitudinal bar and is exposed in a joint core area, column stirrups are prefabricated outside the exposed parts of the column longitudinal bar, and a prefabricated corbelis arranged at the top of a prefabricated reinforced concrete column in the joint core area; the lower portions of two side prefabricated reinforced concrete beams are in lap connection in the jointcore area through a lower longitudinal bar, the upper portions of the two side prefabricated reinforced concrete beams are connected through a beam upper longitudinal bar, which penetrates through beam stirrups and the joint core area and are then poured with high-strength and high-ductility concrete. According to the high-strength and high-ductility concrete fabricated frame structure system, thejoint column longitudinal bar and the beam upper longitudinal bar have no break in the joint core area, so that steel bar connection can be avoided in the joint core area with complex stress but at column inflection points with small bending moment, and structural integrity and anti-seismic properties can be avoided. Without sleeves, the high-strength and high-ductility concrete fabricated framestructure system is convenient to manufacture and install, reduces working procedures, professionals and achieves easy control.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

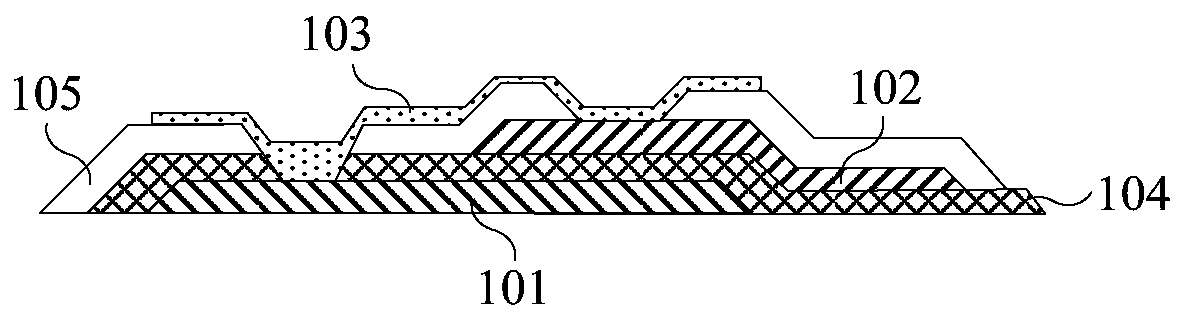

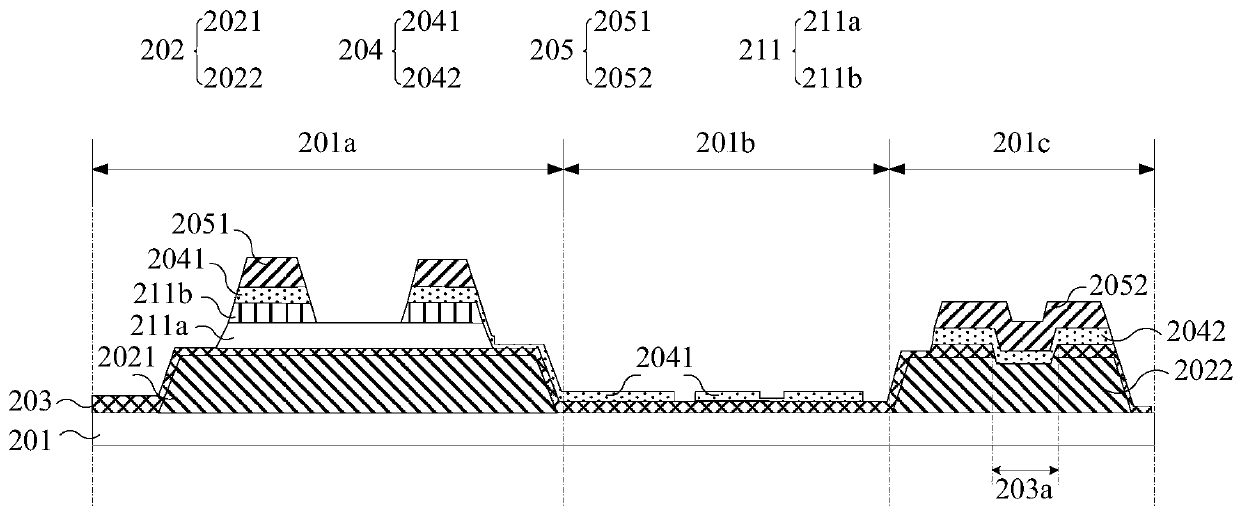

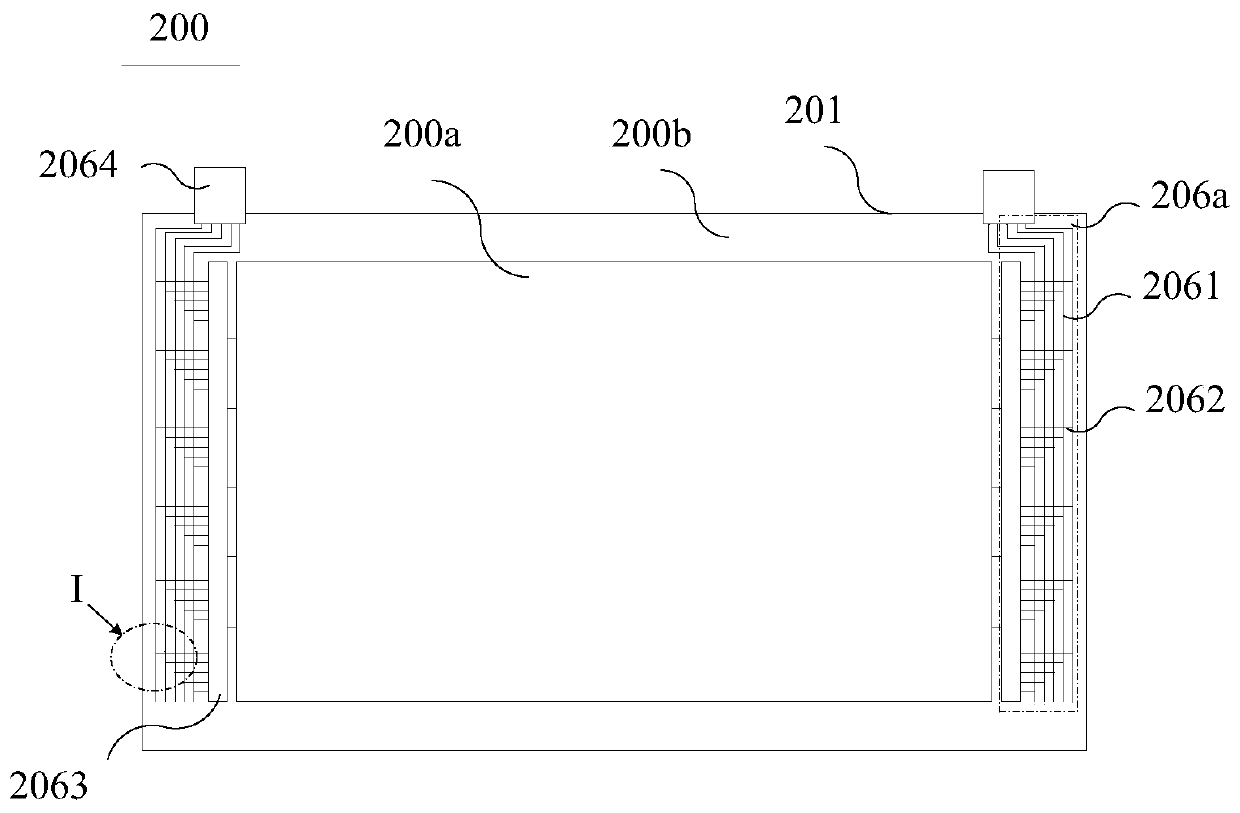

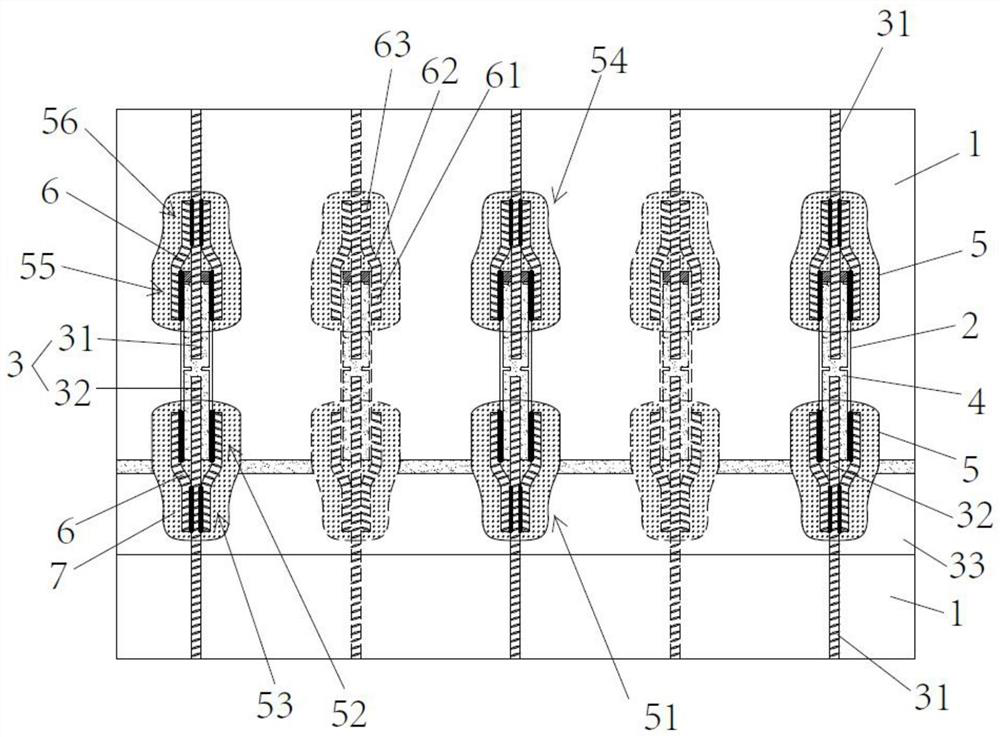

Array substrate, preparation method thereof and display panel

ActiveCN111129036AReduce contact resistanceShorten the lap lengthSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMaterials science

The invention discloses an array substrate, a preparation method and a display panel, and the array substrate comprises: a substrate which is provided with a first region, a second region and a thirdregion; a first metal layer including a first metal member provided in a first region of the substrate and a second metal member provided in a third region of the substrate; a first insulating layer covering the first metal layer and the substrate, wherein a through hole is formed in the position, corresponding to the third area, of the first insulating layer; a conducting layer which comprises afirst conducting part arranged in the first area and the second area and a second conducting part arranged in the third area, wherein at least part of the second conducting part is connected with thesecond metal component through the through hole; and a second metal layer which comprises a third metal component arranged in the first region and a fourth metal component arranged in the third region, wherein the fourth metal component is connected with the second conductive part, so that the contact impedance between the first metal layer and the second metal layer is reduced, the problem that the display panel is easy to generate a gradient line is improved, and the display quality of the display panel is improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

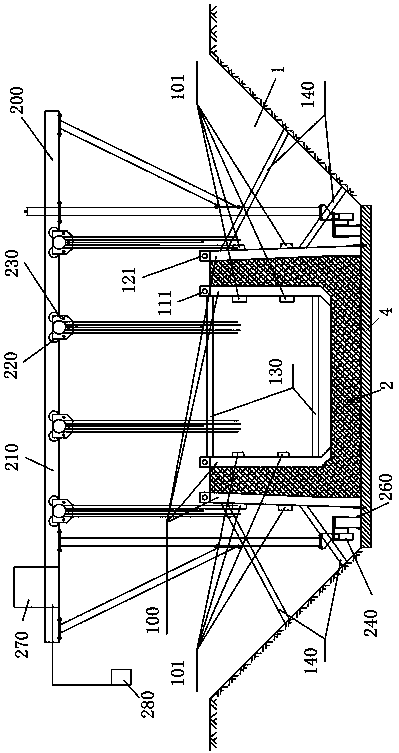

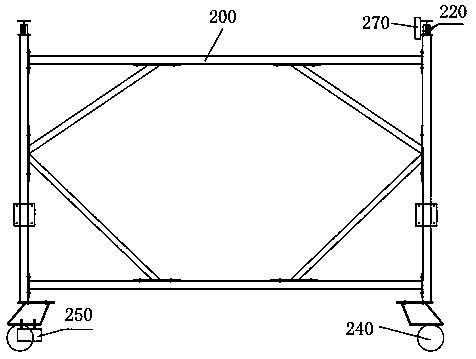

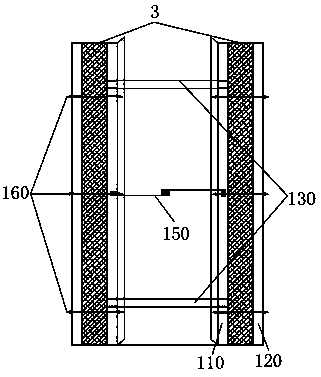

Cable trench construction method using integral movable formwork device

PendingCN109149497AIncrease stiffnessHigh strengthArtificial islandsCable installations in underground tubesRebarMoving frame

The invention relates to a cable trench construction method adopting an integral movable formwork device, comprising the following steps: laying a cushion layer in a foundation pit of the cable trench; The reinforcing bar of the cable trench is bound on the cushion layer, and the welding of the embedded parts is completed; Laying guide rails on both outer sides of the steel bar; Installing a portal movable frame of an integral movable formwork device and hoisting a cable trench steel formwork for cable trench casting molding, wherein the portal movable frame is provided with a hoisting mechanism for hoisting the cable trench steel formwork; Complete the support of cable trench steel formwork; Concrete is poured into the steel formwork of the cable trench; Demoulding of the cable trench steel formwork one day after the cable trench pouring is completed; Moving the steel formwork of the cable trench to the side of the reinforcing bar of the next section to be poured through the portal moving frame; Until the cable trench is finished. The cable trench construction method adopting the integral movable formwork device is conducive to improving the cable trench molding efficiency and good molding effect.

