Adhesive for electronic grade glass fiber yarn and preparation method thereof

A glass fiber yarn and adhesive technology, used in cellulose adhesives, non-polymer adhesive additives, adhesives, etc., can solve the problems of easy re-breakage of yarns, lowering of fabric quality, and high temperature resistance of adhesives. , to achieve the effect of low wire breaking rate and warping rate, reducing downtime and high temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

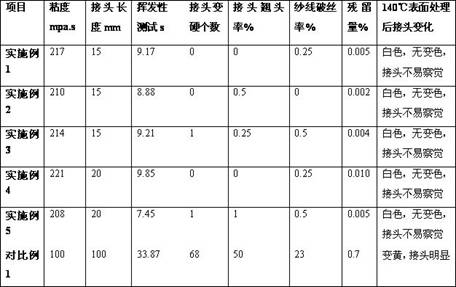

Examples

Embodiment 1

[0026] Examples 1 to 5 are specific examples of an adhesive for electronic grade glass fiber yarn and its preparation method according to the present invention, and Example 1 is the best implementation mode.

[0027] Ethyl cellulose, manufacturer: Sinopharm Chemical Reagents; CAS number: 9004-57-3, density 1.07 g / cm3;

[0028] Sodium carboxymethyl cellulose, manufacturer: Sinopharm Chemical Reagents;

[0029] Dibutyl phthalate, manufacturer: Tianjin Zhiyuan Chemical Reagent Co., Ltd., CAS No.: 84-74-2.

[0030] Example 1

[0031] The adhesive of this embodiment includes the following raw materials in parts by weight: 1.5 parts of ethyl cellulose, 6.5 parts of 40v / v% ethanol aqueous solution, 2.7 parts of sodium carboxymethyl cellulose, and 0.7 parts of dibutyl phthalate;

[0032] The preparation method of the present embodiment adhesive comprises the following steps:

[0033] 1) Put 1.5 parts of ethanol aqueous solution into the stirrer, turn on the stirrer, pour ethyl cell...

Embodiment 2

[0038] The adhesive of this embodiment includes the following raw materials in parts by weight: 1.3 parts of ethyl cellulose, 6.3 parts of 50v / v% ethanol aqueous solution, 2.8 parts of sodium carboxymethyl cellulose, and 0.6 parts of dibutyl phthalate;

[0039] The preparation method of the present embodiment adhesive comprises the following steps:

[0040] 1) Put 2.6 parts of ethanol aqueous solution into the stirrer, turn on the stirrer, pour ethyl cellulose in parts by weight, rotate at 80 rpm, and stir for 2 hours to obtain ethyl cellulose solution;

[0041] 2) Put 3.7 parts of ethanol aqueous solution into the stirrer, turn on the stirrer, pour sodium carboxymethyl cellulose in parts by weight, rotate at 80 rpm, and stir for 2 hours to obtain sodium carboxymethyl cellulose solution;

[0042] 3) Pour the sodium carboxymethylcellulose solution into the ethylcellulose solution at a speed of 120 rpm and stir for 2 hours to obtain a mixed solution;

[0043] 4) Add dibutyl pht...

Embodiment 3

[0045] The adhesive of this embodiment includes the following raw materials in parts by weight: 1.8 parts of ethyl cellulose, 7 parts of 45v / v% ethanol aqueous solution, 2.3 parts of sodium carboxymethyl cellulose, and 0.8 parts of dibutyl phthalate;

[0046] The preparation method of the present embodiment adhesive comprises the following steps:

[0047] 1) Put 2.7 parts of ethanol aqueous solution into the stirrer, turn on the stirrer, pour ethyl cellulose in parts by weight, rotate at 120 rpm, stir for 1.5 hours, and obtain ethyl cellulose solution;

[0048] 2) Put 4.3 parts of ethanol aqueous solution into the stirrer, turn on the stirrer, pour sodium carboxymethyl cellulose in parts by weight, rotate at 120 rpm, and stir for 1.5 hours to obtain sodium carboxymethyl cellulose solution;

[0049] 3) Pour the sodium carboxymethylcellulose solution into the ethylcellulose solution at a speed of 80 rpm, and stir for 3 hours to obtain a mixed solution;

[0050] 4) Add dibutyl pht...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com