Owner:洪火权 +3

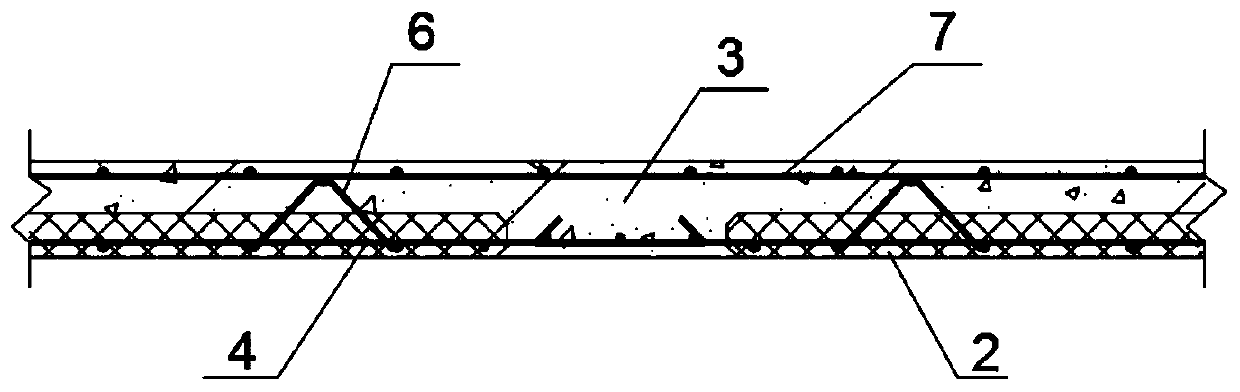

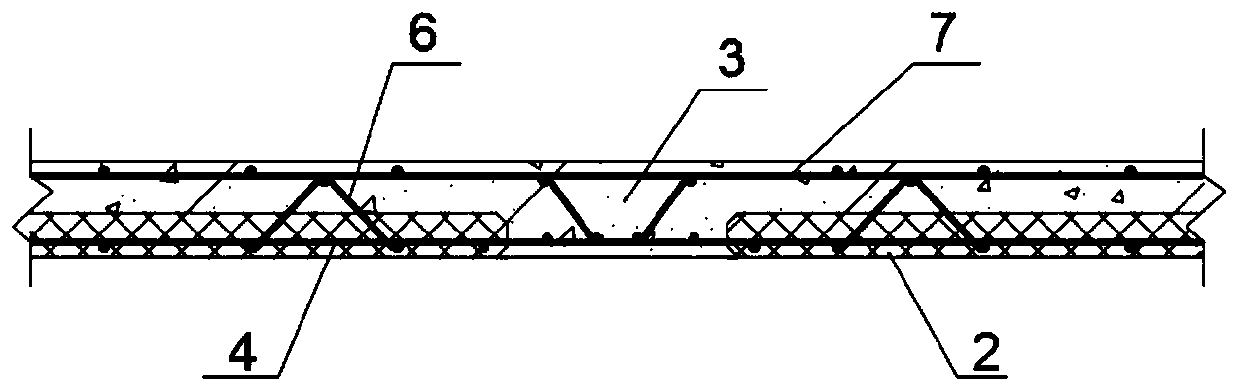

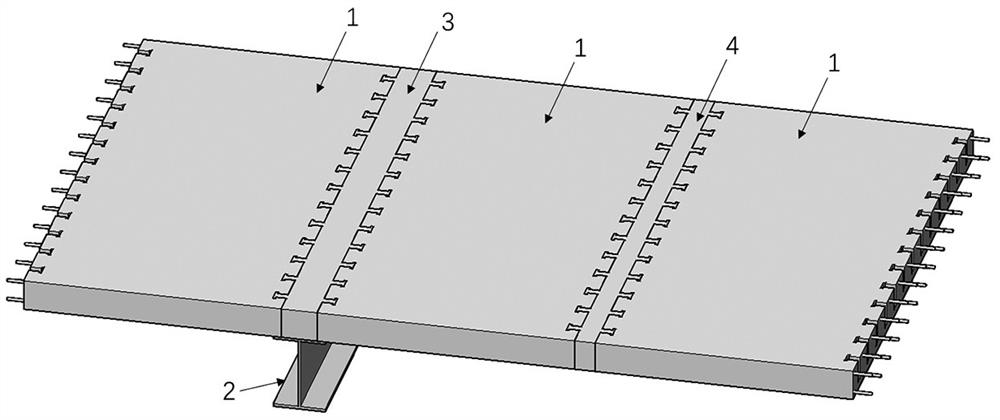

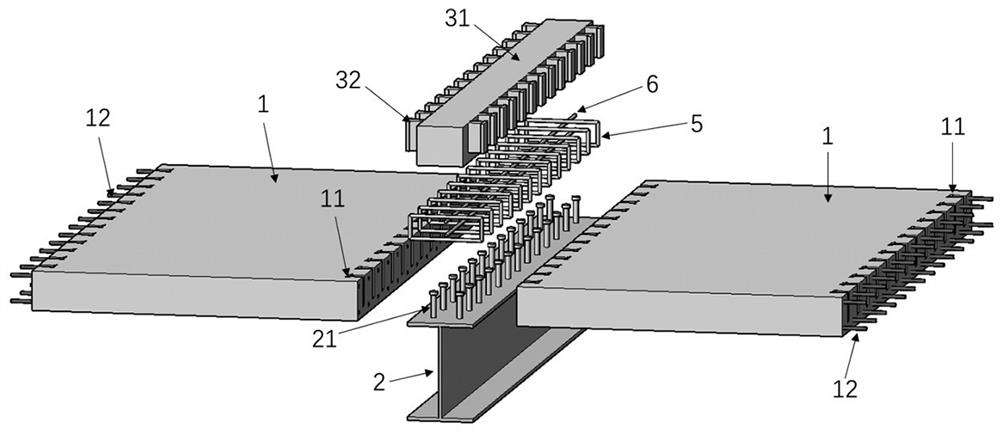

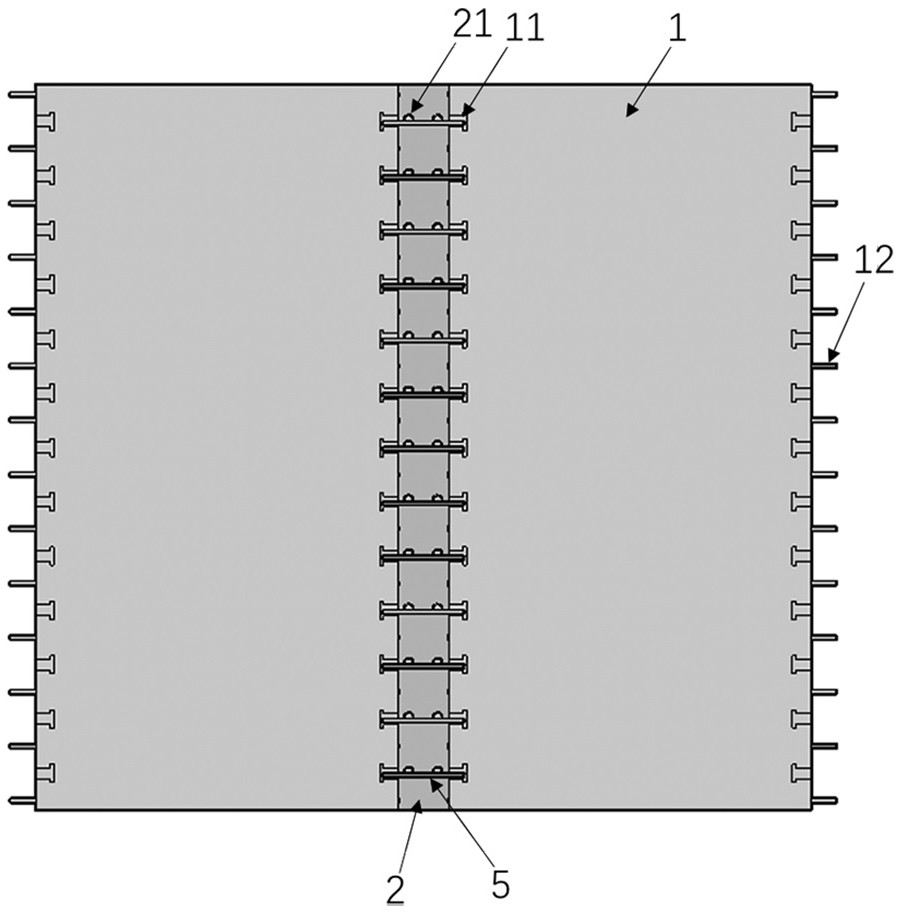

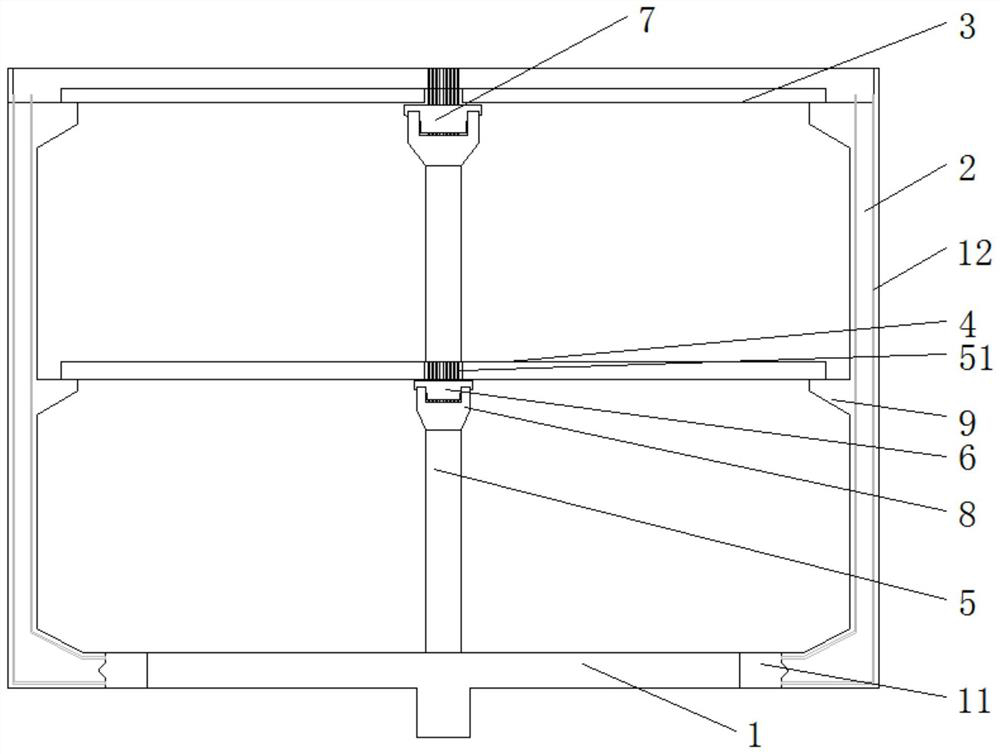

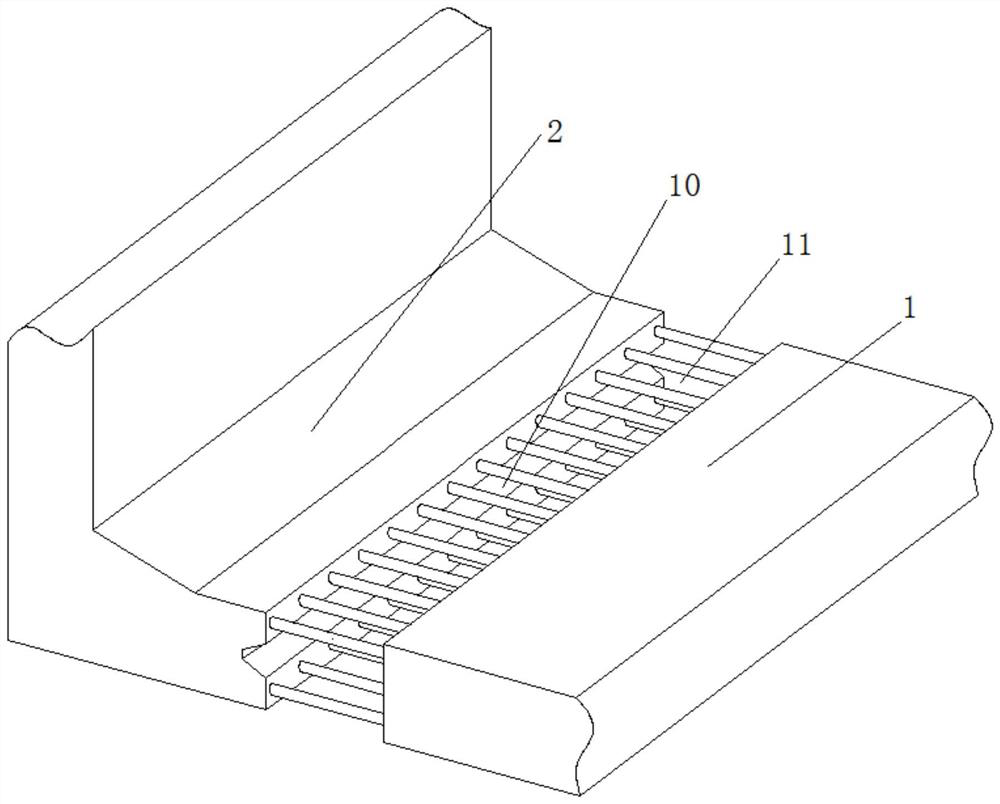

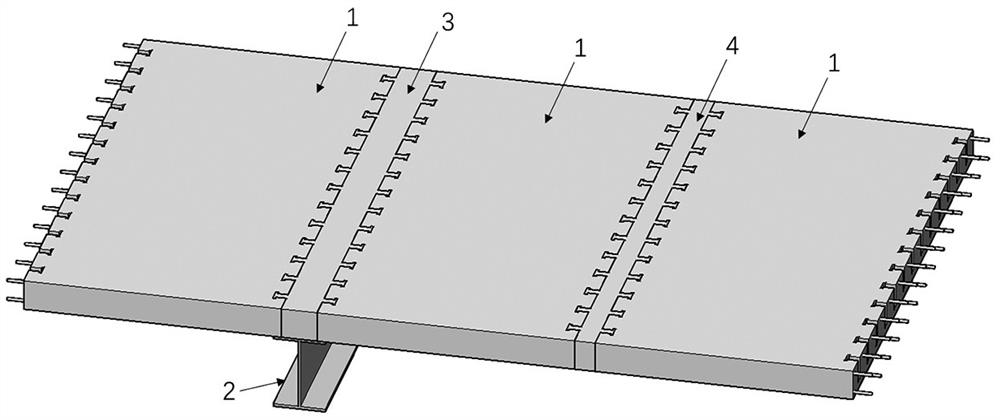

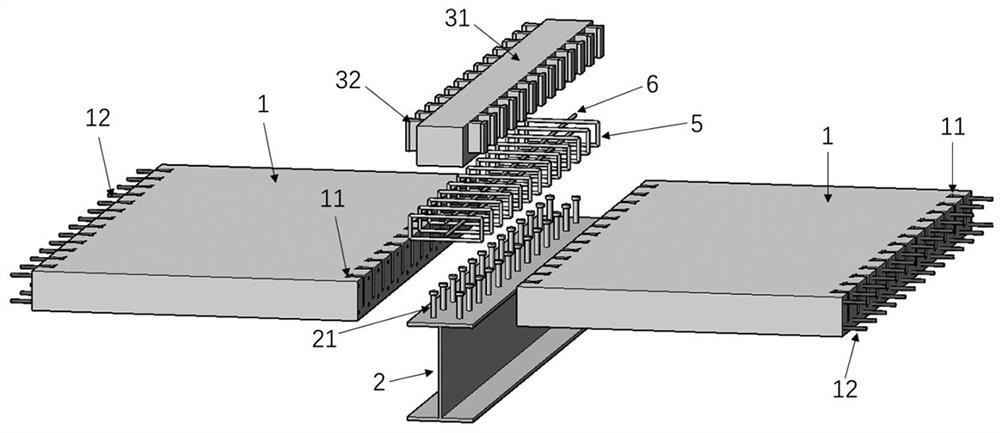

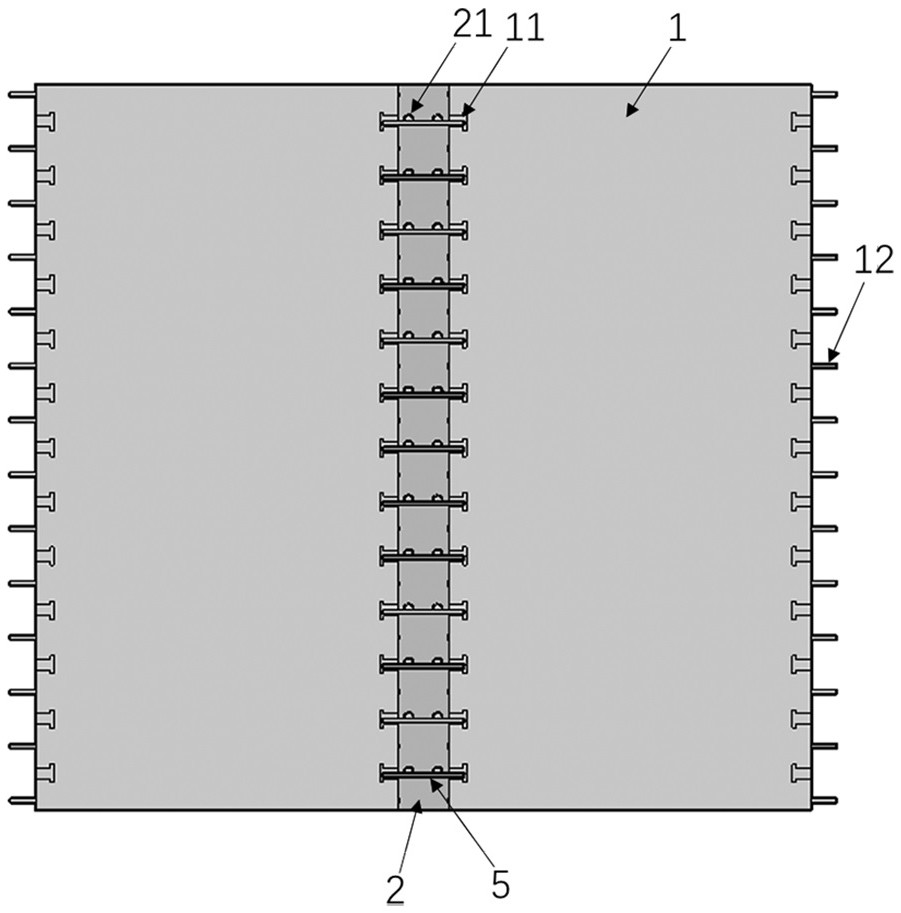

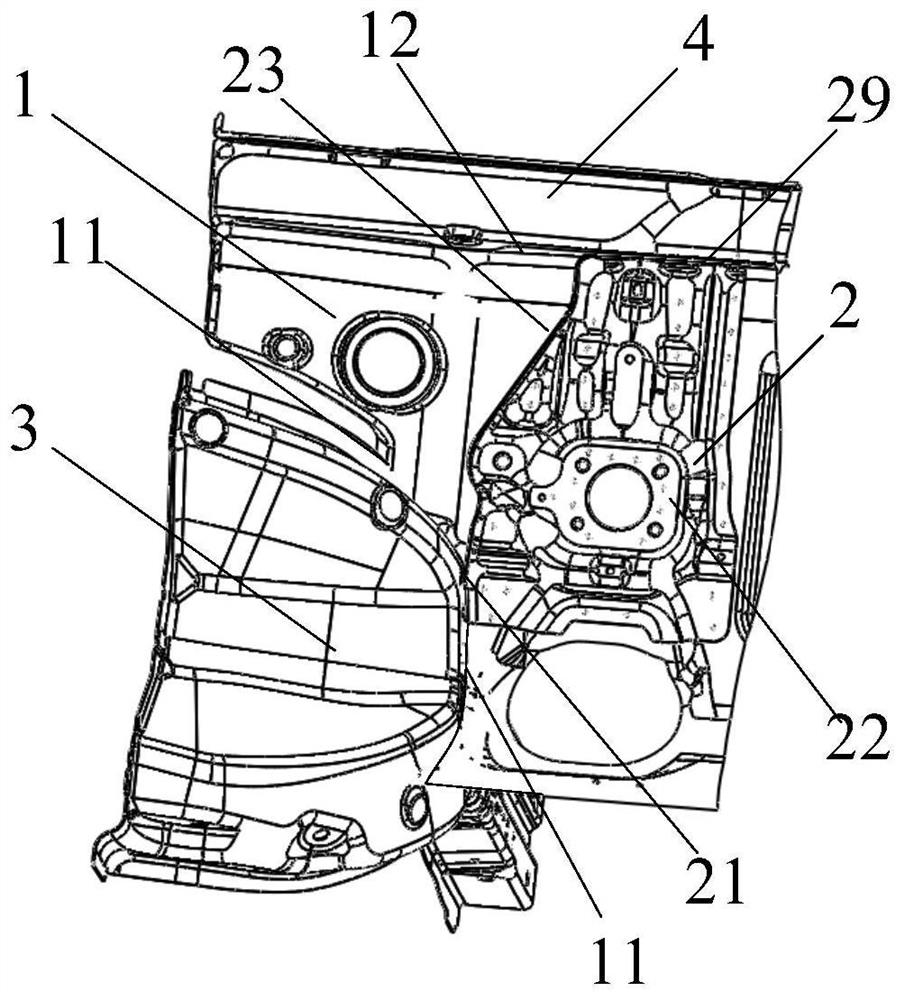

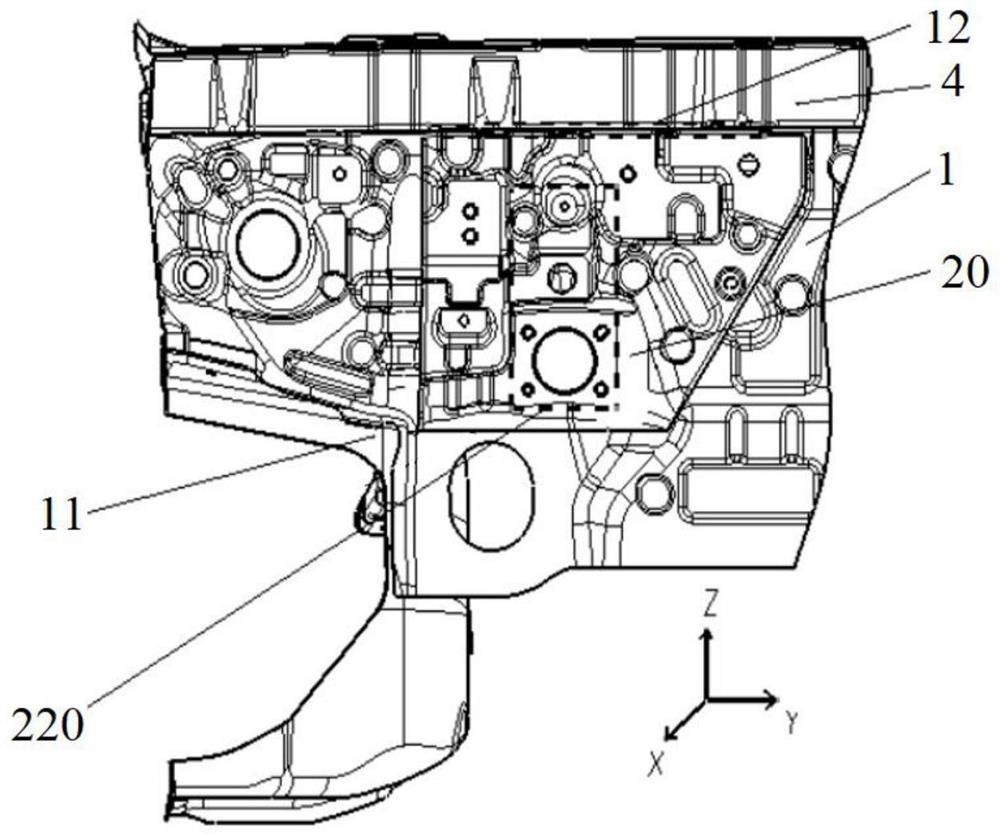

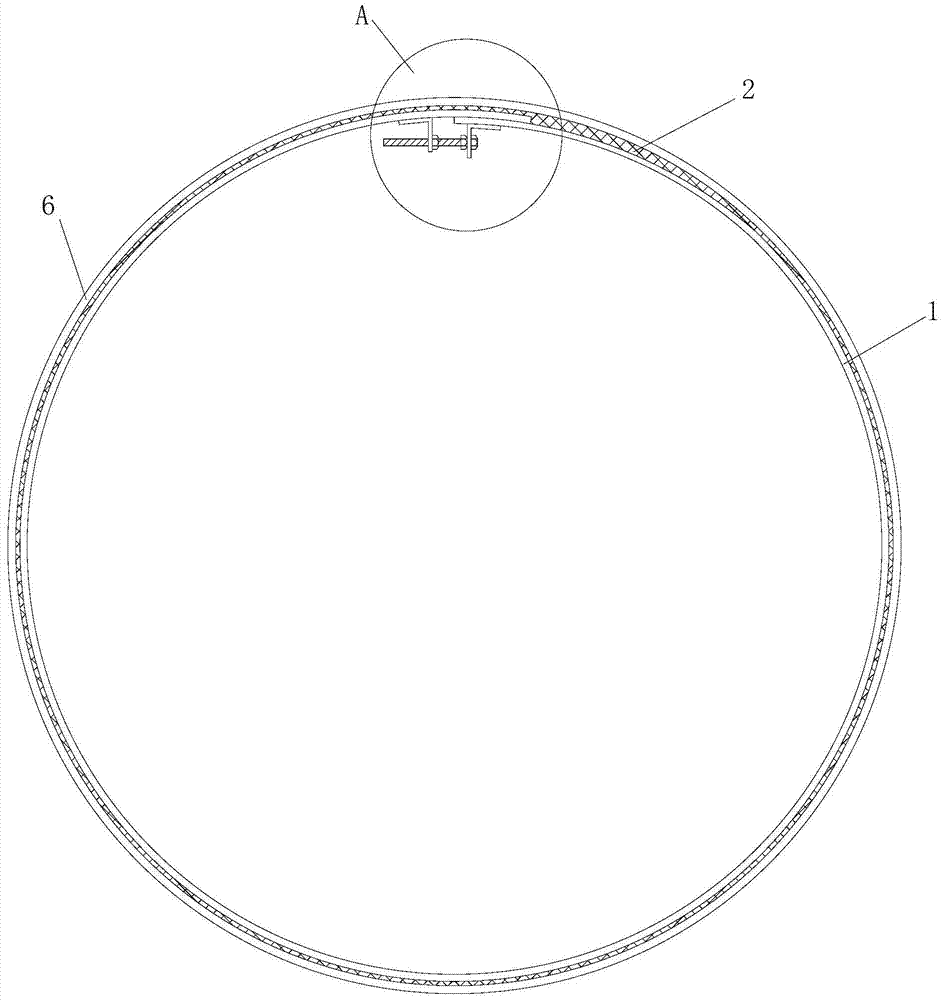

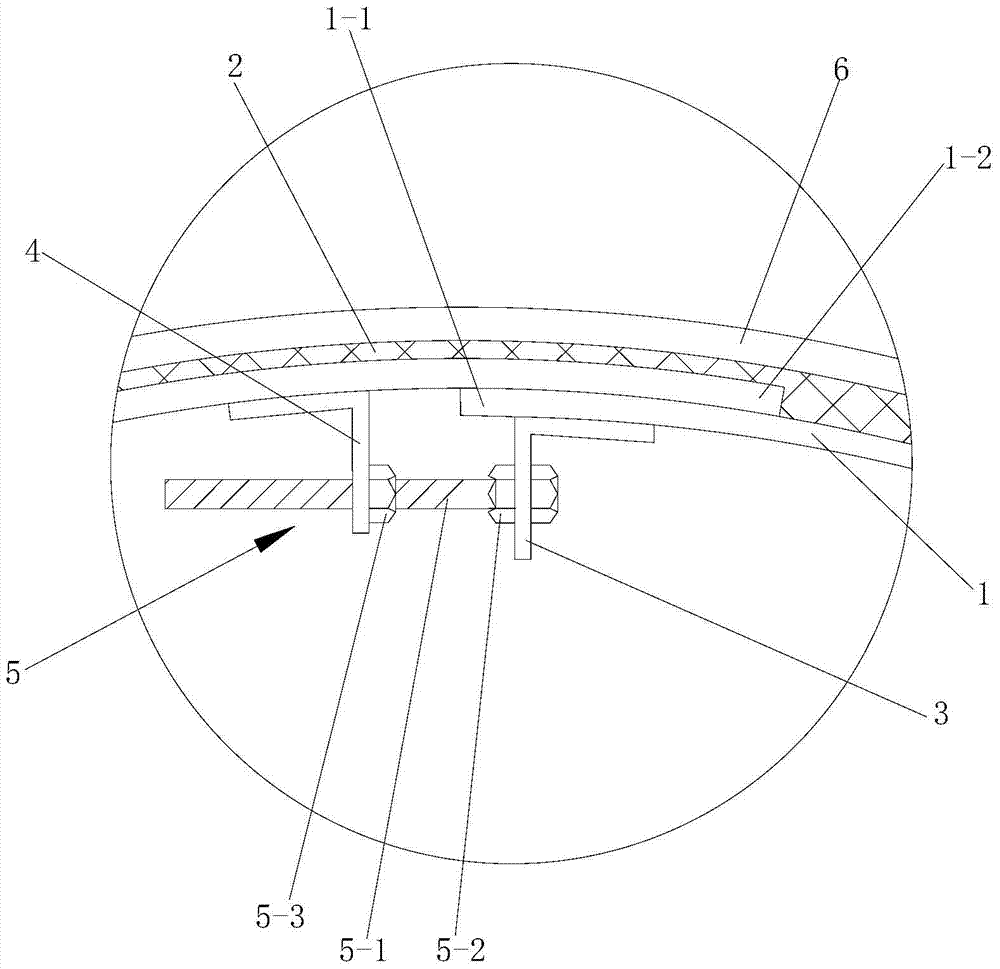

Full-prefabricated assembly type steel-concrete composite floor system and design calculation method

ActiveCN113202219AIncreased shear strengthGuaranteed carrying capacityGeometric CADFloorsFloor slabArchitectural engineering

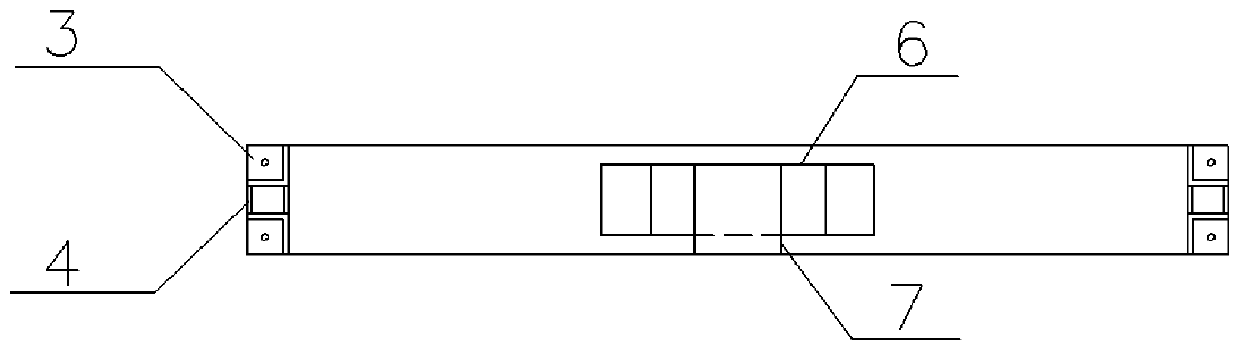

The invention discloses a full-prefabricated assembly type steel-concrete composite floor system and a design calculation method. The floor system comprises prefabricated concrete floors (1), an H-shaped steel beam (2), beam-slab UHPC tenon-and-mortise connection nodes (3) and slab-slab UHPC tenon-and-mortise connection nodes (4), wherein shear-resistant slotted holes (11) are formed in the two sides of each prefabricated concrete floor (1) in the slab thickness direction; stud connecting pieces (21) are welded on the upper flange of the H-shaped steel beam (2); the two prefabricated concrete floors (1) are connected with the H-shaped steel beam (2) through the beam-slab UHPC tenon-and-mortise connection nodes (3); and every two adjacent prefabricated concrete floors (1) are connected through the plate-plate UHPC tenon-and-mortise connection nodes (4). According to the design provided by the invention, the ultra-high performance concrete UHPC is adopted for connection between the prefabricated concrete floors and the H-shaped steel beam and connection between the prefabricated concrete floors, and the fabricated floor system has the advantages of simple structure, reliable performance, convenience and rapidness in construction, green and environmental protection, and the like.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

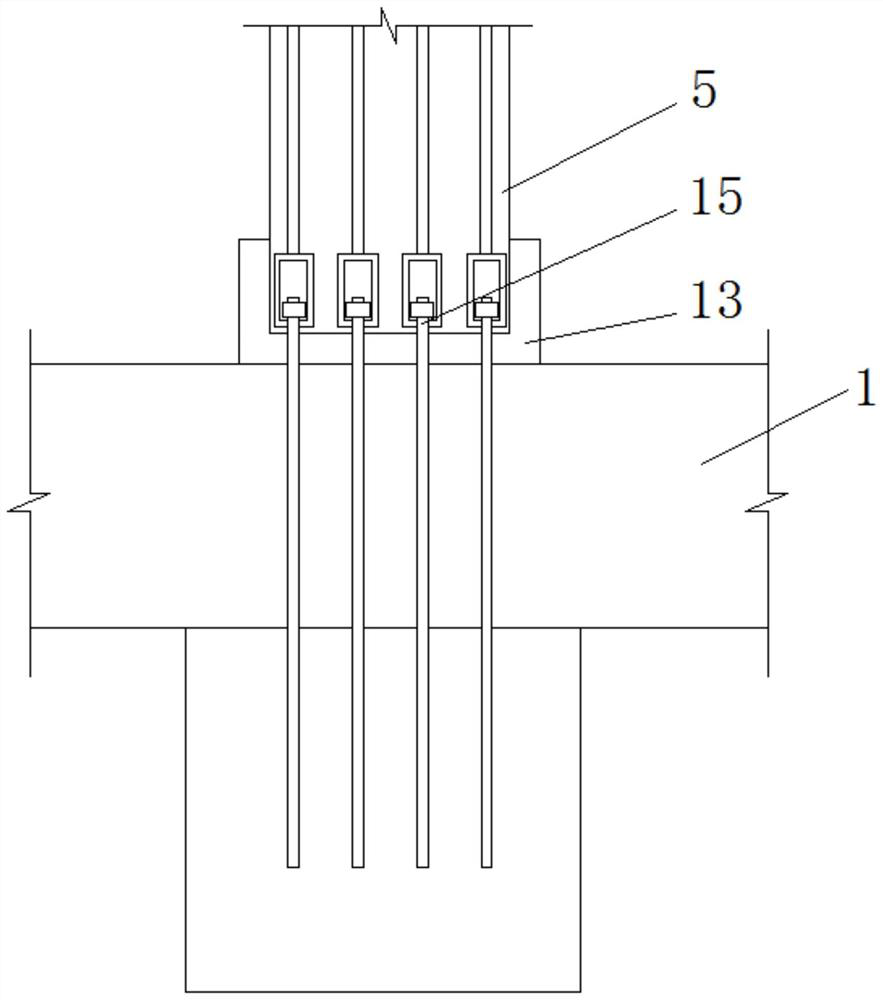

Reinforcing structure for truncation of connecting reinforcing steel bars in sleeves and construction method thereof

ActiveCN111350311AReduce gougingAvoid damageBuilding reinforcementsBuilding material handlingFloor slabLap joint

The invention discloses a reinforcing structure for truncation of connecting reinforcing steel bars in sleeves. The reinforcing structure is used for repairing sleeve grouting joints between prefabricated shear walls, at reinforcing positions, upper connecting parts of the two pre-bent connecting reinforcing steel bars are in lap joint with and welded to the single faces of the two sides of the outer walls of the lack-of-bar sleeves to form weld joints correspondingly, and lower connecting parts of the two pre-bent connecting reinforcing steel bars are in lap joint with and welded to the single faces of the two sides of the lower connecting reinforcing steel bars to form weld joints correspondingly; shear wall chiseling areas and floor chiseling areas are filled with ultrahigh-performanceconcrete; and the prefabricated shear walls and the adjacent lower layers of prefabricated shear walls are connected into a whole at the lack-of-bar sleeves through the upper connecting reinforcing steel bars, the lack-of-bar sleeves, the pre-bent connecting reinforcing steel bars, the lower connecting reinforcing steel bars, grouts, the weld joints and the ultrahigh-performance concrete. The invention further provides a reinforcing method for guiding construction and meeting the reinforcing requirement. The reinforcing structure is little in damage to the original structure, simple in reinforcing connection mode and controllable in cost.

Owner:KUNSHAN CONSTRUCT ENG QUALITY TESTING CENT

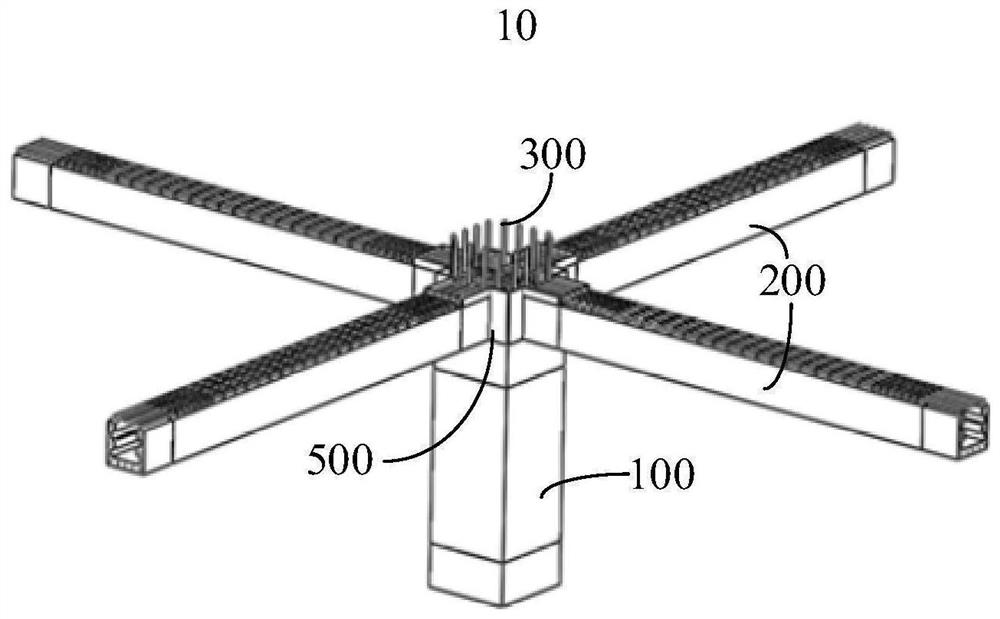

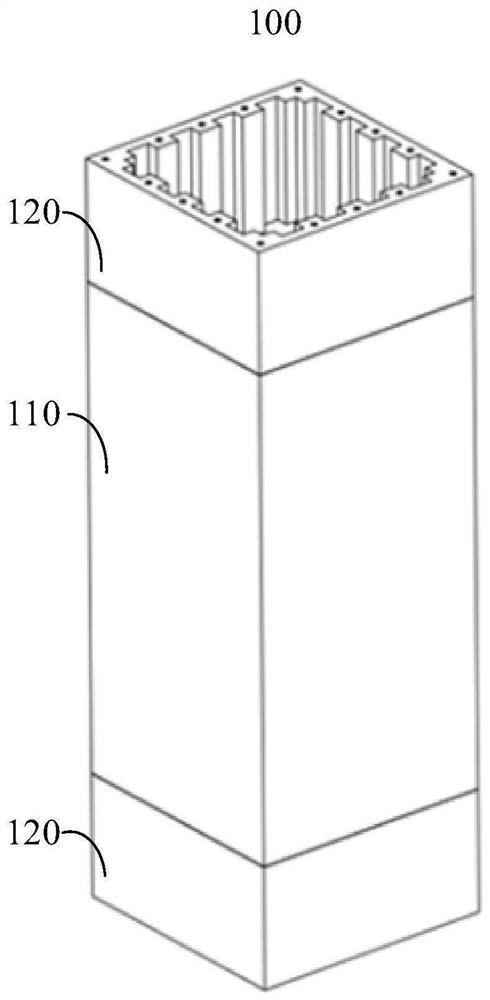

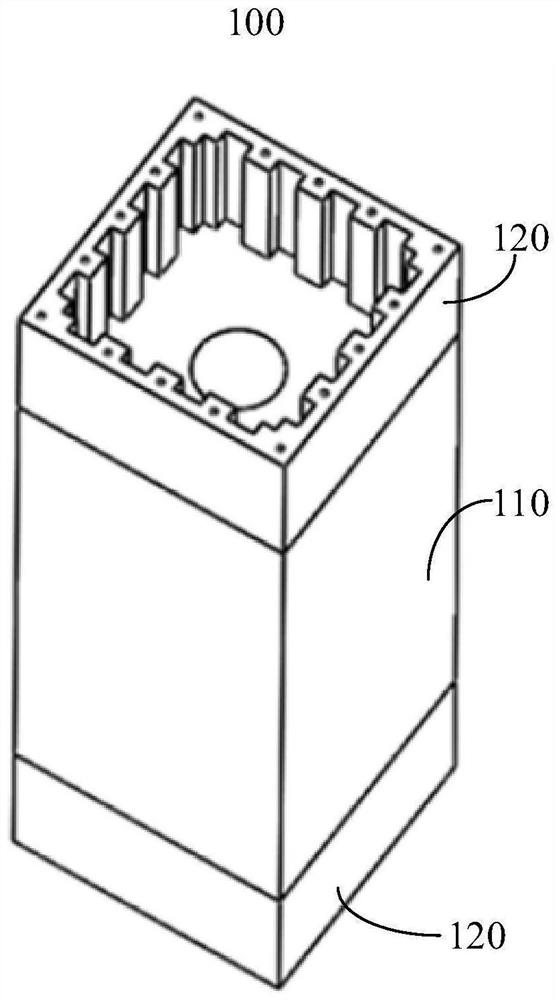

Fabricated beam-column connecting joint and construction method thereof

PendingCN113638491AActive connectionAvoid conflict situationsBuilding constructionsClassical mechanicsLap joint

The invention relates to a fabricated beam-column connecting joint and a construction method. The connecting joint comprises a prefabricated beam and a prefabricated column, wherein a joint core area is formed at the joint of the prefabricated beam and the prefabricated column, column longitudinal bars are arranged on the prefabricated column, the column longitudinal bars of the adjacent prefabricated columns are in lap joint in the joint core area, the prefabricated column is arranged in the joint core area, and a high-strength material is poured in the joint core area to form a post-pouring core area. Compared with the prior art, the connecting joint has the advantages of direct and reliable force transmission, convenience in construction and the like.

Owner:HUADONG BUILDING CO LTD OF CHINA CONSTR FIFTH ENG BUREAU +3

UHPC-based fabricated combined beam-column joint and construction method thereof

ActiveCN112900620ACost controlImprove mechanical propertiesStrutsFloorsEarthquake resistanceArchitectural engineering

The invention relates to a UHPC-based fabricated combined beam-column joint and a construction method thereof. The UHPC-based fabricated combined beam-column joint comprises a prefabricated column, a prefabricated beam and a joint post-pouring area; the mechanical property of the column end of the prefabricated column is higher than that of the column middle; the mechanical property of the beam end of the precast beam is higher than that of the beam middle; and a longitudinal lap-joint steel bar of the joint post-pouring area is in pouring connection with the column end, and a transverse lap-joint steel bar is in pouring connection with the beam end. According to the UHPC-based fabricated combined beam-column joint and the construction method thereof, stirrups for enhancing the structural strength do not need to be arranged in the joint post-pouring area, the beam end and the column end; the longitudinal bar lap-joint length of the prefabricated beam and the prefabricated column can be greatly reduced compared with common concrete; the longitudinal bars of the prefabricated column do not need sleeve connection; the upper steel bars of the prefabricated column and the prefabricated beam are almost not exposed; and the UHPC-based fabricated combined beam-column joint is convenient to construct, the using amount of concrete (such as ultra-high performance concrete) with high mechanical performance is small, and good comprehensive economic benefits and anti-seismic performance are achieved.

Owner:TSINGHUA UNIV

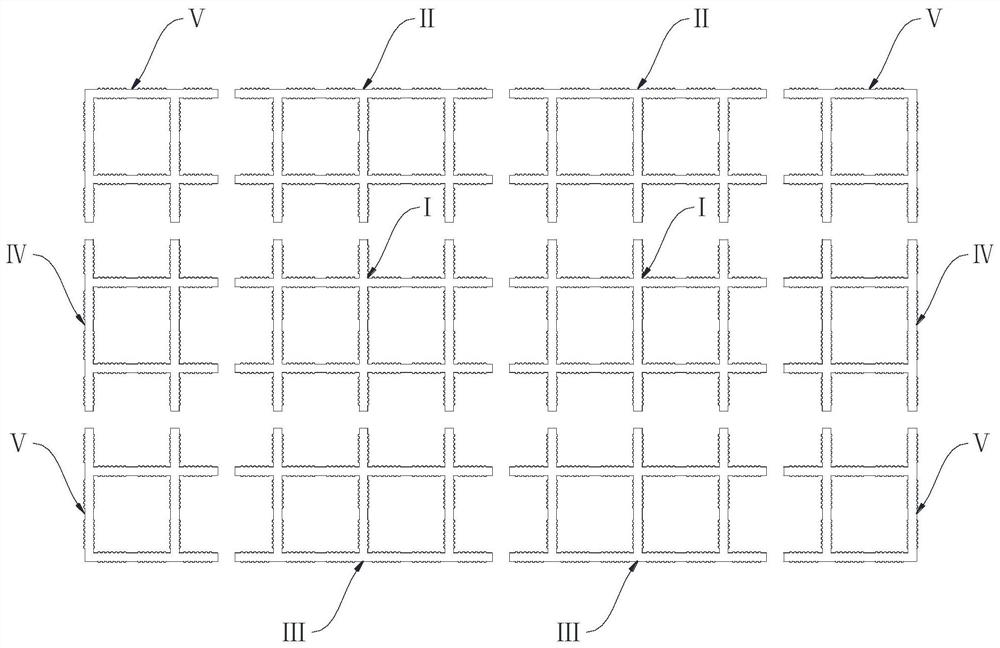

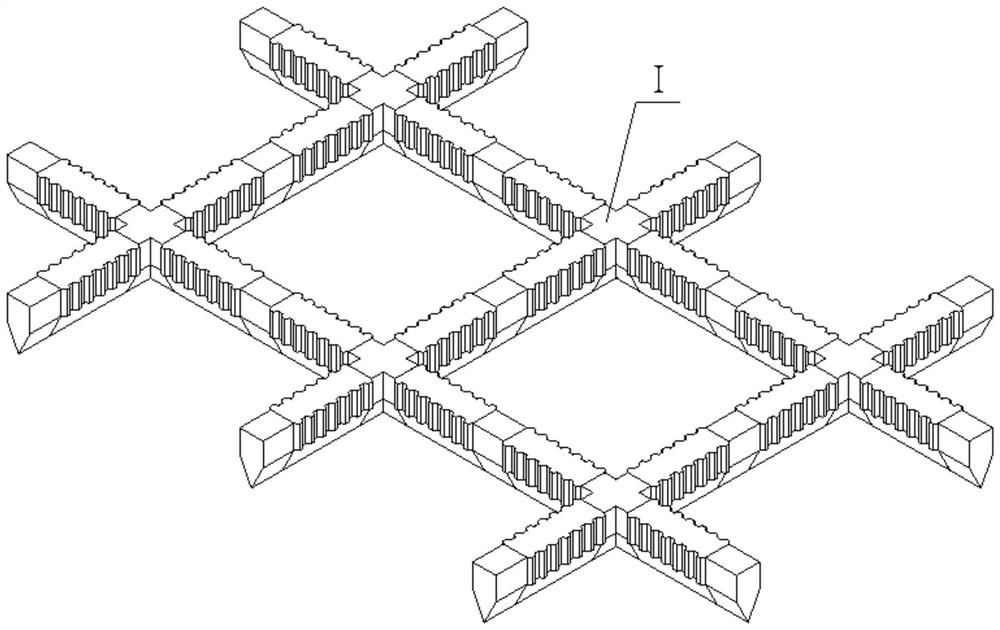

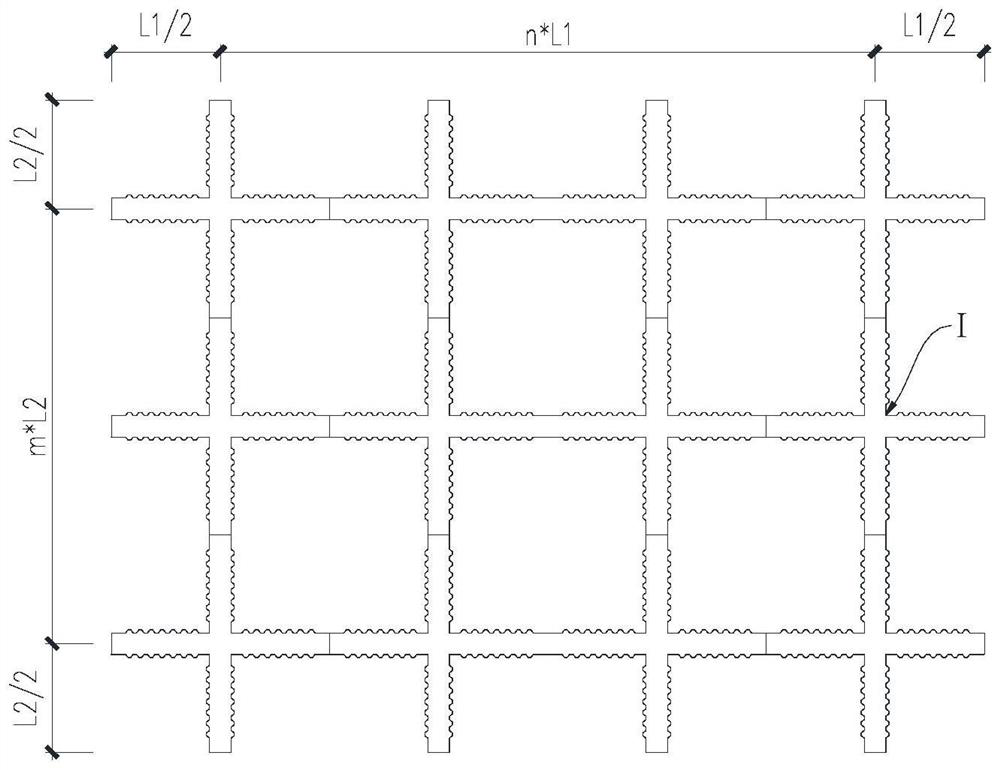

Fabricated sash beam and fabricated rectangular arrangement side slope protection structure

PendingCN112746621ALess Lashing WorkReduce excavationExcavationsReinforced concreteClassical mechanics

The invention discloses a fabricated sash beam and a fabricated rectangular arrangement side slope protection structure, and relates to the field of side slope engineering. The problems that a cast-in-place reinforced concrete sash beam is multiple in construction steps, complex in technological process and multiple in quality control points, and the engineering quality is difficult to guarantee are solved. According to the technical scheme, the fabricated sash beam comprises five modules, namely a middle assembly module, a top assembly module, a bottom assembly module, a side edge assembly module and a corner assembly module, and at least one rectangular sash is formed by cross beams and longitudinal beams of each module; and joints are respectively reserved in the five modules. The five modules can be spliced on the side slope to form a rectangular slope protection structure. A cast-in-place sash beam is converted into a fabricated structure, five modules are prefabricated and maintained in engineering, and on-site formwork supporting and reinforcing steel bar binding work is reduced; and the five modules are installed on the stable slope surface in an embedded mode, the foundation trench excavation volume is reduced, and the product quality is improved.

Owner:POWERCHINA CHENGDU ENG

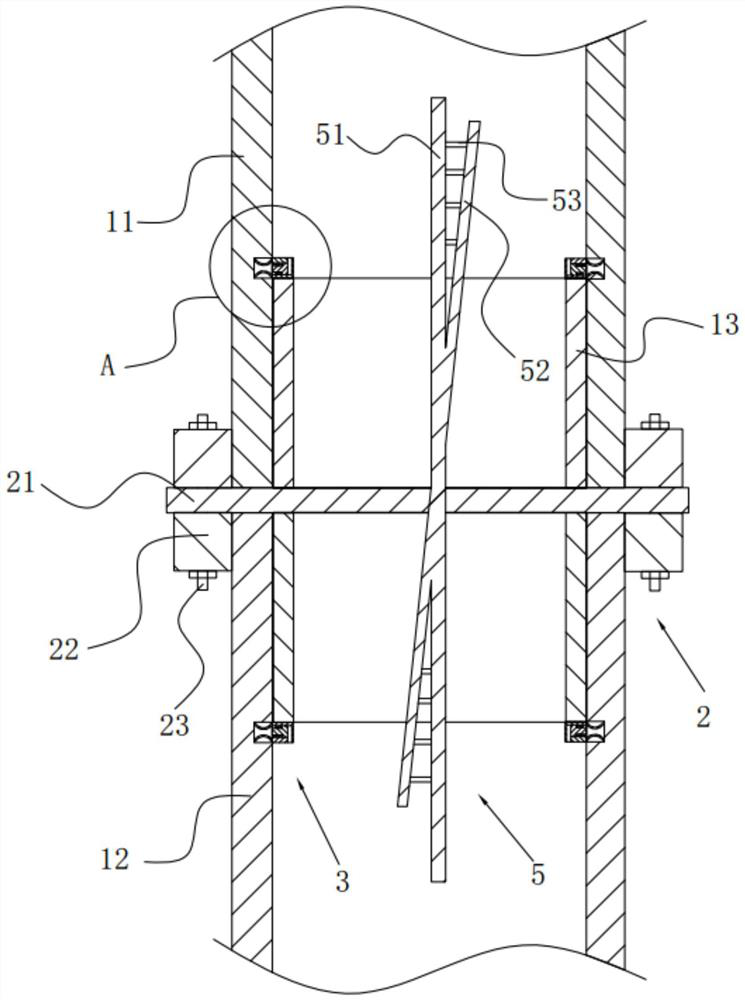

Assembled integral type subway station structure

PendingCN114875965AEasy to transportImprove integrityArtificial islandsProtective foundationArchitectural engineeringSubway station

The invention discloses an assembled integral subway station structure which comprises a cast-in-place bottom plate, prefabricated side walls, a prefabricated top plate, a prefabricated middle plate, a prefabricated middle column, a middle longitudinal beam and a top longitudinal beam. The prefabricated side walls are arranged on the two sides of the cast-in-place bottom plate, and the prefabricated middle column is arranged on the middle side of the upper portion of the cast-in-place bottom plate; the top longitudinal beam and the middle longitudinal beam are arranged on the upper portion and the middle of the prefabricated middle column respectively, and the prefabricated middle column is a double-layer integrated segment column. According to the assembled integral type subway station structure, through organic combination of a prefabricated structure and cast-in-place and UHPC post-pouring at the joints, rigid connection of the joints is achieved, the structural integrity is good, safety and reliability are achieved, compared with full prefabrication, components are lighter, transportation and hoisting are convenient, the requirement for prefabrication and installation precision is low, the construction period can be shortened by 20%, and mold-free and support-free effects are basically achieved; and the on-site labor amount is reduced.

Owner:青岛中科坤泰装配建筑科技有限公司

A fully prefabricated steel-concrete composite floor system and its design calculation method

ActiveCN113202219BIncreased shear strengthGuaranteed carrying capacityGeometric CADFloorsFloor slabArchitectural engineering

The invention discloses a fully prefabricated assembled steel-concrete composite floor system and a design calculation method. The floor system includes a prefabricated concrete floor (1), H-shaped steel beams (2), beam-slab UHPC mortise and tenon connection nodes ( 3) UHPC mortise and tenon connection joints (4) with slabs, in which: the two sides of the precast concrete floor (1) are provided with shear slots (11) along the thickness direction of the slab; the upper flange of the H-shaped steel beam (2) is Stud connectors (21) are welded; two precast concrete floors (1) and H-shaped steel beams (2) are connected by beam-slab UHPC mortise and tenon joints (3); between two adjacent precast concrete floors (1) The board-to-board UHPC mortise and tenon joints (4) are used to connect. The design of the present invention adopts ultra-high-performance concrete UHPC to connect the prefabricated concrete floor, the H-shaped steel beam and the prefabricated concrete floor. The prefabricated floor system has the advantages of simple structure, reliable performance, convenient and fast construction, and environmental protection.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

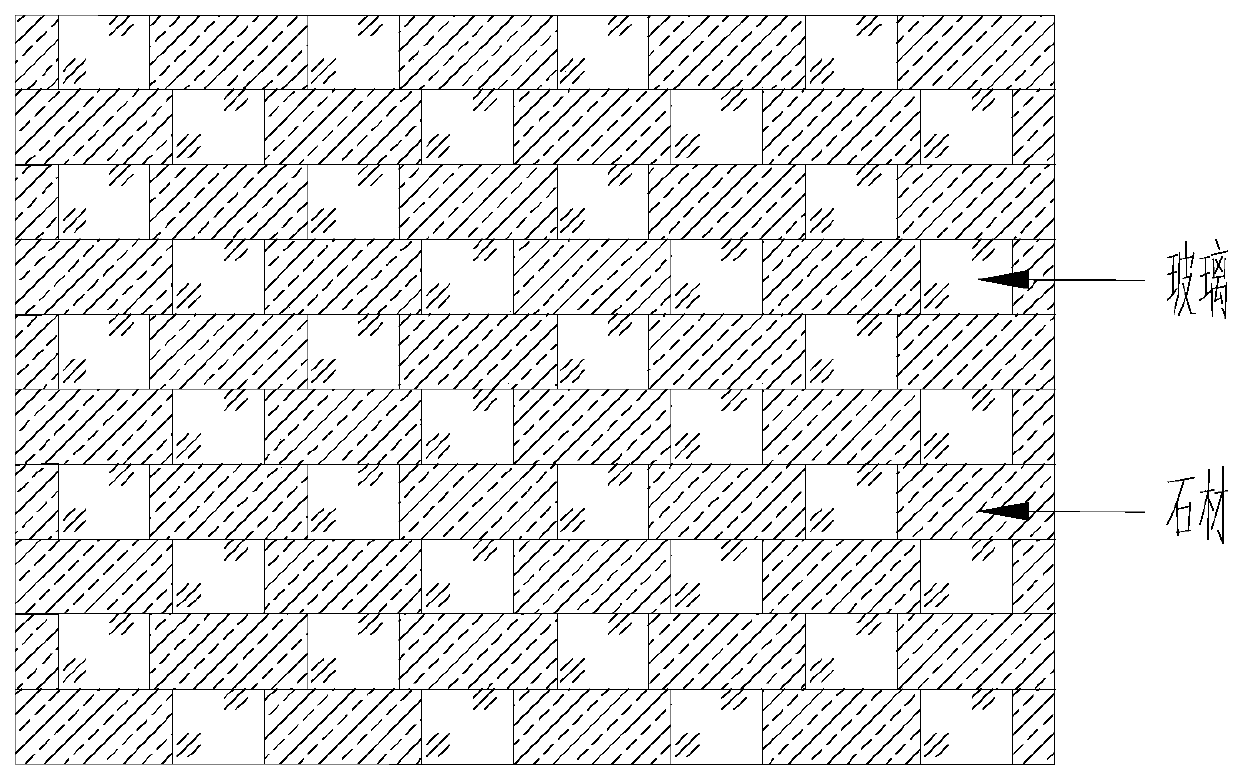

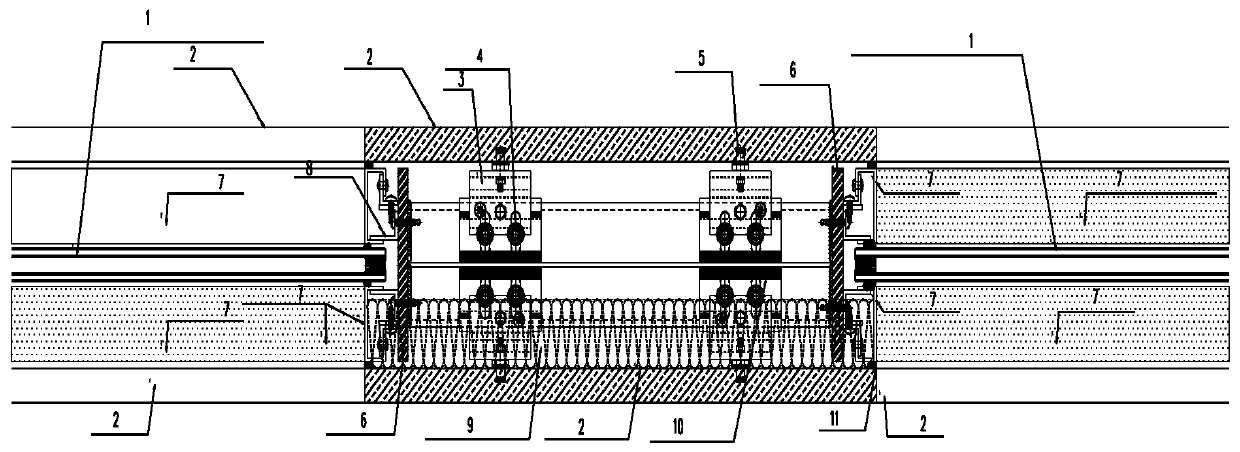

Novel hollow type curtain wall

The invention discloses a novel hollow type curtain wall. The novel hollow type curtain wall comprises stone, hollow tempered glass, aluminum single plates, aluminum alloy pendants I, aluminum alloy pendants II, stainless steel bolts, stainless steel back bolts, vertical steel plates, aluminum alloy angle codes, transverse steel angles, foam strips, weather-resistant sealant and transverse steel plates, wherein each transverse steel plate is connected between each two adjacent vertical steel plates, the hollow tempered glass is clamped between the aluminum single plates on two sides, the aluminum single plates are connected onto the transverse steel plates through the angle codes, each transverse steel angle is connected between each two adjacent vertical steel plates, each transverse steel angle and each aluminum alloy pendant II are connected through each bolt, and the aluminum alloy pendants I are connected with the stone vertically arranged on the outer side through the stainless steel back bolts. The novel hollow type curtain wall uses the steel plates for forming a keel, reduces the overlapping length between each two adjacent units to the utmost, and guarantees perfect effect. The aluminum alloy angle codes and the aluminum single plates form grooves used for fixing the glass, and therefore the novel hollow type curtain wall guarantees the exterior decoration effects ofbeing smooth, and concise and elegant. The stone is fixed on the keel through the steel angles, and therefore the keel structure cannot be exposed.

Owner:无锡金城幕墙装饰工程有限公司

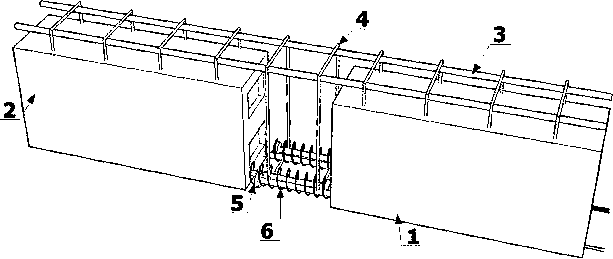

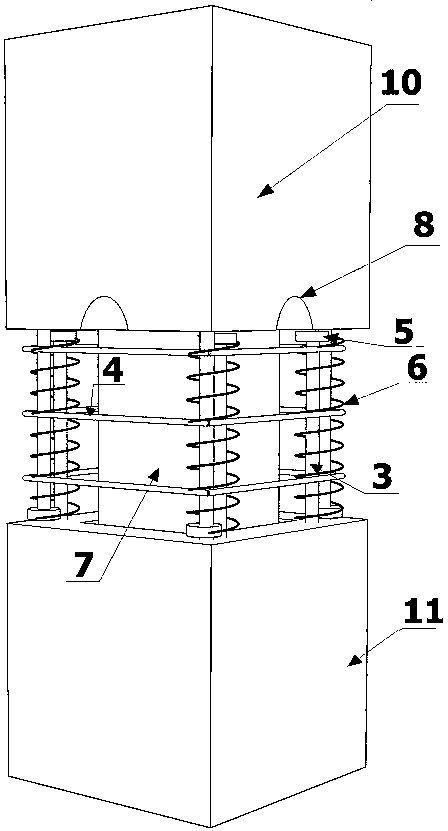

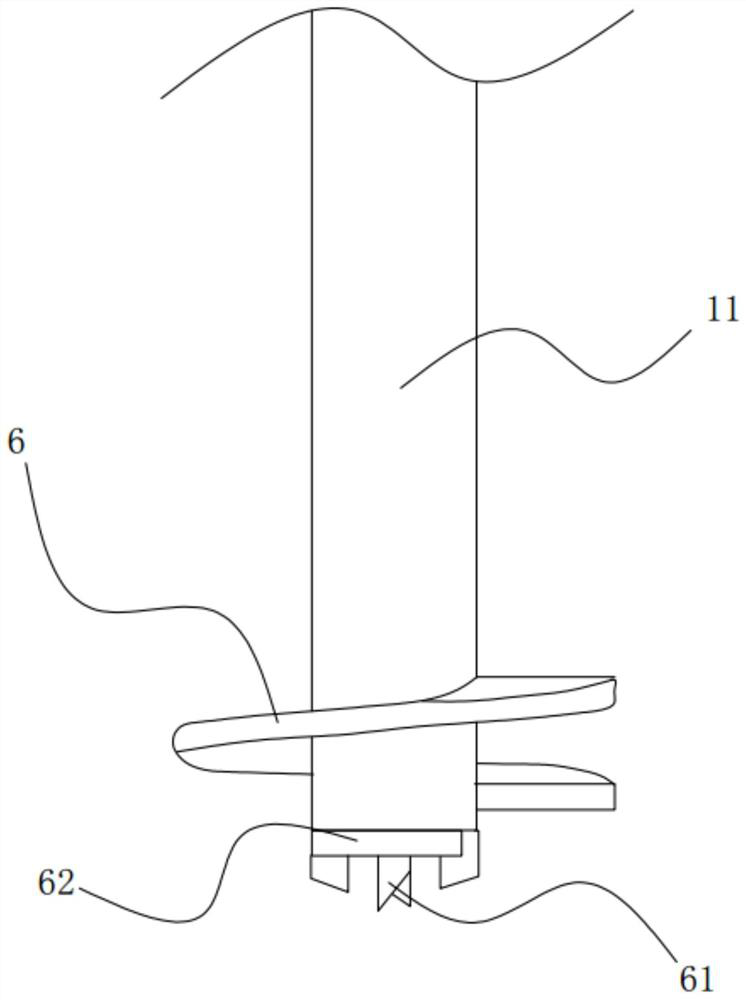

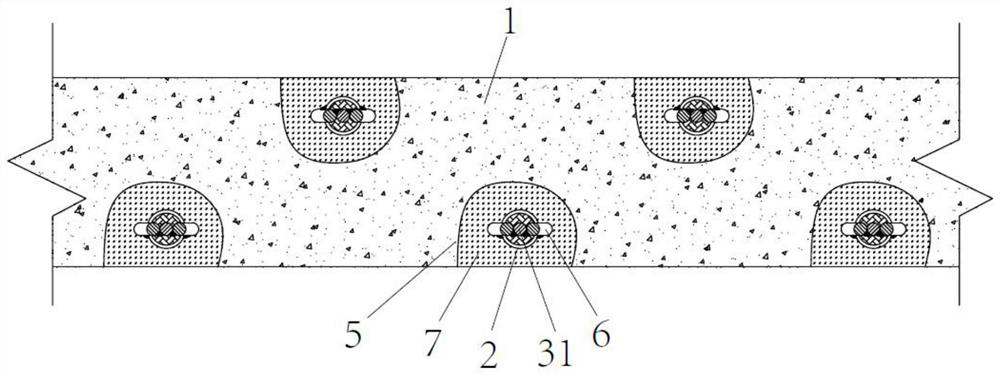

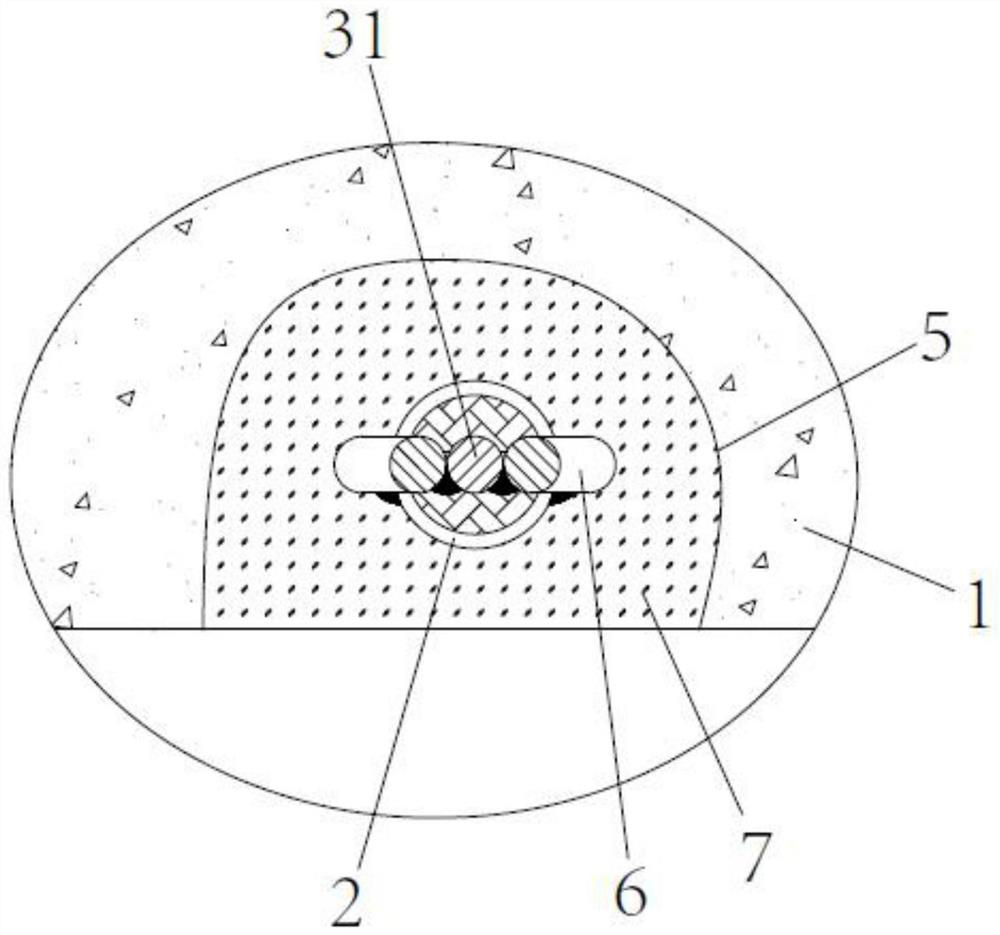

Fabricated high-strength and high-ductility concrete sleeve-free connection structure and method

The invention provides a fabricated high-strength and high-ductility concrete sleeve-free connection structure and method. The fabricated high-strength and high-ductility concrete sleeve-free connection structure comprises prefabricated reinforced concrete beams, the prefabricated reinforced concrete beams comprise hoop ribs and lap joint section longitudinal ribs arranged on the lower portions ofthe beams, the upper portions of the hoop ribs are exposed, and reserved hoop ribs are arranged on the outer sides of the lap joint section longitudinal ribs. The lower portions of the prefabricatedreinforced concrete beams are lapped joint in a staggered mode through the lap joint section longitudinal ribs, and spiral hoop ribs are arranged at the staggered lap joints of the lap joint section longitudinal ribs. The upper portions of the prefabricated reinforced concrete beams are connected through the hoop ribs sequentially penetrating through the reserved hoop ribs and arranged in the prefabricated reinforced concrete beams, the high-strength and high-ductility concrete is post cast in a lap joint section, and the concrete is post cast on the upper portions of the prefabricated reinforced concrete beams. The lap joint length of rebars can be sharply shortened by utilizing the superhigh strength and the adhesive performance of the high-strength and high-ductility concrete, usage ofthe reserved hoop ribs is reduced or even omitted, anchor bending of beam rebars is avoided, and the problem of rebar overcrowding in a joint area is solved. Because a sleeve is not used, factory manufacturing is convenient, mounting is convenient, specialized personnel are not needed, and the quality is easy to control.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

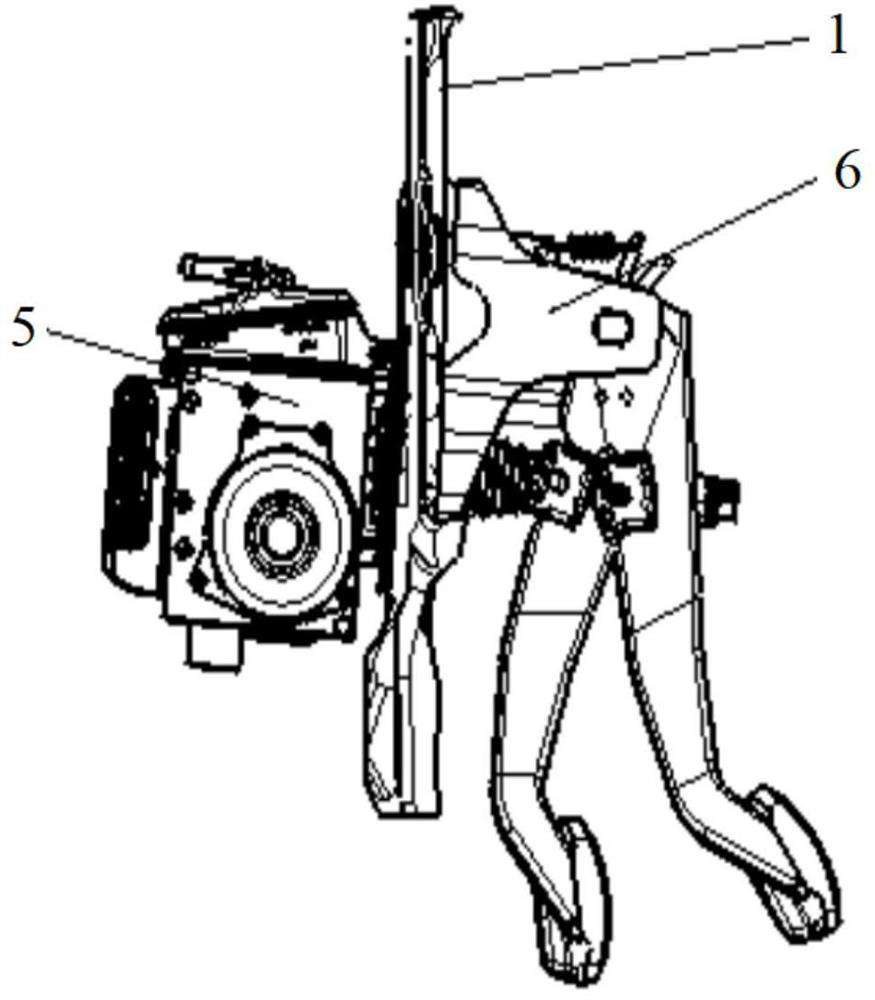

Intelligent integrated braking system mounting structure and mounting method thereof

ActiveCN113682381ANo mutual interferenceEasy to adjustSuperstructure subunitsWelding apparatusLap jointEngineering

The invention relates to the technical field of automobile bodies, in particular to an intelligent integrated braking system mounting structure and a mounting method.The intelligent integrated braking system mounting structure comprises a front wall plate and a reinforcing plate, the upper end of the front wall plate is used for being connected with a gutter channel, and the side edge of the lower end of the front wall plate is provided with a first lap joint edge used for being in lap joint with an engine compartment edge beam; the reinforcing plate is arranged on the inner side of the dash panel, the upper end of the reinforcing plate is used for being connected with the gutter channel, the side edge of the lower end of the reinforcing plate is provided with a second lap joint edge used for being in lap joint with the engine compartment edge beam, the second lap joint edge is located on the inner side of the first lap joint edge by a set distance, and the length of the first lap joint edge is larger than that of the second lap joint edge. The problem that in the prior art, a dash panel cannot meet the requirement for the installation strength of the intelligent integrated braking system can be solved.

Owner:VOYAH AUTOMOBILE TECH CO LTD

A reinforcement structure and construction method for the truncated connecting steel bars in the sleeve

ActiveCN111350311BReduce gougingAvoid damageBuilding reinforcementsBuilding material handlingFloor slabArchitectural engineering

The invention discloses a reinforcing structure for truncation of connecting reinforcing steel bars in sleeves. The reinforcing structure is used for repairing sleeve grouting joints between prefabricated shear walls, at reinforcing positions, upper connecting parts of the two pre-bent connecting reinforcing steel bars are in lap joint with and welded to the single faces of the two sides of the outer walls of the lack-of-bar sleeves to form weld joints correspondingly, and lower connecting parts of the two pre-bent connecting reinforcing steel bars are in lap joint with and welded to the single faces of the two sides of the lower connecting reinforcing steel bars to form weld joints correspondingly; shear wall chiseling areas and floor chiseling areas are filled with ultrahigh-performanceconcrete; and the prefabricated shear walls and the adjacent lower layers of prefabricated shear walls are connected into a whole at the lack-of-bar sleeves through the upper connecting reinforcing steel bars, the lack-of-bar sleeves, the pre-bent connecting reinforcing steel bars, the lower connecting reinforcing steel bars, grouts, the weld joints and the ultrahigh-performance concrete. The invention further provides a reinforcing method for guiding construction and meeting the reinforcing requirement. The reinforcing structure is little in damage to the original structure, simple in reinforcing connection mode and controllable in cost.

Owner:KUNSHAN CONSTRUCT ENG QUALITY TESTING CENT

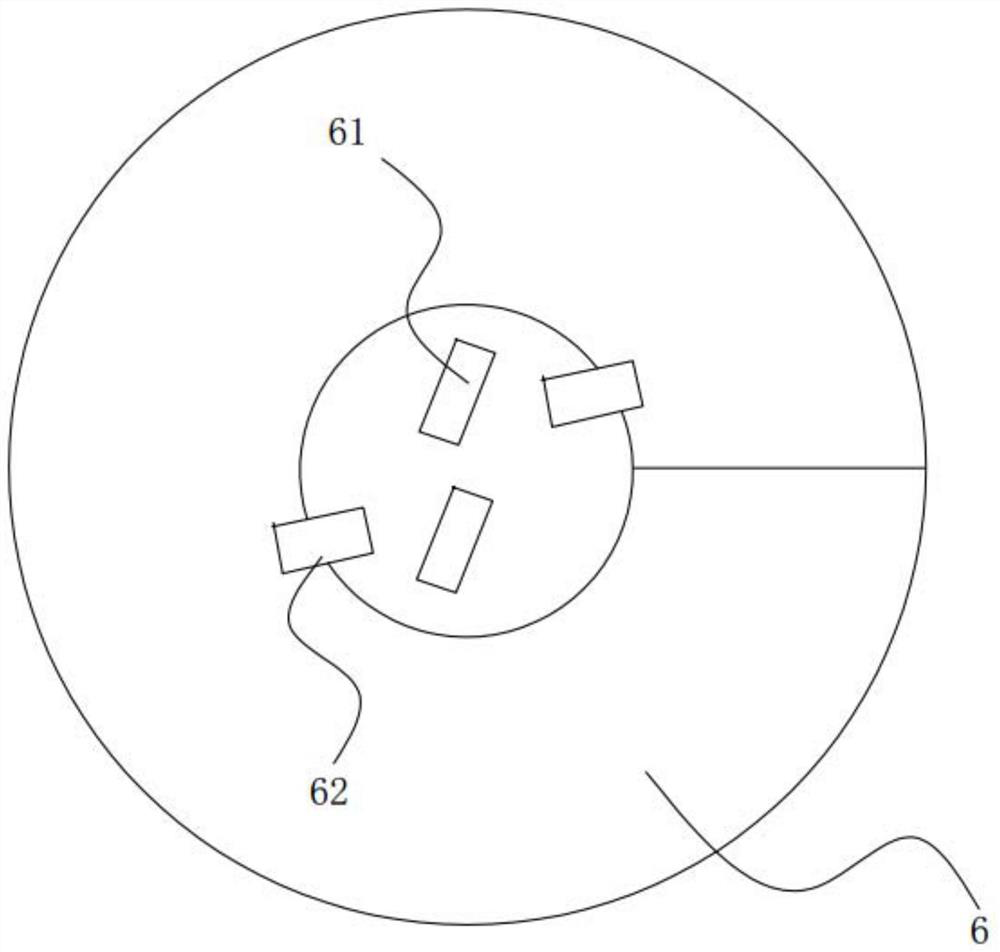

A kind of steel pipe pile construction method

ActiveCN110952535BFacilitate spinningImprove construction efficiencyBulkheads/pilesHelical bladeArchitectural engineering

The present invention relates to the technical field of steel pipe piles, in particular to a construction method of steel pipe piles, which aims to solve the problems in the prior art that steel pipe piles are not easy to be drilled into the ground and maintain the overall verticality of steel pipe piles. The key points of the technology include the following steps: S1. Install the spinning and expanding head steel pipe pile with continuous spiral blades on the outer peripheral surface to the spinning driving device of the piling equipment to adjust the verticality of the steel pipe pile; S2. Drive the steel pipe The pile rotates and drills down into the ground; S3. Judging whether the pile needs to be continued, and if so, proceed to step S4; S4. Install the extended steel pipe pile body on the spinning drive device of the piling equipment to drive the steel pipe pile Rotate with the extended steel pipe pile body and drill down into the stratum; S5. Determine whether to continue the pile, if necessary, repeat step S4 until the design depth required for the overall construction of the steel pipe pile is drilled. The invention can rely on the rotation of the helical blades to press into the ground, greatly speeding up the construction speed and helping to ensure the verticality of the steel pipe piles.

Owner:ROAD & BRIDGE INT +1

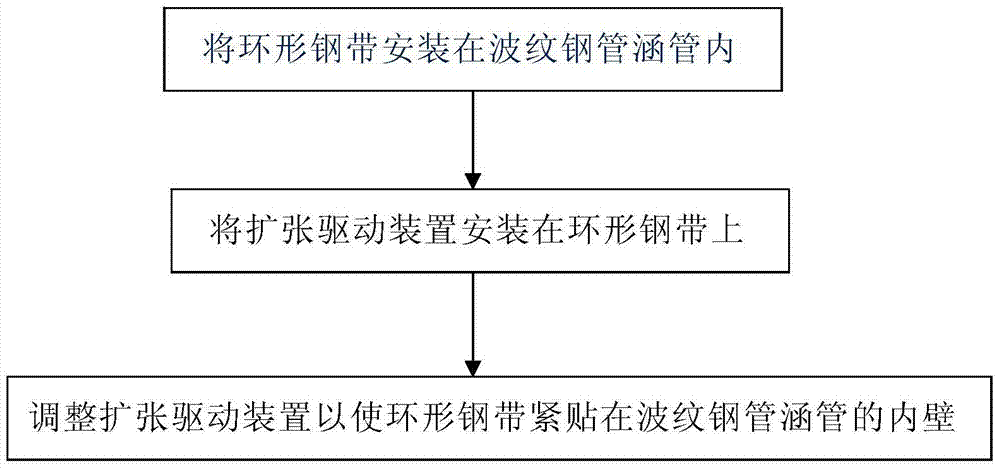

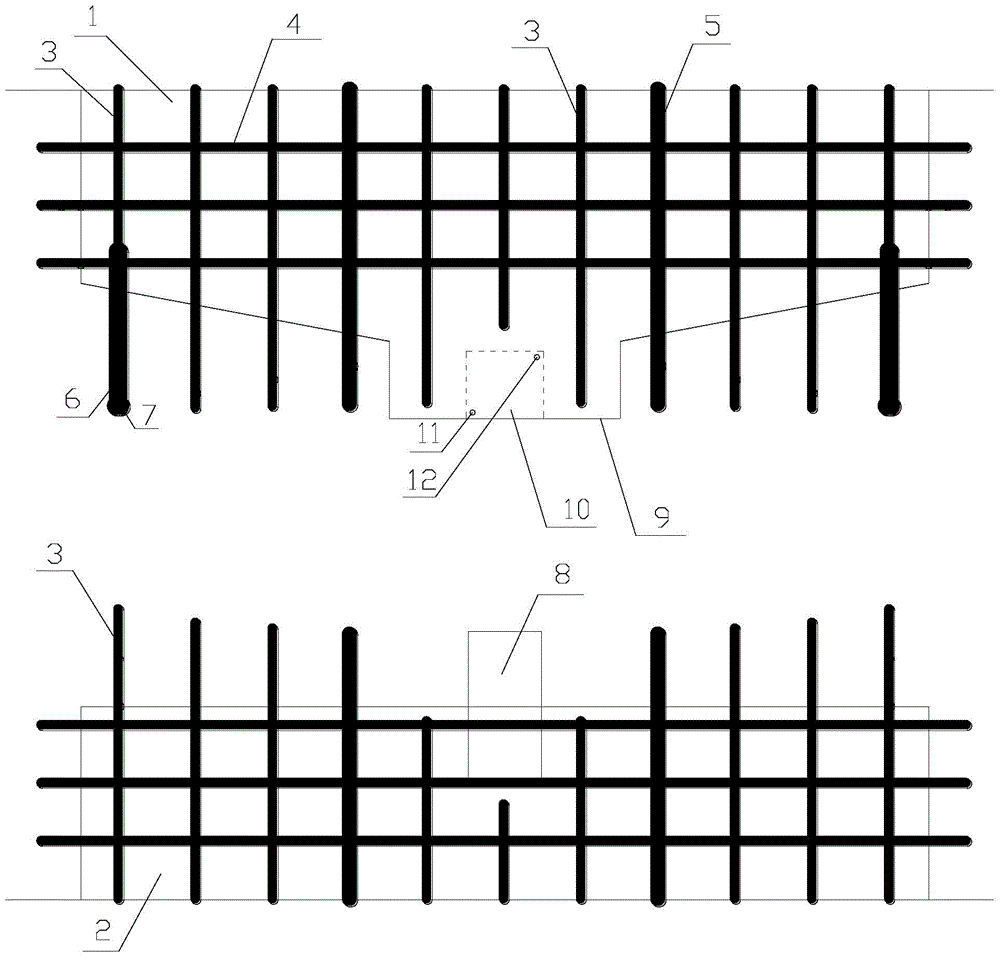

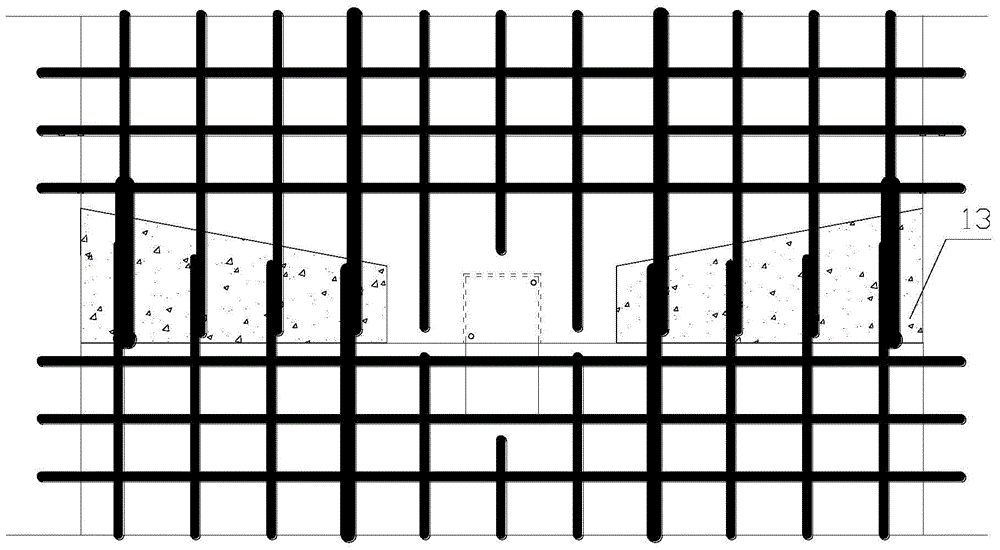

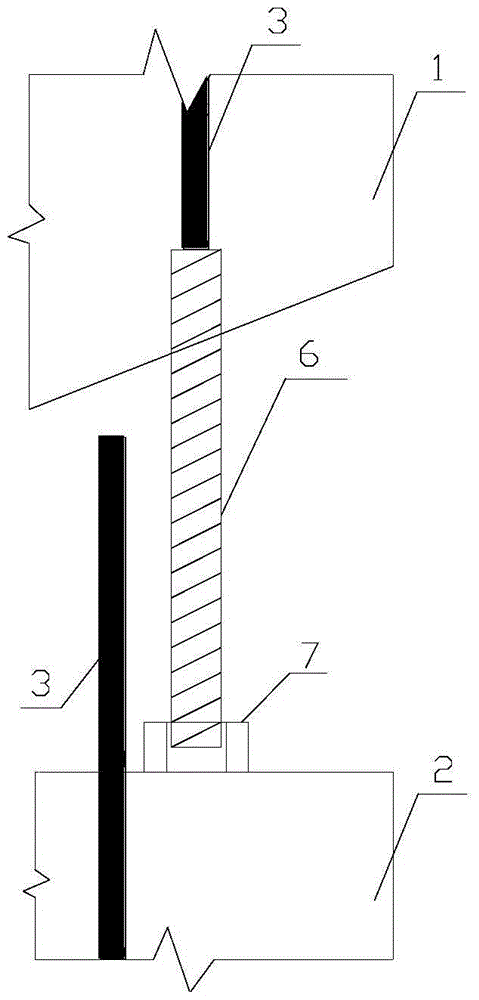

Structure and method of repairing corrugated steel pipe culvert by using expanded annular steel belt

Owner:CHANGAN UNIV

The upper and lower connection structure of the prefabricated shear wall

Owner:TIANJIN UNIV RES INST OF ARCHITECTRUAL DESIGN & URBAN PLANNING +1

Movable type engineering machine and support leg device thereof

InactiveCN101698407BHigh transmission reliabilityIncrease total elongationVehicle fittings for liftingBuilding material handlingGear wheelMovable type

The invention discloses a support leg device used for a movable type engineering machine, comprising a fixed support leg box (1), wherein a first movable support leg (21) arranged on the fixed support leg box (1) is provided with a first gear (31), and the fixed support leg box (1) is provided with a first rack (41) meshed with the first gear (31); the first movable support leg (21) is provided with a second gear (32), and a second movable support leg (22) arranged on the first movable support leg (21) is provided with a second rack (42) meshed with the second gear (32); and the first gear (31) is linked with the second gear (32) under the action of a connecting part, and the first movable support leg (21) and the second movable support leg (22) move towards the same direction. By adopting a rack and pinion pair, the support leg device can be stretched, has simpler structure and simplifies the processing technique. The invention also discloses the movable type engineering machine including the support leg device.

Owner:SANY AUTOMOBILE MFG CO LTD

A reinforcement structure and its construction method for the low strength of the grouting material in the sleeve

ActiveCN111350312BReduce gougingAvoid damageBuilding reinforcementsBuilding material handlingArchitectural engineeringSlurry

The invention discloses a reinforcing structure for low strength of slurry in sleeves. The reinforcing structure covers each sleeve grouting connecting joint at the bottom of a prefabricated shear wall. A reinforcing structure body of the single sleeve grouting connecting joint comprises one sleeve, a connecting steel bar, a grouting material, a chiseling area, pre-bent additional steel bars and ultra-high performance concrete. When the sleeves and the connecting steel bars are in grouting connection through the grouting materials, each sleeve and the corresponding connecting steel bar are welded and connected through two pre-bent additional steel bars, chiseling areas are located on sleeve bodies of the sleeves where the pre-bent additional steel bars are located and the peripheries of the connecting steel bars, and the chiseling areas are filled with the ultra-high performance concrete. The invention further provides a construction method of the above reinforcing structure to guide construction and meet reinforcement requirements. The original sleeve grouting connecting joints can be integrally retained in the reinforcing construction process, the damage to an original structureis reduced, the construction safety is improved, the reinforcing connection mode of the structure is simple, the engineering quantity is small, and the cost is controllable.

Owner:KUNSHAN CONSTRUCT ENG QUALITY TESTING CENT

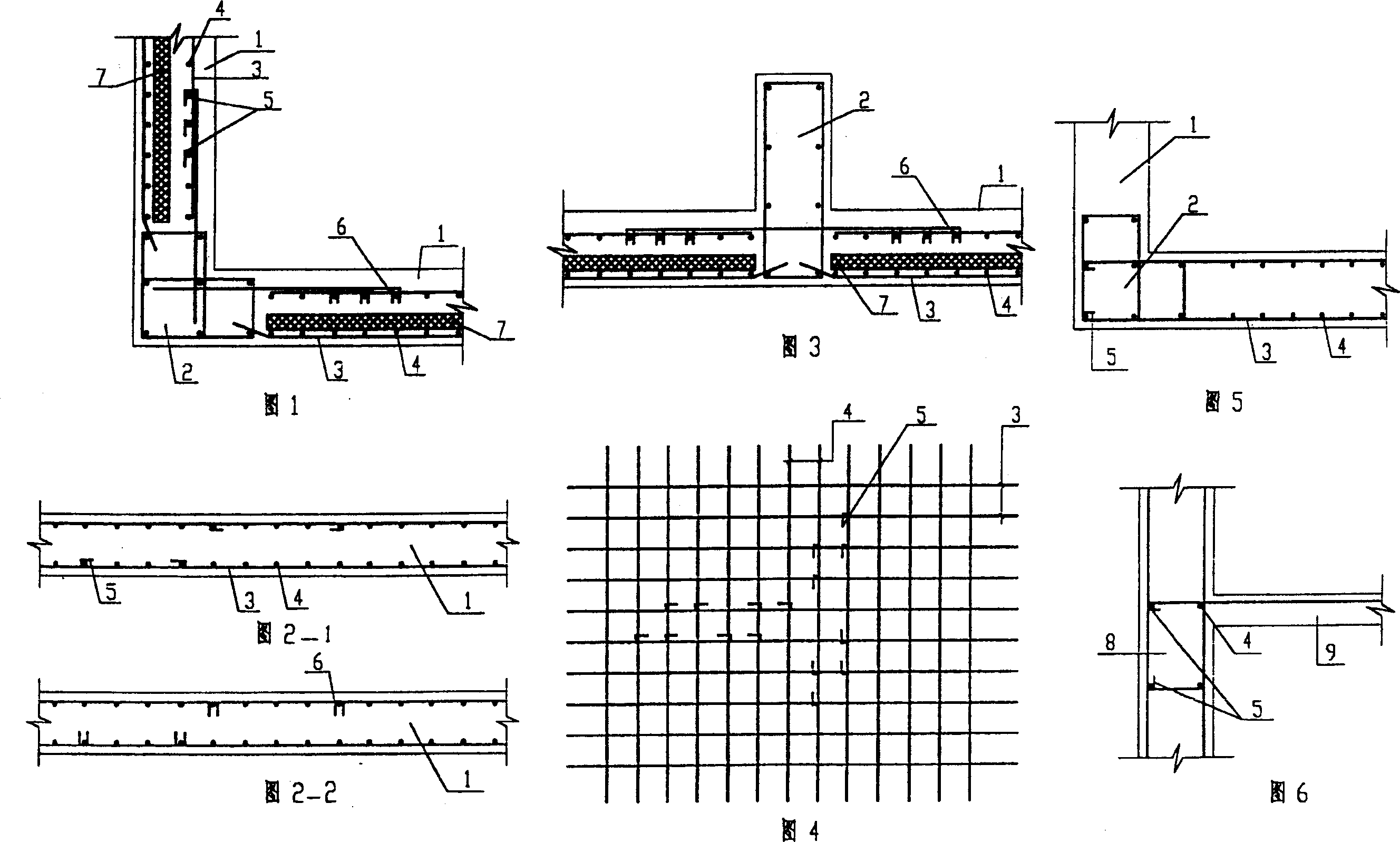

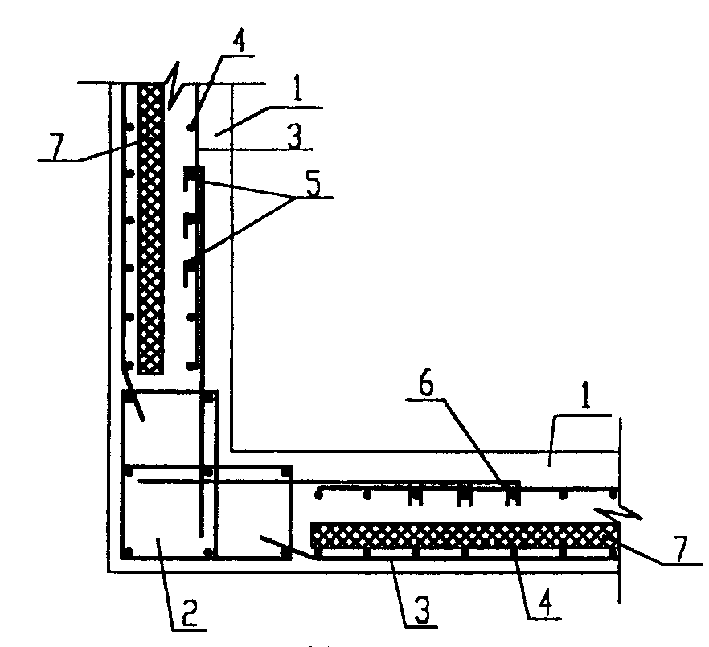

Method for lapped joint or anchoring of reinforcing bars in reinforced concrete member

InactiveCN1161525CIncrease anchoring forceShorten the lap lengthBuilding constructionsReinforced concreteEngineering

A method for lapping or anchoring of reinforcing bars in reinforced concrete member is disclosed. It is suitable for the shear wall, shear structure and multi-wall building. It is characterized by that one or more hooks or anchor clips are welded to the end of the reinforcing bars in wall, beam or pile in order to joint the vertical reinforcing bars with it easily and firmly. Its advantages are saving raw material, and simple construction.

Owner:NORTHERN ENG DESIGN & RES INST CO LTD

Dry and wet mixed connection method of fabricated shear wall

The invention discloses a fabricated shear wall dry-wet mixed connection method. The left ends and the right ends of upper-layer prefabricated wall plates and lower-layer prefabricated wall plates areconnected in a positioned mode through nuts, and then cast-in-place shearing force key structures are formed in the middles of the upper-layer prefabricated wall plates and the lower-layer prefabricated wall plates. According to the fabricated shear wall dry-wet mixed connection method, four steel bar connectors are arranged at the two ends of each upper-layer wall plate correspondingly, groovesare formed in the bottoms of the upper-layer prefabricated wall plates, concrete is poured into the grooves to form the shearing force key structures, connecting steel bars anchored on the lower-layerprefabricated wall plates are locked on the steel bar connectors, and thus the connecting structures of the upper-layer prefabricated wall plates and the lower-layer prefabricated wall plates are convenient to construct and reliable in performance; and the advantages of dry-type connection and wet-type connection are combined, the problems that as for an existing connecting mode, on-site construction is difficult, and the quality is not prone to being ensured are solved effectively, the construction process can be simplified, the assembling quality is improved, the mechanical performance of ashear wall after assembling is improved, and the purpose of reducing cost is achieved.

Owner:TIANJIN UNIV RES INST OF ARCHITECTRUAL DESIGN & URBAN PLANNING +1

Prefabricated shear wall component and construction method thereof

PendingCN111456283AImprove connection strengthShorten the lap lengthWallsShear wallArchitectural engineering

The invention relates to a prefabricated shear wall component and a construction method thereof. The prefabricated shear wall component comprises a wall body, a first grouting hole, a second groutinghole, a first grouting pipe, a second grouting pipe and a connecting piece; the wall body is provided with a first end and a second end which are oppositely arranged, the first grouting hole and the second grouting hole are both formed in the wall body, and the distance between the first grouting hole and the second end is smaller than the distance between the second grouting hole and the second end; the first grouting pipe and the second grouting pipe are both located in the wall body, the first grouting pipe communicates with the first grouting hole and the second end, the second grouting pipe communicates with the second grouting hole and the second end, and the extending direction of the first grouting pipe and the extending direction of the second grouting pipe are both parallel to the connecting line between the first end and the second end; and the connecting piece is embedded in the wall body and extends out of the wall body from the second end. The prefabricated shear wall component is high in assembly rate, easy to construct, and capable of greatly shortening the construction period and improving the construction efficiency; and in addition, the construction method of theprefabricated shear wall component is simple in steps, flexible in construction and suitable for being applied and popularized.

Owner:NO 2 CONSTR GRP CO LTD OF SHANGHAI CONSTR GRP +1

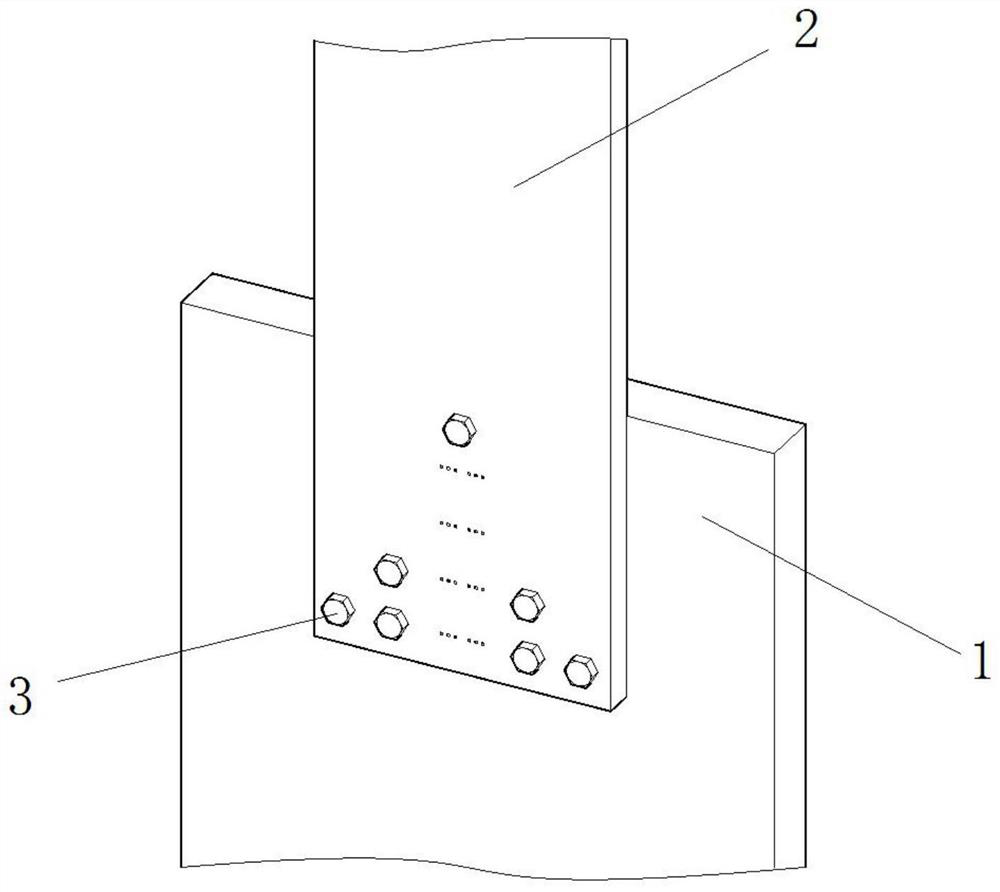

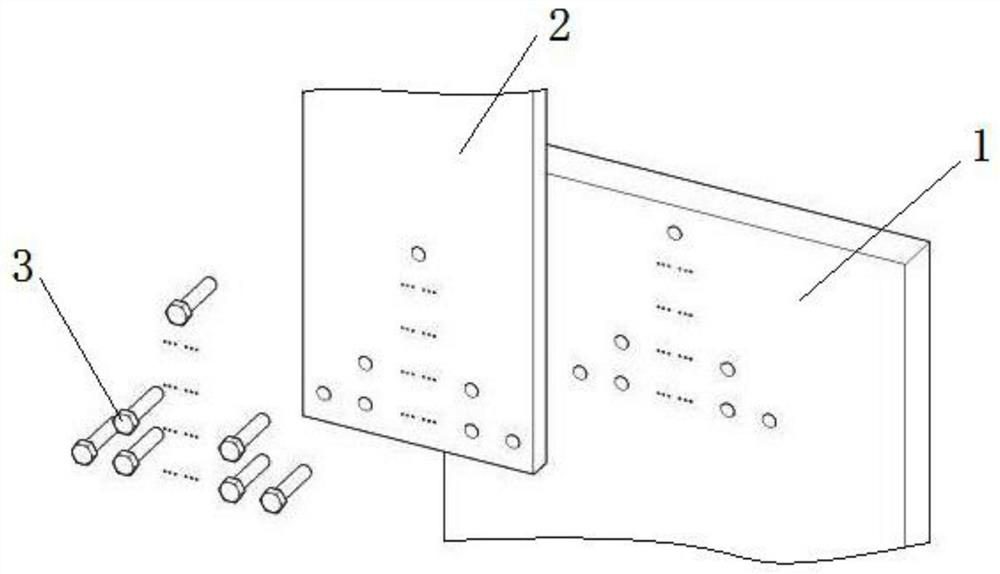

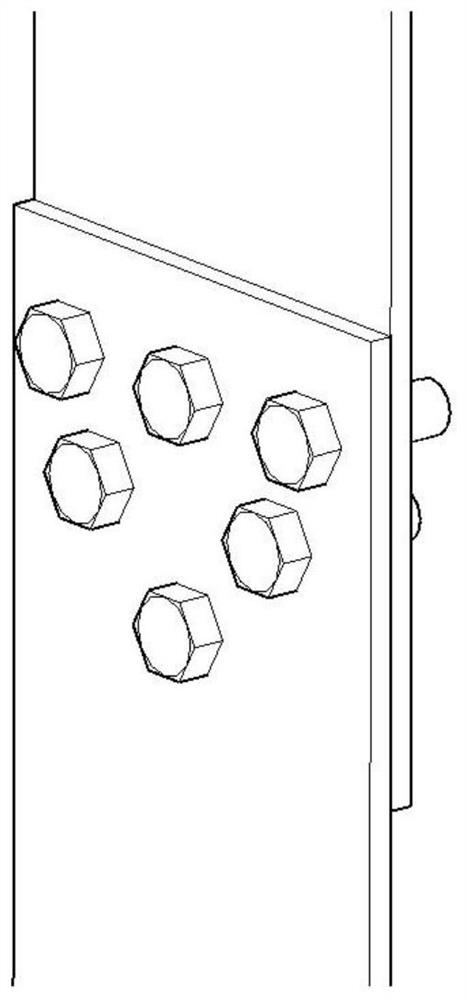

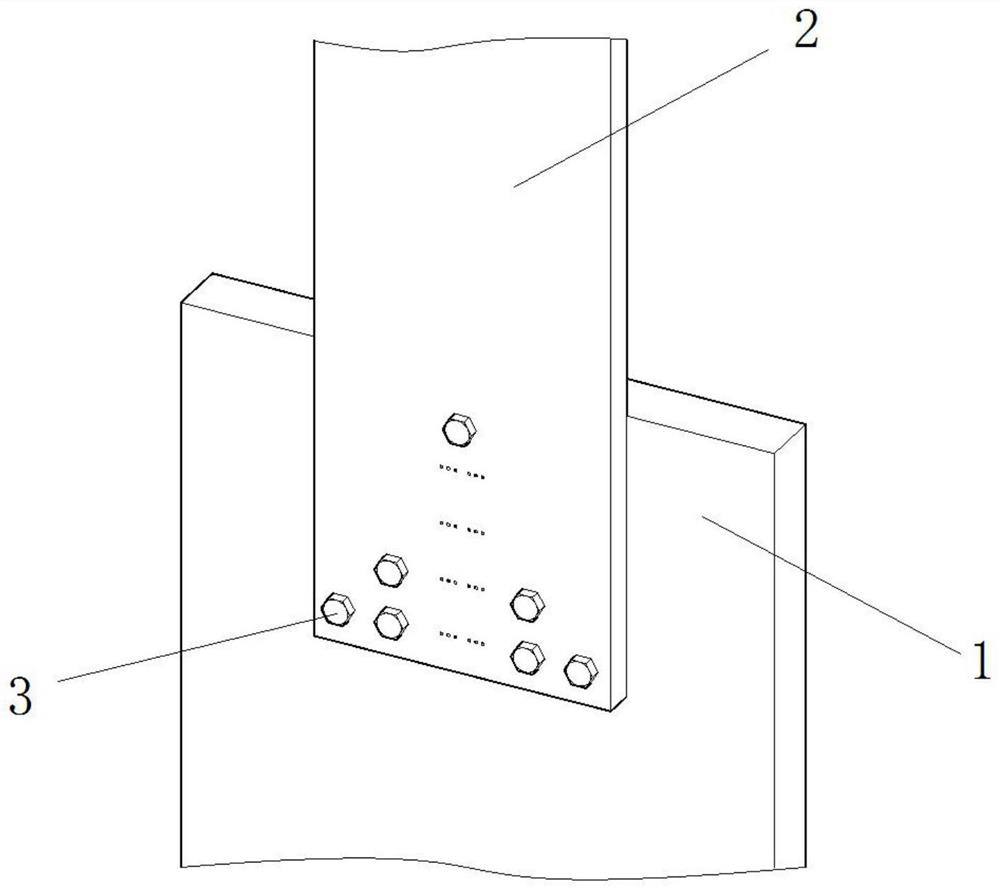

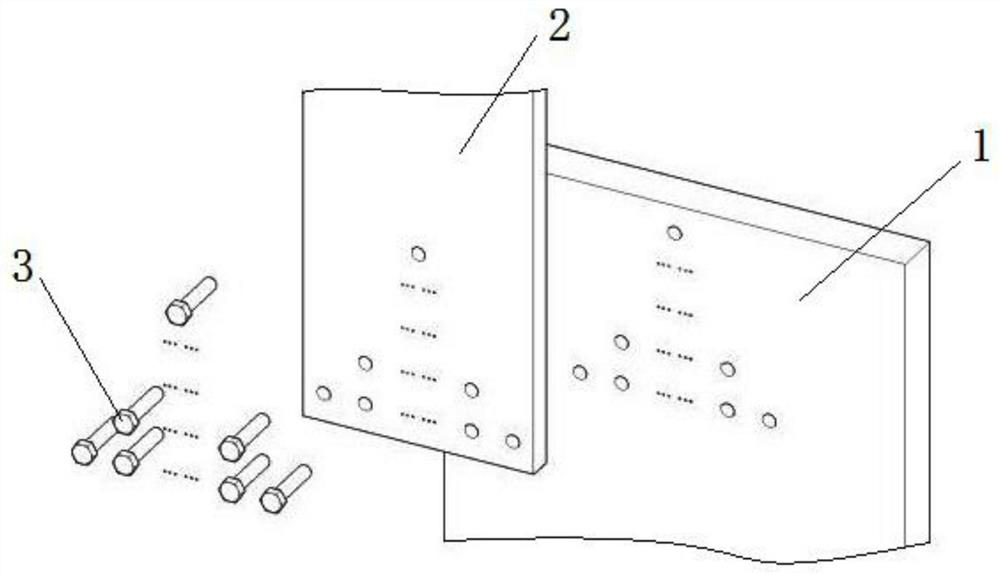

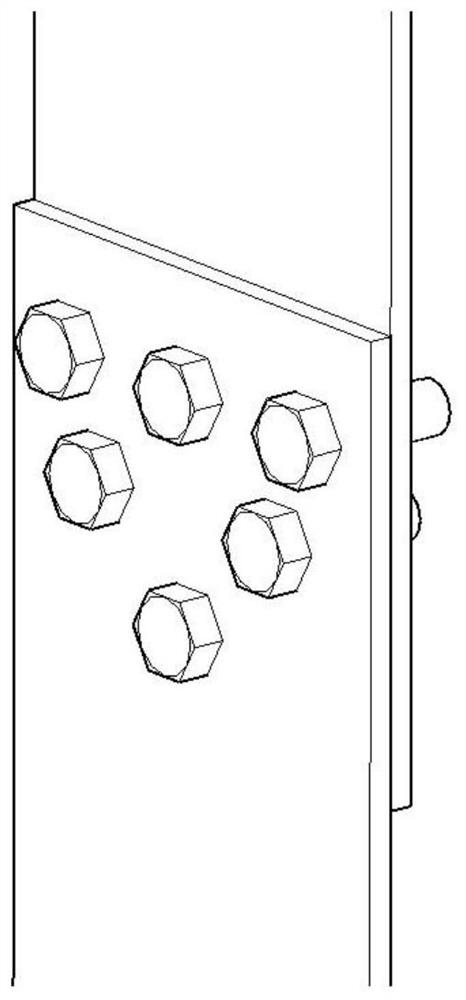

Novel mixed-strength shear-resistant connection joint based on pressure-bearing type high-strength bolts

ActiveCN113389266AIncrease profitAvoid destructionBuilding constructionsBridge engineeringUltimate tensile strength

The invention discloses a novel mixed-strength shear-resistant connecting joint based on pressure-bearing type high-strength bolts, and belongs to the technical field of bridge engineering. The novel mixed-strength shear-resistant connecting joint comprises a first steel plate with high section tensile strength and a second steel plate with low section tensile strength, wherein the first steel plate and the second steel plate are fixedly connected through n bolts, the n bolts are sequentially divided into m rows to be arranged from the end, close to the connecting end, of the second steel plate, the number of the bolts arranged in the first row is n1, the number of the bolts arranged in the second row is n2, the number of the bolts arranged in the mth row is nm in proper order, and the number of the bolts arranged in the first row, the second row, ..., to the mth row is monotonically decreased in sequence. According to the novel mixed-strength shear-resistant connecting joint, while the reliability of the to-be-connected steel plate with low section tensile strength is protected, the material utilization rate of the to-be-connected steel plate with high section tensile strength is high; and under the same joint shearing resistance requirement, the utilization rate of the to-be-connected steel plate with high section tensile strength in the novel joint can be increased by 33%.

Owner:CHONGQING UNIV

Prefabricated composite beam-column joint and its construction method based on uhpc

ActiveCN112900620BCost controlImprove mechanical propertiesStrutsFloorsEarthquake resistanceArchitectural engineering

The invention relates to a UHPC-based assembled composite beam-column node and a construction method thereof. The prefabricated composite beam-column node based on UHPC includes prefabricated column, prefabricated beam and post-casting area of the node. The mechanical properties of the column end of the prefabricated column are higher than those of the column middle. The mechanical properties of the beam end of the prefabricated beam are higher than that of the beam middle. The longitudinal lapping reinforcement in the post-casting area of the node is connected to the end of the column by pouring, and the transverse lapping reinforcement is connected to the end of the beam by pouring. In the above UHPC-based prefabricated composite beam-column joint and its construction method, there is no need to set stirrups for strengthening the structural strength in the post-casting area of the joint, beam end and column end. The lap length of longitudinal reinforcement of precast beams and precast columns can be greatly reduced compared with ordinary concrete. The longitudinal reinforcement of the prefabricated column does not need to be connected by sleeves. The upper reinforcement of prefabricated columns and prefabricated beams is hardly exposed. The prefabricated composite beam-column joint based on UHPC of the present invention is convenient to construct, and the amount of concrete with higher mechanical properties (such as ultra-high performance concrete) is less, and has good comprehensive economic benefits and anti-seismic performance.

Owner:TSINGHUA UNIV

A mixed-strength shear connection based on pressure-bearing high-strength bolts

ActiveCN113389266BIncrease profitAvoid destructionBuilding constructionsBridge engineeringClassical mechanics

The invention discloses a mixed-strength shear connection node based on pressure-bearing high-strength bolts, belonging to the technical field of bridge engineering, which includes a first steel plate with high cross-sectional tensile strength and a second steel plate with low cross-sectional tensile strength, The first steel plate and the second steel plate are fixedly connected by n bolts, starting from the end of the second steel plate close to the connection end, the n bolts are divided into m rows and arranged in sequence, wherein the number of bolts arranged in the first row is n1, the number of bolts in the second row is n2, and so on to the number of bolts in the mth row is nm; the number of bolts set in the first row, the second row... to the mth row decreases monotonically. The invention not only protects the reliability of the steel plates with low section tensile strength to be connected, but also realizes high-efficiency material utilization rate for the steel plates with high section tensile strength to be connected; Connecting steel plates can increase the utilization rate by 33%.

Owner:CHONGQING UNIV

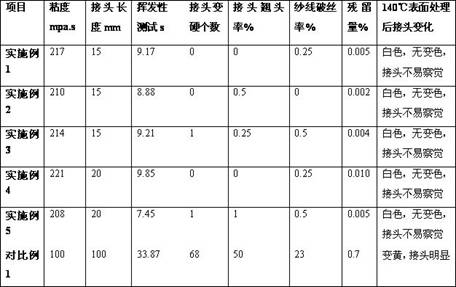

Adhesive for electronic grade glass fiber yarn and preparation method thereof

ActiveCN111548757BGood adhesionHigh viscosityNon-macromolecular adhesive additivesCellulose adhesivesCelluloseYarn

An adhesive used for electronic grade glass fiber yarn and a preparation method thereof belong to the technical field of electronic grade glass fiber. The following raw materials are included in parts by weight: 1-2 parts of ethyl cellulose, 6-8 parts of ethanol aqueous solution, 2-3 parts of sodium carboxymethyl cellulose, and 0.5-1.0 parts of dibutyl phthalate. The preparation method comprises the following steps: 1) mixing and stirring ethanol and ethyl cellulose to obtain an ethyl cellulose solution; 2) mixing and stirring ethanol and sodium carboxymethyl cellulose to obtain a sodium carboxymethyl cellulose solution; 3) ) Pour the sodium carboxymethyl cellulose solution into the ethyl cellulose solution, and stir for 2 to 3 hours to obtain a mixed solution; 4) Add dibutyl phthalate to the mixed solution in parts by weight, and stir evenly to obtain an adhesive agent. The adhesive used for the electronic grade glass fiber yarn of the present invention has strong adhesive force and high temperature resistance, and the joint is not easy to harden after bonding, and is not easy to change color and remain.

Owner:山东兴国大成电子材料有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com